Detection and Inspection of Steel Bars in Reinforced Concrete Structures Using Active Infrared Thermography with Microwave Excitation and Eddy Current Sensors

Abstract

:1. Introduction

- Assessing the dimensions of structural elements and locating damage and defects (such as voids, cracks and inclusions). Here the most popular NDT methods are: ultrasonic sensors and ground penetrating radar [4,5,6,7,8,9,10,11,12]. Both methods are fast and reliable, but the results obtained are not easy to interpret. Active and passive thermography can also be used to inspect the inner structure of concrete, but due to some limitations, in practice these techniques are used to detect defects or plaster damages near the surface [12,13].

- Reinforcement location and corrosion assessment. Here the natural choices are electro- magnetic methods, such as radiography (a very efficient method, but hard to use in practice and dangerous for the operator) [14,15,16,17], eddy current sensors (a promising method, that allows not only the detection of the reinforcement, but also identification) [18,19,20] and impedance tomography, which is, in contrast to previously mentioned methods, a contact technique.

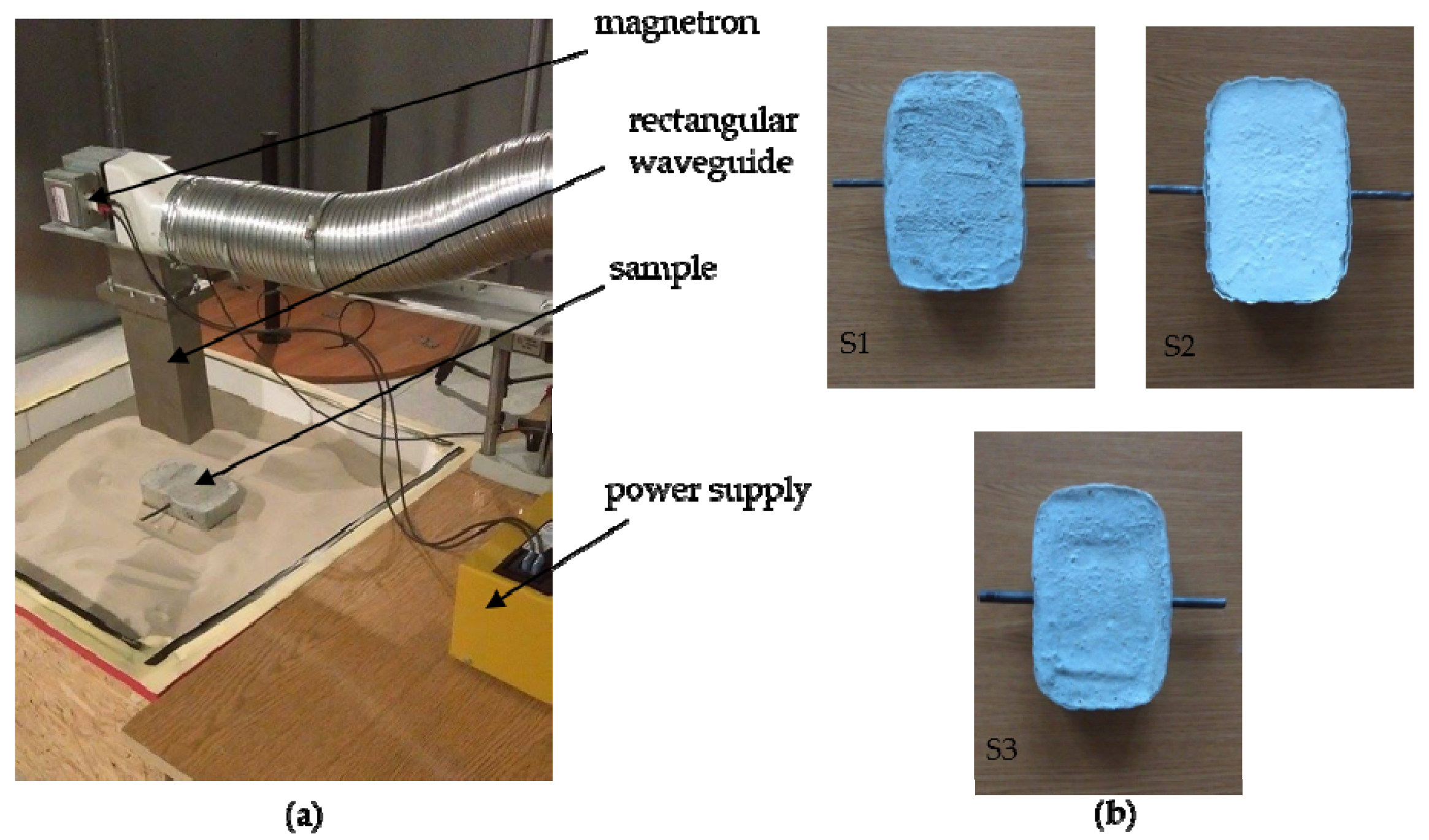

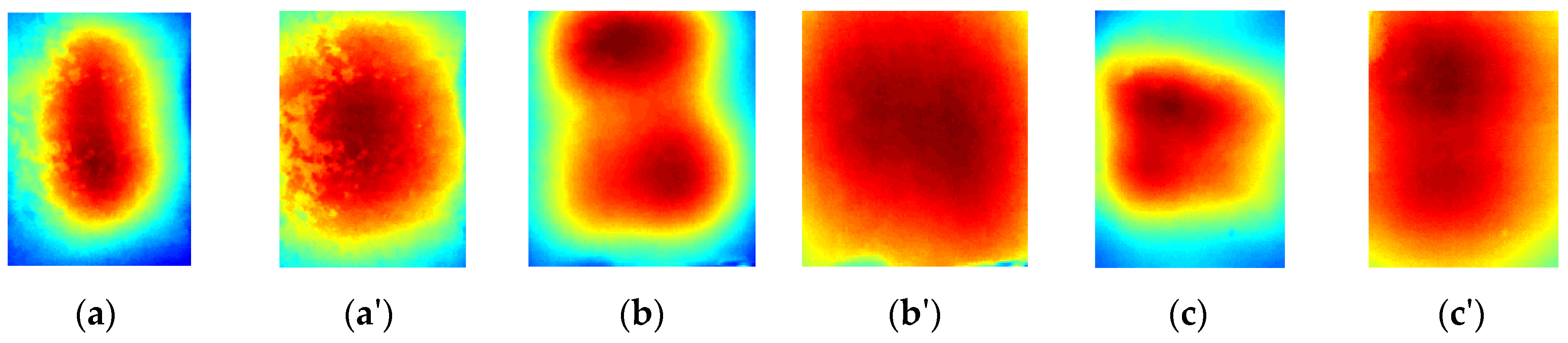

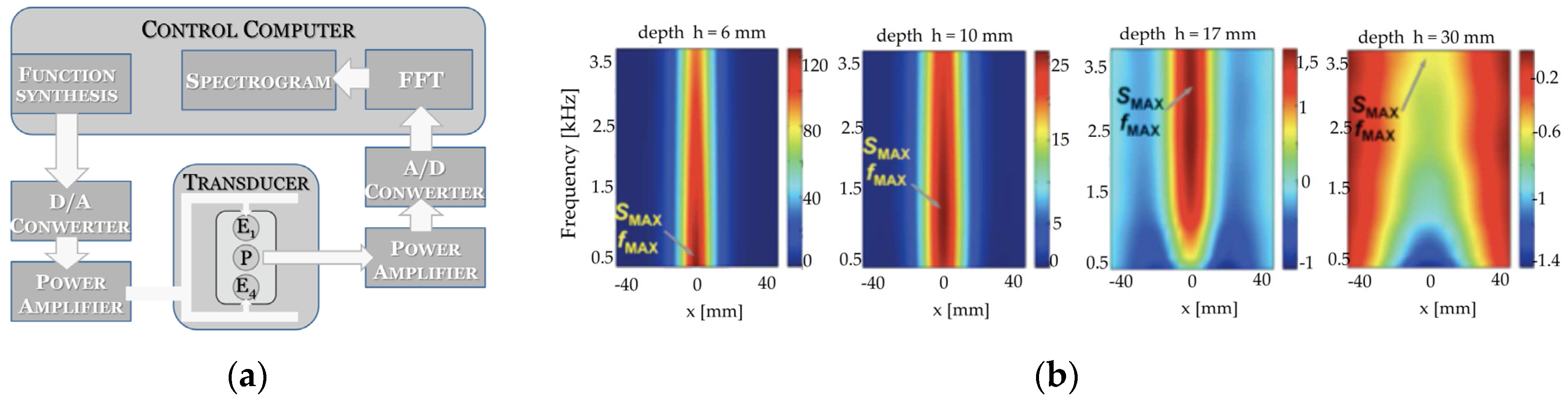

2. Active Infrared Thermography with Microwave Excitation

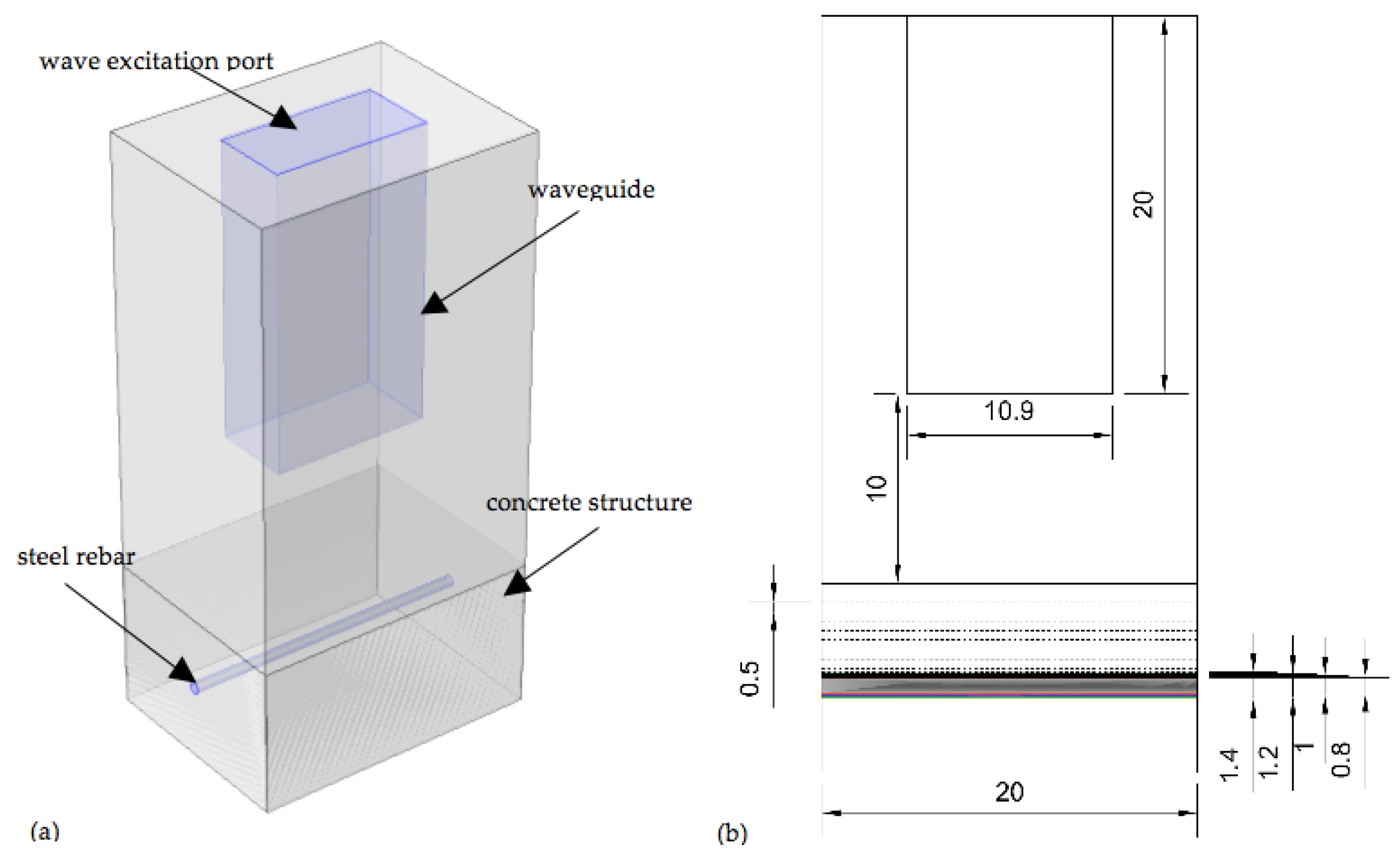

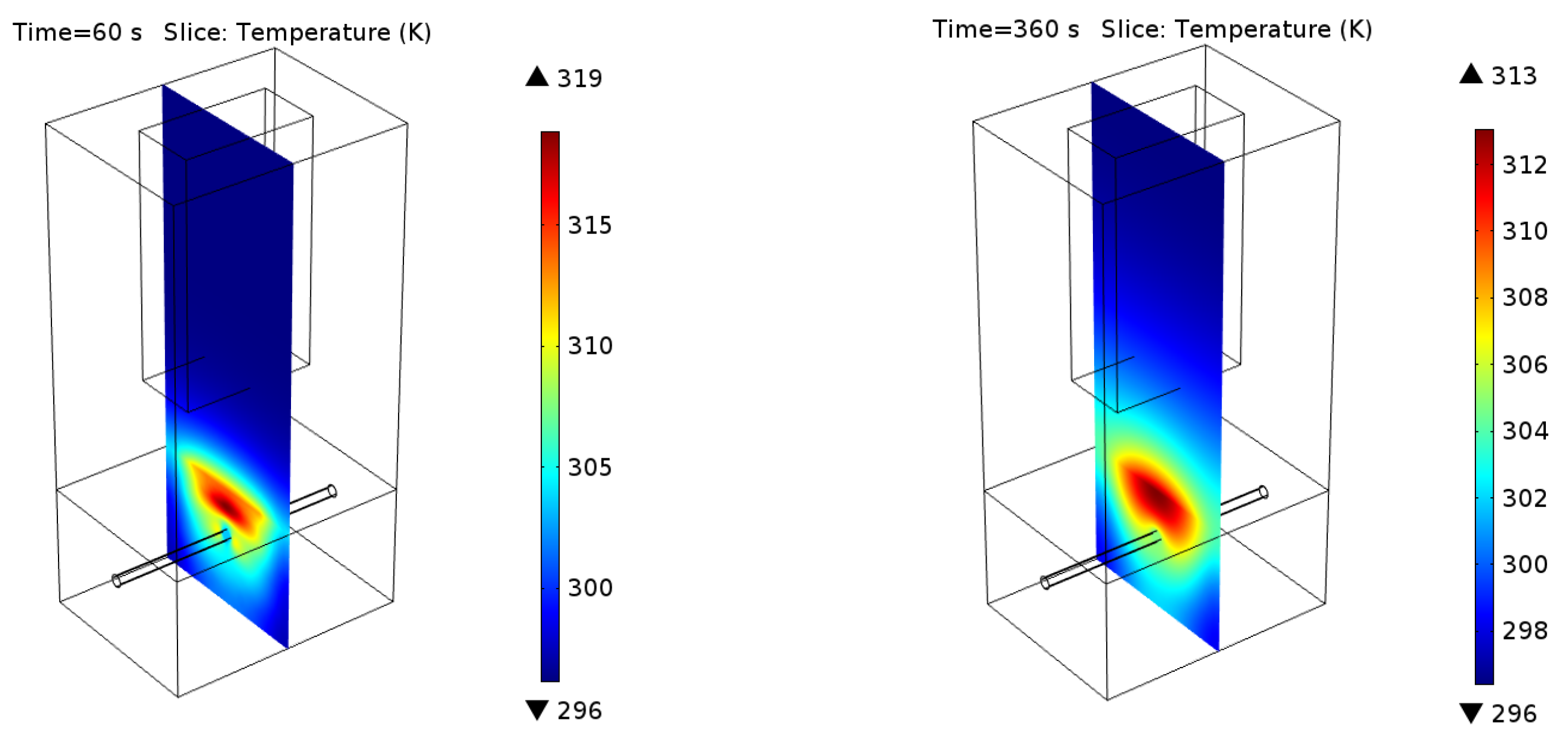

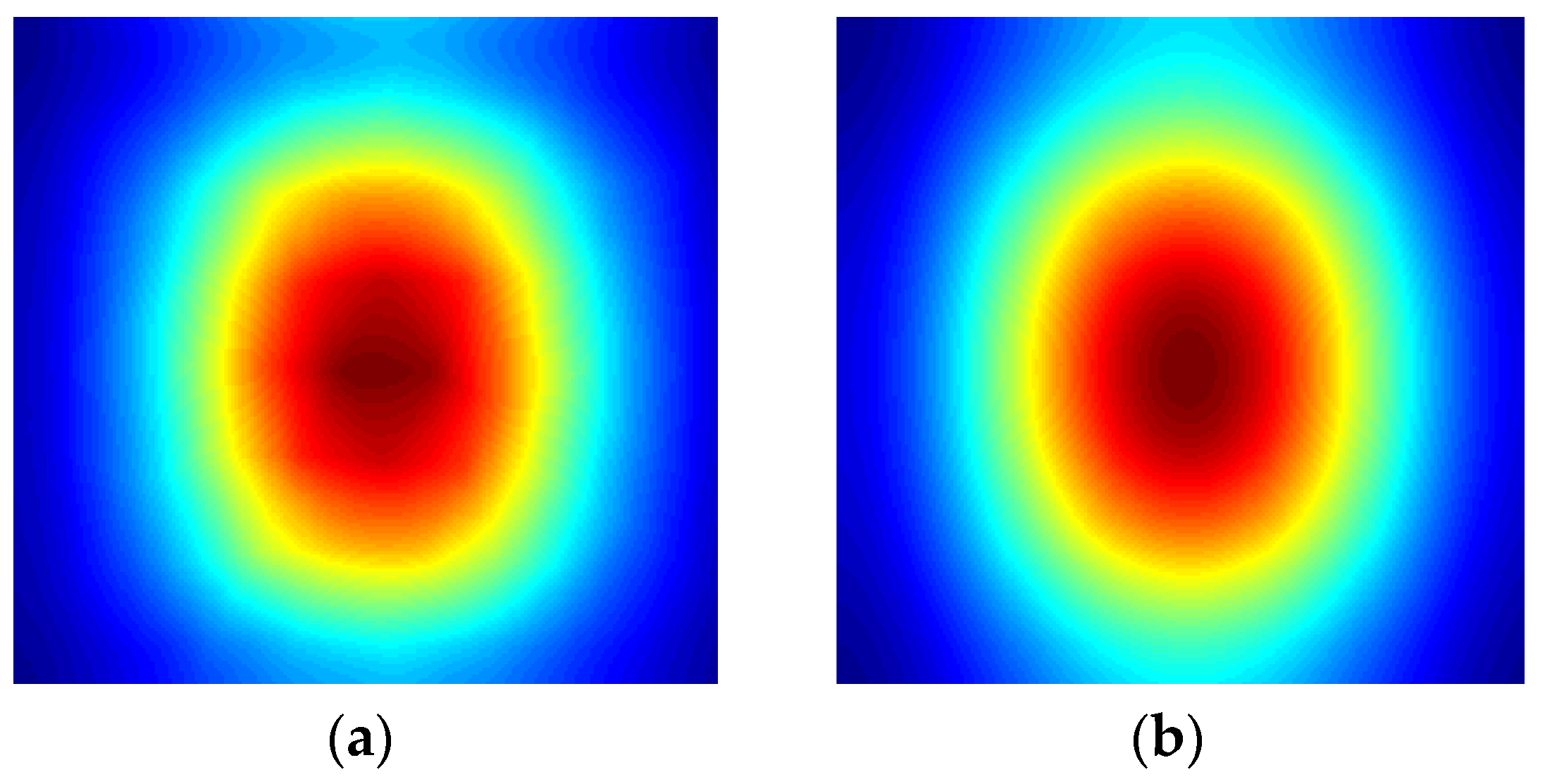

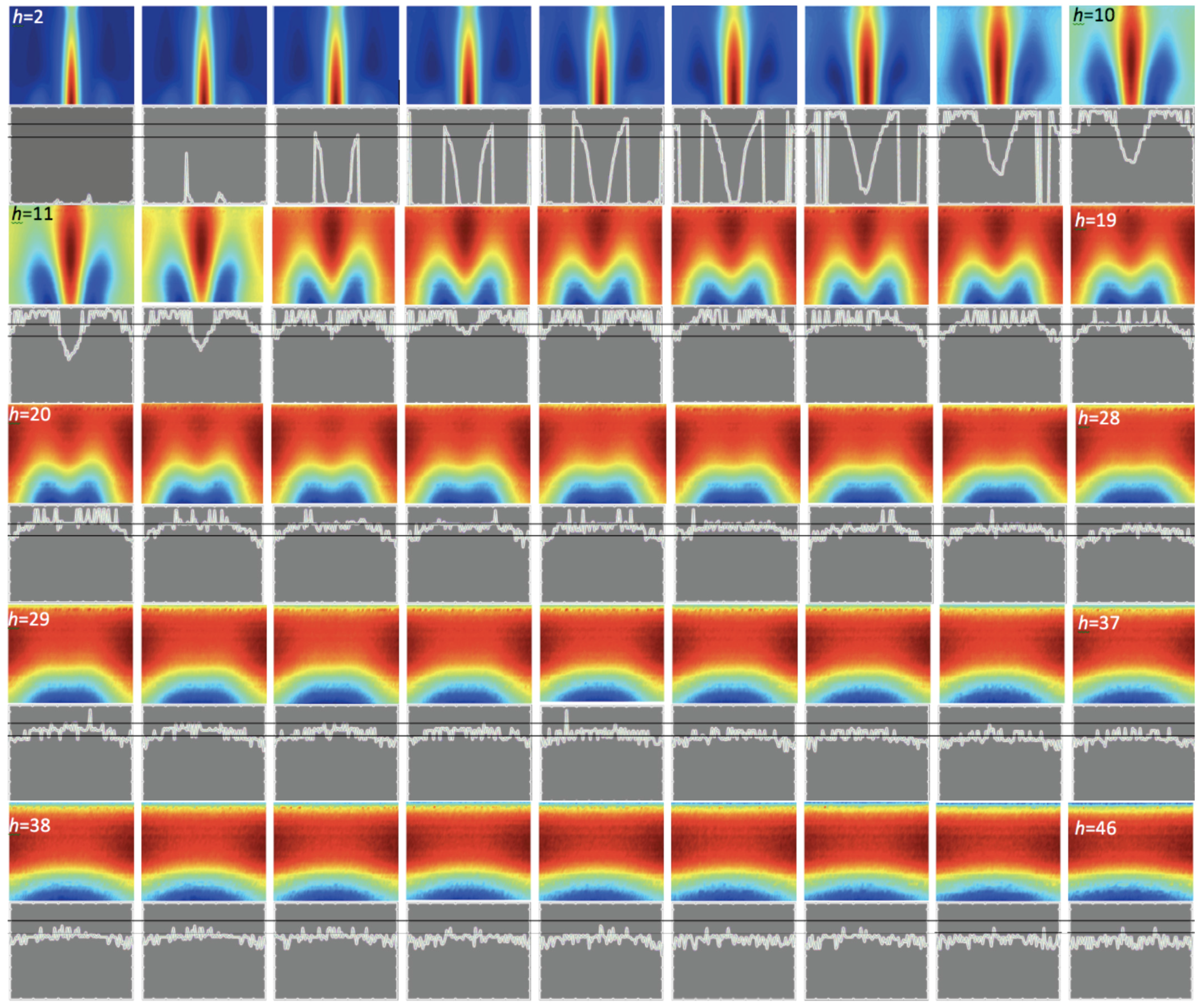

2.1. Numerical Modelling of Microwave Heating

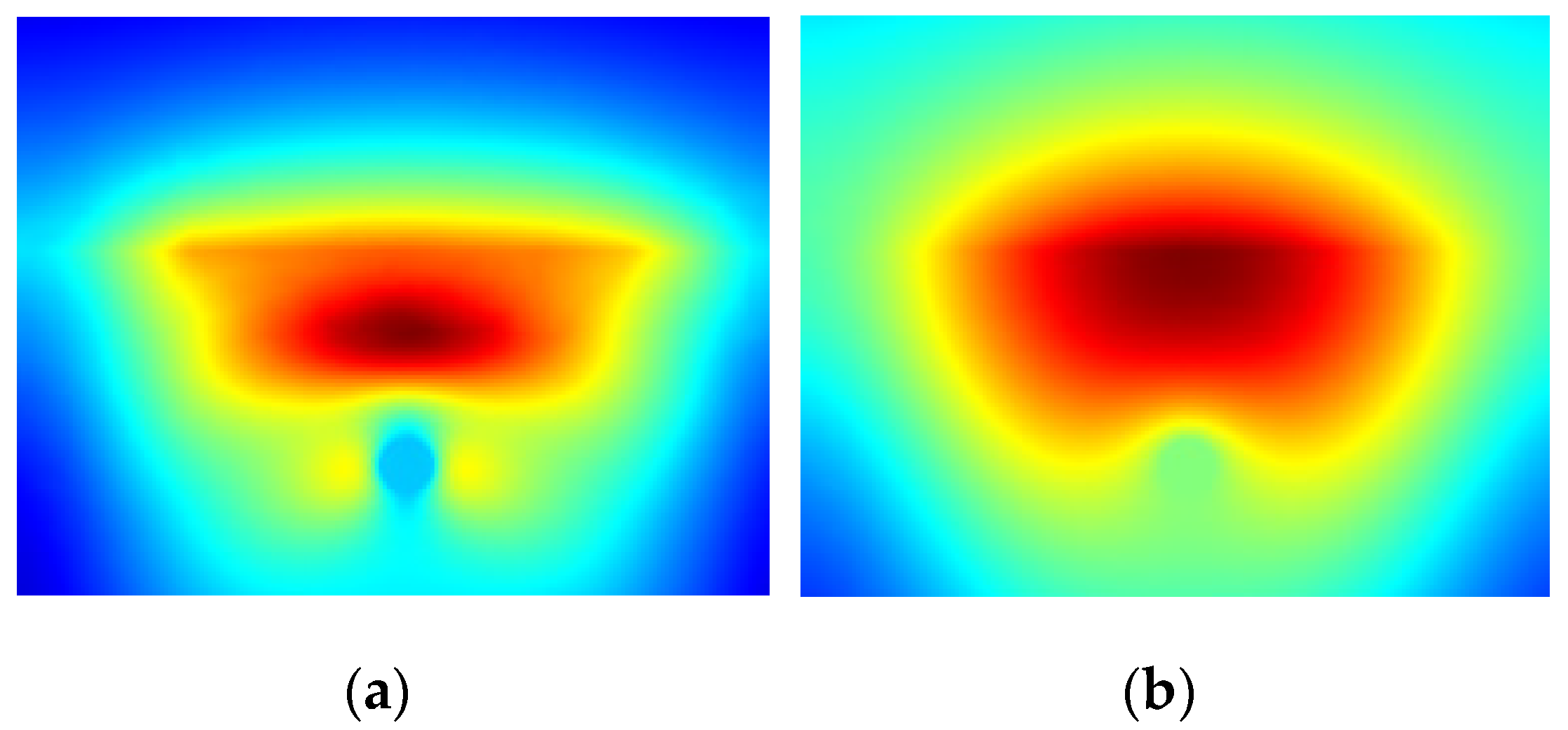

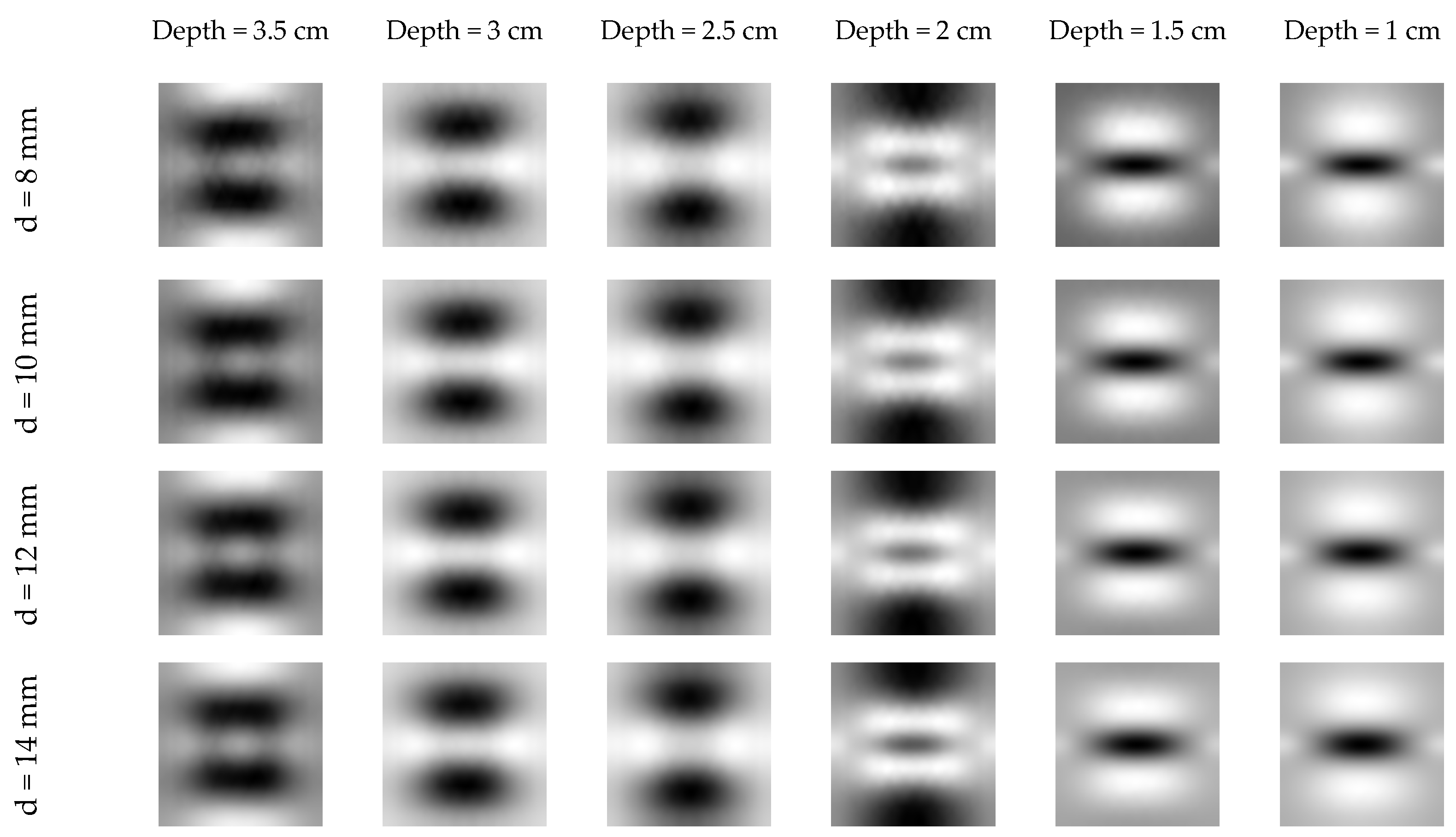

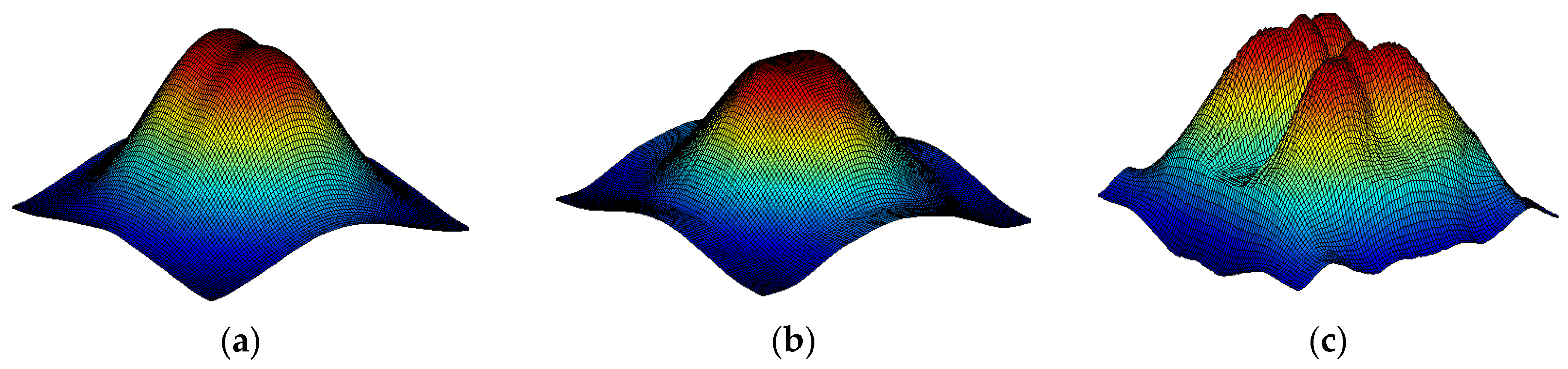

2.2. Experimental Methods and Results

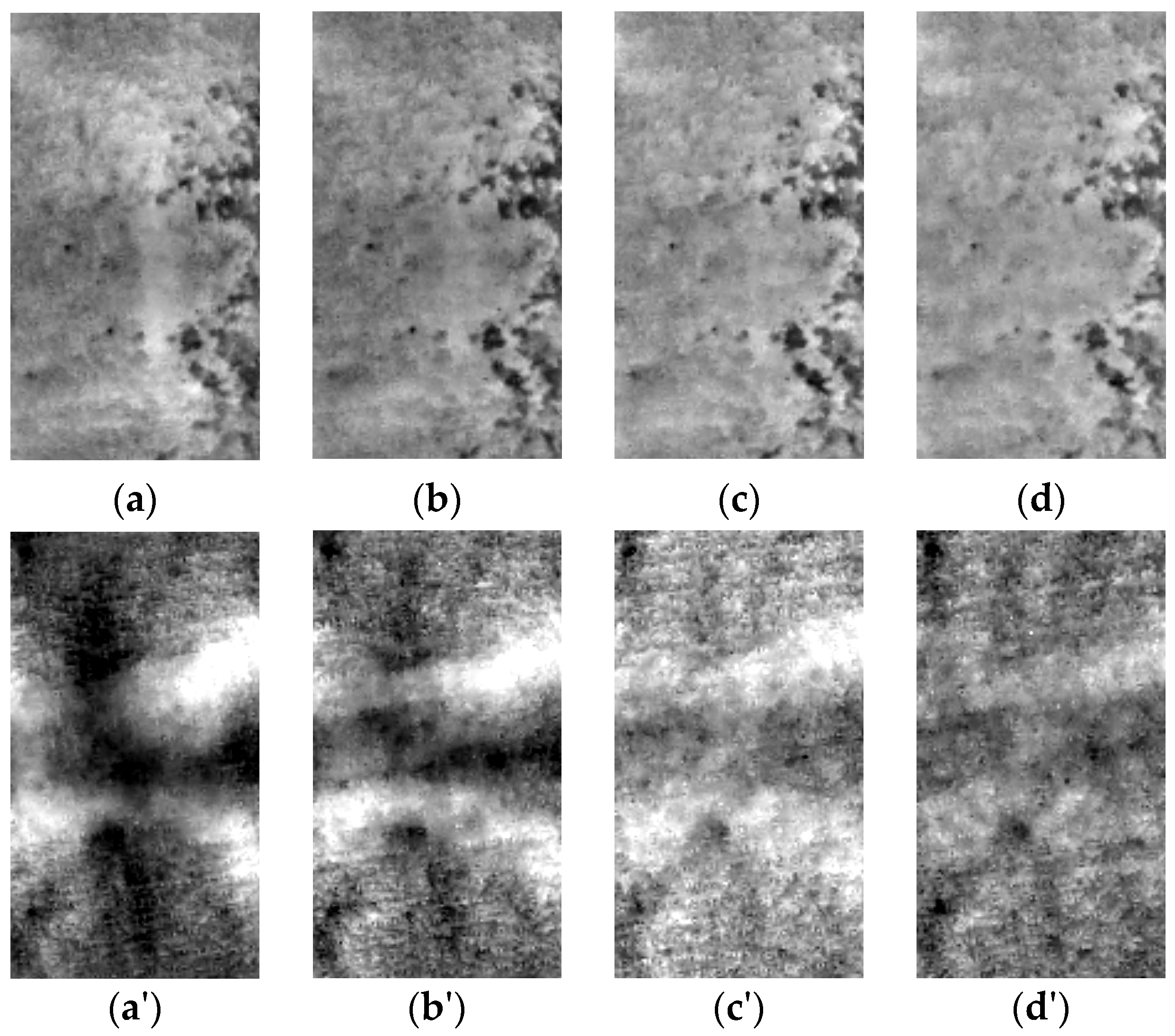

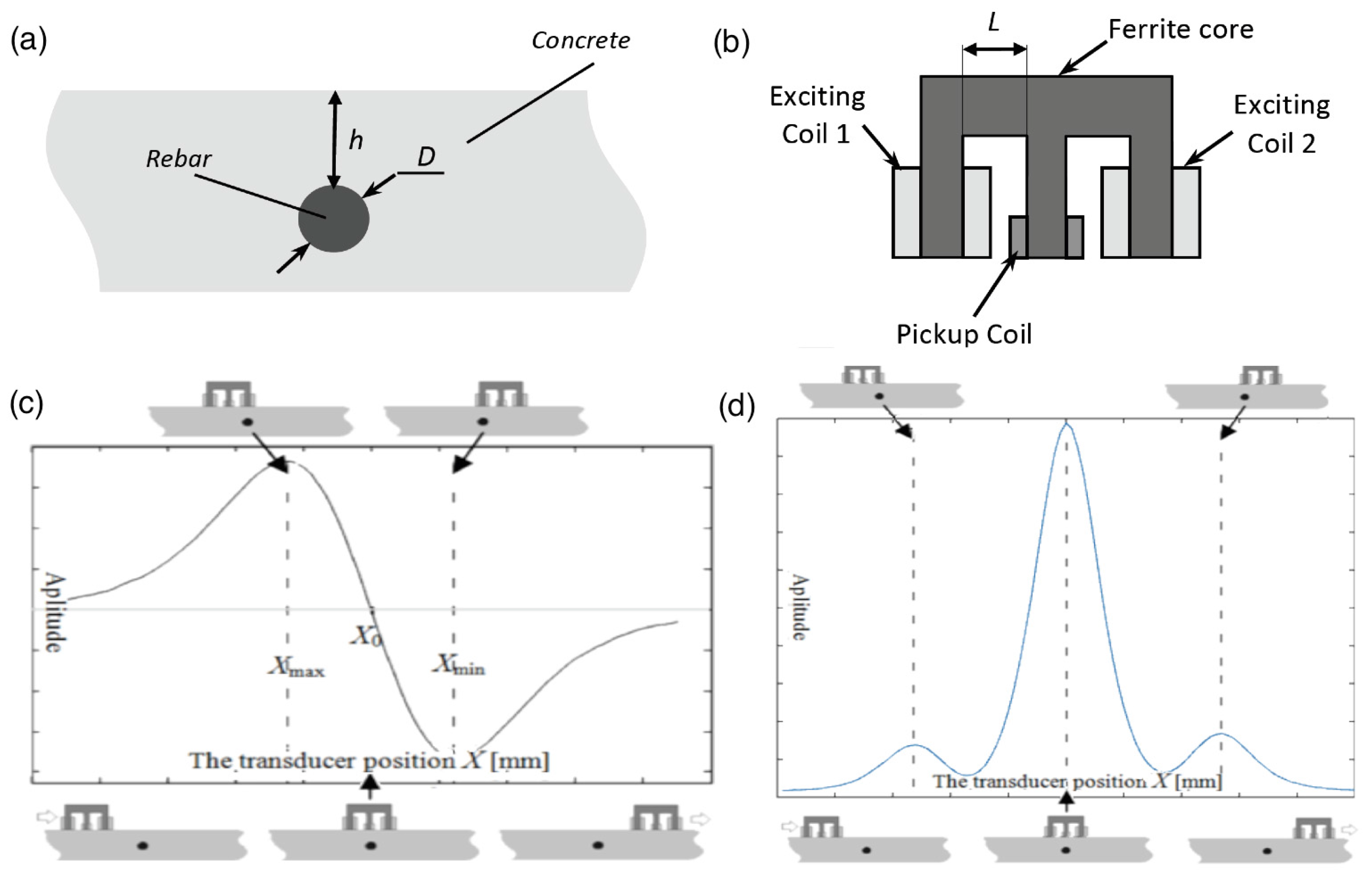

3. Eddy Current Technique

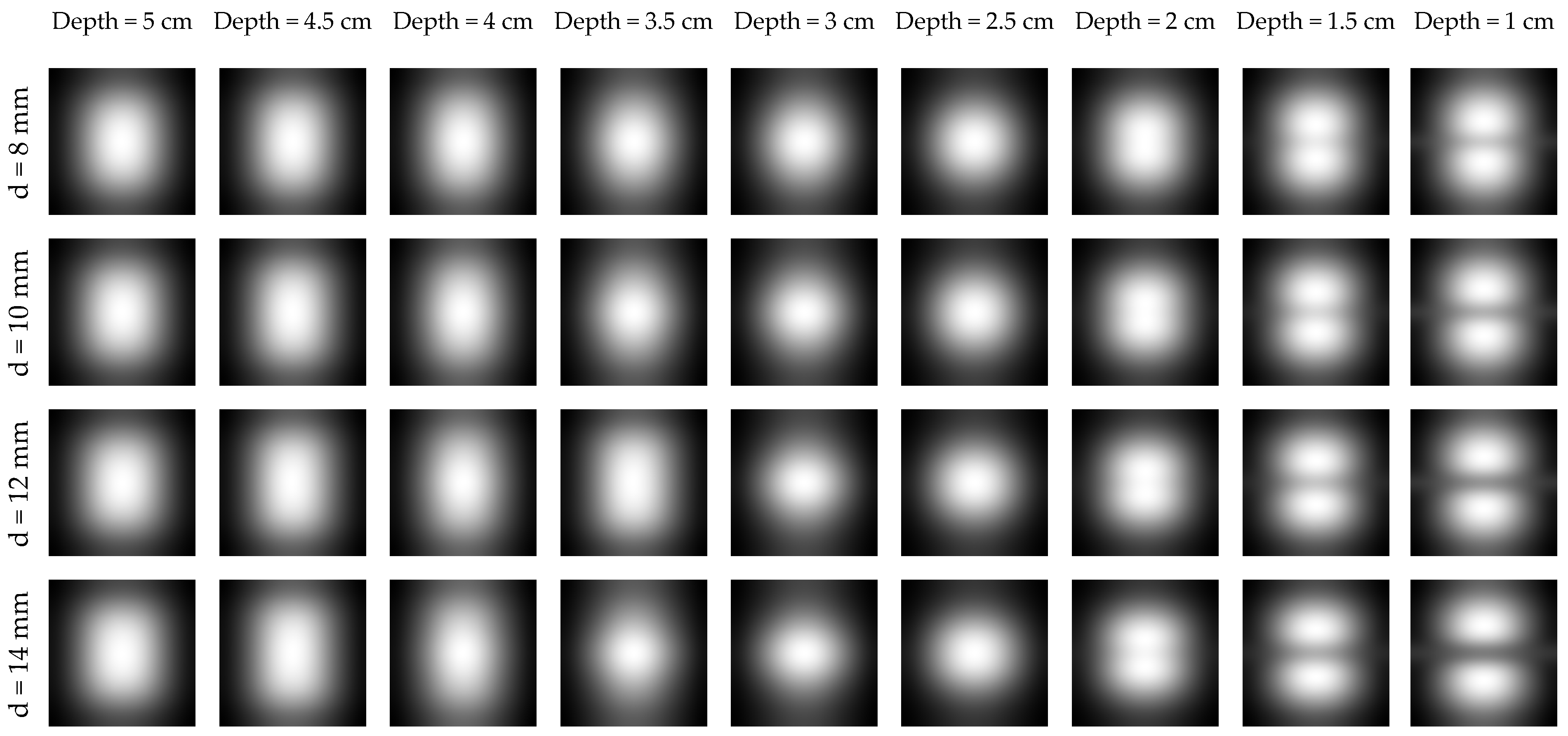

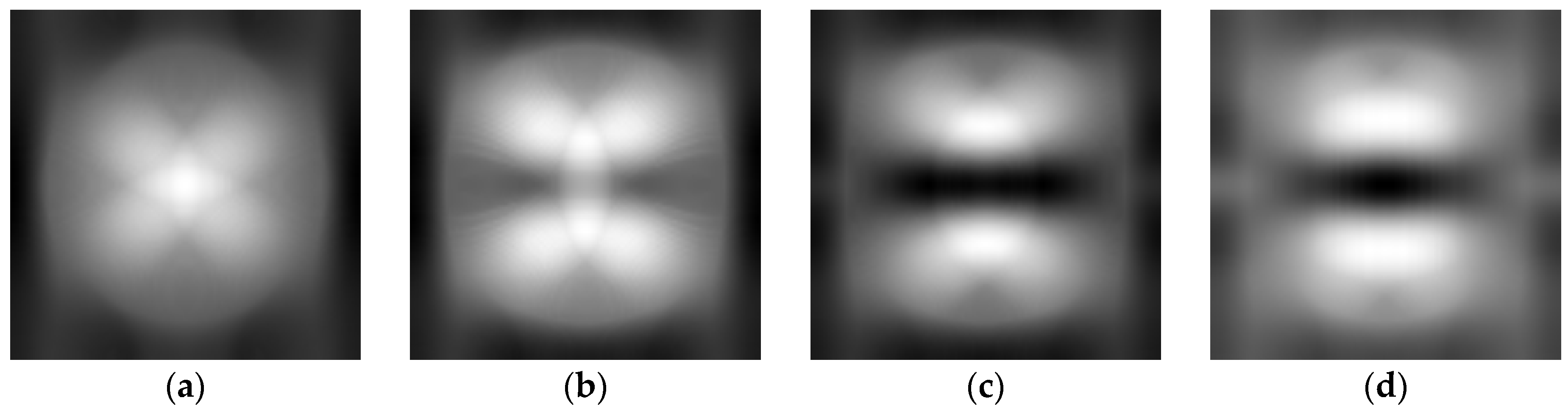

3.1. Single Frequency Methods

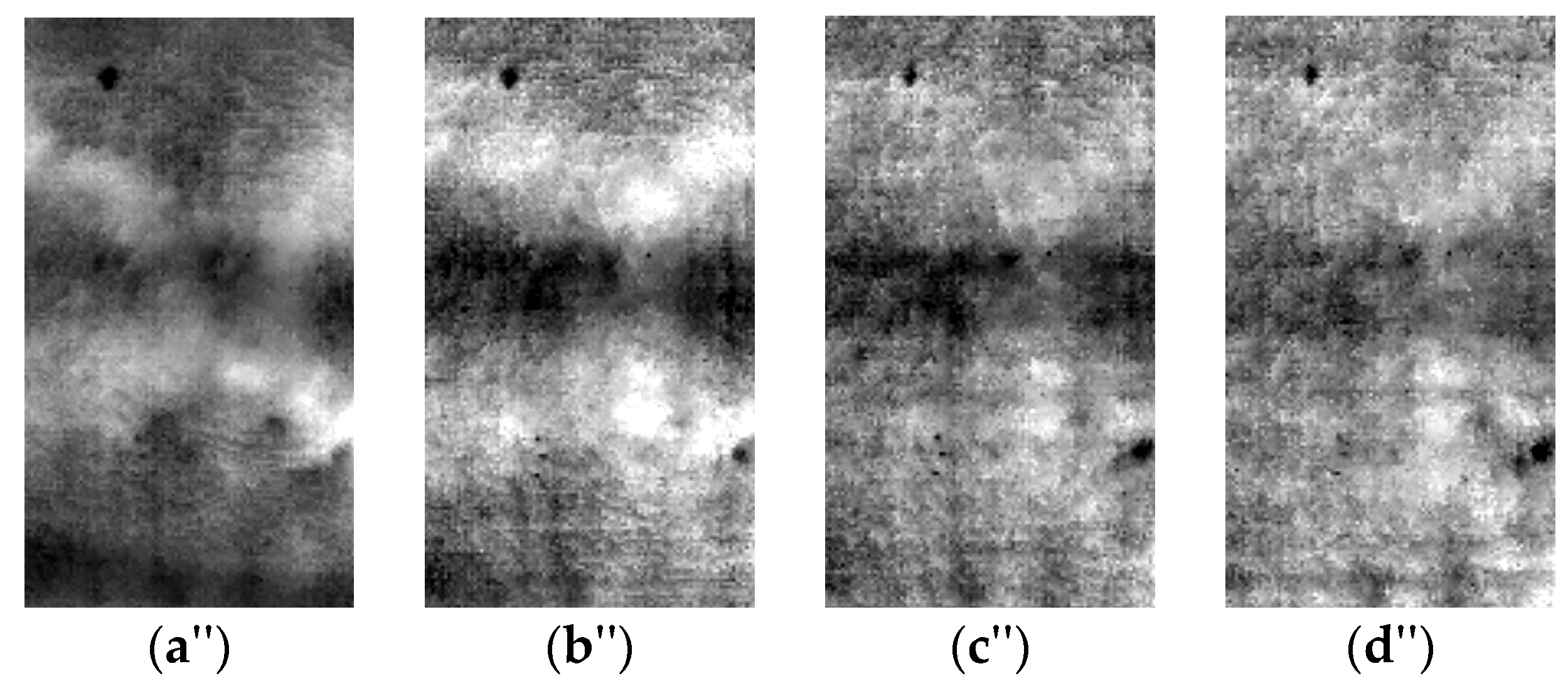

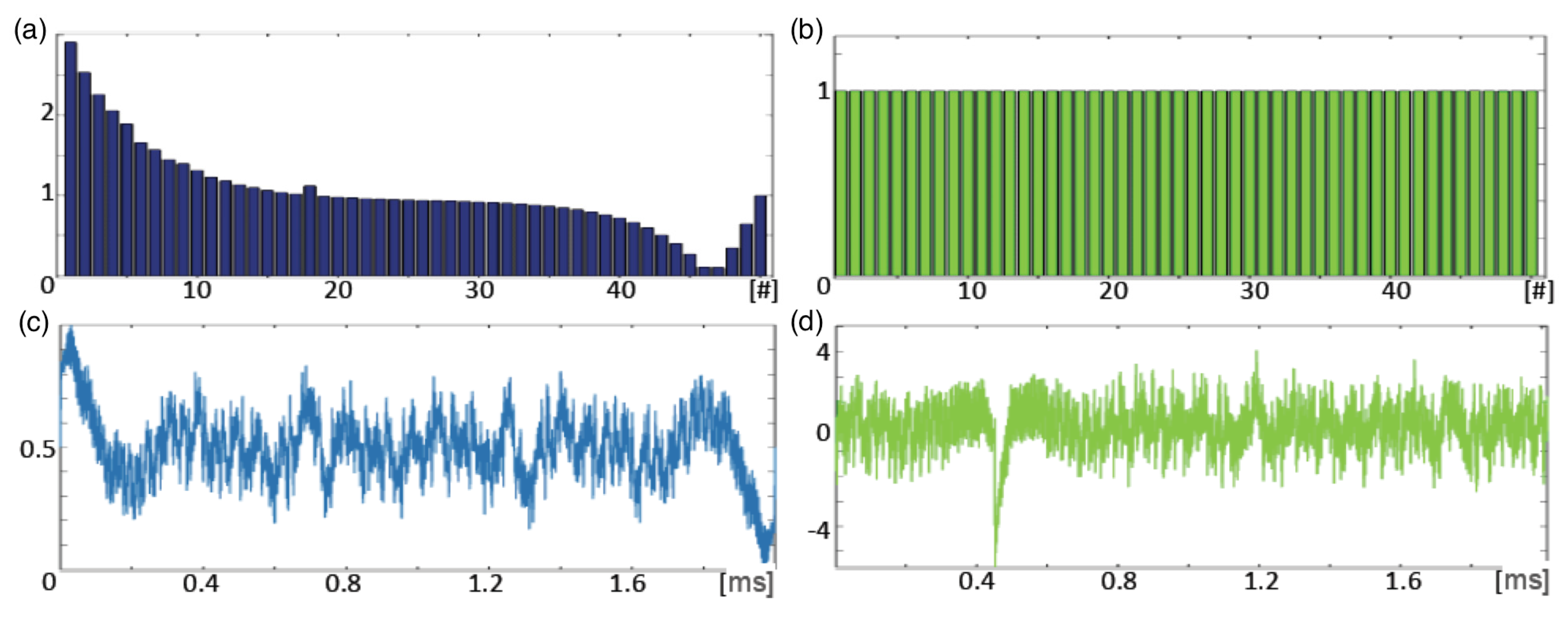

3.2. Massive Multi-Frequency and Spectrogram Method

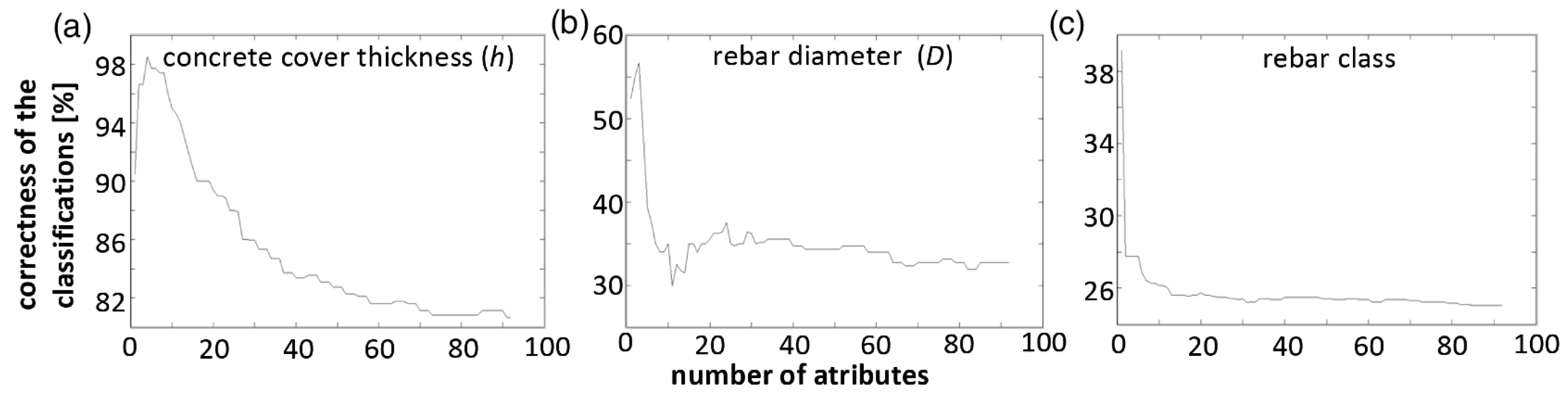

3.3. Results and Identification

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Masoumi, F.; Akgül, F.; Mehrabzadeh, A. Condition Assessment of Reinforced Concrete Bridges by Combined Nondestructive Test Techniques. IACSIT Int. J. Eng. Technol. 2013, 5, 708–711. [Google Scholar] [CrossRef]

- Hoła, J.; Schabowicz, K. State-of-the-art non-destructive methods for diagnostic testing of building structures-anticipated development trends. Arch. Civil Mech. Eng. 2010, 10, 5–18. [Google Scholar] [CrossRef]

- Maierhofer, C.; Reinhardt, H.W.; Dobmann, G. Non-Destructive Evaluation of Reinforced Concrete Structures; Woodhead Publishing CRC Press: Cambridge, UK, 2010. [Google Scholar]

- Sakata, Y.; Ohtsu, M. Crack evaluation in concrete members based on ultrasonic spectroscopy. ACI Mater. J. 1995, 92, 686–698. [Google Scholar]

- Schickert, M. Ultrasonic NDE of concrete. In Proceedings of the 2002 IEEE Ultrasonics Symposium, Munich, Germany, 8–11 October 2003; pp. 739–748.

- Lorenzi, A.; Tisbierek, F.T.; Silva, L.C.P. Ultrasonic Pulse Velocity Analysis in Concrete Specimens. In Proceedings of the IV Conferencia Panamericana de END, Buenos Aires, Argentina, 22–26 October 2007.

- Clayton, D.A. Nondestructive Evaluation of Thick Concrete Structures. In Proceedings of the International Symposium Non-Destructive Testing in Civil Engineering (NDT-CE), Berlin, Germany, 15–17 September 2015.

- Al-Qadi, L.; Lahour, S. Ground Penetrating Radar: State of the Practice for Pavement Assessment. J. Mater. Eval. 2004, 42, 759–763. [Google Scholar]

- Morcous, G.; Erdogmus, E. Use of Ground Penetrating Radar for Construction Quality Assurance of Concrete Pavement; NDOR Project Number P307, FINAL REPORT; University of Nebraska-Lincoln: Lincoln, NE, USA, 2009. [Google Scholar]

- Maierhofer, C. Nondestructive Evaluation of Concrete Infrastructure with Ground Penetrating Radar. ASCE J. Mater. Civil Eng. 2003, 15, 287–297. [Google Scholar] [CrossRef]

- Hasan, M.I.; Yazdani, N. Ground penetrating radar utilization in exploring inadequate concrete covers in a new bridge deck. Case Stud. Construct. Mater. 2014, 1, 104–114. [Google Scholar] [CrossRef]

- Clark, M.; McCann, D.; Forde, M. Application of infrared thermography to the non-destructive testing of concrete and masonry bridges. NDT&E Int. 2003, 36, 265–275. [Google Scholar]

- Maierhofer, C.; Arndt, R.; R̈ollig, M.; Rieck, C.; Walther, A.; Scheel, H.; Hillemeier, B. Application of impulse-thermography for non-destructive assessment of concrete structures. Cem. Concr. Compos. 2006, 28, 393–401. [Google Scholar] [CrossRef]

- Martz, H.; Roberson, G.; Skeate, M.; Schneberk, D.; Azevedo, S. Computerized tomography studies of concrete samples. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 1991, 58, 216–226. [Google Scholar] [CrossRef]

- Martz, H.; Scheberk, D.; Roberson, G.; Monteiro, P. Computerized tomography analysis of reinforced concrete. ACI Mater. J. 1993, 90, 259–264. [Google Scholar]

- Paetsch, O.; Baum, D.; Ehrig, K.; Meinel, D.; Prohaska, S. Automated 3D Crack Detection for Analyzing Damage Processes in Concrete with Computed Tomography. In Proceedings of the ICT Conference Wels 2012, Wels, Austria, 19–21 September 2012; pp. 321–330.

- Paetsch, O.; Baum, D.; Prohaska, S.; Ehrig, K.; Meinel, D.; Ebell, G. 3D Corrosion Detection in Time-dependent CT Images of Concrete. In Proceedings of the Digital Industrial Radiology and Computed Tomography (DIR 2015), Ghent, Belgium, 22–25 June 2015.

- Chady, T.; Enokizono, M. Flaw Reconstruction using a Multi-Frequency Method and an Artificial Intelligence. JSAEM Stud. Appl. Electromagn. Mech. 1999, 8, 203–208. [Google Scholar]

- Chady, T.; Enokizono, M. Multi-frequency exciting and spectrogram based ECT method. J. Magn. Magn. Mater. 2000, 215–216, 700–703. [Google Scholar] [CrossRef]

- Chady, T.; Łopato, P. Flaws Identification Using Eddy Current Differential Transducer and Artificial Neural Networks. In Review of Quantitative Nondestructive Evaluation; Thompson, D.O., Chimenti, D.E., Eds.; American Institute of Physics, AIP CP 820: Melville, NY, USA, 2005; Volume 25, pp. 783–790. [Google Scholar]

- Berowski, P.; Filipowicz, S.F.; Sikora, J.; Wójtowicz, S. Determining Location of Moisture Area of the Wall by 3D Electrical Impedance Tomography. In Proceedings of the 4th World Congress on Industrial Process Tomography, Aizu, Japan, 2–5 September 2005.

- Seppänen, A.; Hallaji, M.; Pour-Ghaz, M. Electrical impedance tomography-based sensing skin for detection of damage in concrete. In Proceedings of the 11th European Conference on Non-Destructive Testing (ECNDT 2014), Prague, Czech Republic, 6–10 October 2014.

- Karhunen, K.; Seppänen, A.; Lehikoinen, A.; Monteiro, P.J.M.; Kaipio, J.P. Electrical resistance tomography imaging of concrete. Cem. Concr. Res. 2010, 40, 137–145. [Google Scholar] [CrossRef]

- Brachelet, F.; Keo, S.; Defer, D.; Breaban, F. Detection of reinforcement bars in concrete slabs by infrared thermography and microwaves excitation. In Proceedings of the QIRT 2014 Civil Engineering & Buildings, Bordeaux, France, 7–11 July 2014.

- Metaxas, A.C.; Meredith, R.J. Industrial Microwave Heating; Peter Peregrinus Ltd.: London, UK, 1983. [Google Scholar]

- Szymanik, B. Zastosowanie Aktywnej Termografii Podczerwonej ze Wzbudzeniem Mikrofalowym do Wykrywania Niemetalicznych min Lądowych. Ph.D. Thesis, West Pomeranian University of Technology, Szczecin, Poland, 2013. [Google Scholar]

- Meredith, R.J. Engineers’ Handbook of Industrial Microwave Heating; Short Run Press: London, UK, 1998. [Google Scholar]

- Makulan, N.; Rattanadechob, P.; Agrawal, D.K. Applications of microwave energy in cement and concrete—A review. Renew. Sustain. Energy Rev. 2014, 37, 715–733. [Google Scholar] [CrossRef]

- Chady, T.; Enokizono, M.; Sikora, R.; Takeuchi, K.; Kinoshita, T. Eddy Current Testing of Concrete Structures. Int. J. Appl. Electromagn. Mech. 2002, 15, 33–37. [Google Scholar]

- Nagata, S.; Chady, T.; Shidouji, M.; Enokizono, M. Development of Practical MFES System for Concrete Materials. In Electromagnetic Nondestructive Evaluation VI; Kojima, F., Takagi, T., Udpa, S.S., Pávó, J., Eds.; IOS Press: Amsterdam, The Netherlands, 2002; pp. 104–107. [Google Scholar]

- Chady, T.; Gratkowski, S.; Nagata, S.; Sikora, R.; Wójtowicz, S. Eddy Current Inspection of Reinforcement Bars in Concrete Structures. In Electromagnetic Nondestructive Evaluation (IX); Udpa, S.S., Nicola Bowler, N., Eds.; IOS Press: Amsterdam, The Netherlands, 2005; pp. 203–210. [Google Scholar]

- Chady, T.; Sikora, R. Optimization of Eddy-Current Sensor for Multifrequency Systems. IEEE Trans. Mag. 2003, 39, 1313–1316. [Google Scholar] [CrossRef]

- Szymanik, B.; Unnikrishnakurup, S.; Balasubramaniam, K. Background Removal Methods in Thermographic Non Destructive Testing of Composite Materials. In Proceeding of the NDE 2014, Pune, India, 4–6 December 2014.

- Chady, T.; Frankowski, P. Electromagnetic Evaluation of Reinforced Concrete Structure. Rev. Prog. Quant. Nondestruct. Eval. 2013, 32, 1355–1362. [Google Scholar]

- Frankowski, P.; Chady, T.; Sikora, R. Identification of Rebars in a Reinforced Mash Using Eddy Current Method and Association Rule Learning. In Proceedings of the Far East NDT, Zhuhai, China, 22–24 June 2015; pp. 202–207.

- Frankowski, P.K.; Chady, T.; Sikora, R. Knowledge Extraction Algorithms Dedicated for Identification of Steel Bars in Reinforced Concrete Structures. Rev. Prog. Quant. Nondestruct. Eval. 2014, 40, 822–827. [Google Scholar]

- Frankowski, P.K. Knowledge Extraction From the Eddy Current Measurement Data, (pl). Inform. Autom. Pomiary Gospod. Ochr. Środowiska 2014, 4.2, 822–827. [Google Scholar]

- Pawlak, Z. Rough Sets: Theoretical Aspects of Reasoning About Data; Kluwer Academic Publishing: Dordrecht, The Netherlands, 1991. [Google Scholar]

- Shearer, C. The CRISP-DM model: The new blueprint for data mining. J. Data Warehous. 2000, 5, 13–22. [Google Scholar]

| Material | Loss Tangent tan δ = ε'' / ε' | Density [kg/m3] | Thermal Conductivity [W/(m·K)] | Heat Capacity at Constant Pressure [J/(kg·K)] |

|---|---|---|---|---|

| Concrete | 0.36/4.5 | 2400 | 0.8 | 750 |

| Steel | Here simulated as conductivity σ = 8.41 × 106 S/m | 7850 | 66 | 490 |

| Air | - | 1.29 | 0.022 | 1010 |

| h [mm] | 5 | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 |

|---|---|---|---|---|---|---|---|---|---|---|

| D | 75% | 81% | 91% | 96% | 92% | 93% | 84% | 75% | 78% | 66% |

| Class | 78% | 83% | 92% | 100% | 87% | 94% | 95% | 79% | 78% | 74% |

| σd80 | 0.530 | 0.480 | 0.295 | 0.257 | 0.295 | 0.295 | 0.257 | 0.498 | 0.561 | 1.114 |

| σd10 | 5.986 | 4.259 | 0.707 | 0.450 | 0.450 | 0.502 | 0.518 | 1.068 | 1.179 | 1.841 |

| Transducer size | T5 | T20 | T25 |

|---|---|---|---|

| Optimal range of h [mm] | 0–25 | 15–35 | 15–35 |

| Correctness of D classification in the optimal range [%] | 94–98 | 84–96 | 91–93 |

| Correctness of D classification for h = 40 to 50 mm [%] | 58–68 | 66–78 | 72–78 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szymanik, B.; Frankowski, P.K.; Chady, T.; John Chelliah, C.R.A. Detection and Inspection of Steel Bars in Reinforced Concrete Structures Using Active Infrared Thermography with Microwave Excitation and Eddy Current Sensors. Sensors 2016, 16, 234. https://doi.org/10.3390/s16020234

Szymanik B, Frankowski PK, Chady T, John Chelliah CRA. Detection and Inspection of Steel Bars in Reinforced Concrete Structures Using Active Infrared Thermography with Microwave Excitation and Eddy Current Sensors. Sensors. 2016; 16(2):234. https://doi.org/10.3390/s16020234

Chicago/Turabian StyleSzymanik, Barbara, Paweł Karol Frankowski, Tomasz Chady, and Cyril Robinson Azariah John Chelliah. 2016. "Detection and Inspection of Steel Bars in Reinforced Concrete Structures Using Active Infrared Thermography with Microwave Excitation and Eddy Current Sensors" Sensors 16, no. 2: 234. https://doi.org/10.3390/s16020234