A Longitudinal Mode Electromagnetic Acoustic Transducer (EMAT) Based on a Permanent Magnet Chain for Pipe Inspection

Abstract

:1. Introduction

2. Principle

2.1. The Principle of the Conventional EMAT

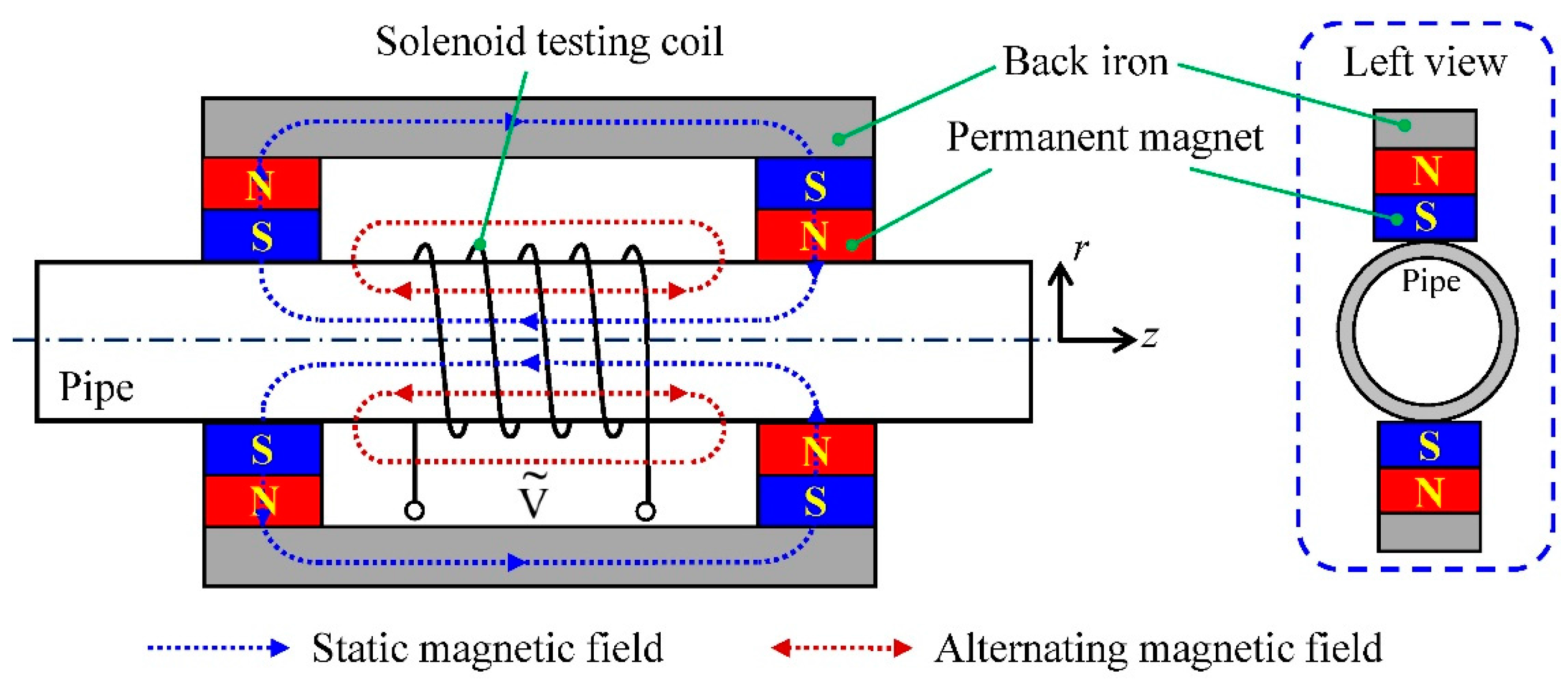

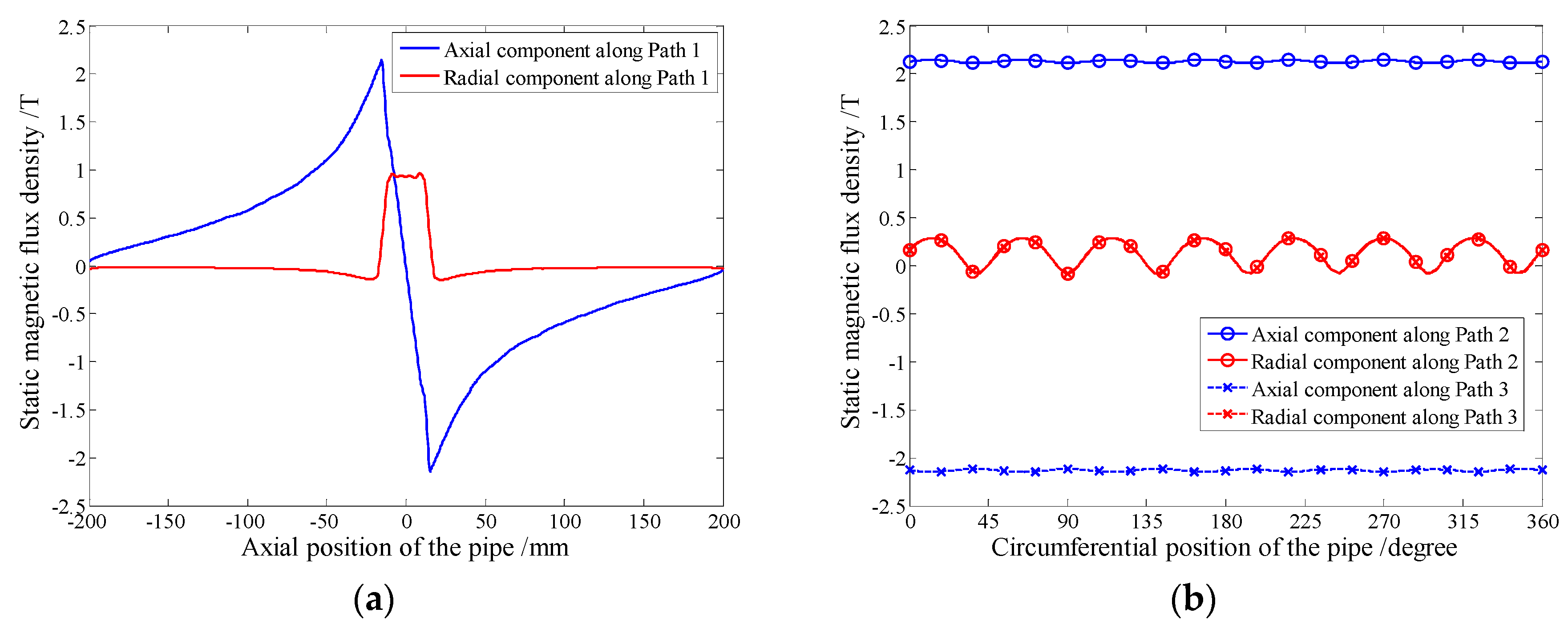

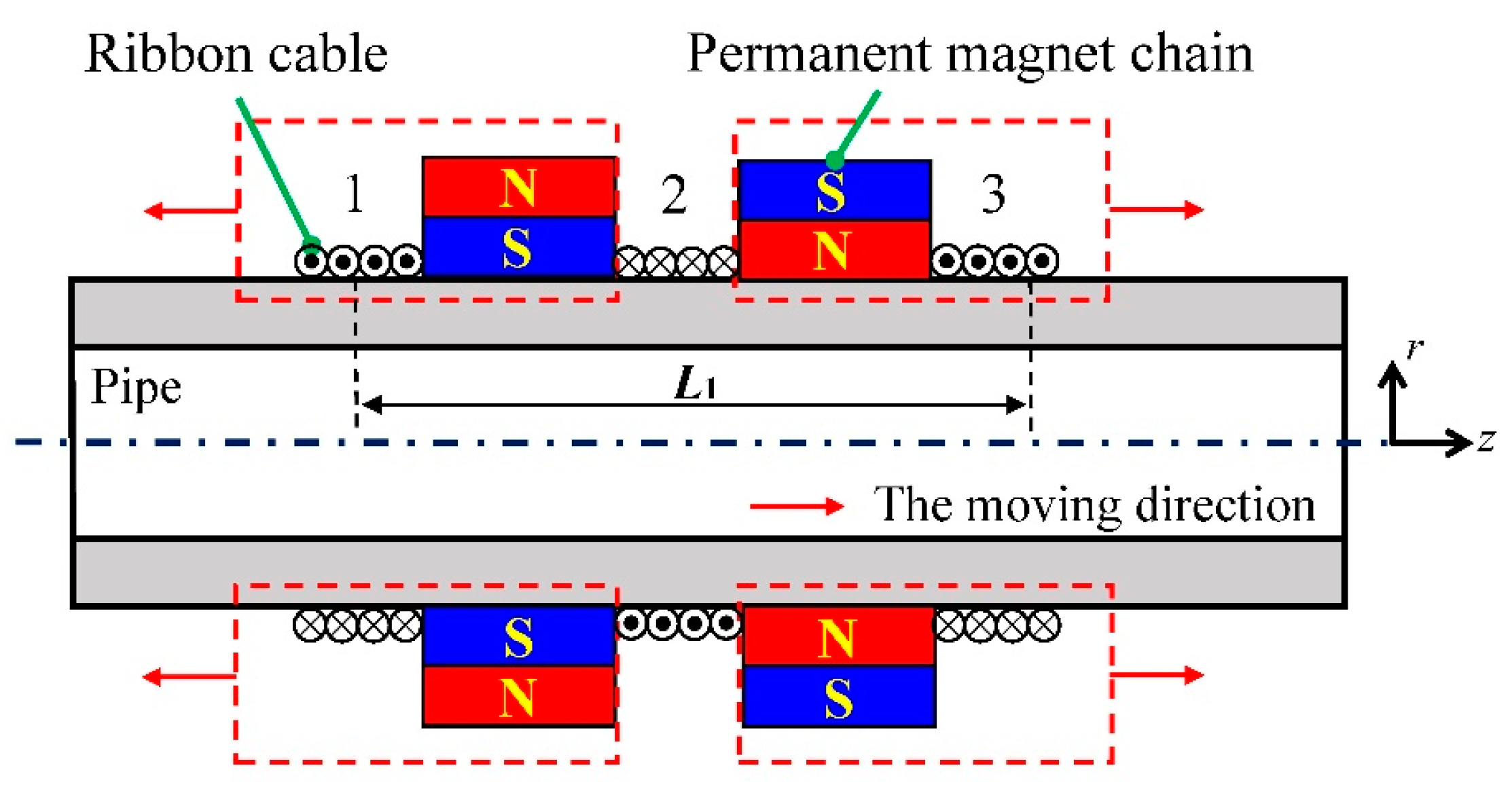

2.2. The Principle of the Proposed EMAT

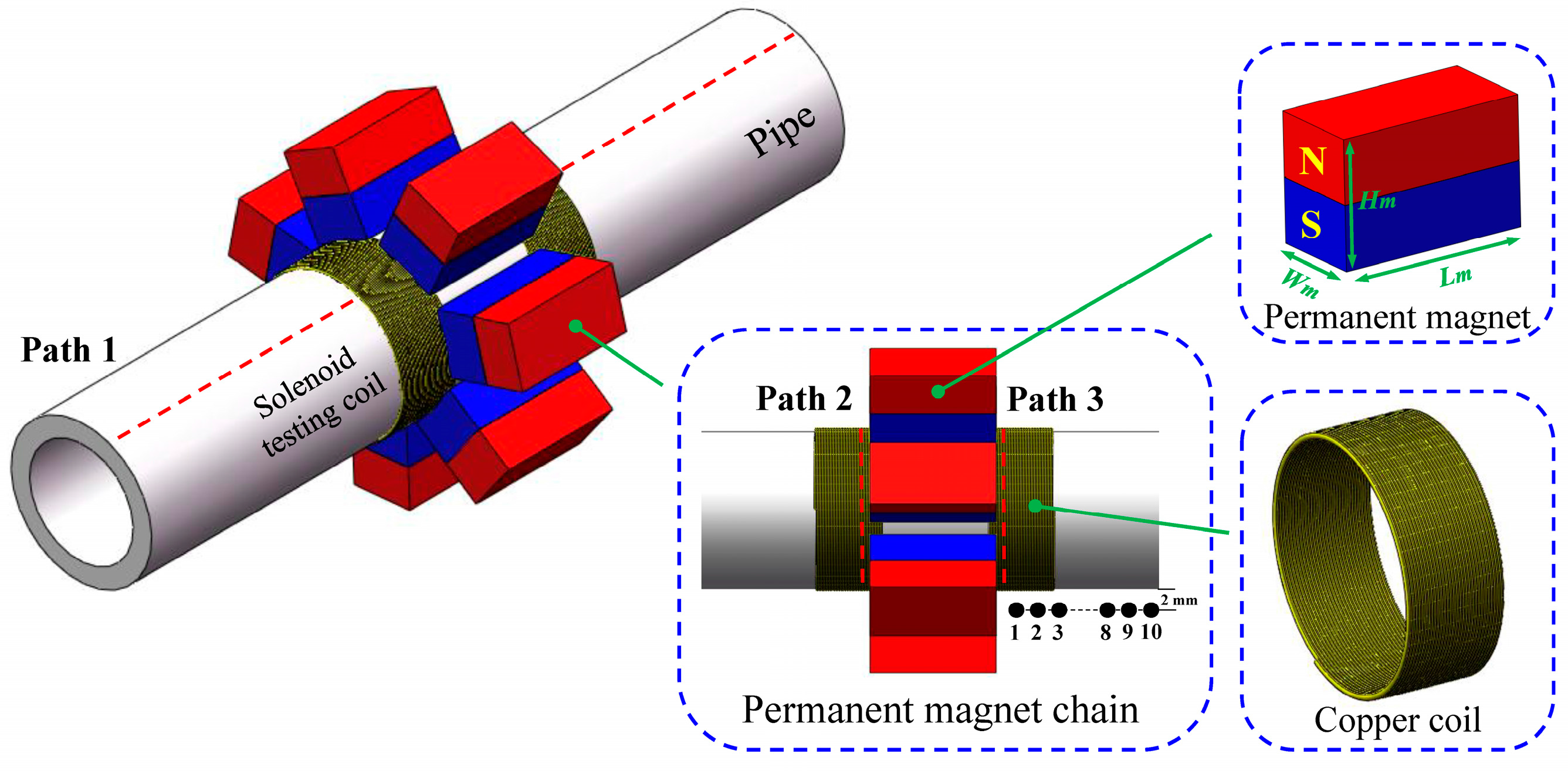

3. The Development of the Proposed EMAT

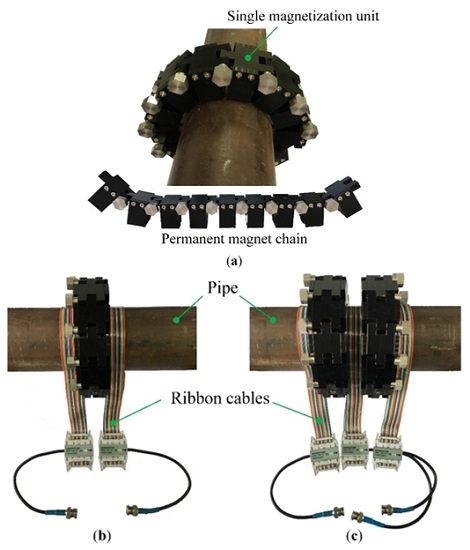

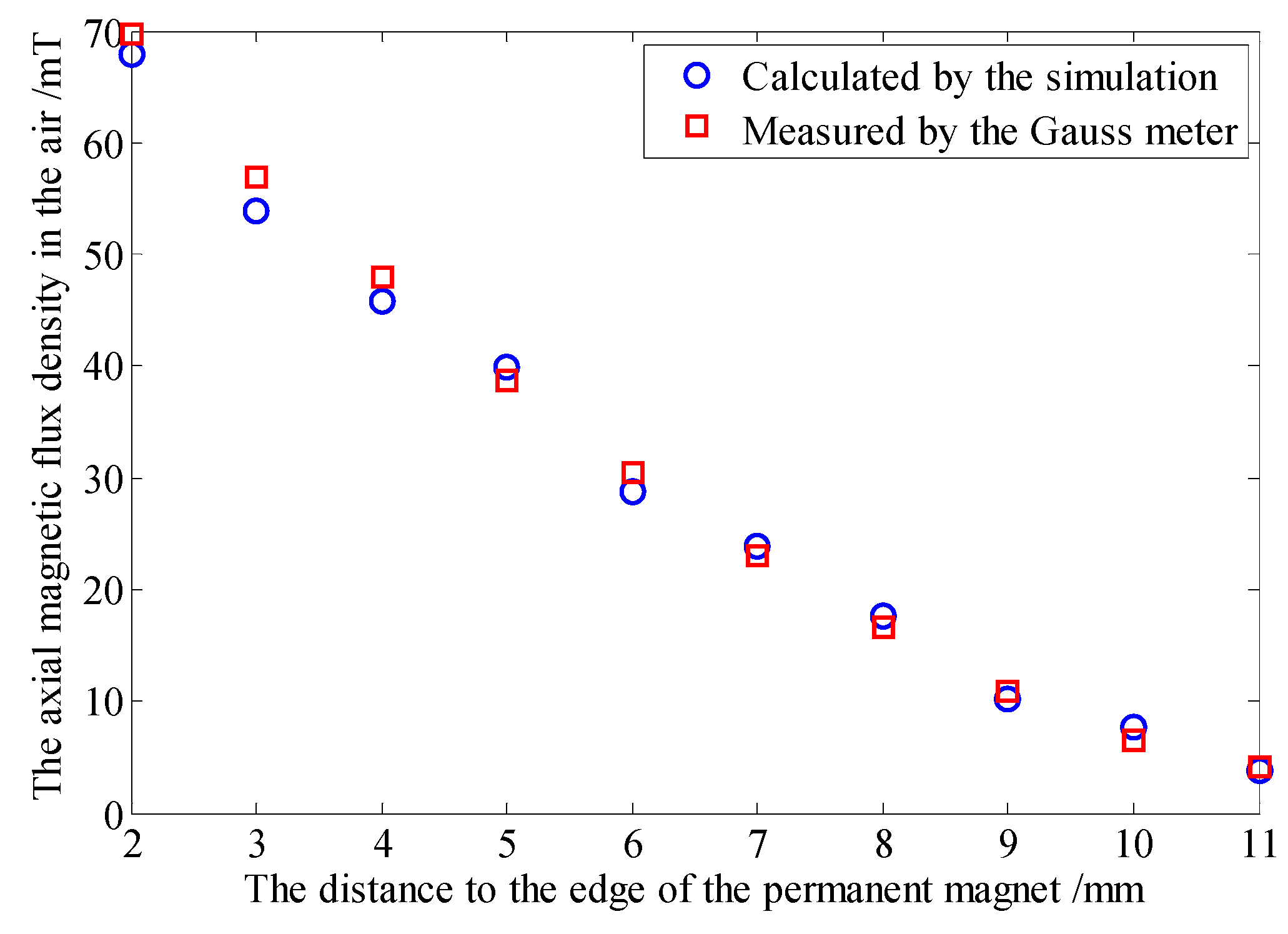

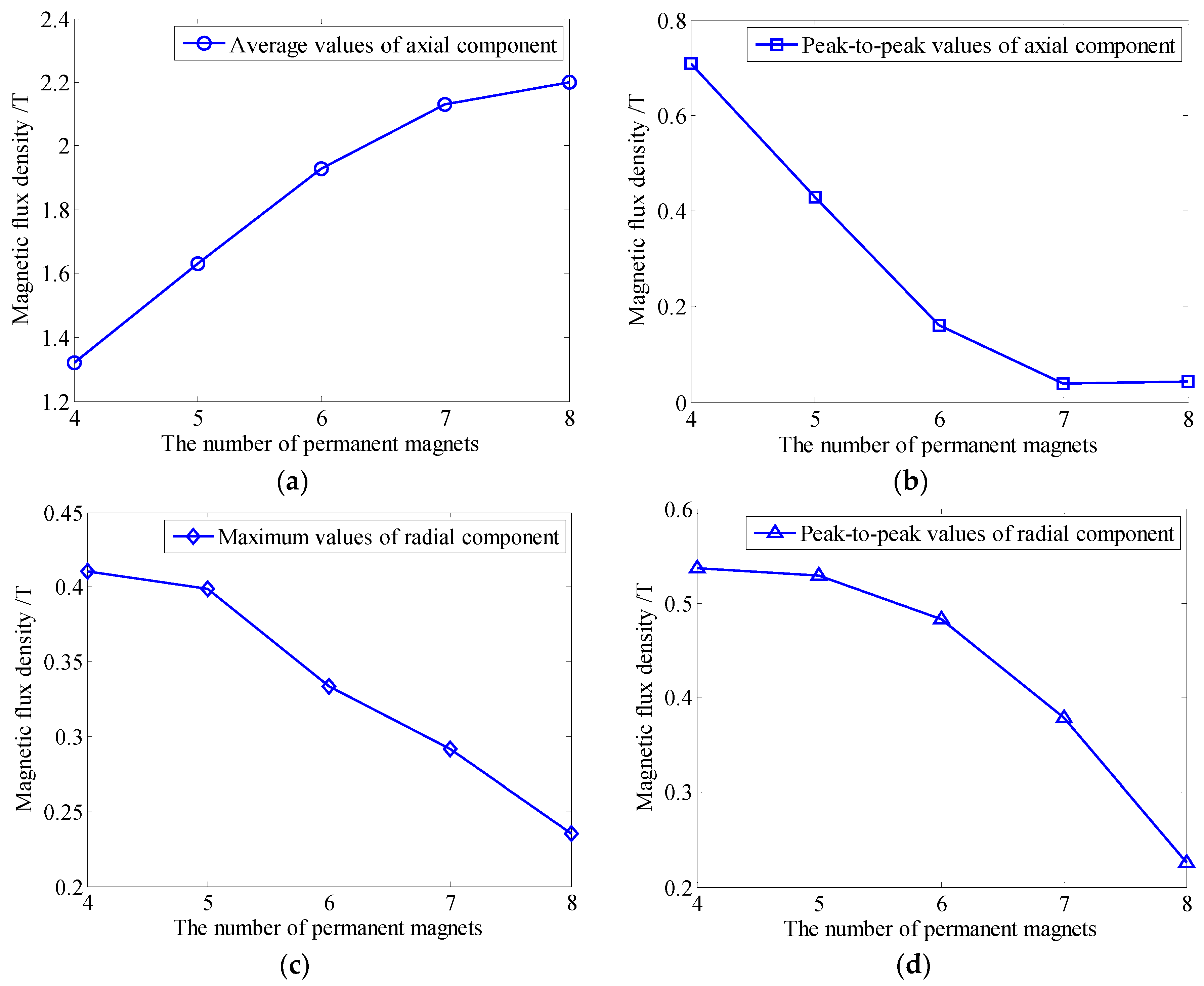

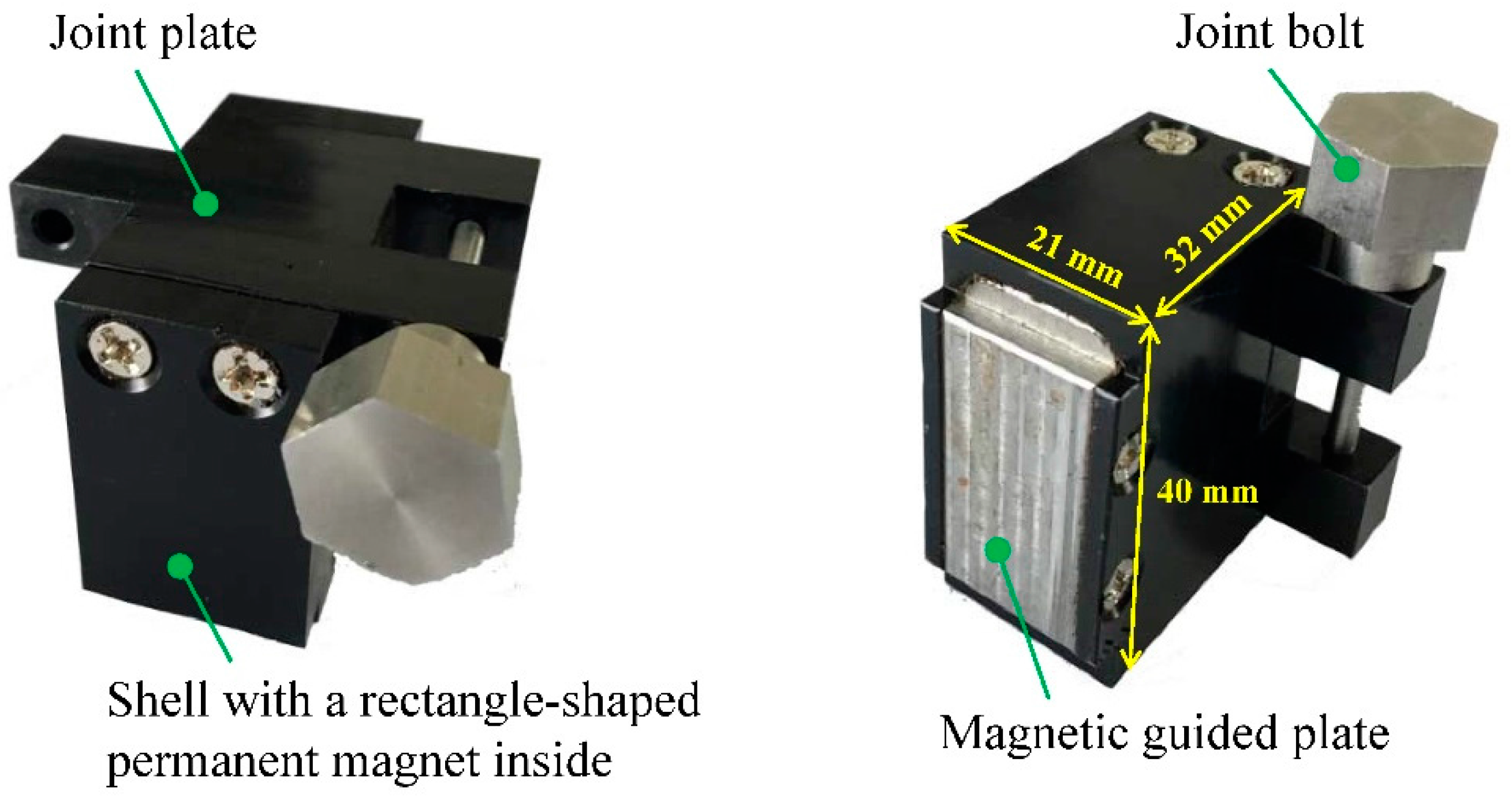

3.1. The Magnetization Unit

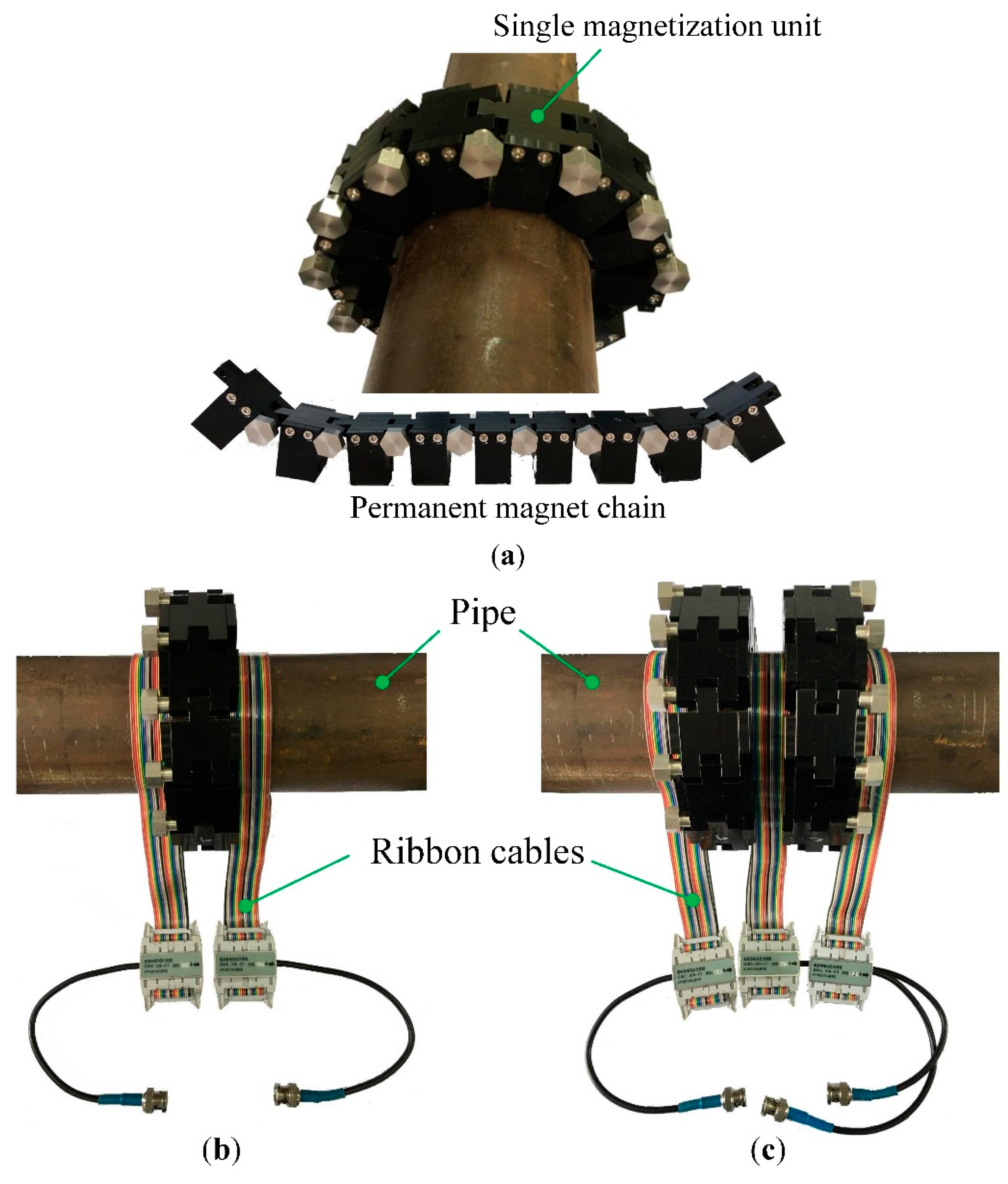

3.2. The Chain Structure

4. Experimental Investigation of the Proposed EMATs

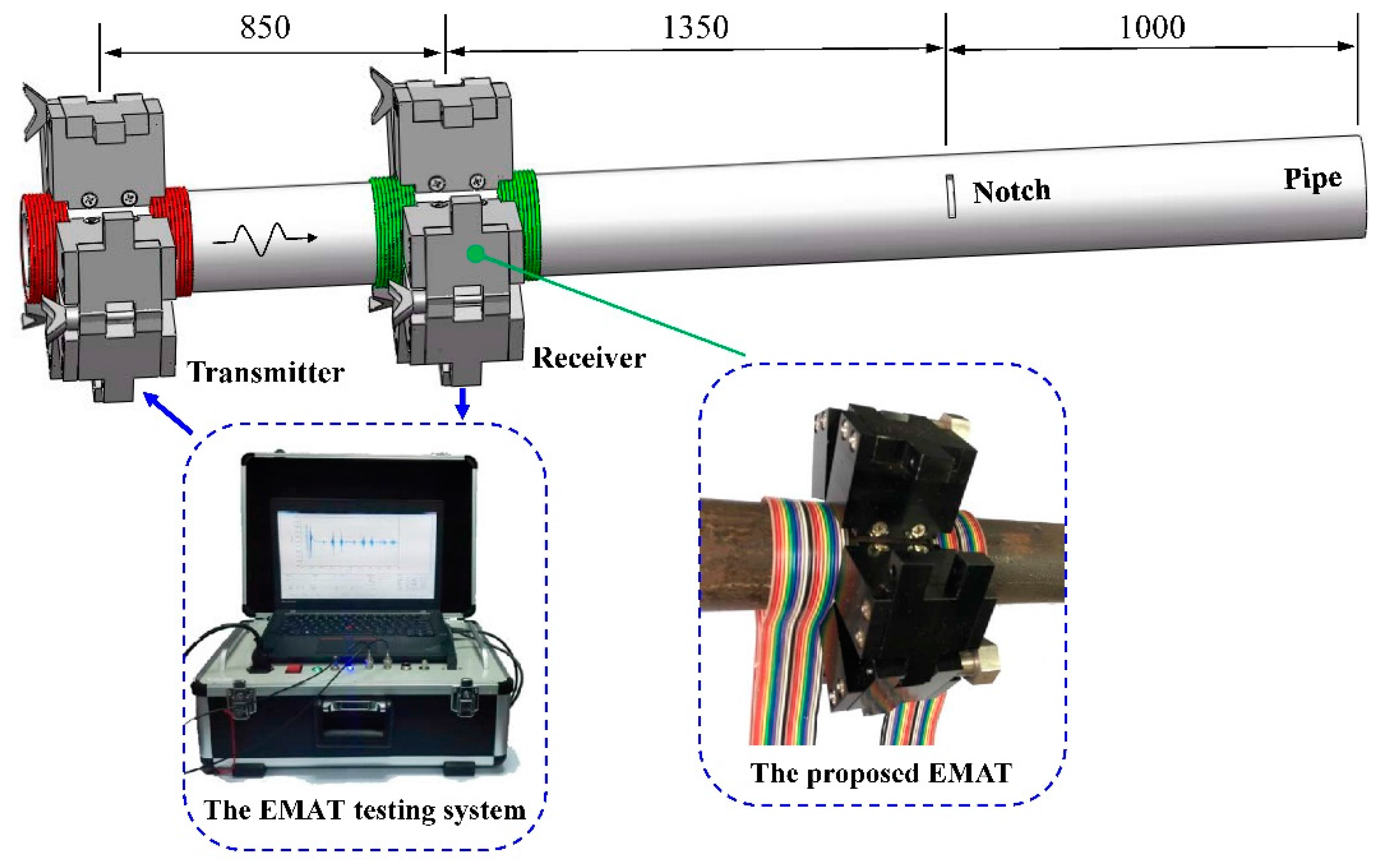

4.1. The Experimental Setup

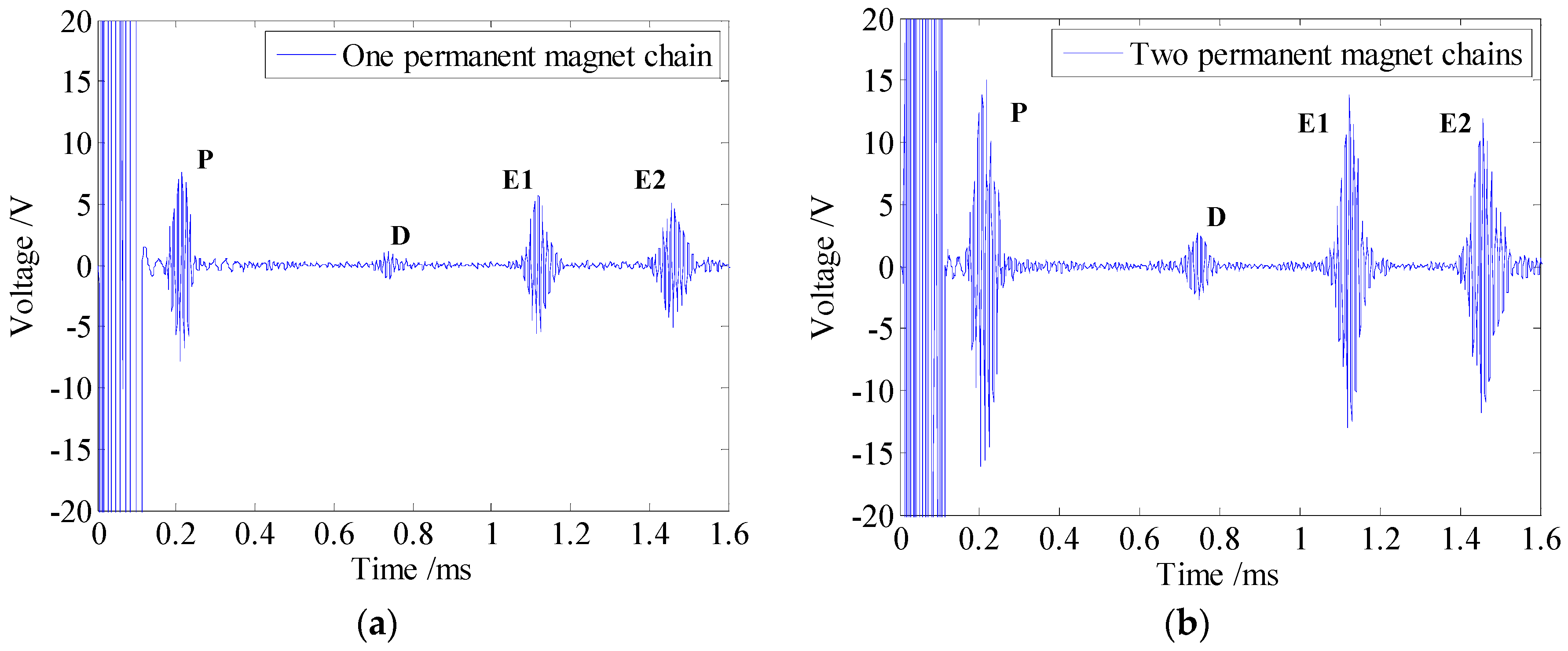

4.2. The Defect Detection Performance

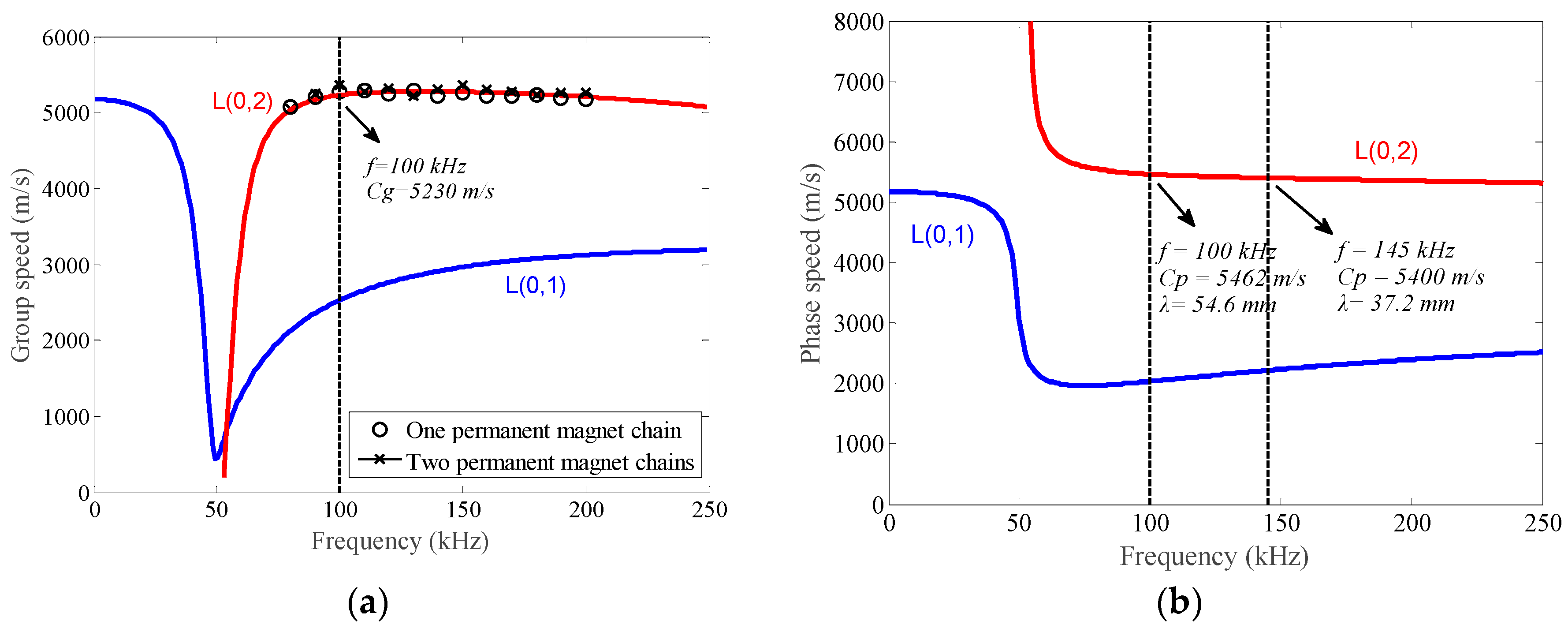

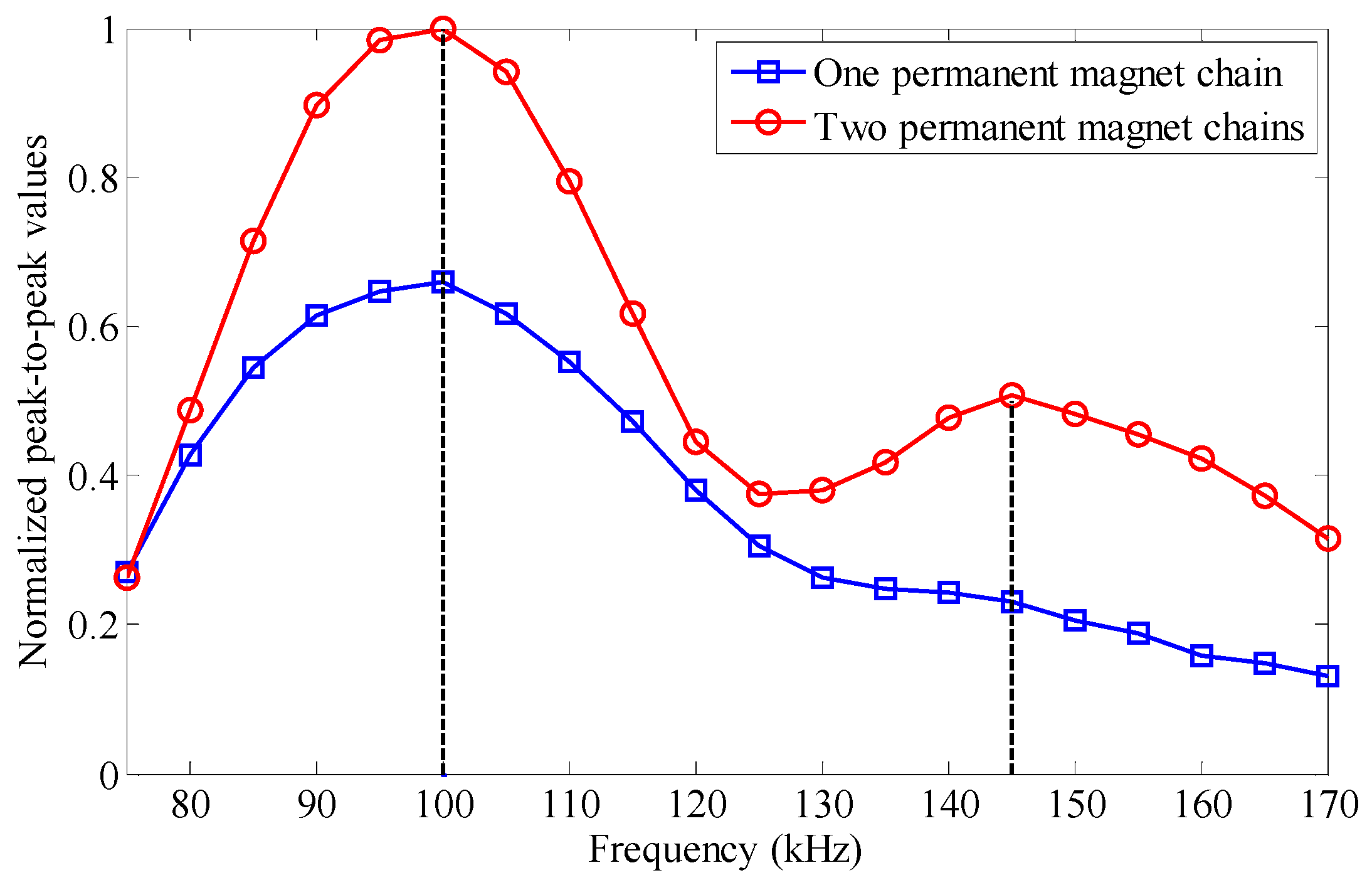

4.3. The Frequency Response Features

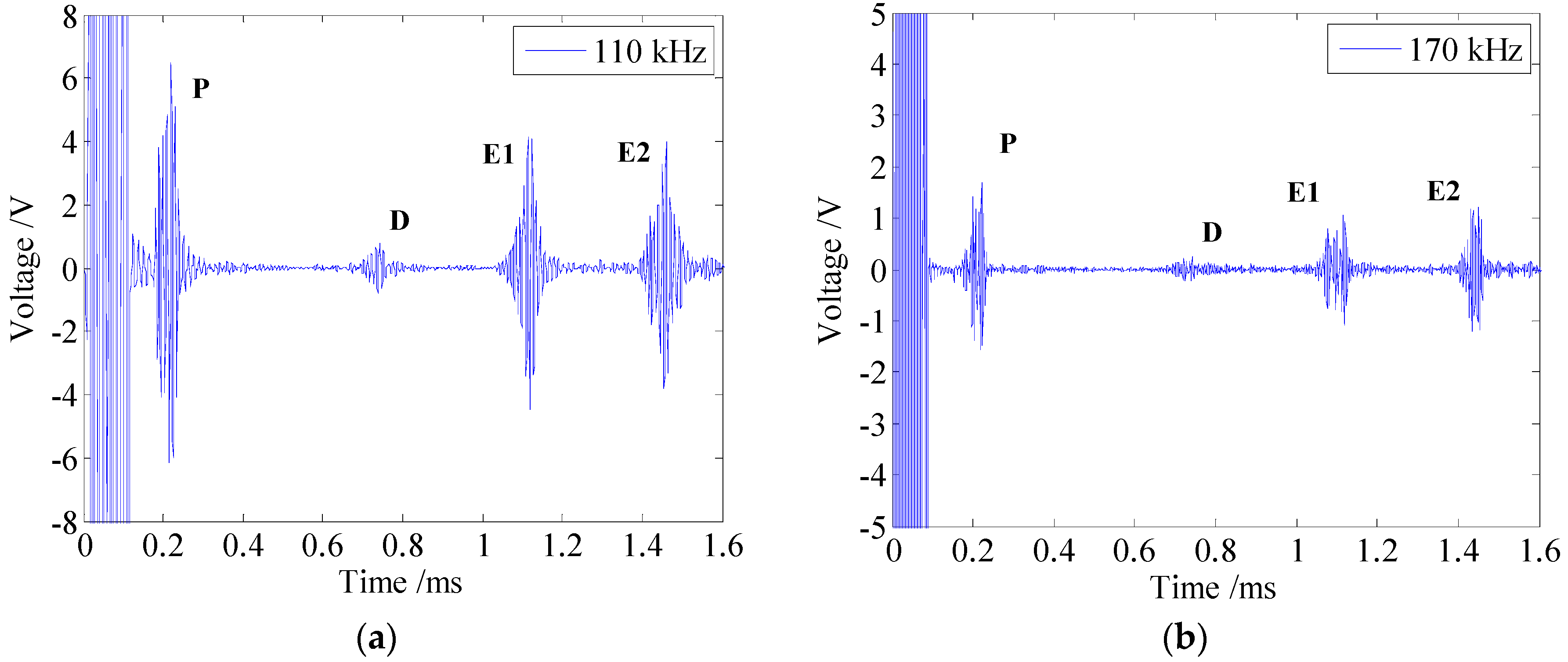

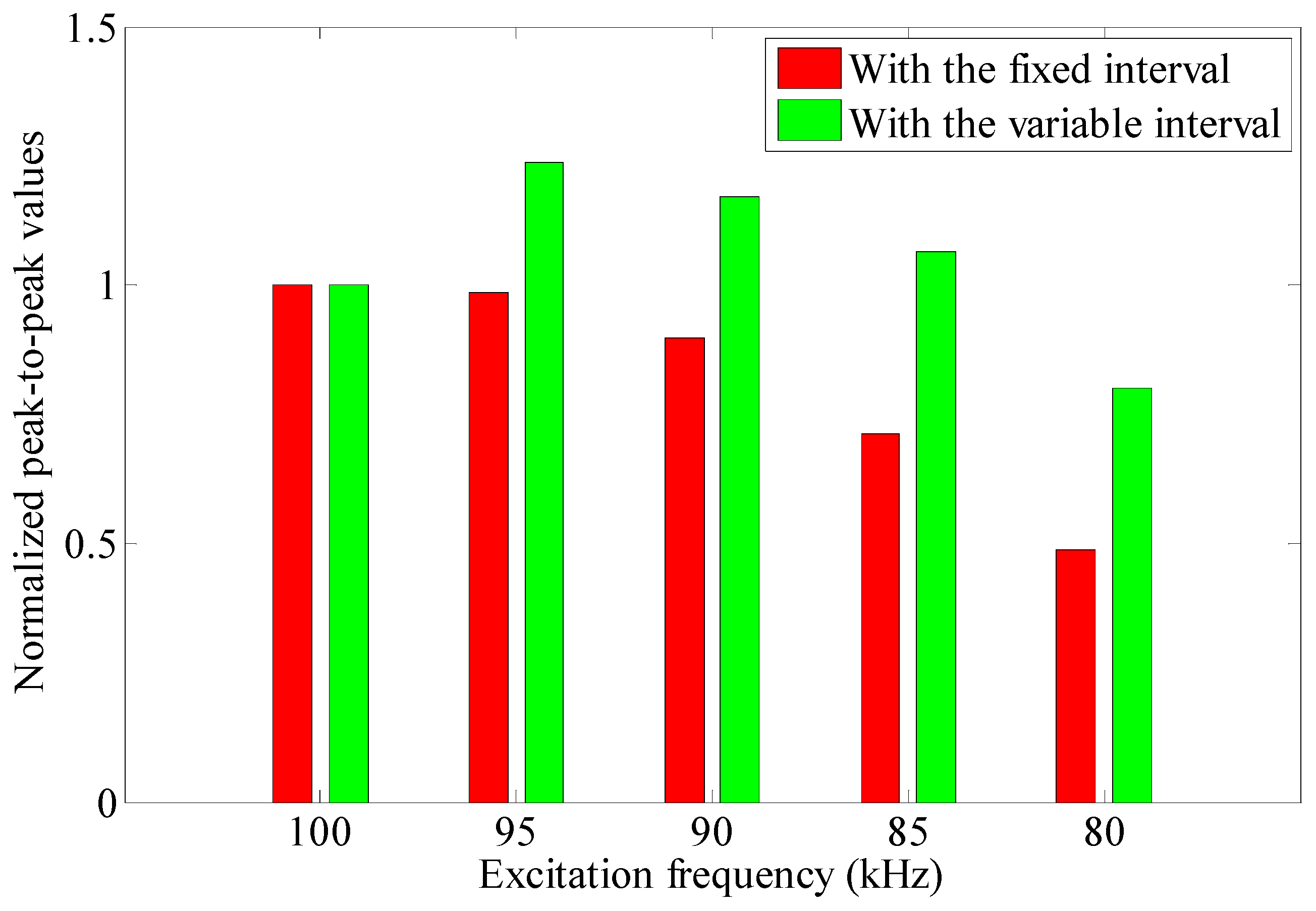

4.4. The Adjustable Optimal Testing Frequency of the Proposed EMAT

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Rose, J.L. A baseline and vision of ultrasonic guided wave inspection potential. J. Press. Vess. Technol. ASME 2002, 124, 273–282. [Google Scholar] [CrossRef]

- Lowe, M.J.S.; Alleyne, D.N.; Cawley, P. Defect detection in pipes using guided waves. Ultrasonics 1998, 36, 147–154. [Google Scholar] [CrossRef]

- Alleyne, D.N.; Pavlakovic, B.; Lowe, M.J.S.; Cawley, P. Rapid, long range inspection of chemical plant pipework using guided waves. AIP Conf. Proc. 2001, 557, 180–187. [Google Scholar]

- Casadei, F.; Delpero, T.; Bergamini, A.; Ermanni, P.; Ruzzene, M. Piezoelectric resonator arrays for tunable acoustic waveguides and metamaterials. J. Appl. Phys. 2012, 112. [Google Scholar] [CrossRef]

- Alleyne, D.N.; Cawley, P. The excitation of Lamb waves in pipes using dry-coupled piezoelectric transducers. J. Nondestruct. Eval. 1996, 15, 11–20. [Google Scholar] [CrossRef]

- Lee, J.H.; Lee, S.J. Application of laser-generated guided wave for evaluation of corrosion in carbon steel pipe. NDT&E Int. 2009, 42, 222–227. [Google Scholar]

- Løvstad, A.; Cawley, P. The reflection of the fundamental torsional guided wave from multiple circular holes in pipes. NDT&E Int. 2011, 44, 553–562. [Google Scholar]

- Ashigwuike, E.C.; Ushie, O.J.; Mackay, R.; Balachandran, W. A study of the transduction mechanisms of electromagnetic acoustic transducers (EMATs) on pipe steel materials. Sens. Actuators A Phys. 2015, 229, 154–165. [Google Scholar] [CrossRef]

- Edwards, R.S.; Sophian, A.; Dixon, S.; Tian, G.Y. Data fusion for defect characterization using a dual probe system. Sens. Actuators A Phys. 2008, 144, 222–228. [Google Scholar] [CrossRef]

- Kwun, H.; Bartels, K.A. Magnetostrictive sensor technology and its applications. Ultrasonics 1998, 36, 171–178. [Google Scholar] [CrossRef]

- Ribichini, R.; Cegla, F.; Nagy, P.B.; Cawley, P. Study and comparison of different EMAT configurations for SH wave inspection. IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 2011, 58, 2571–2581. [Google Scholar] [CrossRef] [PubMed]

- Kwun, H.; Teller, C.M. Magnetostrictive generation and detection of longitudinal, torsional, and flexural waves in a steel rod. J. Acoust. Soc. Am. 1994, 96, 1202–1204. [Google Scholar] [CrossRef]

- Hao, K.S.; Huang, S.L.; Zhao, W.; Wei, Z.; Wang, S.; Huang, Z. A new frequency-tuned longitudinal wave transducer for nondestructive inspection of pipes based on magnetostrictive effect. In Proceedings of the IEEE Sensors Application Symposium, Limerick, Ireland, 23–25 February 2010; pp. 64–68.

- Liu, Z.H.; Zhao, J.C.; Wu, B.; Zhang, Y.N.; He, C.F. Configuration optimization of magnetostrictive transducers for longitudinal guided wave inspection in seven-wire steel strands. NDT&E Int. 2010, 43, 484–492. [Google Scholar]

- Sun, P.F.; Wu, X.J.; Xu, J.; Li, J. Enhancement of the excitation efficiency of the non-contact magnetostrictive sensor for pipe inspection by adjusting the alternating magnetic field axial length. Sensors 2014, 14, 1544–1563. [Google Scholar] [CrossRef] [PubMed]

- Cho, S.H.; Kim, H.W.; Kim, Y.Y. Megahertz-range guided pure torsional wave transduction and experiments using a magnetostrictive transducer. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2010, 57, 1225–1229. [Google Scholar] [PubMed]

- Kim, H.W.; Lee, J.K.; Kim, Y.Y. Circumferential phased array of shear-horizontal wave magnetostrictive patch transducers for pipe inspection. Ultrasonics 2013, 53, 423–431. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.Y.; Kwon, Y.E. Review of Magnetostrictive Patch Transducers and Applications in Ultrasonic Nondestructive Testing of Waveguides. Ultrasonics 2015, 62, 3–19. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.H.; Hu, Y.N.; Fan, J.W.; Yin, W.L.; Liu, X.C.; He, C.F.; Wu, B. Longitudinal mode magnetostrictive patch transducer array employing a multi-splitting meander coil for pipe inspection. NDT&E Int. 2016, 79, 30–37. [Google Scholar]

- Liu, Z.H.; Fan, J.W.; Hu, Y.N.; He, C.F.; Wu, B. Torsional mode magnetostrictive patch transducer array employing a modified planar solenoid array coil for pipe inspection. NDT&E Int. 2015, 69, 9–15. [Google Scholar]

- Sun, K.H.; Cho, S.H.; Kim, Y.Y. Topology design optimization of a magnetostrictive patch for maximizing elastic wave transduction in waveguides. IEEE. Trans. Magn. 2008, 44, 2373–2380. [Google Scholar] [CrossRef]

- Kim, Y.Y.; Park, C.I.; Cho, S.H.; Han, S.W. Torsional wave experiments with a new magnetostrictive transducer configuration. J. Acoust. Soc. Am. 2005, 117, 3459–3468. [Google Scholar] [CrossRef] [PubMed]

- Thompson, R.B. A model for the electromagnetic generation and detection of Rayleigh and Lamb waves. IEEE Trans. Sonics Ultrason. 1973, 20, 340–346. [Google Scholar] [CrossRef]

- Wilcox, P.; Lowe, M.J.S.; Cawley, P. Omnidirectional guided wave inspection of large metallic plate structures using an EMAT array. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2005, 52, 653–665. [Google Scholar] [CrossRef] [PubMed]

- Seher, M.; Huthwaite, P.; Lowe, M.J.S.; Nagy, P.B. Model-based design of low frequency lamb wave EMATs for mode selectivity. J. Nondestruct. Eval. 2015, 34, 1–16. [Google Scholar] [CrossRef]

- Vasile, C.F.; Thompson, R.B. Excitation of horizontally polarized shear elastic waves by electromagnetic transducers with periodic permanent magnets. J. Appl. Phys. 1979, 50, 2583–2588. [Google Scholar] [CrossRef]

- Hirao, M.; Ogi, H. An SH-wave EMAT technique for gas pipeline inspection. NDT&E Int. 1999, 32, 127–132. [Google Scholar]

- Nakamura, N.; Ogi, H.; Hirao, M. Mode conversion and total reflection of torsional waves for pipe inspection. Jpn. J. Appl. Phys. 2013, 52. [Google Scholar] [CrossRef]

- Wang, Y.G.; Wu, X.J.; Sun, P.F.; Li, J. Enhancement of the Excitation Efficiency of a Torsional Wave PPM EMAT array for Pipe Inspection by Optimizing the Element Number of the array Based on 3-D FEM. Sensors 2015, 15, 3471–3490. [Google Scholar] [CrossRef] [PubMed]

- Alleyne, D.N.; Lowe, M.J.S.; Cawley, P. The reflection of guided waves from circumferential notches in pipes. J. Appl. Mech. 1998, 65, 635–641. [Google Scholar] [CrossRef]

- Lowe, M.J.S.; Alleyne, D.N.; Cawley, P. The mode conversion of a guided wave by a part-circumferential notch in a pipe. J. Appl. Mech. 1998, 65, 649–656. [Google Scholar] [CrossRef]

- Sablik, M.J.; Telschow, K.L.; Augustyniak, B.; Grubba, J.; Chmielewski, M. Relationship between magnetostriction and the magnetostrictive coupling coefficient for magnetostrictive generation of elastic waves. AIP Conf. Proc. 2002, 615, 1613–1620. [Google Scholar]

- Wang, S.J.; Kang, L.; Li, Z.C.; Zhai, G.F.; Zhang, L. 3-D modeling and analysis of meander-line-coil surface wave EMATs. Mechatronics 2012, 22, 653–660. [Google Scholar] [CrossRef]

- Thompson, R.B. Physical Principles of Measurements with EMAT Transducers. Phys. Acoust. 1990, 19, 157–200. [Google Scholar]

- Ding, X.; Wu, X.J.; Wang, Y.G. Bolt axial stress measurement based on a mode-converted ultrasound method using an electromagnetic acoustic transducer. Ultrasonics 2014, 54, 914–920. [Google Scholar] [CrossRef] [PubMed]

- Seco, F.; Martín, J.M.; Jiménez, A.; Pons, J.L.; Calderón, L. PCDISP: A tool for the simulation of wave propagation in cylindrical waveguides. In Proceedings of the 9th International Congress on Sound and Vibration, Orlando, FL, USA, 8–11 July 2002; pp. 1–7.

| Object | Parameters | Symbol | Value |

|---|---|---|---|

| Pipe | Outer diameter | Dp | 38 mm |

| Wall thickness | Tp | 5 mm | |

| Length | Lp | 400 mm | |

| Density | 7850 kg/m3 | ||

| Young’s modulus | E | 210 GPa | |

| Poisson’s ratio | v | 0.28 | |

| Resistivity | p | 1.4 × 10−7 Ω·m | |

| Relative magnetic permeability | μr | 200 | |

| Air | Length | La | 800 mm |

| Width | Wa | 150 mm | |

| Height | Ha | 150 mm | |

| Relative magnetic permeability | μa | 1 | |

| Permanent magnet | Length | Lm | 30 mm |

| Width | Wm | 15 mm | |

| Height | Hm | 20 mm | |

| Number | Nm | 4 to 8 | |

| Coercive force | Hm | 955 kA/m | |

| Residual magnetic flux density | Br | 1.45 T | |

| Solenoid testing coil (Copper coil) | Diameter | Dc | 0.17 mm |

| Turn number | Nc | 20 | |

| Lift-off distance | Lc | 0.54 mm | |

| Interval | Ie | 1.25 mm | |

| Resistivity | c | 1.7 × 10−8 Ω·m | |

| Excitation current | Amplitude | Ie | 10 A |

| Frequency | fe | 100 kHz | |

| Cycle | Te | 5 |

| Frequency/kHz | 100 | 95 | 90 | 85 | 80 |

| L1/mm | 109.2 | 115.2 | 122.0 | 129.8 | 138.6 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cong, M.; Wu, X.; Qian, C. A Longitudinal Mode Electromagnetic Acoustic Transducer (EMAT) Based on a Permanent Magnet Chain for Pipe Inspection. Sensors 2016, 16, 740. https://doi.org/10.3390/s16050740

Cong M, Wu X, Qian C. A Longitudinal Mode Electromagnetic Acoustic Transducer (EMAT) Based on a Permanent Magnet Chain for Pipe Inspection. Sensors. 2016; 16(5):740. https://doi.org/10.3390/s16050740

Chicago/Turabian StyleCong, Ming, Xinjun Wu, and Chunqiao Qian. 2016. "A Longitudinal Mode Electromagnetic Acoustic Transducer (EMAT) Based on a Permanent Magnet Chain for Pipe Inspection" Sensors 16, no. 5: 740. https://doi.org/10.3390/s16050740