Probabilistic Model Updating for Sizing of Hole-Edge Crack Using Fiber Bragg Grating Sensors and the High-Order Extended Finite Element Method

Abstract

:1. Introduction

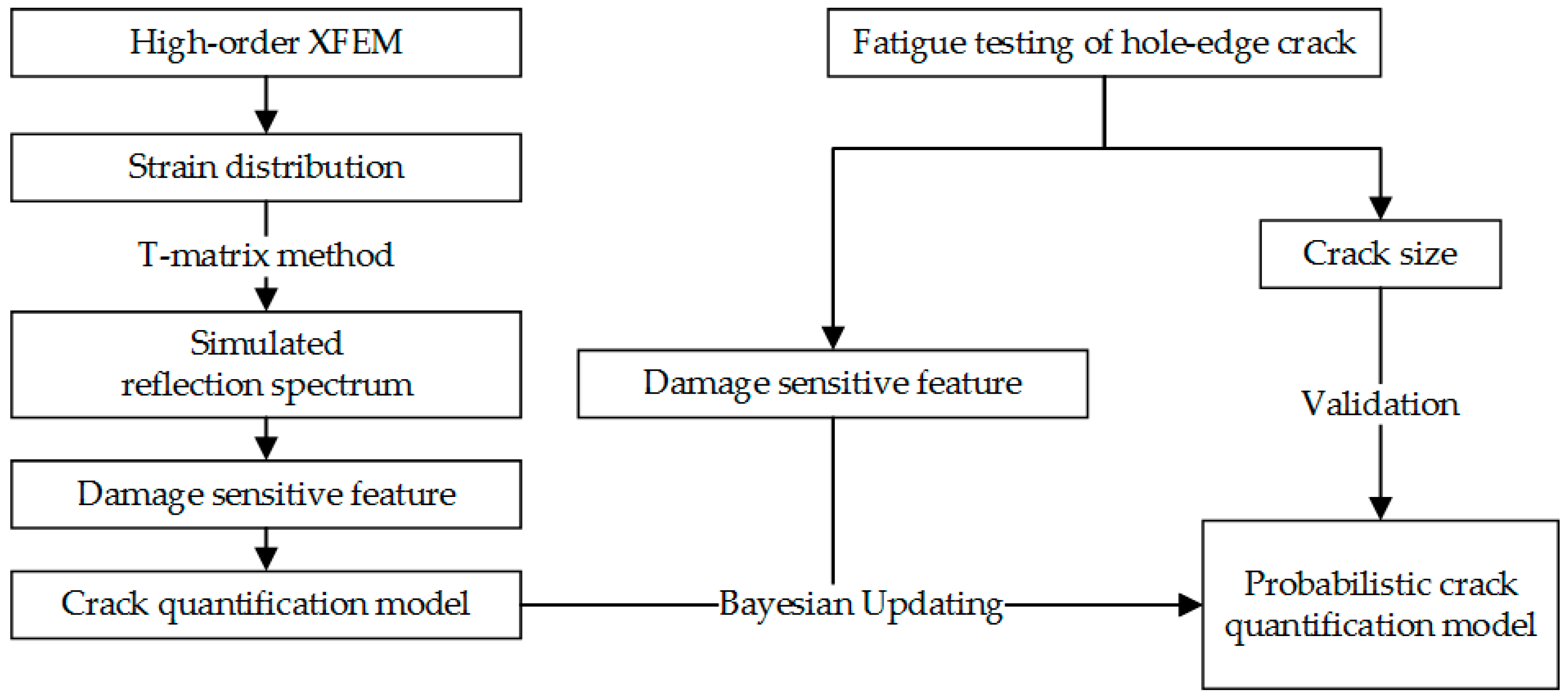

2. Methodology Development

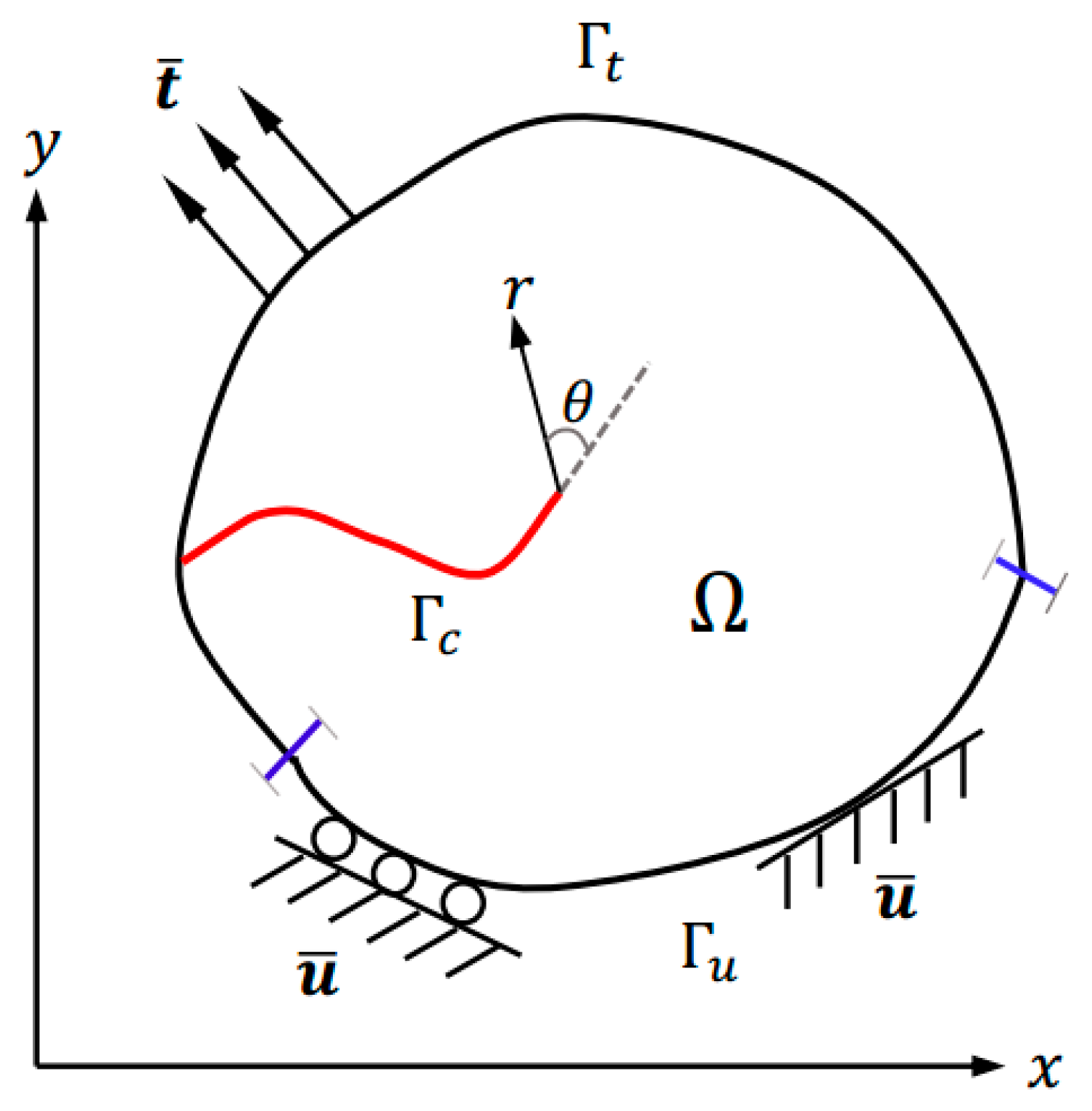

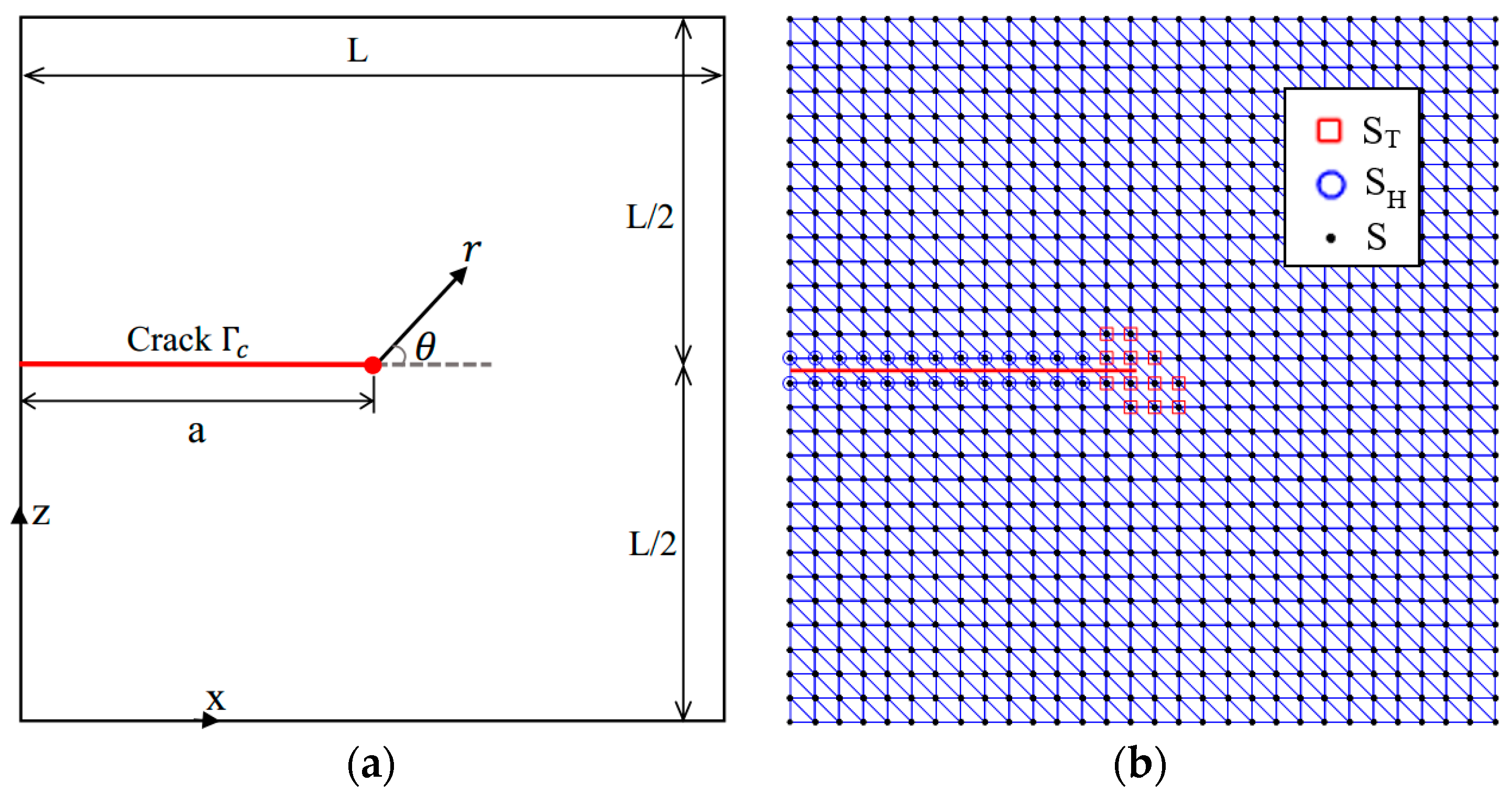

2.1. High-Order Extended Finite Element Method

2.2. T-Matrix Method

3. Fatigue Crack Size Quantification Using XFEM and the T-Matrix Method

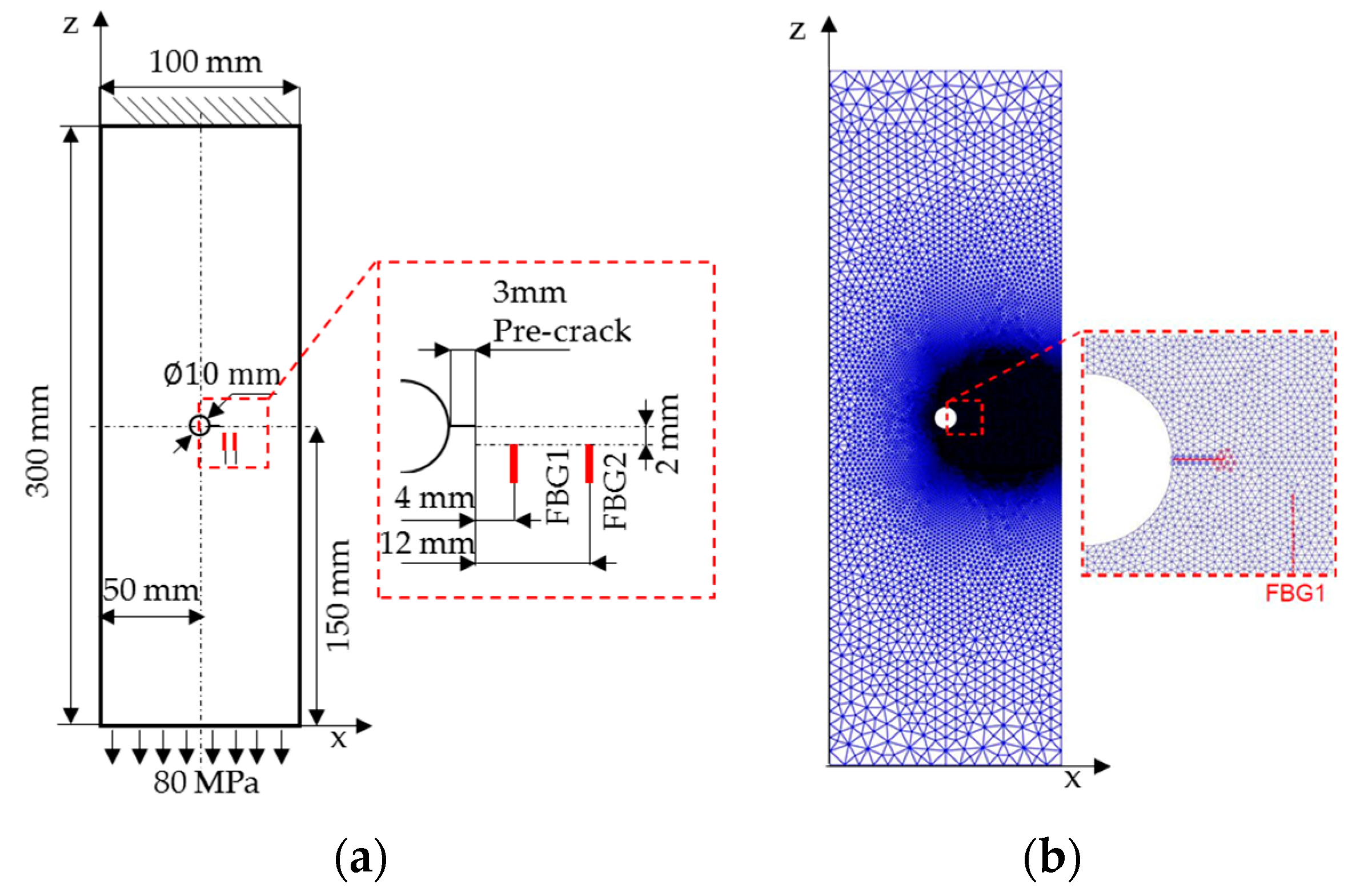

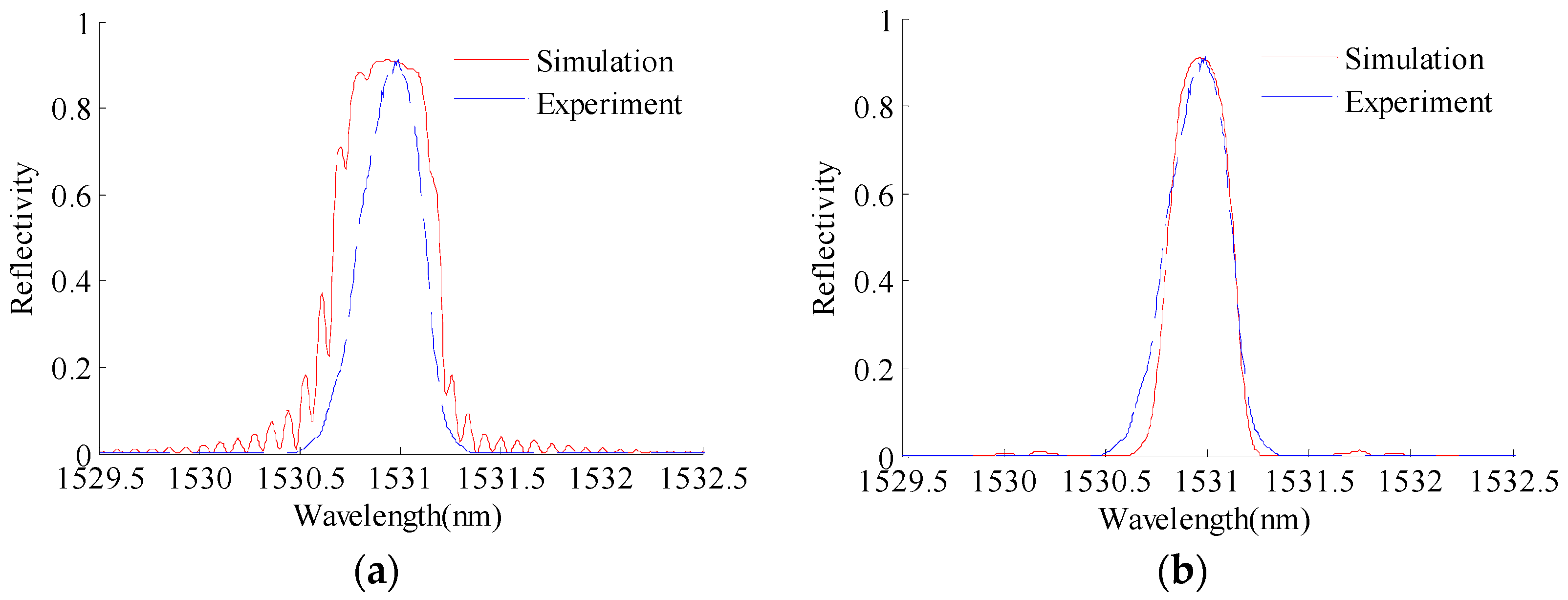

3.1. Structural-Optical Simulation

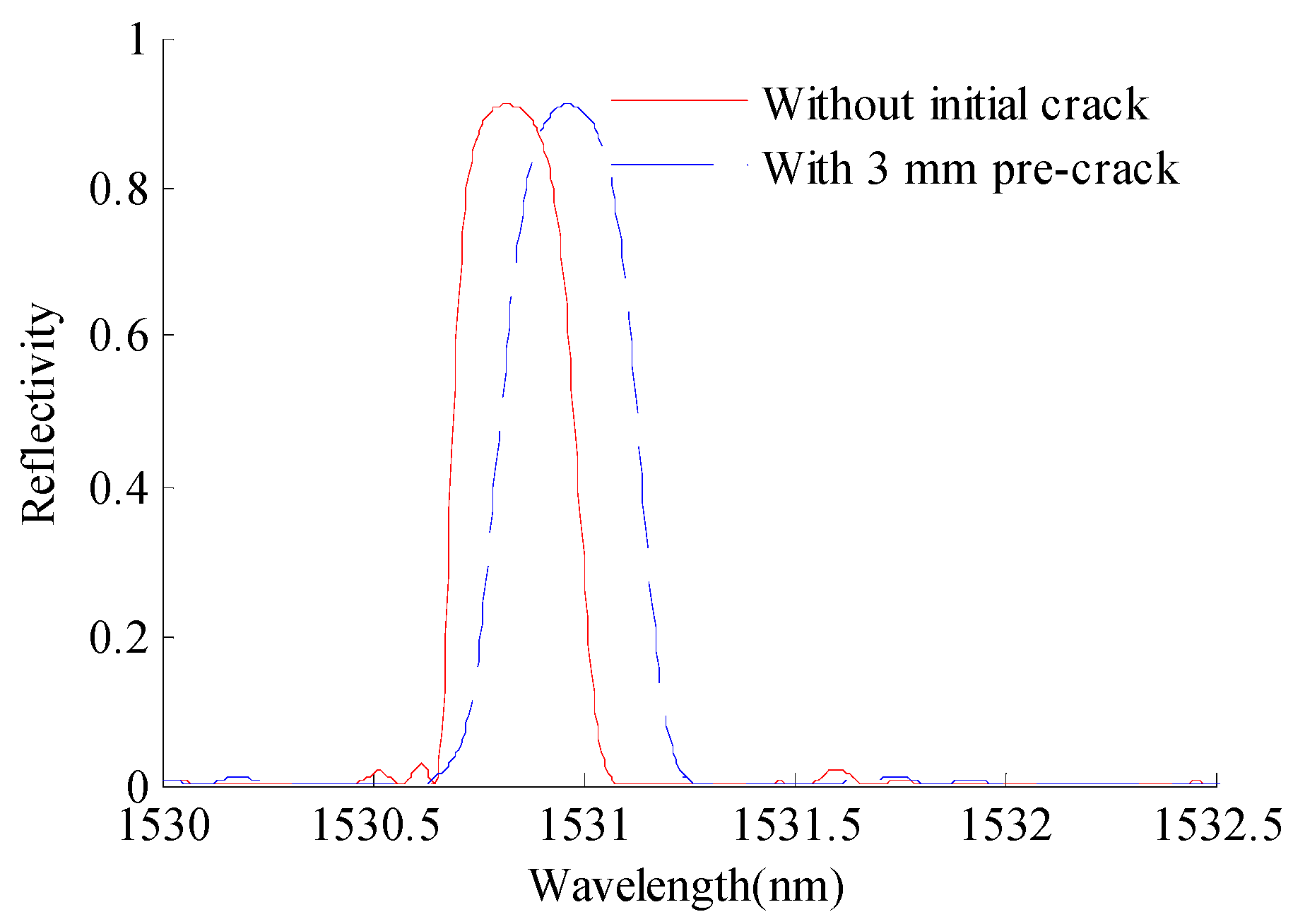

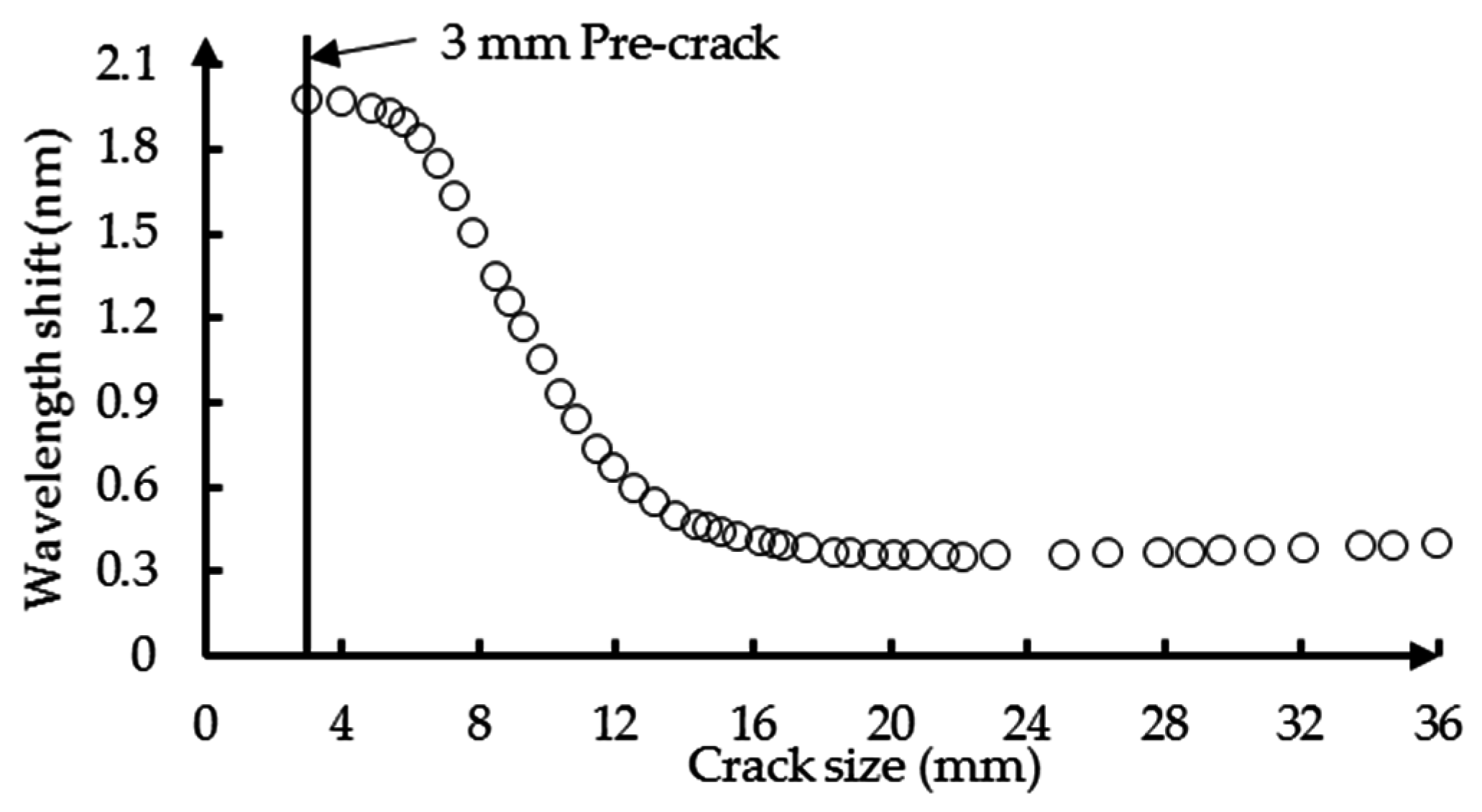

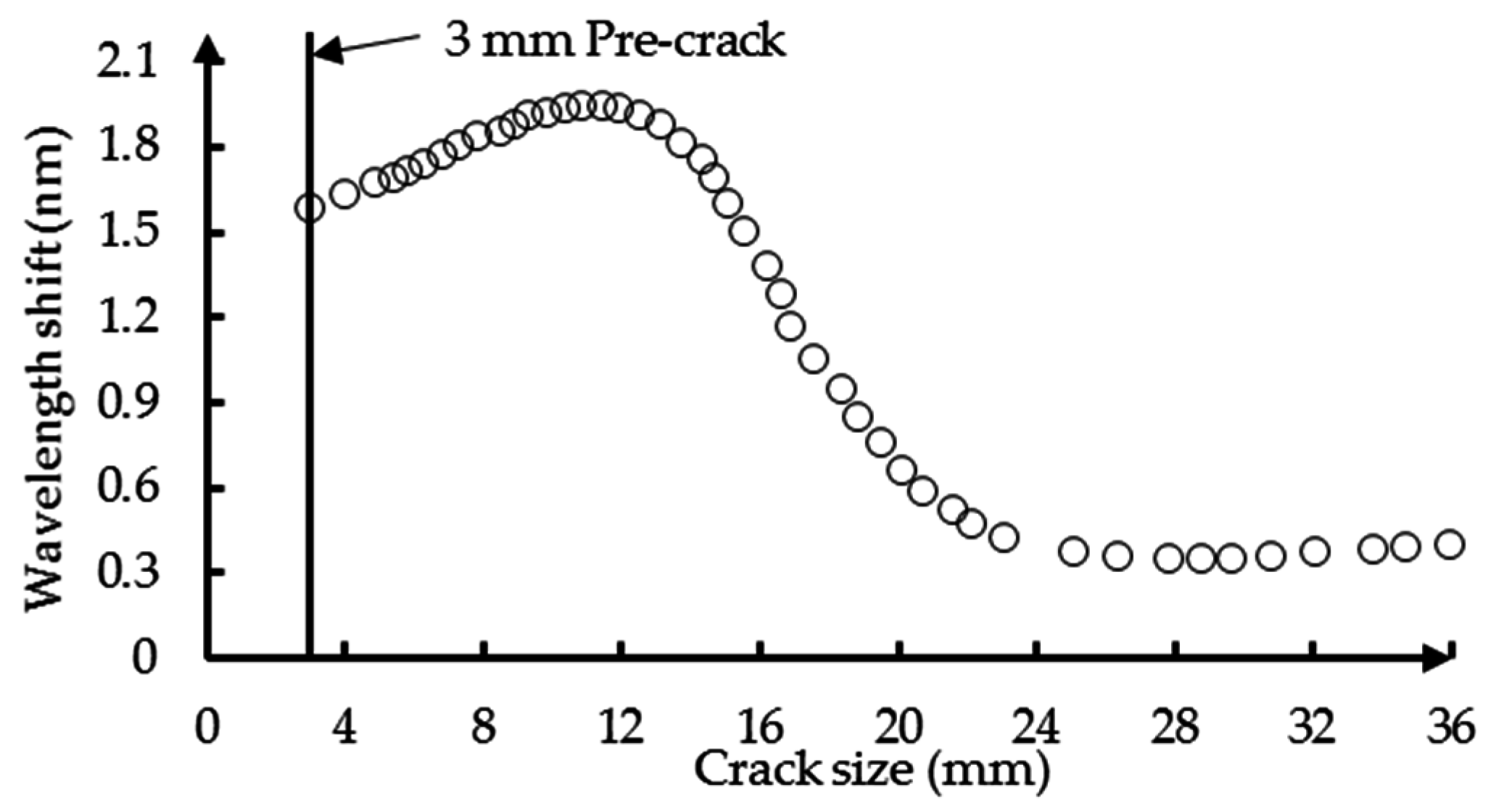

3.2. Extraction of a Damage Sensitive Quantity

3.3. Quantification Model for Crack Size

4. Methodology Validation

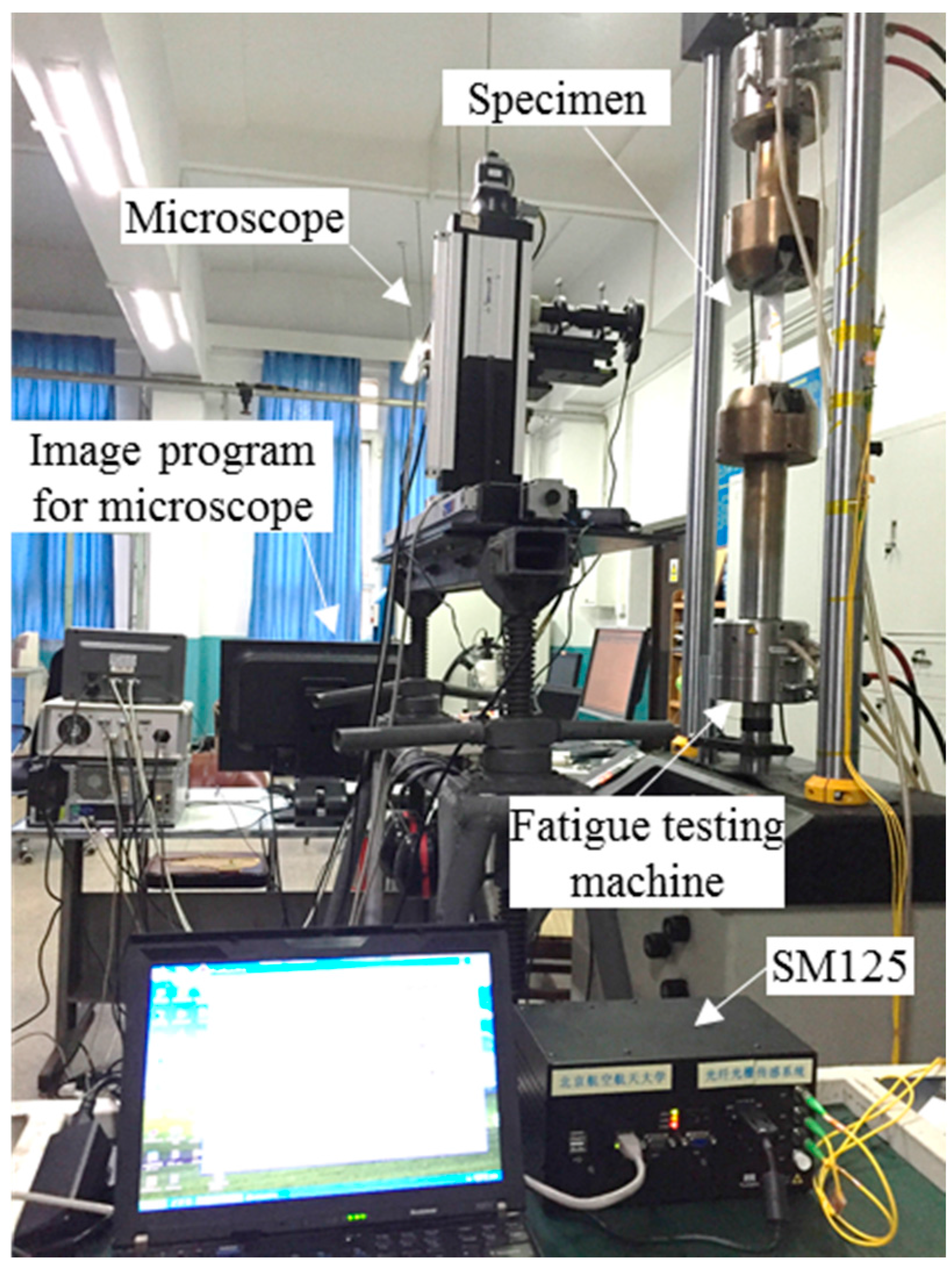

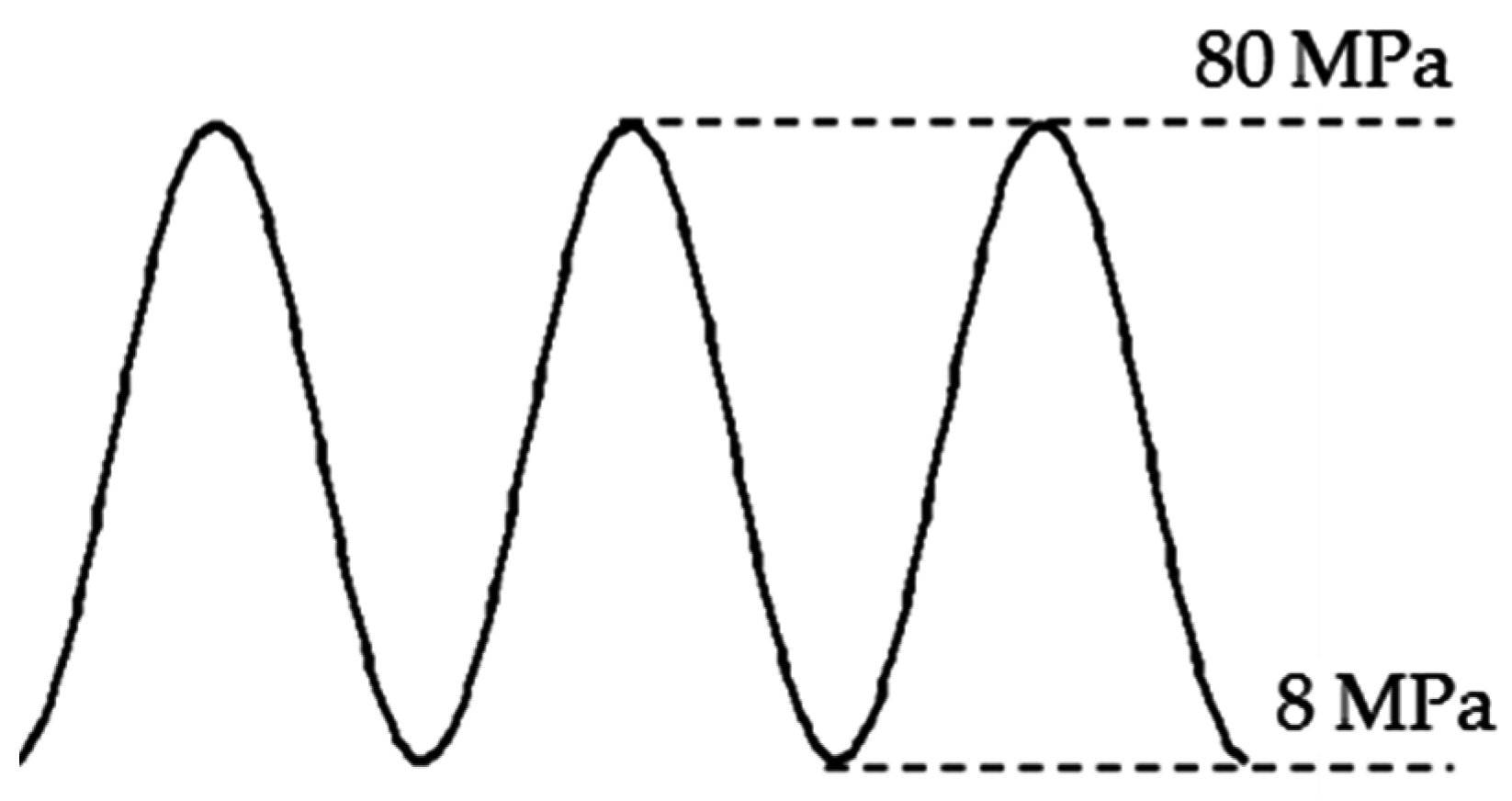

4.1. Experimental Setup

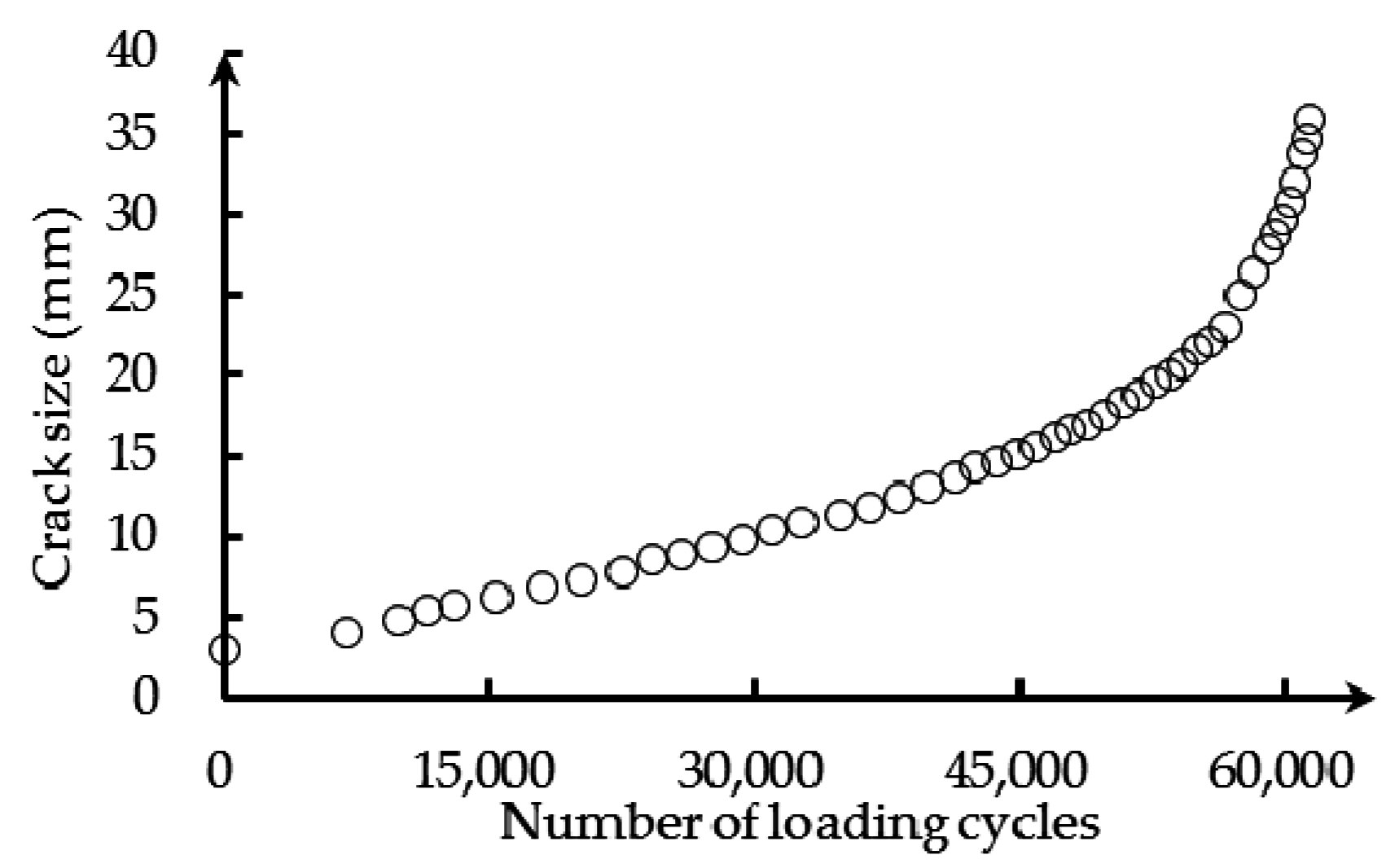

4.2. Experimental Results and Damage Sensitivity Index Extraction

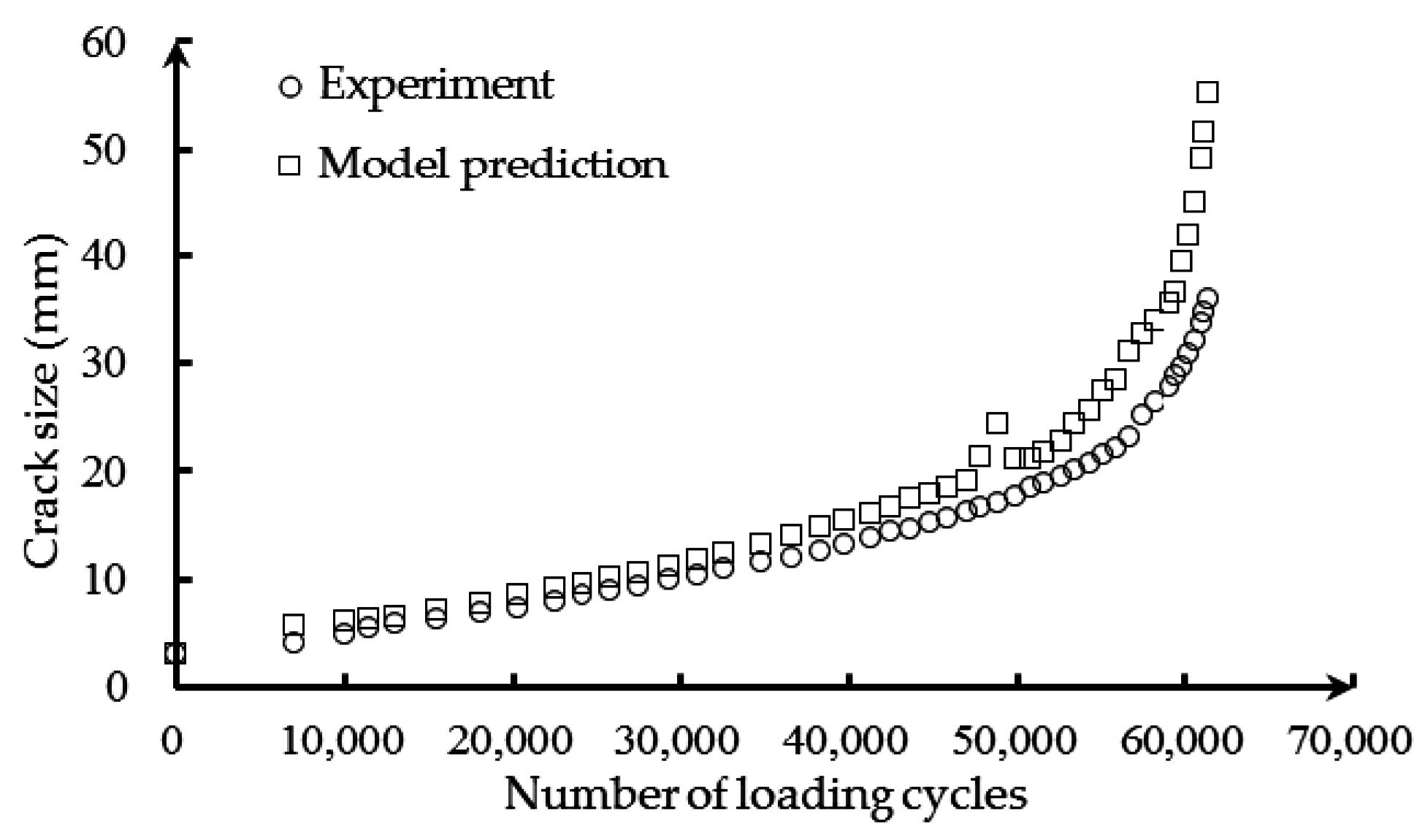

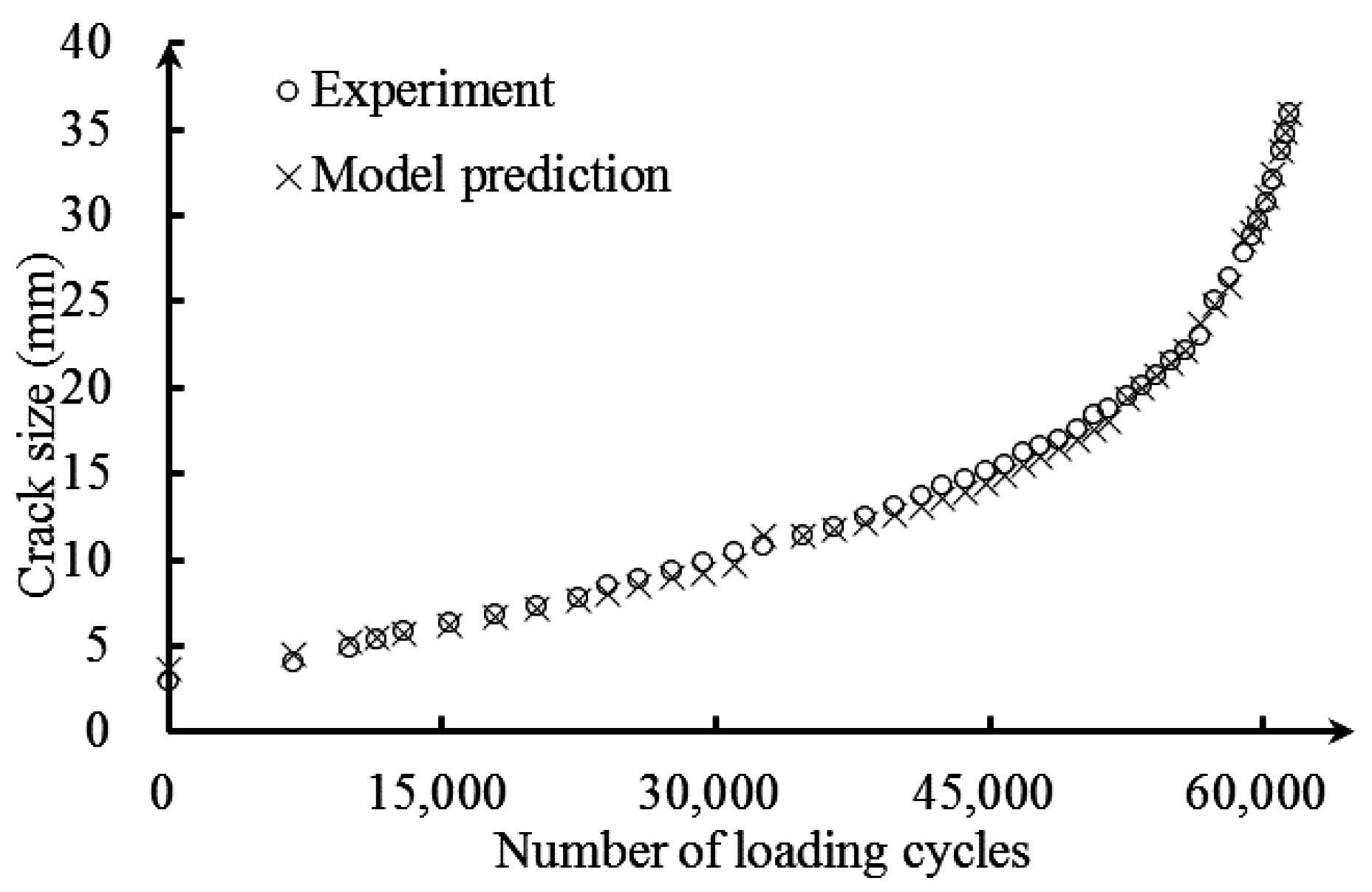

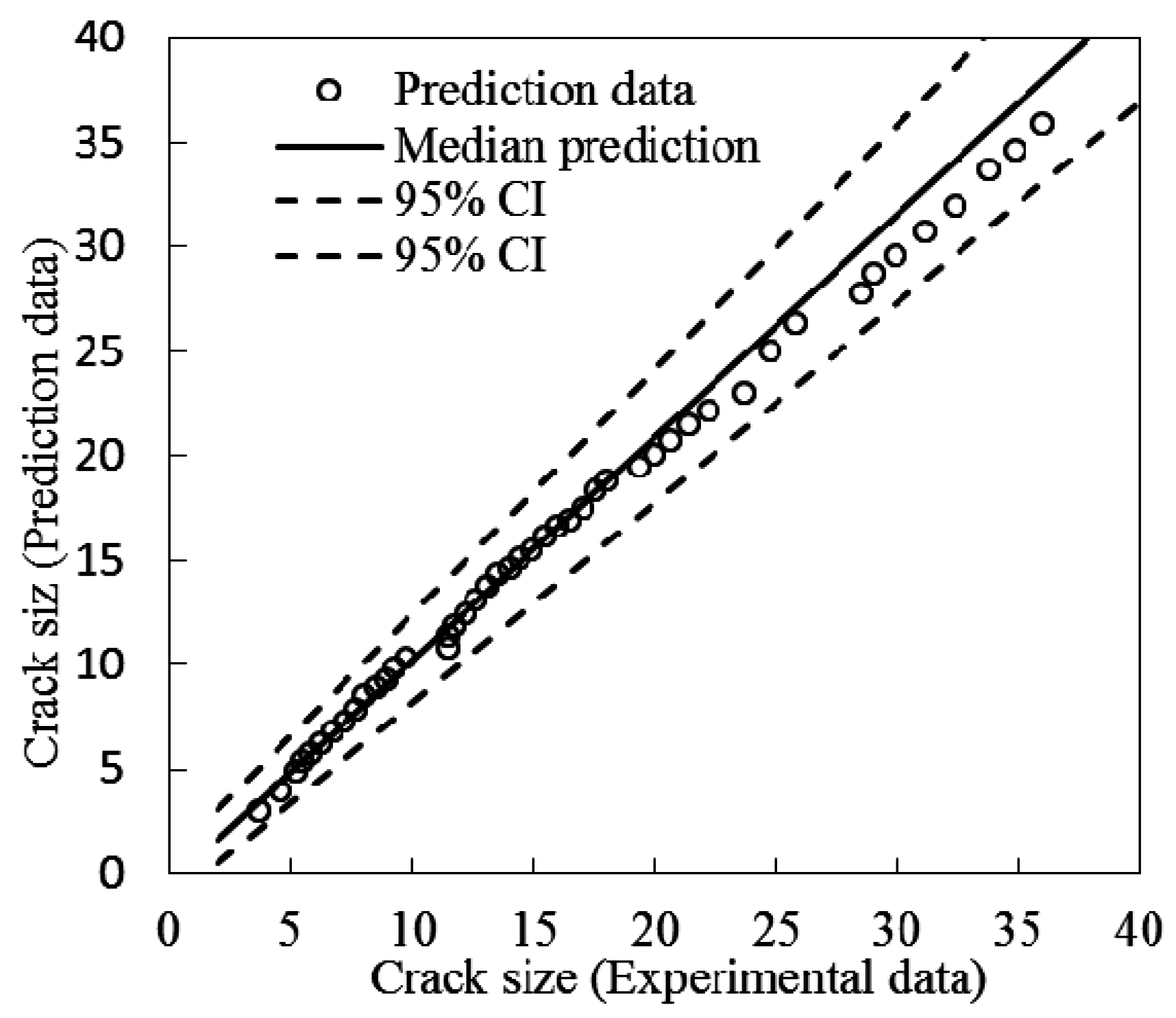

5. Probabilistic Fatigue Crack Sizing Using Experimental Data

5.1. Background of the Bayes’ Theorem and Uncertainty Updating

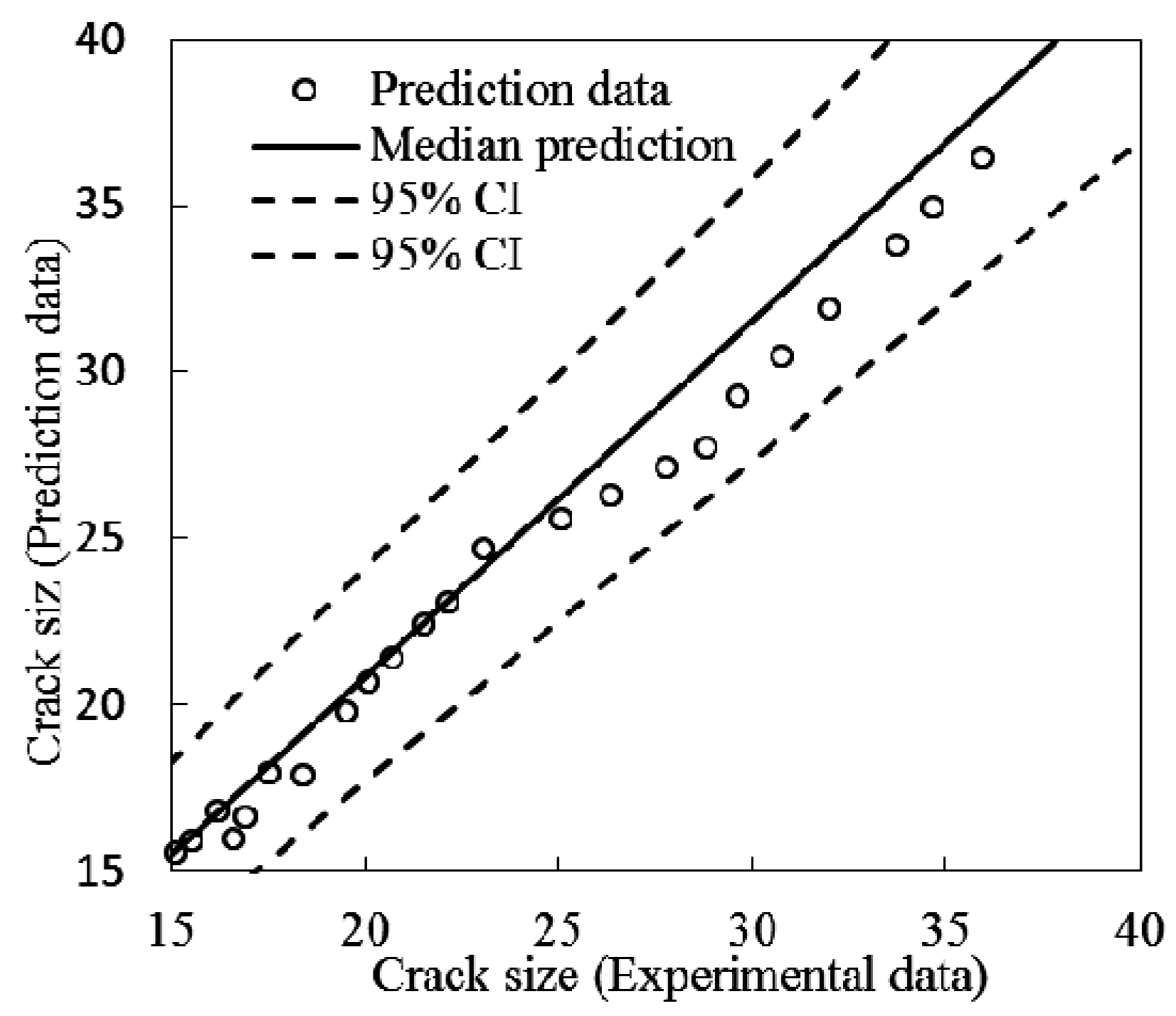

5.2. Crack Quantification Parameters Updating

5.3. Crack Detection for FBG2 Sensor

6. Conclusions

- The high-order XFEM shows great potential in structural health monitoring for modeling crack propagation with high accuracy and low computational cost. Combined with the T-matrix method, the reflection intensity spectrum interacting with different crack sizes can be constructed efficiently.

- The damage wavelength shift index is found to be effective for hole-edge crack size quantification. The detection model can yield satisfactory prediction results for FBG sensors with different locations.

- The proposed methodology uses simulation results as a baseline model and incorporates field measurement data to update the model for real structures. The example presented demonstrates the successful applicability of the approach in crack detection.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Pitt, S.; Jones, R. Multiple-site and widespread fatigue damage in aging aircraft. Eng. Fail. Anal. 1997, 4, 237–257. [Google Scholar] [CrossRef]

- Papazian, J.M.; Nardiello, J.; Silberstein, R.P.; Welsh, G.; Grundy, D.; Craven, C.; Evans, L.; Goldfine, N.; Michaels, J.E.; Michaels, T.E. Sensors for monitoring early stage fatigue cracking. Int. J. Fatigue 2007, 29, 1668–1680. [Google Scholar] [CrossRef]

- Ihn, J.-B.; Chang, F.-K. Detection and monitoring of hidden fatigue crack growth using a built-in piezoelectric sensor/actuator network: II. Validation using riveted joints and repair patches. Smart Mater. Struct. 2004, 13. [Google Scholar] [CrossRef]

- Lu, Y.; Ye, L.; Su, Z.; Yang, C. Quantitative assessment of through-thickness crack size based on lamb wave scattering in aluminium plates. NDT E Int. 2008, 41, 59–68. [Google Scholar] [CrossRef]

- Rizzo, P.; Cammarata, M.; Dutta, D.; Sohn, H.; Harries, K. An unsupervised learning algorithm for fatigue crack detection in waveguides. Smart Mater. Struct. 2009, 18. [Google Scholar] [CrossRef]

- He, J.; Guan, X.; Peng, T.; Liu, Y.; Saxena, A.; Celaya, J.; Goebel, K. A multi-feature integration method for fatigue crack detection and crack length estimation in riveted lap joints using lamb waves. Smart Mater. Struct. 2013, 22. [Google Scholar] [CrossRef]

- Feng, D.; Feng, M.Q. Vision-based multipoint displacement measurement for structural health monitoring. Struct. Control Health Monit. 2015. [Google Scholar] [CrossRef]

- Deng, Y.; Liu, Y.; Feng, D.M.; Li, A.Q. Investigation of fatigue performance of welded details in long-span steel bridges using long-term monitoring strain data. Struct. Control Health Monit. 2015, 22, 1343–1358. [Google Scholar] [CrossRef]

- Li, H.C.H.; Herszberg, I.; Davis, C.E.; Mouritz, A.P.; Galea, S.C. Health monitoring of marine composite structural joints using fibre optic sensors. Compos. Struct. 2006, 75, 321–327. [Google Scholar] [CrossRef]

- Takeda, S.; Yamamoto, T.; Okabe, Y.; Takeda, N. Debonding monitoring of composite repair patches using embedded small-diameter FBG sensors. Smart Mater. Struct. 2007, 16, 763–770. [Google Scholar] [CrossRef]

- Sans, D.; Stutz, S.; Renart, J.; Mayugo, J.A.; Botsis, J. Crack tip identification with long FBG sensors in mixed-mode delamination. Compos. Struct. 2012, 94, 2879–2887. [Google Scholar] [CrossRef]

- Okabe, Y.; Tsuji, R.; Takeda, N. Application of chirped fiber bragg grating sensors for identification of crack locations in composites. Compos. Part A Appl. Sci. Manuf. 2004, 35, 59–65. [Google Scholar] [CrossRef]

- Mizutani, T.; Okabe, Y.; Takeda, N. Quantitative evaluation of transverse cracks in carbon fiber reinforced plastic quasi-isotropic laminates with embedded small-diameter fiber bragg grating sensors. Smart Mater. Struct. 2003, 12, 898–903. [Google Scholar] [CrossRef]

- Bao, P.; Yuan, M.; Dong, S.; Song, H.; Xue, J. Fiber bragg grating sensor fatigue crack real-time monitoring based on spectrum cross-correlation analysis. J. Sound Vib. 2013, 332, 43–57. [Google Scholar] [CrossRef]

- Bernasconi, A.; Carboni, M.; Comolli, L. Monitoring of fatigue crack growth in composite adhesively bonded joints using fiber bragg gratings. Procedia Eng. 2011, 10, 207–212. [Google Scholar] [CrossRef]

- Huang, S.; Leblanc, M.; Ohn, M.M.; Measures, R.M. Bragg intra-grating structural sensing. Appl. Opt. 1995, 34, 5003–5009. [Google Scholar] [CrossRef] [PubMed]

- Huang, G.; Wei, C.; Chen, S.; Yang, G. Reconstruction of structural damage based on reflection intensity spectra of fiber bragg gratings. Meas. Sci. Technol. 2014, 25. [Google Scholar] [CrossRef]

- Takeda, S.; Okabe, Y.; Takeda, N. Delamination detection in cfrp laminates with embedded small-diameter fiber bragg grating sensors. Compos. Part A Appl. Sci. Manuf. 2002, 33, 971–980. [Google Scholar] [CrossRef]

- Yashiro, S.; Okabe, T.; Toyama, N.; Takeda, N. Monitoring damage in holed cfrp laminates using embedded chirped FBG sensors. Int. J. Solids Struct. 2007, 44, 603–613. [Google Scholar] [CrossRef]

- Ussorio, M.; Wang, H.; Ogin, S.L.; Thorne, A.M.; Reed, G.T.; Tjin, S.C.; Suresh, R. Modifications to FBG sensor spectra due to matrix cracking in a gfrp composite. Constr. Build. Mater. 2006, 20, 111–118. [Google Scholar] [CrossRef]

- Mckenzie, I.; Jones, R.; Marshall, I.H.; Galea, S. Optical fibre sensors for health monitoring of bonded repair systems. Compos. Struct. 2000, 50, 405–416. [Google Scholar] [CrossRef]

- Melenk, J.M.; Babuška, I. The partition of unity finite element method: Basic theory and applications. Comput. Methods Appl. Mech. Eng. 1996, 139, 289–314. [Google Scholar] [CrossRef]

- Moës, N.; Dolbow, J.; Belytschko, T. A finite element method for crack growth without remeshing. Int. J. Numer. Methods Eng. 1999, 46, 131–150. [Google Scholar] [CrossRef]

- Dolbow, J.; Moës, N.; Belytschko, T. Discontinuous enrichment in finite elements with a partition of unity method. Finite Elem. Anal. Des. 2000, 36, 235–260. [Google Scholar] [CrossRef]

- Wang, Y.; Waisman, H. Progressive delamination analysis of composite materials using XFEM and a discrete damage zone model. Comput. Mech. 2015, 55, 1–26. [Google Scholar] [CrossRef]

- Wang, Y.; Waisman, H. From diffuse damage to sharp cohesive cracks: A coupled XFEM framework for failure analysis of quasi-brittle materials. Comput. Methods Appl. Mech. Eng. 2015, 299, 57–89. [Google Scholar] [CrossRef]

- Waisman, H.; Chatzi, E.; Smyth, A.W. Detection and quantification of flaws in structures by the extended finite element method and genetic algorithms. Int. J. Numer. Methods Eng. 2010, 82, 303–328. [Google Scholar] [CrossRef]

- Chatzi, E.N.; Hiriyur, B.; Waisman, H.; Smyth, A.W. Experimental application and enhancement of the XFEM-ga algorithm for the detection of flaws in structures. Comput. Struct. 2011, 89, 556–570. [Google Scholar] [CrossRef]

- Jung, J.; Taciroglu, E. Modeling and identification of an arbitrarily shaped scatterer using dynamic XFEM with cubic splines. Comput. Methods Appl. Mech. Eng. 2014, 278, 101–118. [Google Scholar] [CrossRef]

- Jung, J.; Jeong, C.; Taciroglu, E. Identification of a scatterer embedded in elastic heterogeneous media using dynamic XFEM. Comput. Methods Appl. Mech. Eng. 2013, 259, 50–63. [Google Scholar] [CrossRef]

- Yan, G.; Sun, H.; Waisman, H. A guided bayesian inference approach for detection of multiple flaws in structures using the extended finite element method. Comput. Struct. 2015, 152, 27–44. [Google Scholar] [CrossRef]

- Beck, J.L.; Katafygiotis, L.S. Updating models and their uncertainties. I: Bayesian statistical framework. J. Eng. Mech. 1998, 124, 455–461. [Google Scholar] [CrossRef]

- Zhang, R.; Mahadevan, S. Model uncertainty and bayesian updating in reliability-based inspection. Struct. Saf. 2000, 22, 145–160. [Google Scholar] [CrossRef]

- Beck, J.L.; Au, S.K. Bayesian updating of structural models and reliability using markov chain monte carlo simulation. J. Eng. Mech. 2002, 128, 380–391. [Google Scholar] [CrossRef]

- Sankararaman, S.; Mahadevan, S. Bayesian methodology for diagnosis uncertainty quantification and health monitoring. Struct. Control Health Monit. 2013, 20, 88–106. [Google Scholar] [CrossRef]

- Williams, M.L. On the stress distribution at the base of a stationary crack. ASME J. Appl. Mech. 1957, 24, 109–114. [Google Scholar] [CrossRef]

- Zamani, A.; Gracie, R.; Eslami, M.R. Cohesive and non-cohesive fracture by higher-order enrichment of XFEM. Int. J. Numer. Methods Eng. 2012, 90, 452–483. [Google Scholar] [CrossRef]

- Lan, M.; Waisman, H.; Harari, I. A direct analytical method to extract mixed-mode components of strain energy release rates from irwin’s integral using extended finite element method. Int. J. Numer. Methods Eng. 2013, 95, 1033–1052. [Google Scholar] [CrossRef]

- Liu, X.Y.; Xiao, Q.Z.; Karihaloo, B.L. XFEM for direct evaluation of mixed mode sifs in homogeneous and bi-materials. Int. J. Numer. Methods Eng. 2004, 59, 1103–1118. [Google Scholar] [CrossRef]

- Ródenas, J.J.; González-Estrada, O.A.; Tarancón, J.E.; Fuenmayor, F.J. A recovery-type error estimator for the extended finite element method based on singular + smooth stress field splitting. Int. J. Numer. Methods Eng. 2008, 76, 545–571. [Google Scholar] [CrossRef]

- Prange, C.; Loehnert, S.; Wriggers, P. Error estimation for crack simulations using the XFEM. Int. J. Numer. Methods Eng. 2012, 91, 1459–1474. [Google Scholar] [CrossRef]

- Bordas, S.; Duflot, M. Derivative recovery and a posteriori error estimate for extended finite elements. Comput. Methods Appl. Mech. Eng. 2007, 196, 3381–3399. [Google Scholar] [CrossRef]

- Yamada, M.; Sakuda, K. Analysis of almost-periodic distributed feedback slab waveguides via a fundamental matrix approach. Appl. Opt. 1987, 26, 3474–3478. [Google Scholar] [CrossRef] [PubMed]

- Lamberti, A.; Vanlanduit, S.; De, P.B.; Berghmans, F. Influence of fiber bragg grating spectrum degradation on the performance of sensor interrogation algorithms. Sensors 2014, 14, 24258–24277. [Google Scholar] [CrossRef] [PubMed]

- Rao, Y.J. In-fibre bragg grating sensors. Meas. Sci. Technol. 1998, 8, 1837–1844. [Google Scholar] [CrossRef]

- Erdogan, T. Fiber grating spectra. J. Lightwave Technol. 1997, 15, 1277–1294. [Google Scholar] [CrossRef]

- Prabhugoud, M.; Peters, K. Modified transfer matrix formulation for bragg grating strain sensors. J. Lightwave Technol. 2004, 22, 2302–2309. [Google Scholar] [CrossRef]

- Do, D.D.; Lee, K.Y.; Kim, N. Low-crosstalk demultiplexer based on apodized volume holographic grating. In Proceedings of the International Workshop on Photonics and Applications, Hanoi, Vietnam, 5–8 April 2004.

- Park, C.; Peters, K. Comparison of damage measures based on fiber bragg grating spectra. Meas. Sci. Technol. 2012, 23, 25105–25117. [Google Scholar] [CrossRef]

- Okabe, Y.; Kosaka, T.; Takeda, N. Detection of transverse cracks in composites by using embedded FBG sensors. Smart Mater. Struct. 2000, 3986, 832–838. [Google Scholar] [CrossRef]

- Lau, K.T.; Chan, C.C.; Zhou, L.M.; Jin, W. Strain monitoring in composite-strengthened concrete structures using optical fibre sensors. Compos. Part B Eng. 2001, 32, 33–45. [Google Scholar] [CrossRef]

- Askins, C.G.; Putnam, M.A.; Friebele, E.J. Instrumentation for interrogating many-element fiber bragg grating arrays. Proc. SPIE Int. Soc. Opt. Eng. 1995, 2444, 1–32. [Google Scholar]

- Hutchinson, J.W. Plastic stress and strain fields at a crack tip. J. Mech. Phys. Solids 1968, 16, 337–342. [Google Scholar] [CrossRef]

- Guan, X.; He, J.; Rasselkorde, E.M.; Zhang, J.; Abbasi, W.A.; Zhou, S.K. Probabilistic fatigue life prediction and structural reliability evaluation of turbine rotors integrating an automated ultrasonic inspection system. J. Nondestruct. Eval. 2014, 33, 51–61. [Google Scholar] [CrossRef]

- Guan, X.; Jha, R.; Liu, Y. Model selection, updating, and averaging for probabilistic fatigue damage prognosis. Struct. Saf. 2011, 33, 242–249. [Google Scholar] [CrossRef]

- Alleyne, D.N.; Cawley, P. Optimization of lamb wave inspection techniques. NDT E Int. 1992, 25, 11–22. [Google Scholar] [CrossRef]

- Guan, X.; Zhang, J.; Zhou, S.; Rasselkorde, E.M.; Abbasi, W. Probabilistic modeling and sizing of embedded flaws in ultrasonic non-destructive inspections for fatigue damage prognostics and structural integrity assessment. NDT E Int. 2014, 61, 1–9. [Google Scholar] [CrossRef]

- Yang, J.; He, J.; Guan, X.; Wang, D.; Chen, H.; Zhang, W.; Liu, Y. A probabilistic crack size quantification method using in-situ lamb wave test and bayesian updating. Mech. Syst. Signal Process. 2015. [Google Scholar] [CrossRef]

- Guan, X.; He, J.; Jha, R.; Liu, Y. An efficient analytical bayesian method for reliability and system response updating based on laplace and inverse first-order reliability computations. Reliab. Eng. Syst. Saf. 2012, 97, 1–13. [Google Scholar] [CrossRef]

- Bell, S. A Beginner’s Guide to Uncertainty of Measurement; National Physical Laboratory: Teddington, UK, 2001. [Google Scholar]

- Hastings, W.K. Monte carlo sampling methods using markov chains and their applications. Biometrika 1970, 57, 97–109. [Google Scholar] [CrossRef]

- Fort, G.; Moulines, E.; Priouret, P. Convergence of adaptive and interacting Markov chain Monte Carlo algorithms. Ann. Stat. 2011, 39, 3262–3289. [Google Scholar] [CrossRef]

- American Institute of Aeronautics and Astronautics (AIAA). An new technique in analytical reliability estimation involving multi-modal distributions: An extended laplace approximation approach. In Proceedings of the AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Boston, MA, USA, 8–11 April 2013.

| Polar Coordinate r (mm) | High-Order XFEM | Standard XFEM | ||

|---|---|---|---|---|

| Normal Stress (MPa) | Relative Error (%) | Normal Stress (MPa) | Relative Error (%) | |

| 0.001 | 11.87 | 1.29 | 8.76 | 27.19 |

| 0.01 | 3.95 | 0.58 | 3.19 | 19.52 |

| 0.05 | 1.80 | 0.77 | 1.62 | 9.10 |

| 0.1 | 1.26 | 0.24 | 1.34 | 5.95 |

| 0.3 | 0.76 | 2.53 | 0.83 | 14.37 |

| 0.6 | 0.50 | 2.85 | 0.47 | 8.94 |

| Material | Elastic Modulus (MPa) | Poisson’s Ratio | Yield Strength (MPa) | Tensile Strength (MPa) |

|---|---|---|---|---|

| AL7075-T6 | 73100 | 0.33 | 503 | 572 |

| Parameter | Sensors | |

|---|---|---|

| FBG1 | FBG2 | |

| Modulation mode of refractive index | Cosine | Cosine |

| Effective refractive index | 1.445 | 1.465 |

| Poisson’s ratio | 0.17 | 0.17 |

| Grating length L (mm) | 10.2 | 10.6 |

| Center wavelength (nm) | 1529.11 | 1544.95 |

| Photo-elastic coefficient | 0.113 | 0.113 |

| Photo-elastic coefficient | 0.252 | 0.252 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, J.; Yang, J.; Wang, Y.; Waisman, H.; Zhang, W. Probabilistic Model Updating for Sizing of Hole-Edge Crack Using Fiber Bragg Grating Sensors and the High-Order Extended Finite Element Method. Sensors 2016, 16, 1956. https://doi.org/10.3390/s16111956

He J, Yang J, Wang Y, Waisman H, Zhang W. Probabilistic Model Updating for Sizing of Hole-Edge Crack Using Fiber Bragg Grating Sensors and the High-Order Extended Finite Element Method. Sensors. 2016; 16(11):1956. https://doi.org/10.3390/s16111956

Chicago/Turabian StyleHe, Jingjing, Jinsong Yang, Yongxiang Wang, Haim Waisman, and Weifang Zhang. 2016. "Probabilistic Model Updating for Sizing of Hole-Edge Crack Using Fiber Bragg Grating Sensors and the High-Order Extended Finite Element Method" Sensors 16, no. 11: 1956. https://doi.org/10.3390/s16111956