SAW Humidity Sensor Sensitivity Enhancement via Electrospraying of Silver Nanowires

Abstract

:1. Introduction

2. Materials and Methods

2.1. Chemicals

2.2. Instruments and Devices

2.3. Synthesis of Silver Nanowires

2.4. SAW Device Preparation

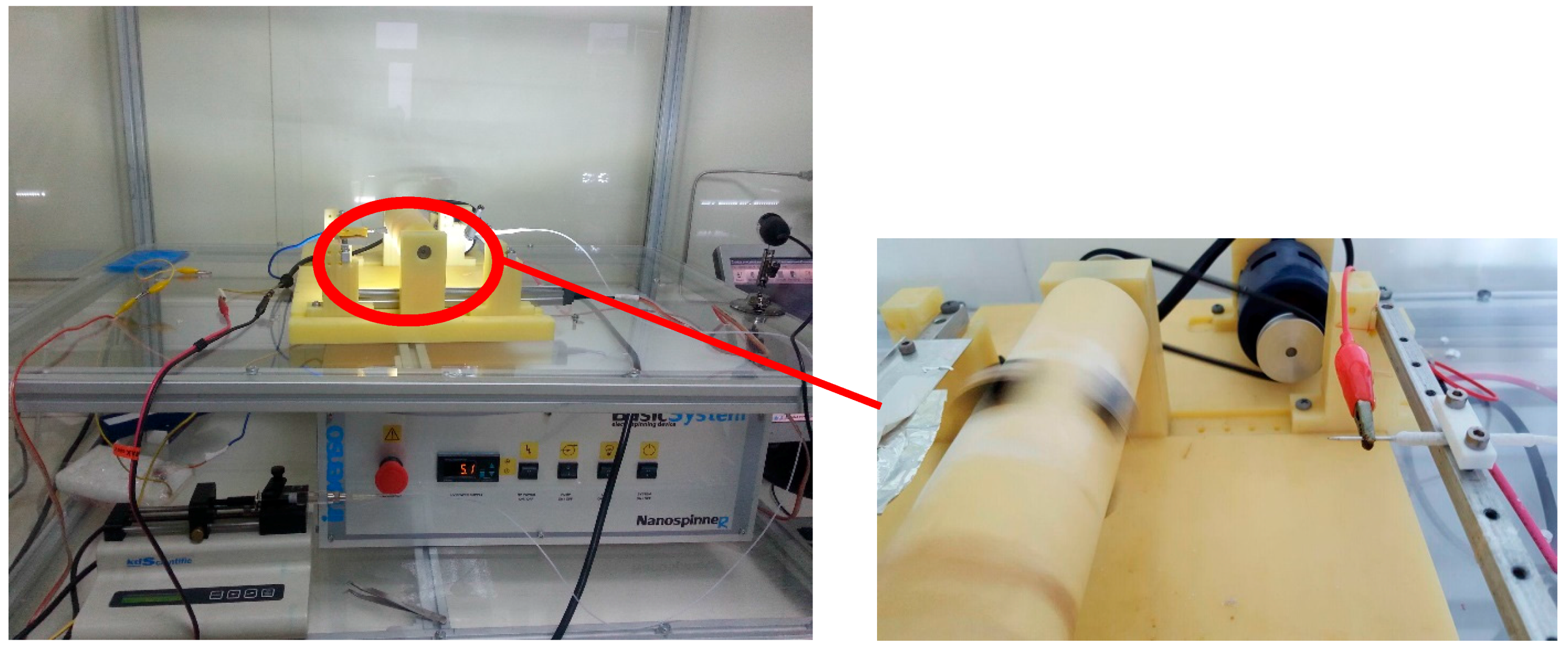

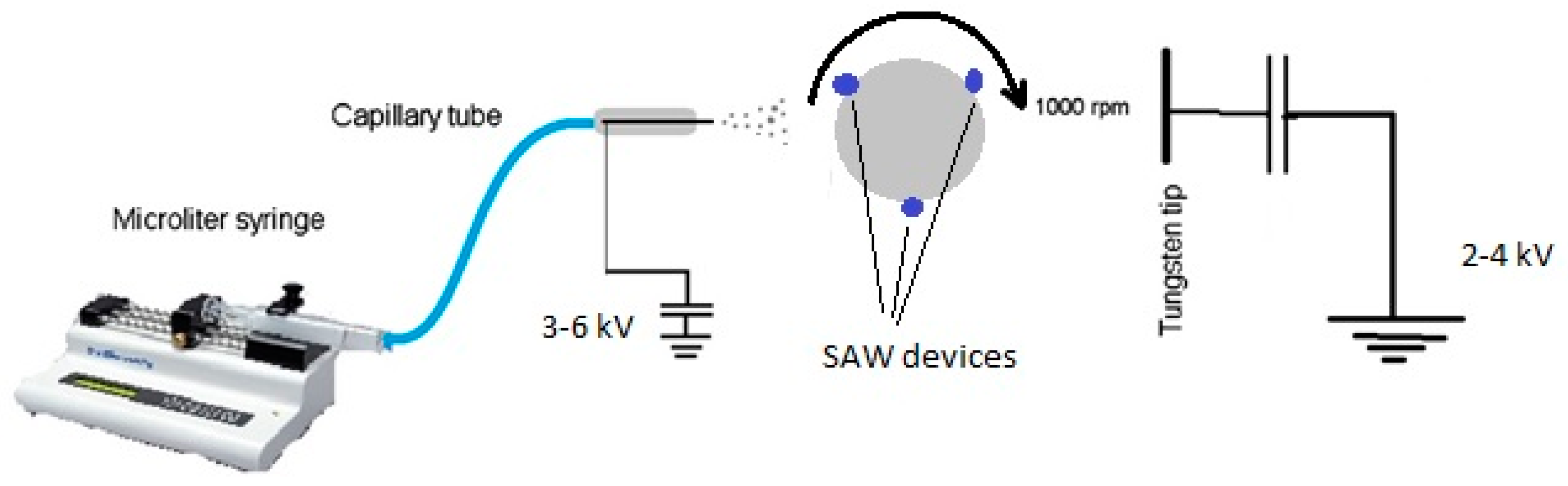

2.5. Electro-Spray Coating

3. Results and Discussion

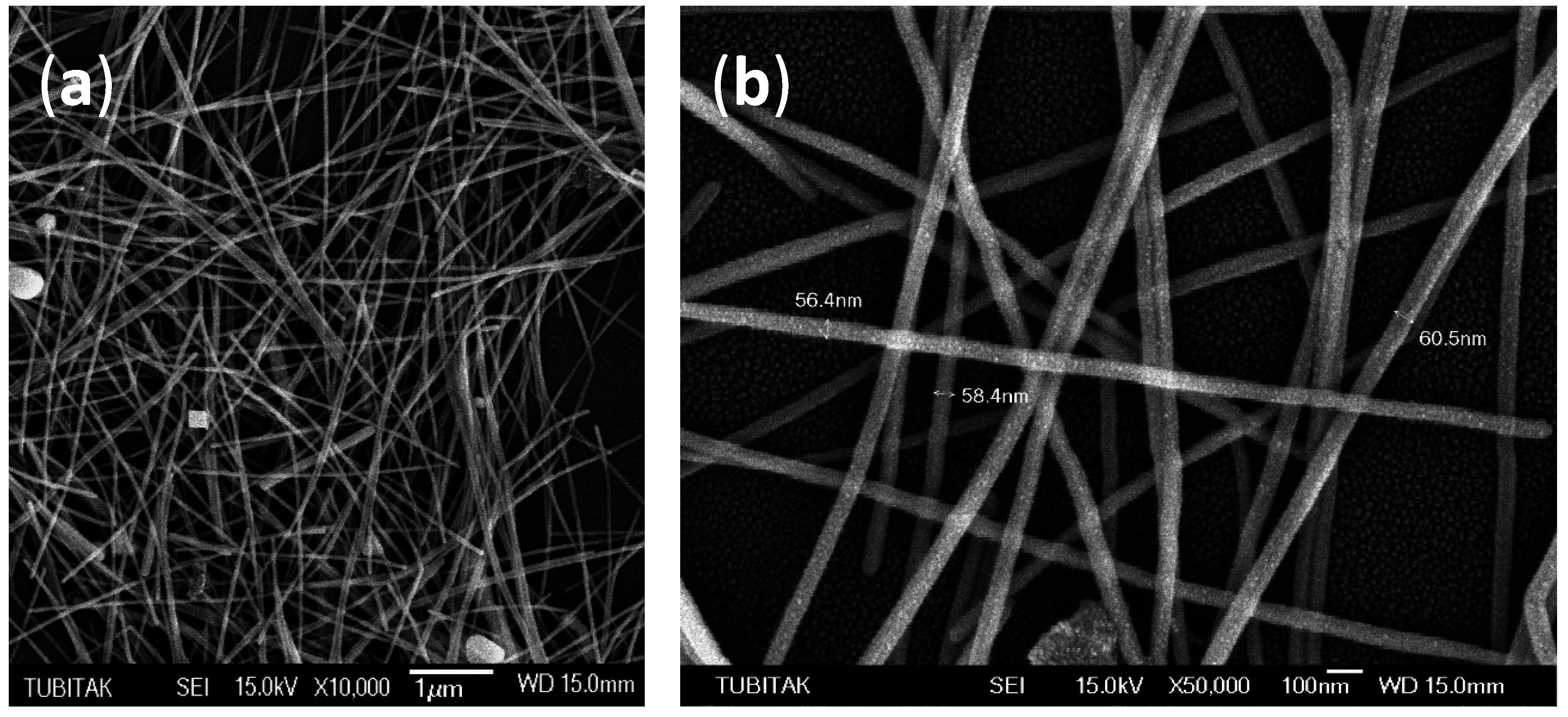

3.1. Characterization of Synthesized Silver Nanowires

3.2. Characterization of the AgNW-Coated SAW Sensor

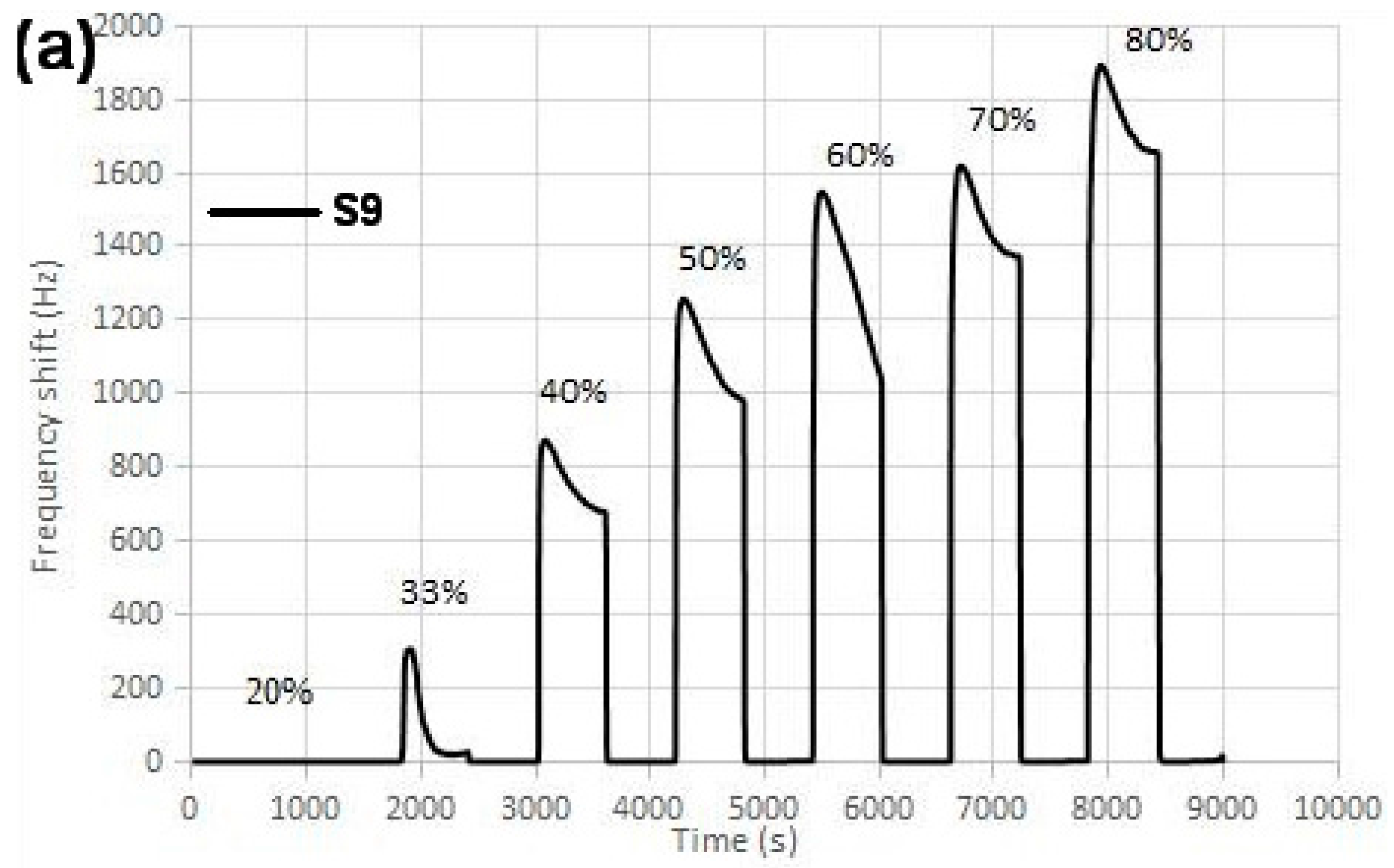

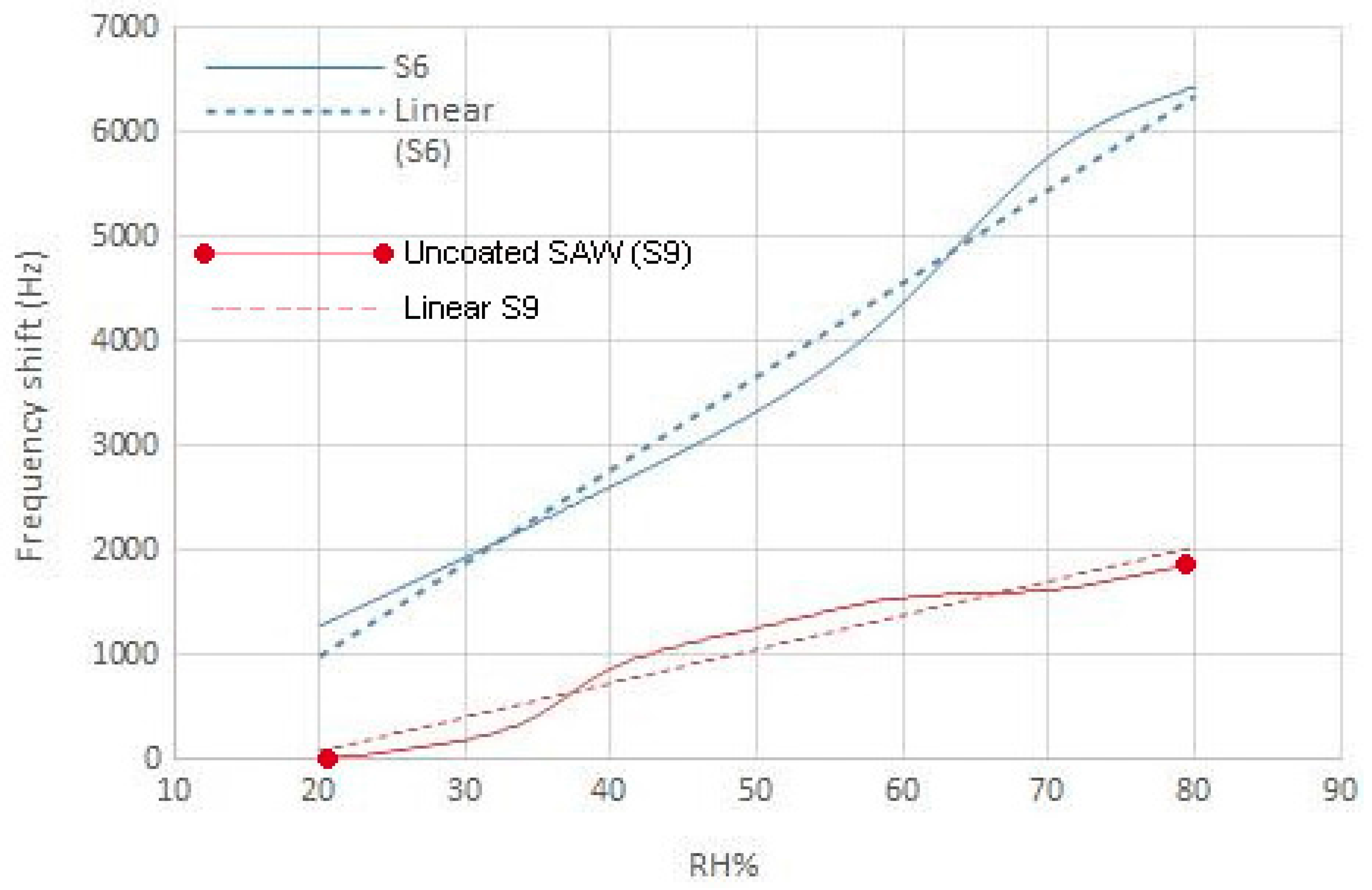

3.3. Sensor Measurement Results

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Yamazoe, N.; Shimizu, Y. Humidity sensors: Principles and applications. Sens. Actuators 1986, 10, 379–398. [Google Scholar] [CrossRef]

- Chen, Z.; Lu, C. Humidity sensors: A review of materials and mechanisms. Sens. Lett. 2005, 3, 274–295. [Google Scholar] [CrossRef]

- Kolpakov, S.A.; Gordon, N.T.; Mou, C.; Zhou, K. Toward a new generation of photonic humidity sensors. Sensors 2014, 14, 3986–4013. [Google Scholar] [CrossRef] [PubMed]

- Consales, M.; Buosciolo, A.; Cutolo, A.; Breglio, G.; Irace, A.; Buontempo, S.; Petagna, P.; Giordano, M.; Cusano, A. Fiber optic humidity sensors for high-energy physics applications at CERN. Sens. Actuators B Chem. 2011, 159, 66–74. [Google Scholar] [CrossRef]

- Lin, C.-M.; Chen, Y.-Y.; Felmetsger, V.V.; Senesky, D.G.; Pisano, A.P. AlN/3C–SiC Composite Plate Enabling High-Frequency and High-Q Micromechanical Resonators. Adv. Mater. 2012, 24, 2722–2727. [Google Scholar] [CrossRef] [PubMed]

- Blank, T.A.; Eksperiandova, L.P.; Belikov, K.N. Recent trends of ceramic humidity sensors development: A review. Sens. Actuators B Chem. 2016, 228, 416–442. [Google Scholar] [CrossRef]

- Tasaltin, C.; Ebeoglu, M.A.; Ozturk, Z.Z. Acoustoelectric effect on the responses of saw sensors coated with electrospun ZnO nanostructured thin film. Sensors 2012, 12, 12006–12015. [Google Scholar] [CrossRef]

- Hong, H.-S.; Chung, G.-S. Controllable growth of oriented ZnO nanorods using Ga-doped seed layers and surface acoustic wave humidity sensor. Sens. Actuators B Chem. 2014, 195, 446–451. [Google Scholar] [CrossRef]

- Hong, H.-S.; Phan, D.-T.; Chung, G.-S. High-sensitivity humidity sensors with ZnO nanorods based two-port surface acoustic wave delay line. Sens. Actuators B Chem. 2012, 171, 1283–1287. [Google Scholar] [CrossRef]

- Guo, Y.J.; Zhang, J.; Zhao, C.; Ma, J.Y.; Pang, H.F.; Hu, P.A.; Placido, F.; Gibson, D.; Zu, X.T.; Zu, H.Y.; et al. Characterization and humidity sensing of ZnO/42° YX LiTaO3 love wave devices with ZnO nanorods. Mater. Res. Bull. 2013, 48, 5058–5063. [Google Scholar] [CrossRef]

- Penza, M.; Antolini, F.; Vittori-Antisari, M. Carbon nanotubes-based surface acoustic waves oscillating sensor for vapour detection. Thin Solid Films 2005, 472, 246–252. [Google Scholar] [CrossRef]

- Buvailo, A.; Xing, Y.; Hines, J.; Borguet, E. Thin polymer film based rapid surface acoustic wave humidity sensors. Sens. Actuators B Chem. 2011, 156, 444–449. [Google Scholar] [CrossRef]

- Ricco, A.J.; Martin, S.J.; Zipperian, T.E. Surface acoustic wave gas sensor based on film conductivity changes. Sens. Actuators 1985, 8, 319–333. [Google Scholar] [CrossRef]

- Penza, M.; Aversa, P.; Cassano, G.; Wlodarski, W.; Kalantar-Zadeh, K. Layered saw gas sensor with single-walled carbon nanotube-based nanocomposite coating. Sens. Actuators B Chem. 2007, 127, 168–178. [Google Scholar] [CrossRef]

- Tashtoush, N.M. SAW Humidity Sensor and an Environmental Electronic Nose System. Ph.D. Thesis, Concordia University, Montreal, QC, Canada, 1996. [Google Scholar]

- Li, D.J.; Zhao, C.; Fu, Y.Q.; Luo, J.K. Engineering silver nanostructures for surface acoustic wave humidity sensors sensitivity enhancement. J. Electrochem. Soc. 2014, 161, B151–B156. [Google Scholar] [CrossRef]

- Li, Y.; Li, P.; Yang, M.; Lei, S.; Chen, Y.; Guo, X. A surface acoustic wave humidity sensor based on electrosprayed silicon-containing polyelectrolyte. Sens. Actuators B Chem. 2010, 145, 516–520. [Google Scholar] [CrossRef]

- Sheng, L.; Chen, D.; Chen, Y. A surface acoustic wave humidity sensor with high sensitivity based on electrospun MWCNT/Nafion nanofiber films. Nanotechnology 2011, 22, 265504. [Google Scholar] [CrossRef] [PubMed]

- Dubas, S.T.; Vimolvan, P. Humic acid assisted synthesis of silver nanoparticles and its application to herbicide detection. Mater. Lett. 2008, 62, 2661–2663. [Google Scholar] [CrossRef]

- Coskun, S.; Aksoy, B.; Unalan, H.E. Polyol synthesis of silver nanowires: An extensive parametric study. Cryst. Growth Des. 2011, 11, 4963–4969. [Google Scholar] [CrossRef]

| No | Rotator | Volume | Injection Rate | Concentration | Frequency Shift in Air |

|---|---|---|---|---|---|

| S1 | 1000 rpm | 0.75 mL | 2 mL/h | 0.25 mg/mL | 240 KHz |

| S2 | 1000 rpm | 0.25 mL | 2 mL/h | 0.5 mg/mL | 165 KHz |

| S3 | 1000 rpm | 0.25 mL | 2 mL/h | 0.25 mg/mL | 123 KHz |

| S4 | 1000 rpm | 0.25 mL | 1 mL/h | 0.25 mg/mL | 91 KHz |

| S5 | 1000 rpm | 0.25 mL | 1 mL/h | 0.75 mg/mL | 220 KHz |

| S6 | 1000 rpm | 0.5 mL | 1 mL/h | 0.5 mg/mL | 262 KHz |

| S7 | 1000 rpm | 0.25 mL | 1 mL/h | 0.5 mg/mL | 158 KHz |

| S8 | 1000 rpm | 0.5 mL | 1 mL/h | 0.25 mg/mL | 188 KHz |

| S9 | - | - | - | Uncoated SAW Device | - |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sayar Irani, F.; Tunaboylu, B. SAW Humidity Sensor Sensitivity Enhancement via Electrospraying of Silver Nanowires. Sensors 2016, 16, 2024. https://doi.org/10.3390/s16122024

Sayar Irani F, Tunaboylu B. SAW Humidity Sensor Sensitivity Enhancement via Electrospraying of Silver Nanowires. Sensors. 2016; 16(12):2024. https://doi.org/10.3390/s16122024

Chicago/Turabian StyleSayar Irani, Farid, and Bahadir Tunaboylu. 2016. "SAW Humidity Sensor Sensitivity Enhancement via Electrospraying of Silver Nanowires" Sensors 16, no. 12: 2024. https://doi.org/10.3390/s16122024