1. Introduction

Contactless micro-particle manipulation in a liquid has drawn considerable interest in many biomedical, biological, and physical applications [

1,

2,

3]. The trapping mechanism employed in contact-less micro-particle manipulation techniques can be hydrodynamic [

4], dielectrophoretic [

5], optical [

6], magnetic, or acoustic [

7]. Among these, optical and acoustic techniques are the most common. However, optical tweezers make use of laser light sources which are expensive and may also damage the cells by the generation of heat. Furthermore, the short wavelength of laser light cannot capture large particles, or operate in a medium of high opacity. Acoustic tweezers discriminate between different particles based on their density and compressibility. The long wavelength used by acoustic tweezers can capture a large group of particles at one time. Such a high trapping capacity is essential for certain kinds of practical experiments.

Acoustic tweezers manipulate particles using either a standing wave or a single beam. Early acoustic tweezers utilized two counter-propagating, focused ultrasound beams to produce a standing wave at 3.5 MHz, which could capture a frog’s egg or a latex particle 270 µm in diameter in water [

8]. In another application, acoustic tweezers utilized an ultrasound standing wave linear array and a reflector at 2.1 MHz to capture alumina micro-particles with a diameter of 16 µm [

9]. In addition, a standing surface acoustic wave (SSAW) focusing technique can be applied to a micro-fluid channel. An interdigital transducer (IDT) deposited on a lead zirconate titanate (PZT) substrate and driven by an AC signal produced a standing wave at the IDT, which allowed the capture of micro-particles at the pressure nodes or antinodes of the standing wave [

10]. Standing waves can also be used to levitate particles. An acoustic levitation device, which used a stepping circular vibrating plate and a reflector, could form a standing wave that would levitate a sample and hold it at the pressure node [

11]. Ding demonstrated SSAW-based acoustic tweezers that can manipulate particles, cells, or organisms [

12].

In contrast, acoustic tweezers based on a single beam use tightly focused transducers to capture micro-particles at the focal point. In an early work, a 30 MHz LiNbO

3 transducer was used to capture a lipid micro-droplet of a diameter of 126 µm [

13]. In another study, acoustic tweezers based on a PZT transducer and an air-reflector Fresnel lens could capture microspheres 70–90 µm in diameter at a frequency of 17.9 MHz [

14]. A linear phase array containing 64 elements operated at 26 MHz could capture 45-µm-diameter polystyrene micro-particles [

15]. Lam proposed a 200 MHz lensless transducer that can manipulate a single microsphere of 5 or 10 µm in diameter in distilled water [

16].

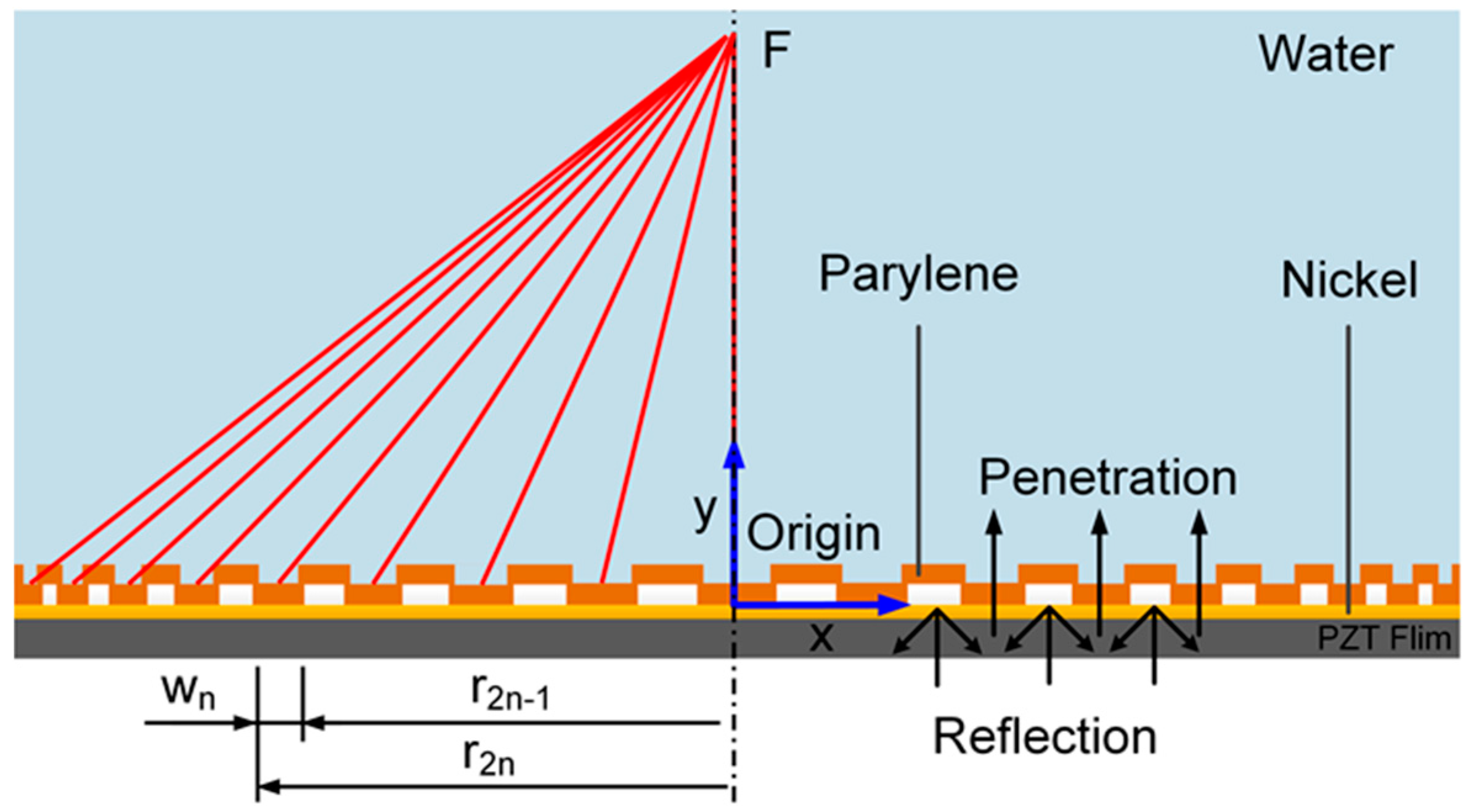

In this study, acoustic tweezers (

Figure 1) built on a PZT transducer with top and bottom electrodes have been proposed. The electrodes were patterned into annular rings to form an acoustic Fresnel lens such that the acoustic waves generated by the annular zones form a beam that has low-energy trapping zones [

17]. Some interesting experimental results for particle trapping at the focal plane have been reported in another study by Choe et al. [

14]. Our paper aims to simulate the acoustic intensity, acoustic pressure, gradient force, and particle distribution of the acoustic tweezers on the longitudinal plane through the focal point. The finite element method (FEM) was used to conduct numerical simulations of the tweezers’ design which employed acoustic pressure fields produced by air-reflector Fresnel lenses. The simulation results clearly demonstrated that the single beam could effectively capture micro-particles. The simulation results will be beneficial to the future applications and optimization of the acoustic tweezers.

2. Theory

In a Fresnel lens design, if the distance from each annular zone to the focal point is a multiple of the wavelength, the acoustic waves will reach the focal point in-phase, or the waves will constructively interfere. This type of acoustic wave source is called the Fresnel half-wave band (FHWB) zone.

The acoustic wavelength in a liquid (

) and the designed focal length (

) determine the diameter of each annular acoustic wave zone. In practice, every annular zone has a radial width (

) and to minimize the destructive wave interference due to the phase variance along the zone width, the radii of the FHWB zone (

are designed according to [

18]

where

k = 1,2,3…, n.

According to acoustic impedance theory, an acoustic wave will be reflected largely at the interface of two media if the acoustic impedance of the media differs appreciably. In the simulation, an air-reflector lens was designed by using parylene and air as the media. The acoustic impedance of parylene is similar to that of water and is relatively higher than that of air. Therefore, the acoustic wave produced by the transducer will pass through the parylene layer but reflect at the air region, as shown in

Figure 1. The reflectance of the acoustic wave can be calculated by Equation (2), based on which the most suitable design and media for the Fresnel lens can be selected [

19].

where

and

are the acoustic impedances of the two media;

and

are the incidence angle and transmission angle.

The acoustic tweezers are immersed in the inviscid working fluid and a sinusoidal signal of angular frequency

is applied to it. The acoustic beam is time-harmonic and can be represented by the acoustic pressure

and velocity field

, both being coordinated at time

and position

. Therefore, the pressure-velocity relation in the first-order approximations can be described in terms of the conservation of the momentum equation as follows [

20]:

where

,

is the density, and

is the acoustic speed in the working fluid. For simplicity, the time-harmonic term

is neglected. Then, the acoustic pressure potential energy can be described as [

20]

where

is the particle volume;

and

are the acoustic contrast factors, calculated as

where

and

are the mass density and acoustic speed of the particle, respectively. The gradient force will trap the micro-particle at the minima of the potential energy

U. This gradient force (

) is calculated by [

20]:

Therefore, the acoustic trapping force of the gradient force is affected by several parameters such as the acoustic wave frequency, acoustic intensity, particle size, and type of acoustic medium.

3. Simulation

The FEM software COMSOL MultiphysicsTM was used to simulate the acoustic pressure field. The simulation module included the acoustic pressure, particle tracing for fluid flow, electrostatics, and solid mechanics. The simulation environment was set as an elastohydrodynamic fluid. According to FHWB theory, the dimension of the annular acoustic zone of the air-Fresnel lens should follow Equation (1).

The piezoelectric transducer element (PZT-5H) was 20 mm in diameter. The host medium was water with the following characteristics: density

= 1000 kg/m

3, acoustic speed

= 1481 m/s, kinematic viscosity

= 10

−6 m

2/s, and acoustic impedance 1.48 MRayls. In the micro-particle distribution simulation, the density of the particle was set to 1000 kg/m

3 and the diameters used in the simulations were 50, 100, and 150 µm. The material parameters of the air and parylene are listed in

Table 1. The voltage and resonance frequency applied to the acoustic tweezers component were 100 V

peak-to-peak and 2.4 MHz, respectively. Two-dimensional numerical simulations were performed for the acoustic tweezers. Typically, the Fresnel lens focused on only a single point at a focal length of 10 λ, which was about 6.16 mm along the y-axis.

There are 295,390 nodes used in our simulation. The mesh geometry type used in this paper was free-triangular. For the mesh, the maximum element size was 0.05 mm while the minimum element size was 0.444 µm, which was one-tenth the dimension of the thinnest membrane. The element size range was chosen as a trade-off of the calculation time and the smoothness of the simulation results.

4. Results and Discussion

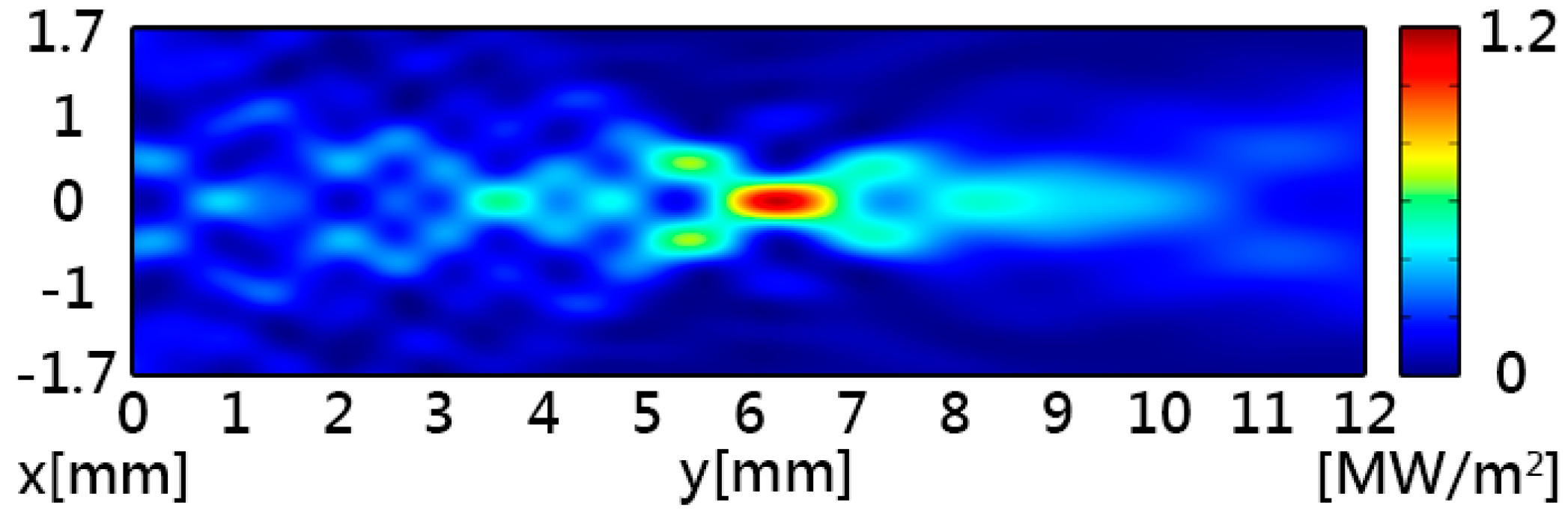

Figure 2 shows the simulated acoustic intensity with a maximum intensity of 1.15 MW/m

2 at the focal point.

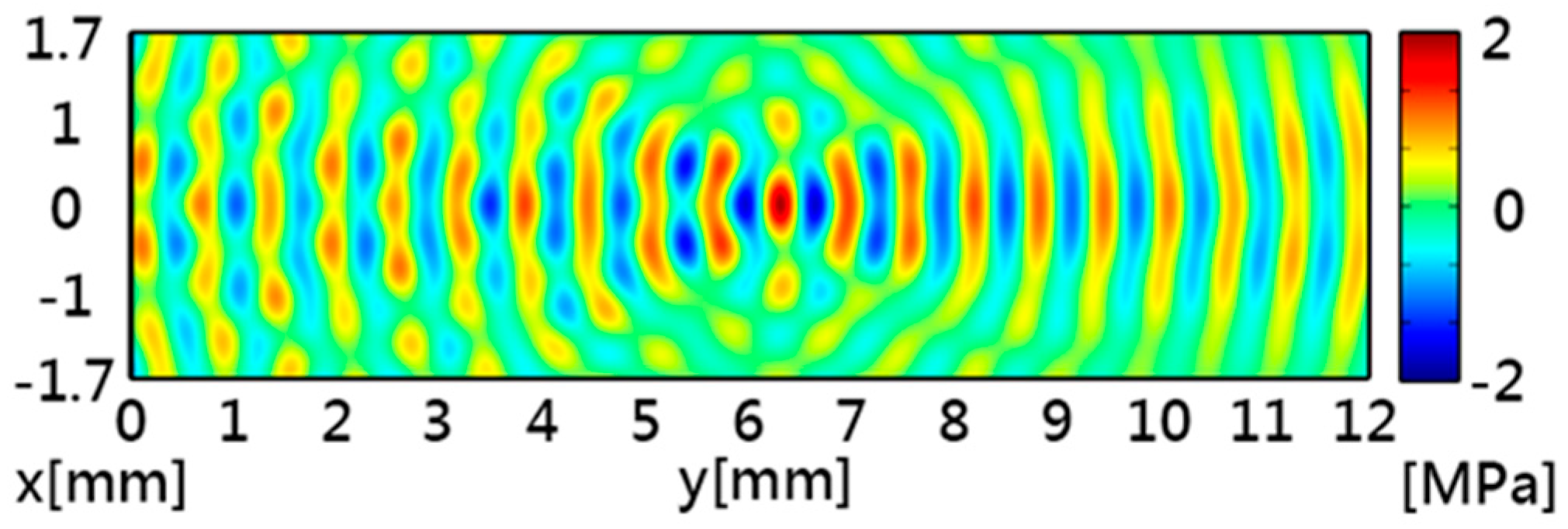

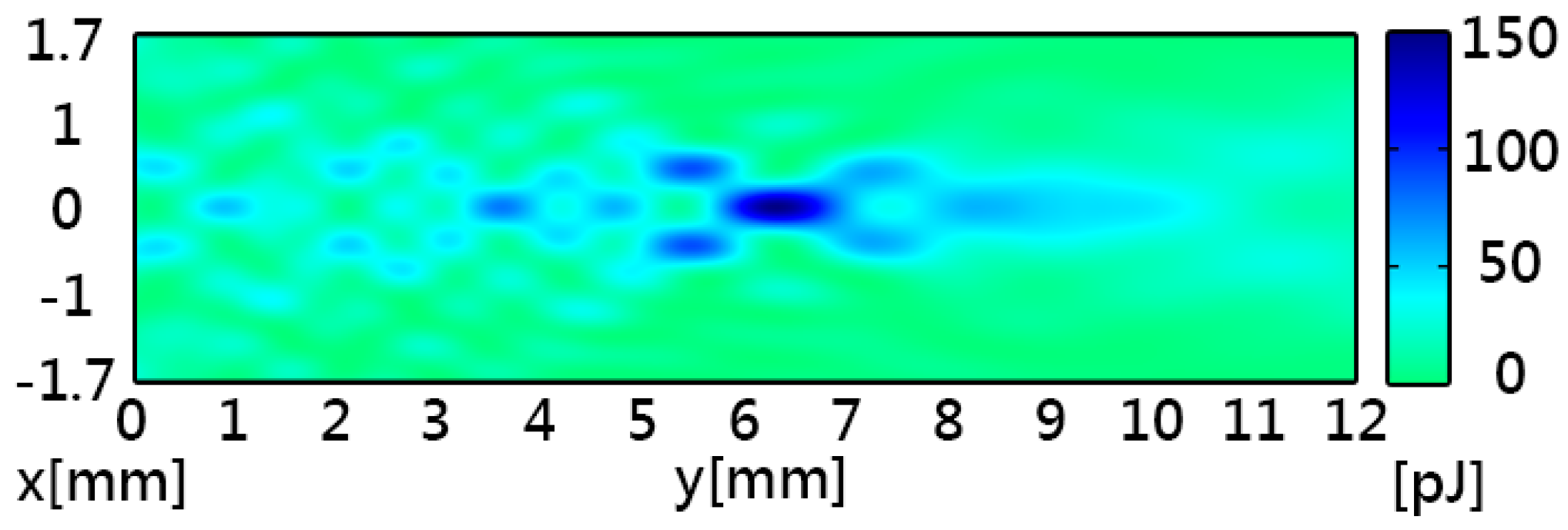

Figure 3 shows the simulated acoustic pressure, which had similar distribution patterns to the acoustic intensity. The acoustic potential energy is the crucial characteristic for particle trapping, and it can be calculated by using Equations (5) and (6). In

Figure 4, the pattern of potential energy for the acoustic tweezers shows the pattern of the particle distributions. According to the potential well theory, particles will stay in regions of low potential energy which are surrounded by higher-energy regions.

The two-dimensional simulation results of trapping for the three particle diameters are shown in

Figure 5. There was an agreement between the simulated acoustic potential energy and the simulated particle distributions, and the patterns of the retained particles matched the patterns of the low energy regions. The diameter of the particle also influences the particle capture and capture duration. The particle distribution patterns with a small diameter matched the low energy areas better than those with a larger diameter. In addition, it can be observed that the acoustic tweezers have different pattern formation times. In the beginning (

t = 10 s), only the particles near the Fresnel lens gather in the low-acoustic-potential-energy regions. After 30 s (

t = 30 s), the particles at any location were able to form a durable pattern. This is caused by energy decay in the water medium: the energy is higher near the PZT transducer.

Along the central axis, the acoustic tweezers gather most of the particles at 4.1–4.35, 5.2–5.6, and 7.3–7.8 mm. However, particles in other locations were gradually pushed to the low-energy areas. There were several low-potential-energy regions that could be used for particle trapping, around 2.1, 3, 4.2, 5.3 and 7.4 mm, as can be seen in

Figure 6. There is a similarity between the simulated acoustic potential energy and the particle distribution.

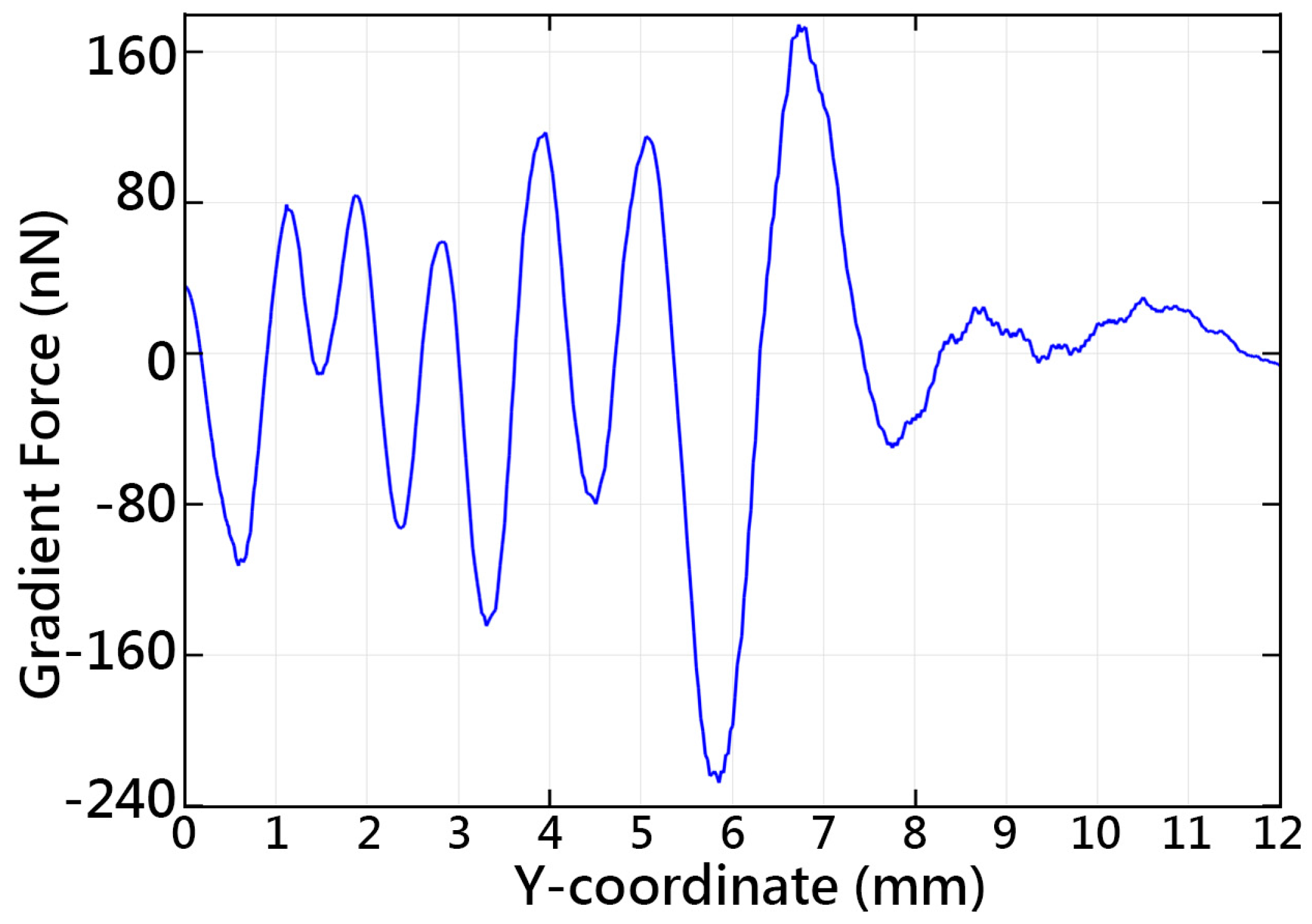

Figure 7 shows the simulated acoustic gradient force along the central axis found using Equation (6). The particles are captured in the low-potential-energy regions properly surrounded by high-energy regions. It can be seen that the particles could be retained at locations of zero force which correspond to the extrema of the acoustic forces. The maximum force magnitudes of the tweezers can reach 231 nN.

5. Conclusions

Multi-trapping Fresnel lens acoustic tweezers based on PZT transducers are an effective method for simultaneous manipulation of micro-particles. Based on the FEM numerical simulation results, acoustic tweezers operating at a frequency of 2.4 MHz and an input voltage of 100 Vpeak-to-peak can trap and sustain particles in water. A simulated acoustic field with a maximum intensity of 1.15 MW/m2 was observed. The acoustic tweezers have a maximum acoustic pressure magnitude of 1.95 MPa around the focal point. The simulations showed two main regions for particle trapping along the central axis at around 5.3 mm and 7.4 mm. Both regions have wide potential wells compared to others. In some specific low-energy regions, the particles were gradually pushed away to gather in a nearby low-energy region. The trapping force and acoustic potential energy are on the order of nano-newton and pico-joule magnitude. The zero-potential-energy regions correspond to the regions of the extrema of the acoustic gradient forces. This single-beam–based acoustic trapping technique may provide a simple and economical research tool, especially for cell-trapping applications.

Acknowledgments

This material is based upon work supported by the Ministry of Science and Technology, Taiwan, under contract no. MOST 105-2218-E-008-008, MOST 105-2911-I-008-504, and MOST 105-2221-E-008-043. We are grateful to the National Center for High-performance Computing, Taiwan, for providing software and facilities. The authors thank Hao-Ting Wang for assistance.

Author Contributions

Y.-L.T. and S.-J.C. conceived and designed the simulation; Y.-L.T., S.-J.C. and Y.-R.H. analyzed the data; Y.-L.T. and S.-J.C wrote the paper.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Grier, D.G. A revolution in optical manipulation. Nature 2003, 424, 810–816. [Google Scholar] [CrossRef] [PubMed]

- Laurell, T.; Petersson, F.; Nilsson, A. Chip integrated strategies for acoustic separation and manipulation of cells and particles. Chem. Soc. Rev. 2007, 36, 492–506. [Google Scholar] [CrossRef] [PubMed]

- Friend, J.; Yeo, L.Y. Microscale acoustofluidics: Microfluidics driven via acoustics and ultrasonics. Rev. Mod. Phys. 2011, 83, 647. [Google Scholar] [CrossRef]

- Lutz, B.R.; Chen, J.; Schwartz, D.T. Hydrodynamic tweezers: 1. Noncontact trapping of single cells using steady streaming microeddies. Anal. Chem. 2006, 78, 5429–5435. [Google Scholar] [CrossRef] [PubMed]

- Pohl, H.A. The motion and precipitation of suspensoids in divergent electric fields. J. Appl. Phys. 1951, 22, 869–871. [Google Scholar] [CrossRef]

- Ashkin, A.; Dziedzic, J.M.; Bjorkholm, J.E.; Chu, S. Observation of a single-beam gradient force optical trap for dielectric particles. Opt. Lett. 1986, 11, 288–290. [Google Scholar] [CrossRef] [PubMed]

- Torr, G.R. The acoustic radiation force. Am. J. Phys. 1984, 52, 402–408. [Google Scholar] [CrossRef]

- Wu, J. Acoustical tweezers. J. Acoust. Soc. Am. 1991, 89, 2140–2143. [Google Scholar] [CrossRef] [PubMed]

- Kozuka, T.; Tuziuti, T.; Mitome, H.; Fukuda, T. Control of a standing wave field using a line-focused transducer for two-dimensional manipulation of particles. Jpn. J. Appl. Phys. 1998, 37, 2974. [Google Scholar] [CrossRef]

- Shi, J.; Ahmed, D.; Mao, X.; Lin, S.C.S.; Lawit, A.; Huang, T.J. Acoustic tweezers: Patterning cells and microparticles using standing surface acoustic waves (SSAW). Lab Chip 2009, 9, 2890–2895. [Google Scholar] [CrossRef] [PubMed]

- Otsuka, T.; Higuchi, K.; Seya, K. Consideration of sample dimension for ultrasonic levitation. In Proceedings of the IEEE 1990 Ultrasonics Symposium, Honolulu, HI, USA, 4–7 December 1990; pp. 1271–1274.

- Ding, X.; Lin, S.C.; Kiraly, B.; Yue, H.; Li, S.; Chiang, I.K.; Shi, J.; Benkovic, S.J.; Huang, T.J. On-chip manipulation of single microparticles, cells, and organisms using surface acoustic waves. Proc. Natl. Acad. Sci. USA 2012, 109, 11105–11109. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.; Teh, S.Y.; Lee, A.; Kim, H.H.; Lee, C.; Shung, K.K. Single beam acoustic trapping. Appl. Phys. Lett. 2009, 95, 073701. [Google Scholar] [CrossRef] [PubMed]

- Choe, Y.; Kim, J.W.; Shung, K.K.; Kim, E.S. Microparticle trapping in an ultrasonic Bessel beam. Appl. Phys. Lett. 2011, 99, 233704. [Google Scholar] [CrossRef] [PubMed]

- Zheng, F.; Li, Y.; Hsu, H.S.; Liu, C.; Chiu, C.T.; Lee, C.; Kim, H.H.; Shung, K.K. Acoustic trapping with a high frequency linear phased array. Appl. Phys. Lett. 2012, 101, 214104. [Google Scholar] [CrossRef] [PubMed]

- Lam, K.H.; Hsu, H.S.; Li, Y.; Lee, C.; Lin, A.; Zhou, Q.; Kim, E.S.; Shung, K.K. Ultrahigh frequency lensless ultrasonic transducers for acoustic tweezers application. Biotechnol. Bioeng. 2013, 110, 881. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.; Du, G. Acoustic radiation force on a small compressible sphere in a focused beam. J. Acoust. Soc. Am. 1990, 87, 997–1003. [Google Scholar] [CrossRef]

- Lee, C.; Pang, W.; Hill, S.C.; Yu, H.; Kim, E.S. Airborne particle generation through acoustic ejection of particles-in-droplets. Aerosol. Sci. Technol. 2008, 42, 832–841. [Google Scholar] [CrossRef]

- Lee, C.Y.; Yu, H.; Kim, E.S. Acoustic ejector with novel lens employing air-reflectors. In Proceedings of the IEEE Micro Electro Mechanical Systems Conference, Istanbul, Turkey, 22–26 January 2006; pp. 170–173.

- Silva, G.T.; Baggio, A.L. Designing single-beam multitrapping acoustical tweezers. Ultrasonics 2015, 56, 449–455. [Google Scholar] [CrossRef] [PubMed]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).