Microwave Moisture Sensing of Seedcotton: Part 1: Seedcotton Microwave Material Properties

Abstract

:1. Introduction

- (1)

- Presenting the basic microwave material properties of seedcotton (part one);

- (2)

- Developing prediction equations relating microwave material properties to moisture content of bulk-packaged seedcotton, given there is a known weight of the bulk package (part two);

- (3)

- Assessing accuracy of previously reported 9–15 GHz density-independent equations (developed for use in corn and wheat) for prediction of moisture in seedcotton in the 1–2.5 GHz band, without the need for weighing the material (part two);

- (4)

- Examine the potential of density-independent prediction equations relating microwave material properties to moisture content of bulk-packaged seedcotton (part two).

1.1. Literature Review: Theory

- (1)

- Seedcotton is a complex material comprised of five main constituents (air, water, burs, sticks, seeds and cotton lint). As such, stripper harvested cotton, with a high by-product content of burs and sticks (30% by mass), is expected to exhibit a different microwave response than cleaner seedcotton such as that harvested with picker harvesters (6% by-product content).

- (2)

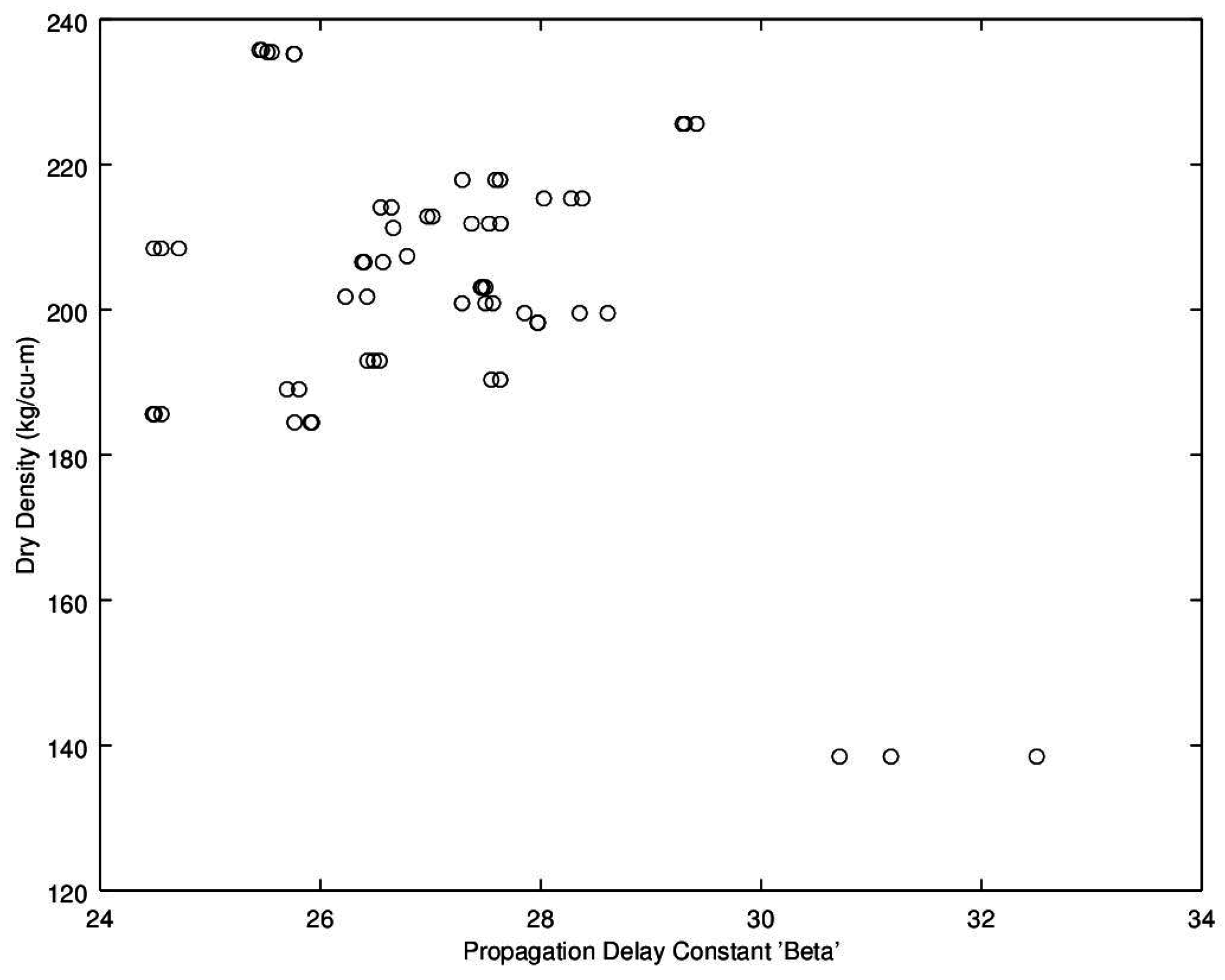

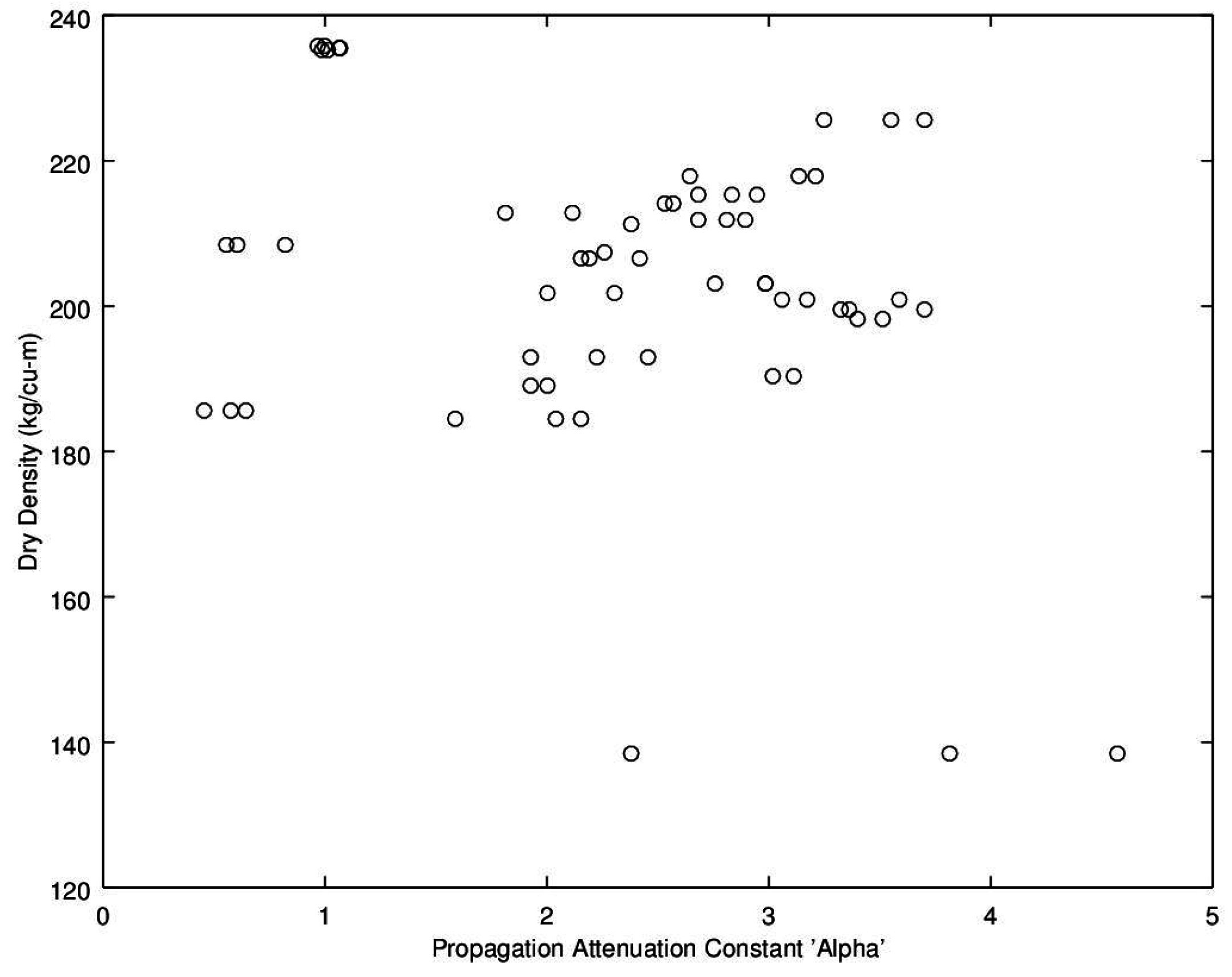

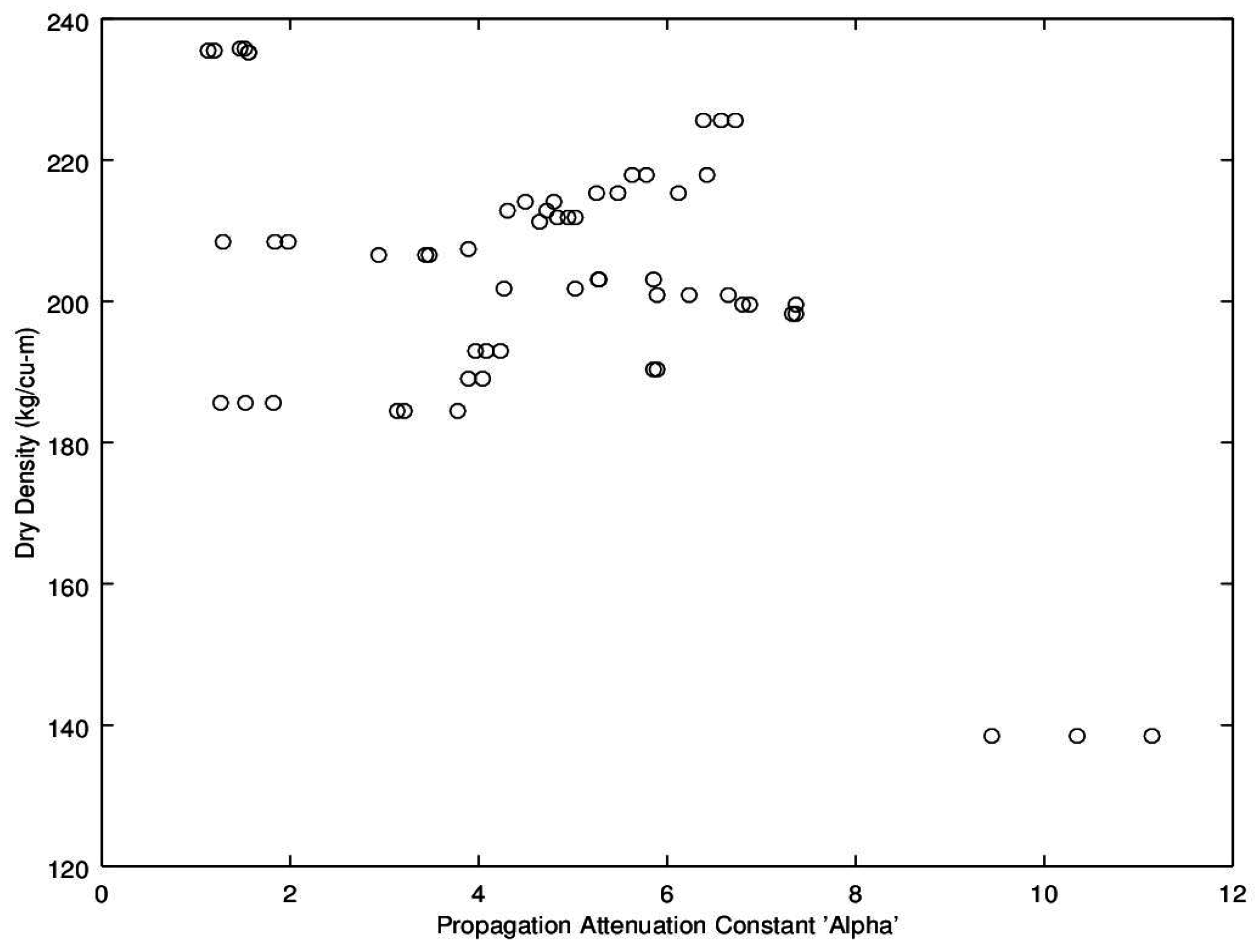

- The volumetric air content of seedcotton is significantly larger than the materials reported in the literature (density of seedcotton varies from 0.28–0.36 g·cm−3 whereas wheat and corn are nearly twice this value). Hence, it is expected that seedcotton will exhibit a measurable depression in the electrical permittivity of the bulk seedcotton, in comparison to cereal crops’ response.

- (3)

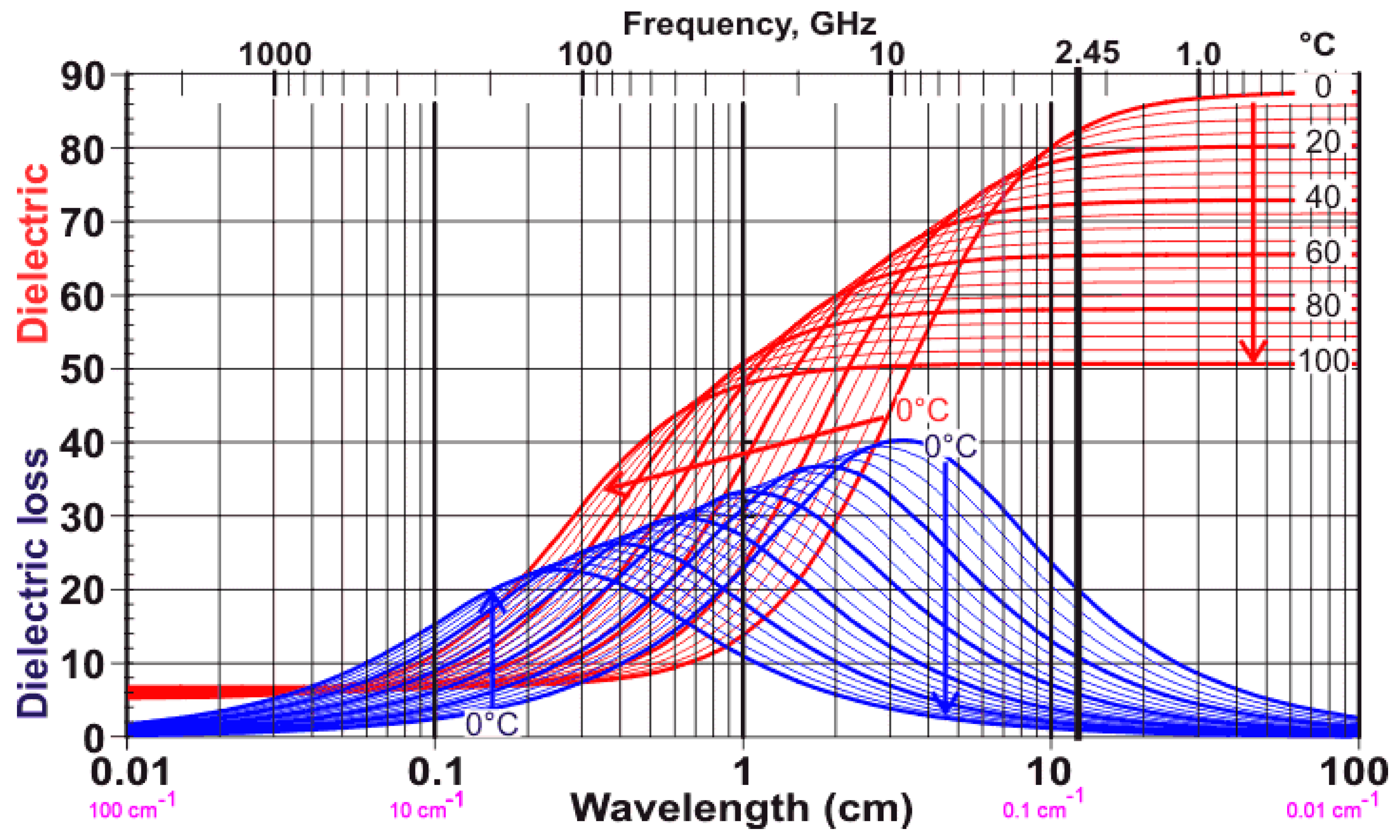

- Due to the character of free water’s microwave response, as a function of frequency, 10+ GHz X-band, and above, responses are likely to be very different than those observed from the lower 1–2 GHz region of interest to this research (Figure 3).

- (4)

- Temperature depresses the permittivity, and dielectric loss of free water and water in bulk matrix of materials have been widely reported to follow this same trend.

- (5)

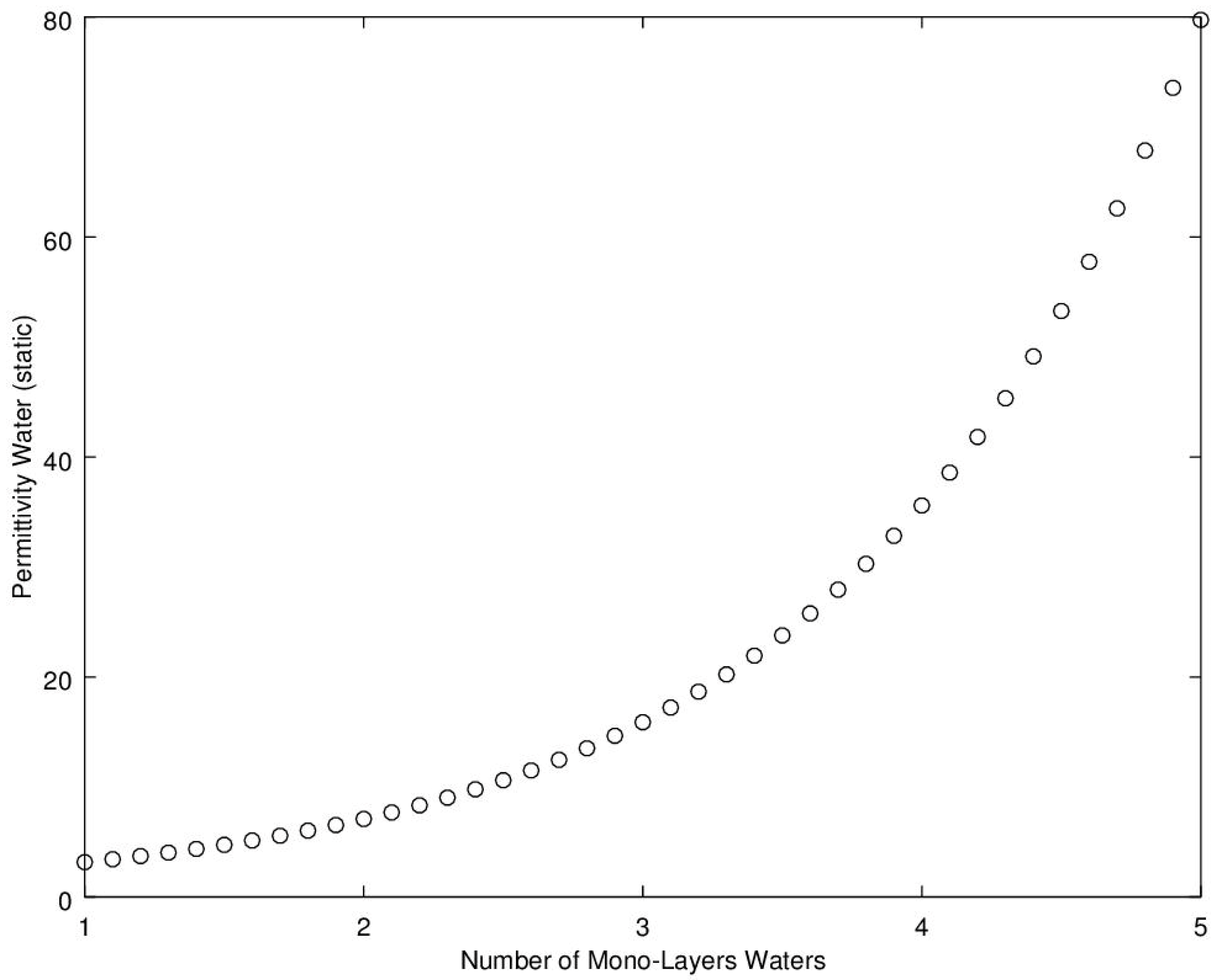

- High specific surface area materials have a reduced permittivity response, in comparison to low specific materials. Hence it is expected that equations may be reproducible between materials with similar specific surface areas. Conversely, the microwave response is very likely to differ as the surface area of the material of interest moves away from the model material.

- (6)

- Minimal to no measurable response to salts from particulate accumulation of dust due to wind transport of erodible top-soils.

1.2. Literature Review: Measurements

- γ ≡ complex propagation constant

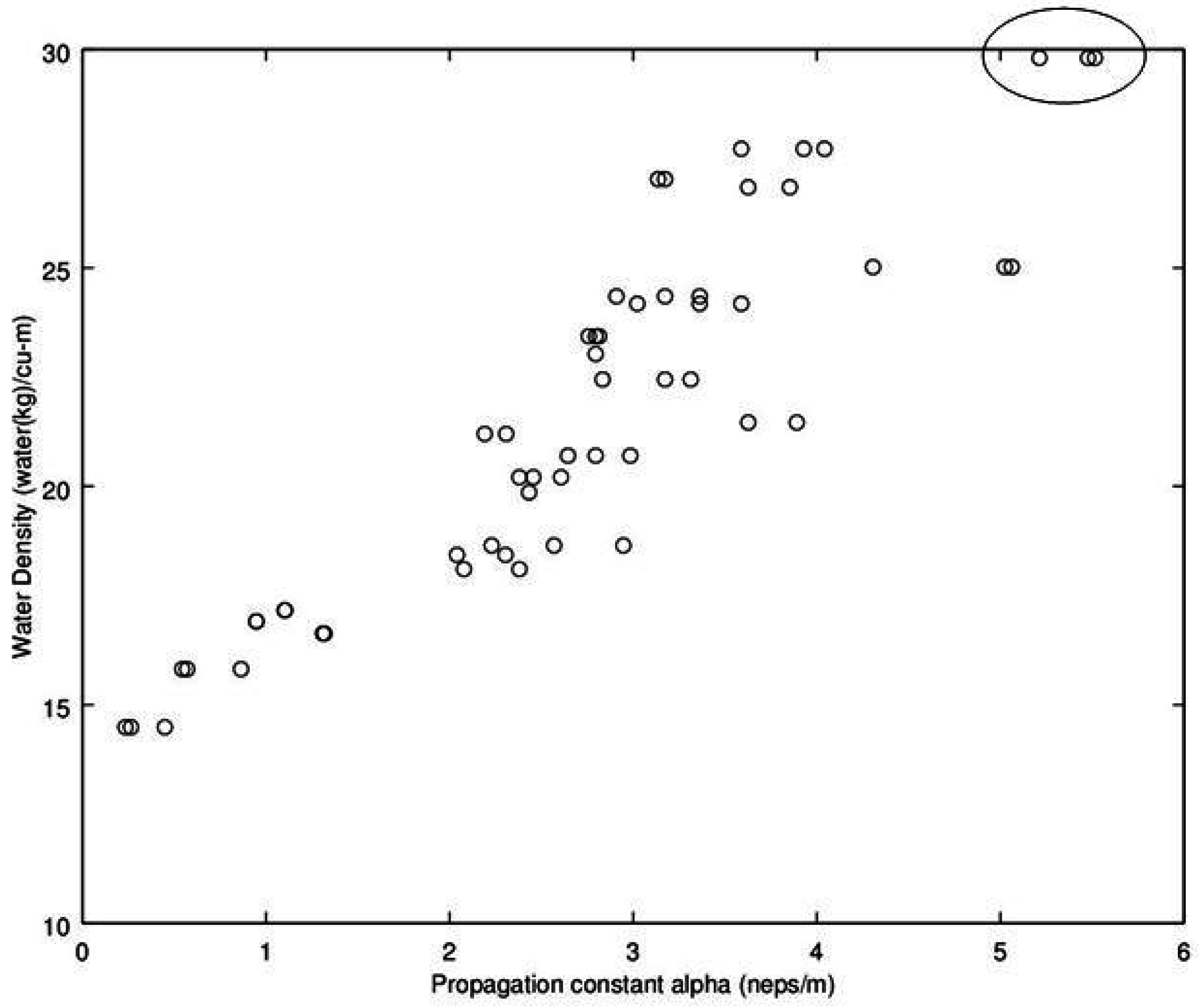

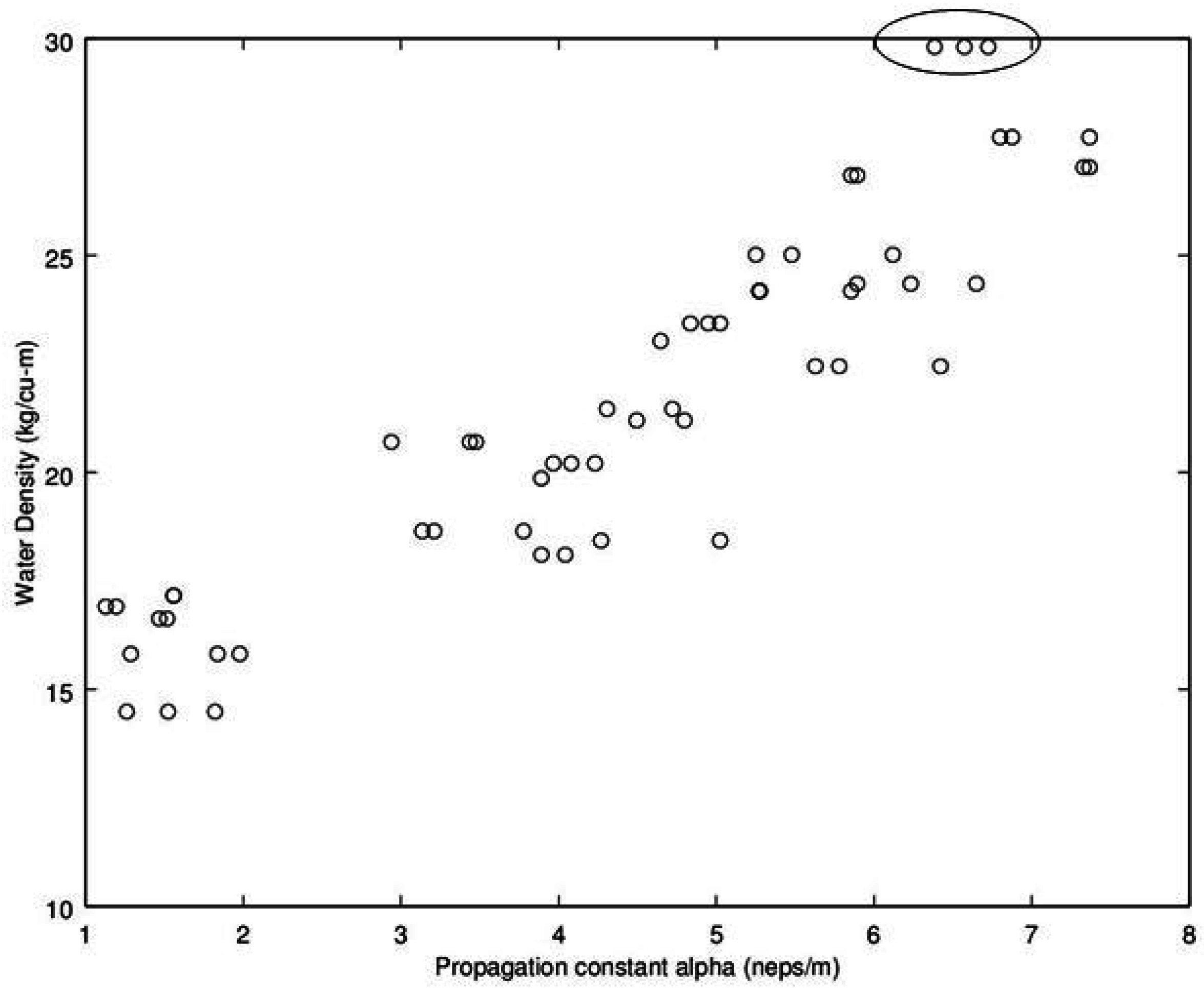

- α ≡ propagation attenuation constant (neps·m−1)

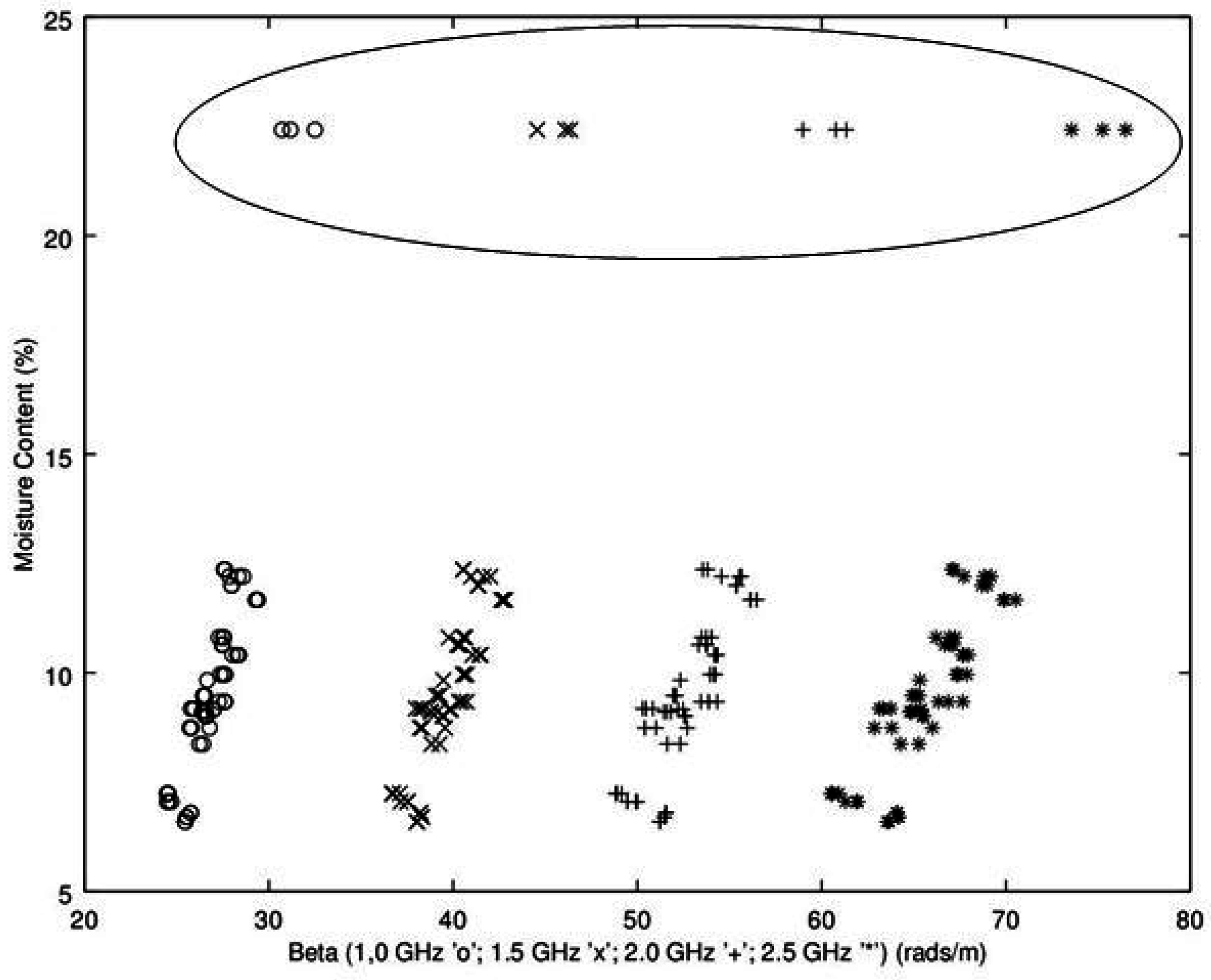

- β ≡ propagation delay constant (rads·m−1)

- ε’ ≡ real portion of complex electrical permittivity (dielectric constant) (F·m−1)

- ε” ≡ imaginary portion of complex electrical permittivity (dielectric damping)

- j ≡ imaginary number = [−1] 0.5

- ω ≡ frequency of electromagnetic wave (rads·s−1)

- μο ≡ permeability of free space (H·m−1)

- a and b ≡ proportionality constants

- mc ≡ moisture content

- θ ≡ phase delay of signal caused by insertion of material (rads)

- A ≡ attenuation of signal (# from 0:1)

- R ≡ (A/θ)

2. Materials and Methods

Experimental Design

3. Results

- Wet_Density ≡ (wet weight of the module)/(volume [m3])

- WD ≡ Water_Density ≡ (weight of water)/(volume [m3])

4. Conclusions

Author Contributions

Conflicts of Interest

Disclaimer

References

- Pelletier, M.G. Multipath Interference Investigation for Cotton Bale Microwave Moisture Sensing. J. Cotton Sci. 2004, 8, 170–178. [Google Scholar]

- Pelletier, M.G.; Barnes, E.M. Microwave imaging of cotton bales. Sensors 2008, 8, 7241–7258. [Google Scholar] [CrossRef]

- Pelletier, M.G.; Viera, J.A.; Wanjura, J.D.; Holt, G.A. Accurate permittivity measurements for microwave imaging via ultra-wideband removal of spurious reflectors. Sensors 2010, 10, 8491–8503. [Google Scholar] [CrossRef] [PubMed]

- Pelletier, M.G.; Viera, J.A.; Schwartz, R.C.; Evett, S.R.; Lascano, R.J.; McMichael, R.L. Analysis of coaxial soil cell in reflection and transmission. Sensors 2011, 11, 2592–2610. [Google Scholar] [CrossRef] [PubMed]

- Hoppe, W.; Meyer, W.; Schilz, W. Density-independent moisture metering in fibrous materials using a Double Cut-off Gunn-Oscillator. IEEE Trans. Microw. Theory Tech. 1981, 28, 1449–1452. [Google Scholar] [CrossRef]

- Sun, Z.J.; Young, G.D. Saline Clayey Soil Moisture Measurement Using Time-Domain Reflectometry. In Proceedings of the TDR 2001 Symposium, Evanston, IL, USA, 5–7 September 2001.

- Thorpe, J.M. The dielectric behaviours of vapours adsorbed on porous solids. Trans. Faraday Soc. 1959, 55, 442–454. [Google Scholar] [CrossRef]

- Bockris, J.O.M.; Devanathan, M.A.V.; Muller, K. On the structure of charged interfaces. R. Soc. Lond. A 1963, 274, 55–79. [Google Scholar] [CrossRef]

- Lamm, G.; Pack, G.R. Local dielectric constants and Poisson-Boltzmann calculations of DNA counterion distributions. Int. J. Quantum Chem. 1977, 65, 1087–1093. [Google Scholar] [CrossRef]

- Dani, O.; Wraith, J.M. Temperature effects on soil bulk dielectric permittivity measured by time domain reflectometry: A physical model. Water Resour. Res. 1999, 35, 371–383. [Google Scholar]

- Robinson, D.A.; Jones, S.B.; Wraith, J.M.; Or, D.; Friedman, S.P. A review of advances in dielectric and electrical conductivity measurement in soils using time domain reflectometry. Vados. Zone J. 2003, 2, 444–475. [Google Scholar] [CrossRef]

- Schwartz, R.C.; Evett, S.R.; Pelletier, M.G.; Bell, J.M. Complex permittivity model for time domain reflectometry soil water content sensing: I. Theory Soil Sci. Soc. Am. J. 2009, 73, 886–897. [Google Scholar] [CrossRef]

- Boyarskii, D.A.; Tikhonov, V.V.; Komarova, N.Y. Model of dielectric constant of bound water in soil for applications of microwave remote sensing. Prog. Electromagn. Res. 2002, 35, 251–269. [Google Scholar] [CrossRef]

- Weast, R.C. CRC Handbook of Chemistry and Physics, 67th ed.; CRC Press: Boca Raton, FL, USA, 1986. [Google Scholar]

- Hippel, A.V. Dielectric Materials and Applications; Artech House Publishing: Boston, MA, USA, 1995; pp. 301–370. [Google Scholar]

- Nelson, S.O.; Trabelsi, S. Principles for microwave moisture and density measurements in grain and seeds. J. Microw. Power Electromagn. Energy 2004, 39, 107–117. [Google Scholar] [CrossRef] [PubMed]

- Chaplin, M. Water Structure and Science. Available online: http://www1.lsbu.ac.uk/water/microwave_water.html (accessed on 31 October 2016).

- Nelson, S.O. RF and microwave dielectric properties of shelled, yellow-dent field corn. Trans. ASAE 1979, 22, 1451–1457. [Google Scholar] [CrossRef]

- Pelletier, M.G.; Schwartz, R.C.; Holt, G.A.; Wanjura, J.D.; Green, T.R. Frequency Domain Probe Design for High Frequency Sensing of Soil Moisture. Agriculture 2016. submitted for publication. [Google Scholar]

- Stuchly, S.; Kraszewski, A.W. Method for the Determination of Water Content in Solids, Liquids and Gases by Means of Microwaves and Arrangement for Application of This Method. Polish Patent 51,731, 4 May 1969. [Google Scholar]

- Meyer, W.; Schilz, W. A microwave method for density independent determination of the moisture content of solids. J. Phys. D Appl. Phys. 1980, 13, 1823. [Google Scholar] [CrossRef]

- Meyer, W.; Schilz, W. Feasibility study of density-independent moisture measurement with microwaves. IEEE Trans. Microw. Theory Tech. 1981, 29, 732–739. [Google Scholar] [CrossRef]

- Trabelsi, S.; Nelson, S.O. Free-space measurement of dielectric properties of cereal grain and oilseed at microwave frequencies. Meas. Sci. Technol. 2003, 14, 589. [Google Scholar] [CrossRef]

- Pozar, D.M. Microwave Engineering, 2nd ed.; John Wiley and Sons, Inc.: New York, NY, USA, 1998; pp. 275–278. [Google Scholar]

- Kress-Rogers, E.; Kent, M. Microwave measurement of powder moisture and density. J. Food Eng. 1987, 6, 345–376. [Google Scholar] [CrossRef]

- Kent, M. Application of two-variable microwave techniques to composition analysis problem. Trans. Inst. Meas. Control 1989, 11, 58–62. [Google Scholar] [CrossRef]

- Zhang, Y.; Okamura, S. New Density-independent Moisture Measurement Using Microwave Phase Shifts at Two Frequencies. IEEE Trans. Instrum. Meas. 1999, 48, 1208–1211. [Google Scholar] [CrossRef]

- Kraszewski, A.W.; Nelson, S.O. Density-independent moisture determination in wheat by microwave measurement. Trans. ASAE 1991, 34, 1776–1783. [Google Scholar] [CrossRef]

- Trabelsi, S.; Kraszewski, A.W.; Nelson, S.O. New density-independent calibration function for microwave sensing of moisture content in particulate materials. IEEE Trans. Instrum. Meas. 1998, 47, 613–622. [Google Scholar] [CrossRef]

- Shepherd, J.V. Standard Procedures for Foreign Matter and Moisture Analytical Tests Used in Cotton Ginning Research; Pneumatic Fractionator Method. In USDA Agricultural Handbook 422; Government Printing Office: Washington, DC, USA, 1972; pp. 1–3. [Google Scholar]

- Shepherd, J.V. Standard Procedures for Foreign Matter and Moisture Analytical Tests Used in Cotton Ginning Research; Method of Oven Drying Seed Cotton. In USDA Agricultural Handbook 422; Government Printing Office: Washington, DC, USA, 1972; pp. 6–7. [Google Scholar]

- Kraszewski, A.W.; Trabelsi, S.; Nelson, S.O. Wheat permittivity measurements in free space. J. Microw. Power Electromagn. Energy 1996, 31, 135–141. [Google Scholar] [CrossRef]

| Frequency (GHz) | RMS Error | r2 |

|---|---|---|

| 1 | 1.98 | 0.781 |

| 1.5 | 2.12 | 0.797 |

| 2 | 2.2 | 0.781 |

| 2.5 | 2.2 | 0.782 |

| Frequency (GHz) | RMS Error | r2 |

|---|---|---|

| 1 | 0.96 | 0.914 |

| 1.5 | 1.07 | 0.893 |

| 2 | 1.08 | 0.892 |

| 2.5 | 1.1 | 0.888 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pelletier, M.G.; Wanjura, J.D.; Holt, G.A. Microwave Moisture Sensing of Seedcotton: Part 1: Seedcotton Microwave Material Properties. Sensors 2016, 16, 1843. https://doi.org/10.3390/s16111843

Pelletier MG, Wanjura JD, Holt GA. Microwave Moisture Sensing of Seedcotton: Part 1: Seedcotton Microwave Material Properties. Sensors. 2016; 16(11):1843. https://doi.org/10.3390/s16111843

Chicago/Turabian StylePelletier, Mathew G., John D. Wanjura, and Greg A. Holt. 2016. "Microwave Moisture Sensing of Seedcotton: Part 1: Seedcotton Microwave Material Properties" Sensors 16, no. 11: 1843. https://doi.org/10.3390/s16111843