Sparse Reconstruction for Micro Defect Detection in Acoustic Micro Imaging

Abstract

:1. Introduction

2. Method

| Algorithm 1. Pseudocode of AMISR |

| 1: Input: Oversampled C-scan image y, point spread function k, regularization parameters δ, ε, λ 2: Initialization , flag = 1 3: while (flag), do 4: 5: 6: if 7: , flag = 0 8: end 9: end 10: Calculate TCR |

| 11: Output: Reconstruct image , TCR |

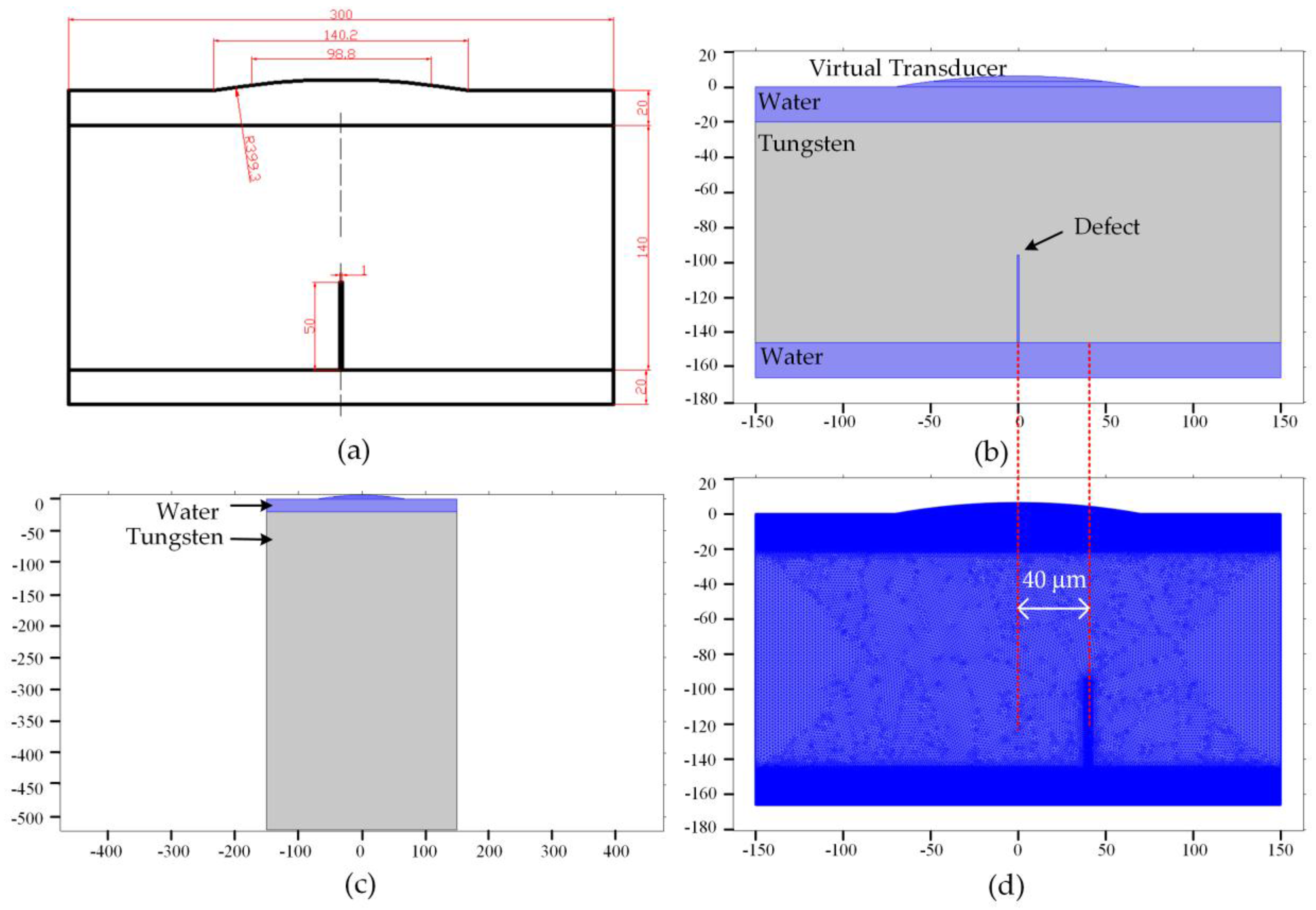

3. Point Spread Function (PSF)

3.1. Modeling

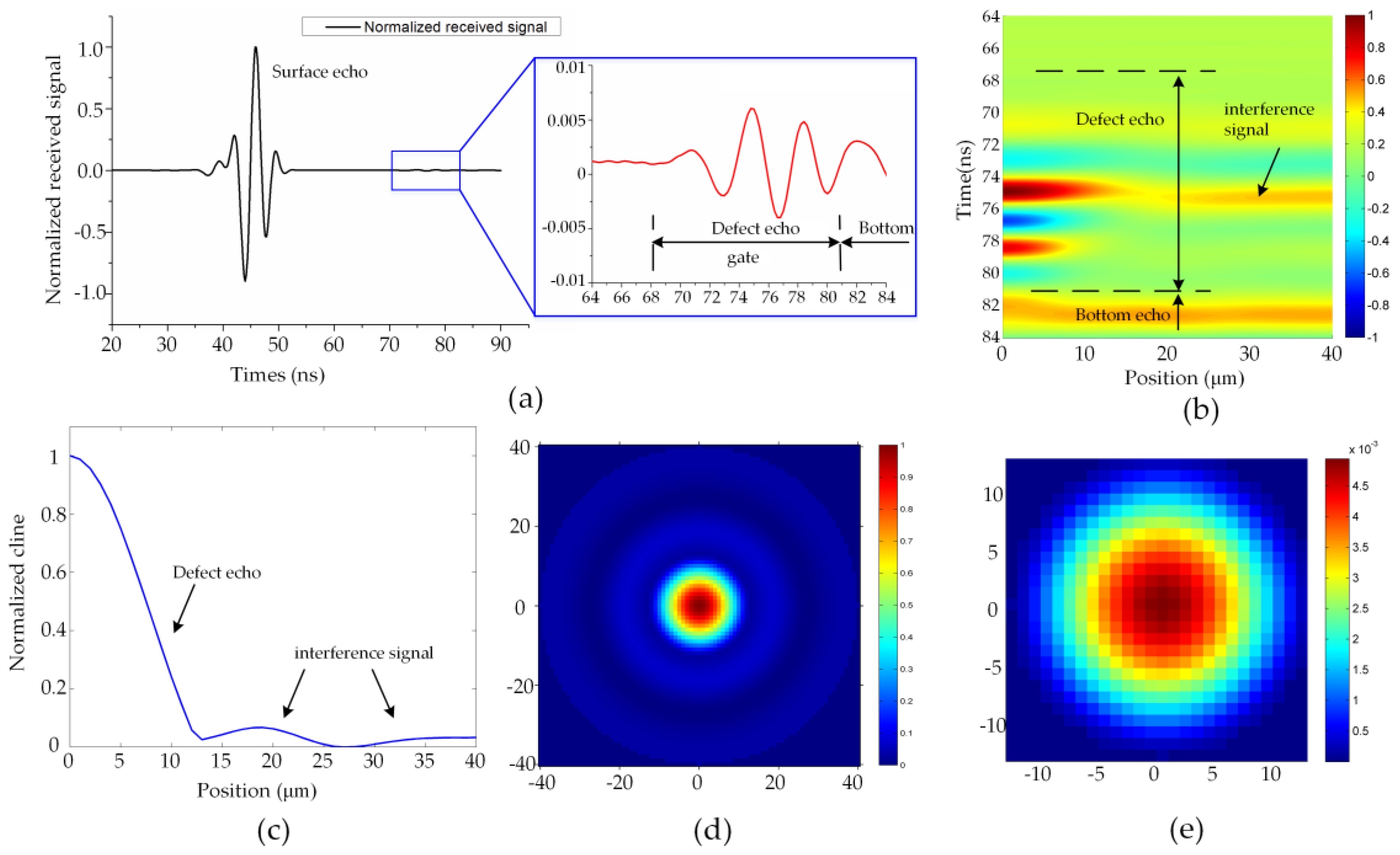

3.2. Characteristics of the VT

3.3. C-Scan and PSF

4. Experimental Verification

4.1. Single Groove

4.2. Two Grooves

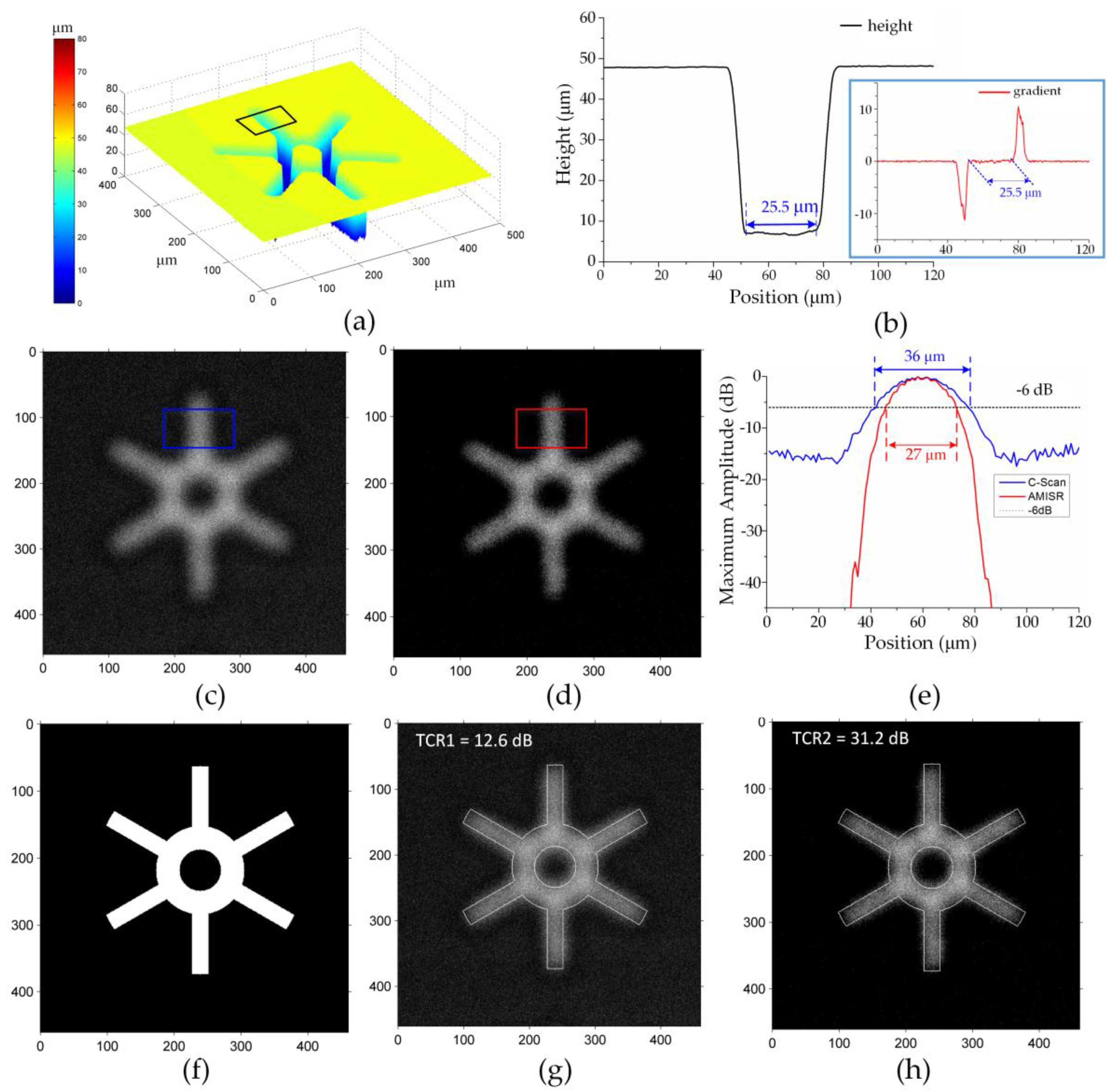

4.3. Complex Defect

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| AMI | Acoustic microscopy imaging |

| SAM | Scanning acoustic microscopy |

| PSF | Point spread function |

| TCR | Target-to-clutter ratio |

| LTI | Linear time invariant |

| ISTA | Iterative shrinkage-thresholding algorithm |

| AMISR | Acoustic microscopy imaging sparse reconstruction |

| VT | Virtual transducer |

| ICP | Inductive couple plasmas |

| LSCM | Laser scanning confocal microscopy |

References

- Wang, F.L.; Wang, F. Rapidly void detection in TSVs with 2-D X-ray imaging and artificial neural networks. IEEE Trans. Semicond. Manuf. 2014, 2, 246–251. [Google Scholar] [CrossRef]

- Wang, F.L.; Wang, F. Void Detection in TSVs with X-ray image multithreshold segmentation and artificial neural networks. IEEE Trans. Compon. Packag. Manuf. 2014, 7, 1245–1250. [Google Scholar] [CrossRef]

- Lu, X.N.; Liao, G.L.; Zha, Z.Y.; Xia, Q.; Shi, T.L. A novel approach for flip chip solder joint inspection based on pulsed phase thermography. NDT E Int. 2011, 6, 484–489. [Google Scholar]

- Brand, S.; Czurratis, P.; Hoffrogge, P.; Temple, D.; Malta, D.; Reed, J.; Petzold, M. Extending acoustic microscopy for comprehensive failure analysis applications. J. Mater. Sci. Mater. Electron. 2011, 10, 1580–1593. [Google Scholar] [CrossRef]

- Martin, E.; Larato, C.; Clément, A.; Saint-Paul, M. Detection of delaminations in sub-wavelength thick multi-layered packages from the local temporal coherence of ultrasonic signals. NDT E Int. 2008, 4, 280–291. [Google Scholar]

- Brand, S.; Lapadatu, A.; Djuric, T.; Czurratis, P.; Schischka, J.; Petzold, M. Scanning acoustic gigahertz microscopy for metrology applications in three-dimensional integration technologies. J. Micro/Nanolithogr. MEMS MOEMS 2014, 13, 011207. [Google Scholar] [CrossRef]

- Errico, C.; Pierre, J.; Pezet, S.; Desailly, Y.; Lenkei, Z.; Couture, O.; Tanter, M. Ultrafast ultrasound localization microscopy for deep super-resolution vascular imaging. Nature 2015, 7579, 499–502. [Google Scholar] [CrossRef] [PubMed]

- Viessmann, O.M.; Eckersley, R.J.; Christensen-Jeffries, K.; Tang, M.X.; Dunsby, C. Acoustic super-resolution with ultrasound and microbubbles. Phys. Med. Biol. 2016, 18, 6447–6458. [Google Scholar] [CrossRef] [PubMed]

- Kwak, D.R.; Yoshida, S.; Sasaki, T.; Todd, J.A.; Park, I.K. Evaluation of near-surface stress distributions in dissimilar welded joint by scanning acoustic microscopy. Ultrasonics 2016, 67, 9–17. [Google Scholar] [CrossRef] [PubMed]

- Su, L.; Zha, Z.Y.; Lu, X.N.; Shi, T.L.; Liao, G.L. Using BP network for ultrasonic inspection of flip chip solder joints. Mech. Syst. Signal Process. 2013, 32, 183–190. [Google Scholar] [CrossRef]

- Su, L.; Shi, T.L.; Xu, Z.S.; Lu, X.N.; Liao, G.L. Defect inspection of flip chip solder bumps using an ultrasonic transducer. Sensors 2013, 12, 16281–16291. [Google Scholar] [CrossRef]

- Zhang, G.M.; Zhang, C.Z.; Harvey, D.M. Sparse signal representation and its applications in ultrasonic NDE. Ultrasonics 2012, 3, 351–363. [Google Scholar] [CrossRef] [PubMed]

- Zhang, G.M.; Harvey, D.M.; Braden, D.R. Advanced acoustic microimaging using sparse signal representation for the evaluation of microelectronic packages. IEEE Trans. Adv. Packag. 2006, 29, 271–283. [Google Scholar] [CrossRef]

- Mor, E.; Aladjem, M.; Azoulay, A. Cluster-enhanced sparse approximation of overlapping ultrasonic echoes. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2015, 2, 373–386. [Google Scholar] [CrossRef] [PubMed]

- Carcreff, E.; Bourguignon, S.; Idier, J.; Simon, L. A linear model approach for ultrasonic inverse problems with attenuation and dispersion. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2014, 7, 1191–1203. [Google Scholar] [CrossRef] [PubMed]

- Jin, H.R.; Yang, K.J.; Wu, S.W.; Wu, H.T.; Chen, J. Sparse deconvolution method for ultrasound images based on automatic estimation of reference signals. Ultrasonics 2016, 67, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Wu, H.T.; Chen, J.; Wu, S.W.; Jin, H.R.; Yang, K.J. A model-based regularized inverse method for ultrasonic B-scan image reconstruction. Meas. Sci. Technol. 2015, 26, 10540110. [Google Scholar] [CrossRef]

- Guarneri, G.; Pipa, D.; Junior, F.; de Arruda, L.; Zibetti, M. A sparse reconstruction algorithm for ultrasonic images in nondestructive testing. Sensors 2015, 4, 9324–9343. [Google Scholar] [CrossRef] [PubMed]

- Canumalla, S. Resolution of broadband transducers in acoustic microscopy of encapsulated ICs: Transducer selection. IEEE Trans. Compon. Packag. Technol. 1999, 4, 582–592. [Google Scholar] [CrossRef]

- Lee, C.S.; Zhang, G.M.; Harvey, D.M.; Qi, A. Characterization of micro-crack propagation through analysis of edge effect in acoustic microimaging of microelectronic packages. NDT E Int. 2016, 79, 1–6. [Google Scholar]

- Lee, C.S.; Zhang, G.M.; Harvey, D.M.; Ma, H.W.; Braden, D.R. Finite element modelling for the investigation of edge effect in acoustic micro imaging of microelectronic packages. Meas. Sci. Technol. 2016, 27, 25601. [Google Scholar] [CrossRef]

- Lee, C.S.; Zhang, G.M.; Harvey, D.M.; Ma, H.W. Development of C-Line plot technique for the characterization of edge effects in acoustic imaging: A case study using flip chip package geometry. Microelectron. Reliab. 2015, 12, 2762–2768. [Google Scholar] [CrossRef]

- Lee, C.S. Numerical Study for Acoustic Micro-Imaging of Three Dimensional Microelectronic Packages. Ph.D. Thesis, Liverpool John Moores University, Liverpool, UK, 2014. [Google Scholar]

- Efrat, N.; Glasner, D.; Apartsin, A.; Nadler, B.; Levin, A. Accurate blur models vs. image priors in single image super-resolution. In Proceedings of the IEEE International Conference on Computer Vision (ICCV), New York, NY, USA, 29 August 2013; pp. 2832–2839.

- Krishnan, D.; Tay, T.; Fergus, R. Blind deconvolution using a normalized sparsity measure. In Proceedings of the IEEE Computer Vision and Pattern Recognition (CVPR), Providence, RI, USA, 20 June 2011; pp. 233–240.

- Beck, A.; Teboulle, M. A fast iterative shrinkage-thresholding algorithm for linear inverse problems. SIAM J. Imaging Sci. 2009, 2, 183–202. [Google Scholar] [CrossRef]

- Shao, W.Z.; Li, H.B.; Elad, M. Bi-l0-l2-norm regularization for blind motion deblurring. J. Vis. Commun. Image Represnet. 2015, 33, 42–59. [Google Scholar] [CrossRef]

- Tuysuzoglu, A.; Kracht, J.M.; Cleveland, R.O.; Cetin, M.; Karl, W.C. Sparsity driven ultrasound imaging. J. Acoust. Soc. Am. 2012, 21, 1271–1281. [Google Scholar] [CrossRef] [PubMed] [Green Version]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Shi, T.; Su, L.; Wang, X.; Hong, Y.; Chen, K.; Liao, G. Sparse Reconstruction for Micro Defect Detection in Acoustic Micro Imaging. Sensors 2016, 16, 1773. https://doi.org/10.3390/s16101773

Zhang Y, Shi T, Su L, Wang X, Hong Y, Chen K, Liao G. Sparse Reconstruction for Micro Defect Detection in Acoustic Micro Imaging. Sensors. 2016; 16(10):1773. https://doi.org/10.3390/s16101773

Chicago/Turabian StyleZhang, Yichun, Tielin Shi, Lei Su, Xiao Wang, Yuan Hong, Kepeng Chen, and Guanglan Liao. 2016. "Sparse Reconstruction for Micro Defect Detection in Acoustic Micro Imaging" Sensors 16, no. 10: 1773. https://doi.org/10.3390/s16101773