Development of an FBG Sensor Array for Multi-Impact Source Localization on CFRP Structures

Abstract

:1. Introduction

2. Localization Algorithm

2.1. Principle of Multiple Signal Classification Algorithm

2.2. Estimation of the Number of Impacts

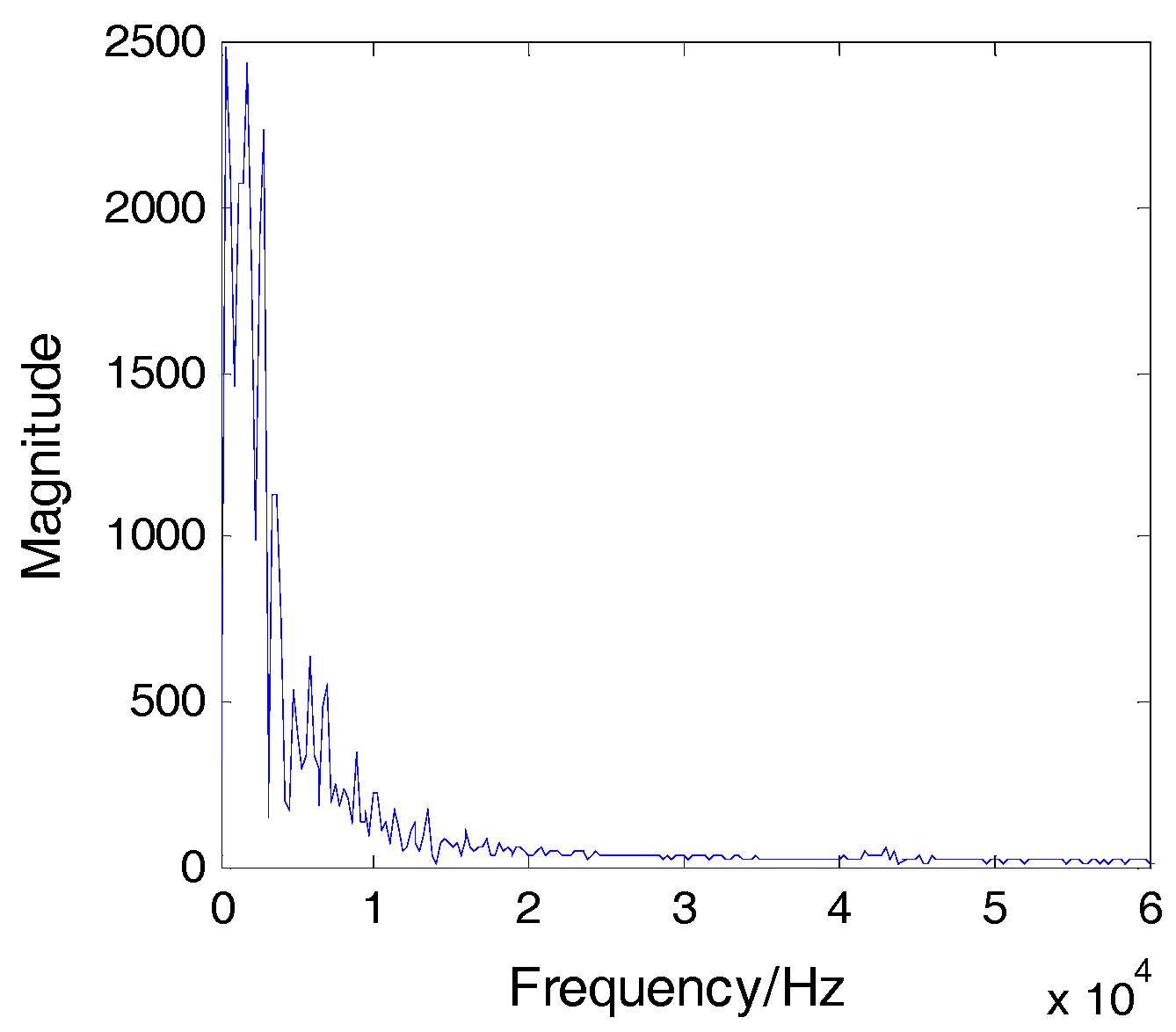

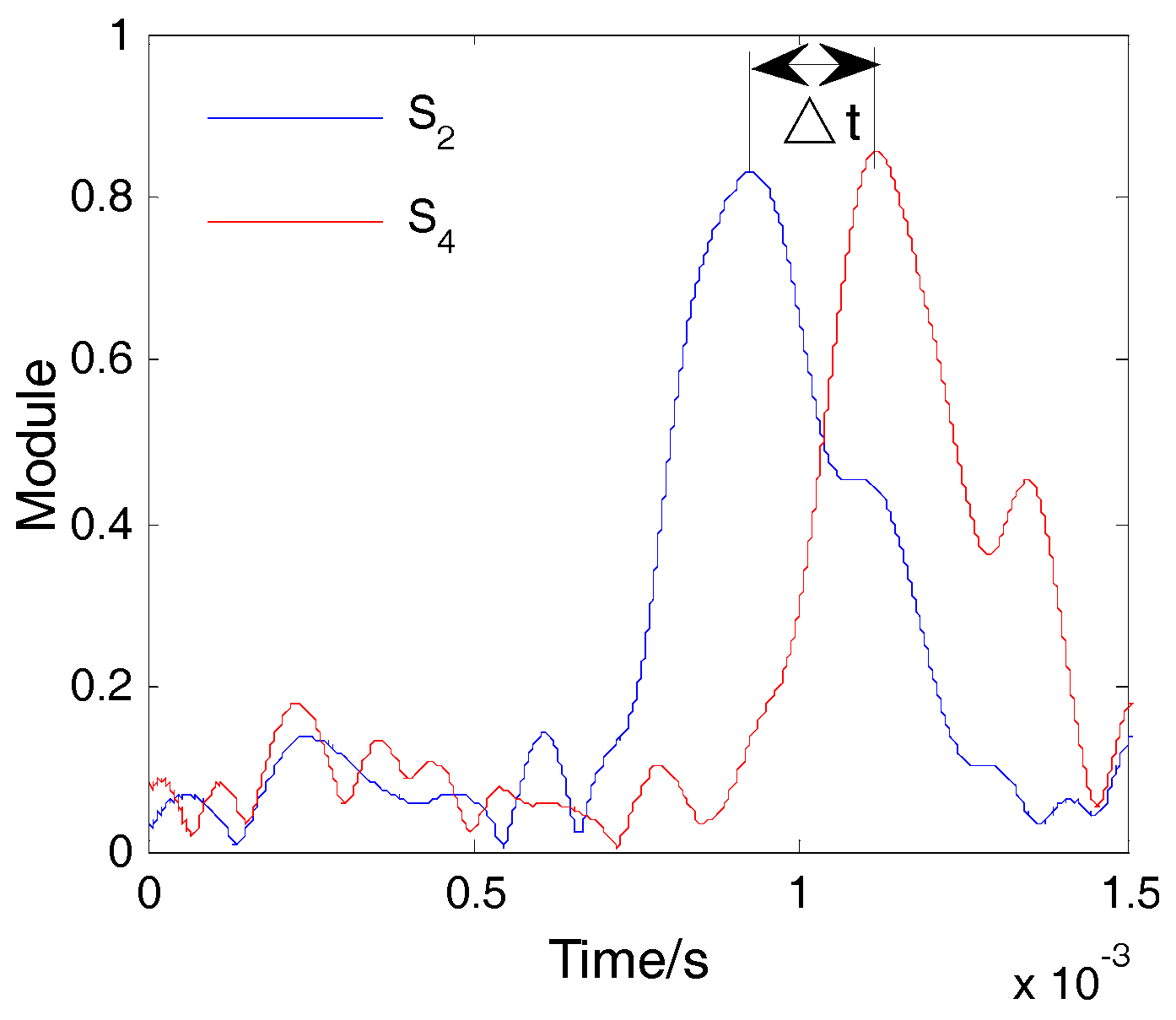

2.3. Shannon Wavelet Transform

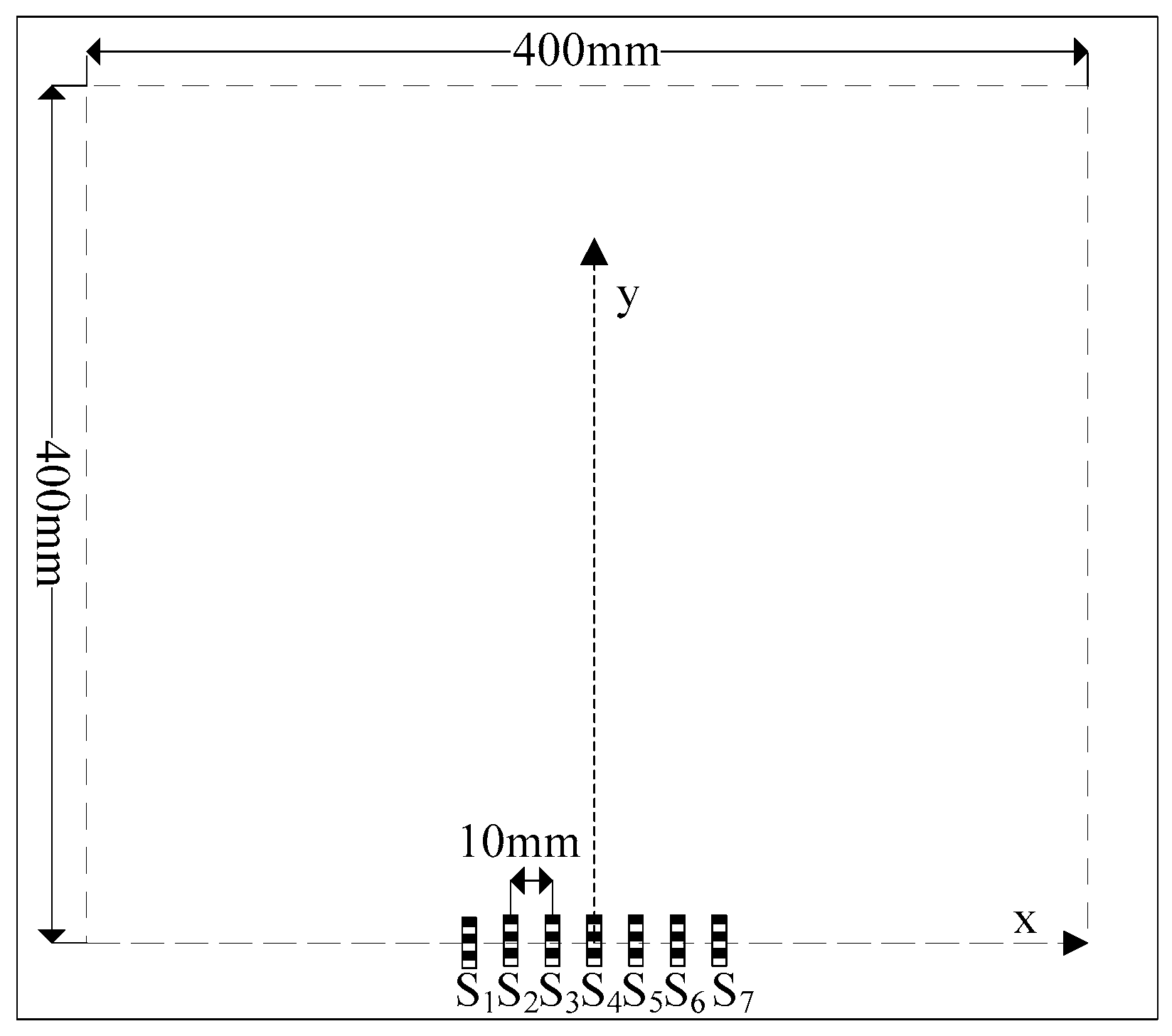

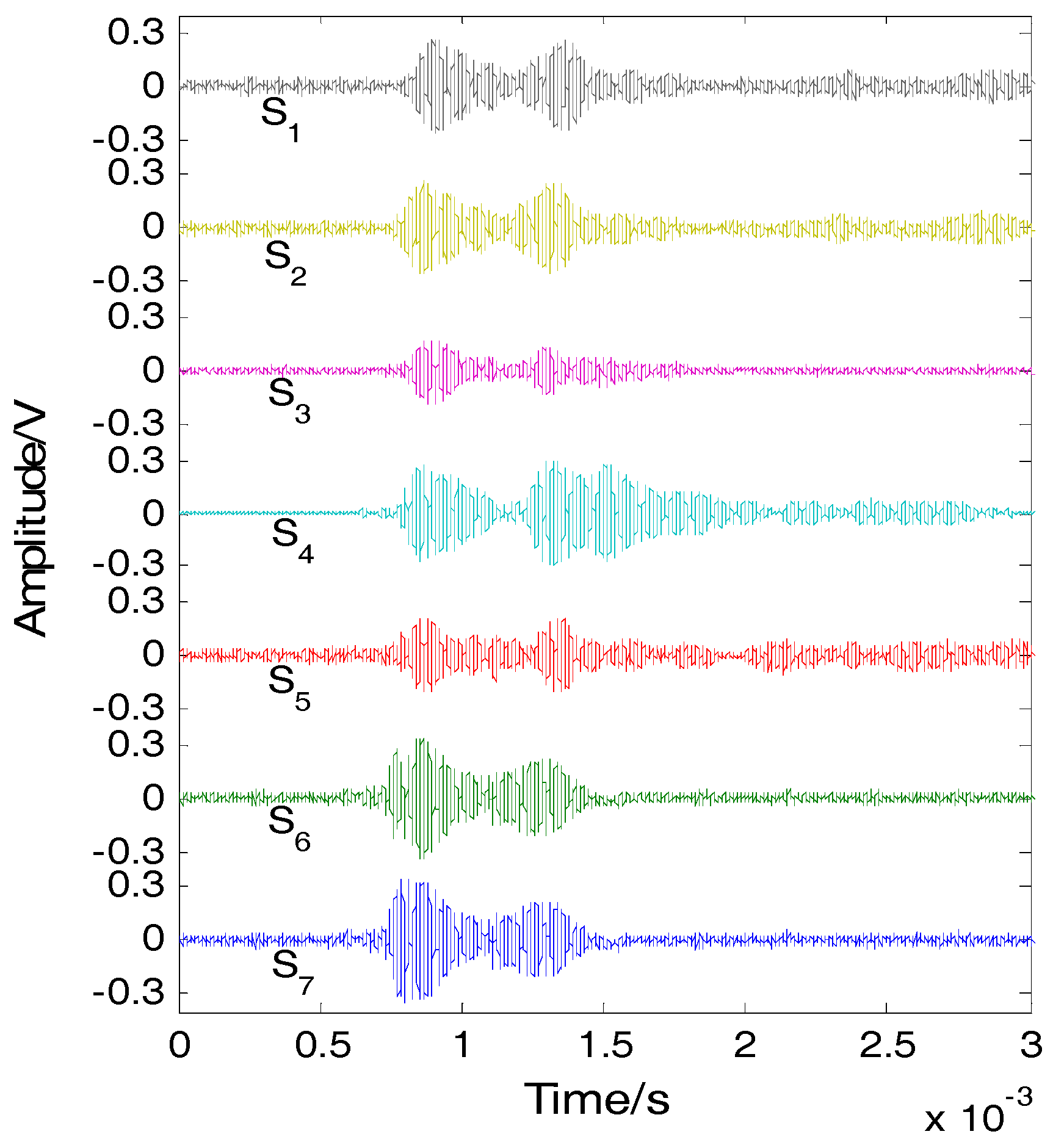

3. Experiments

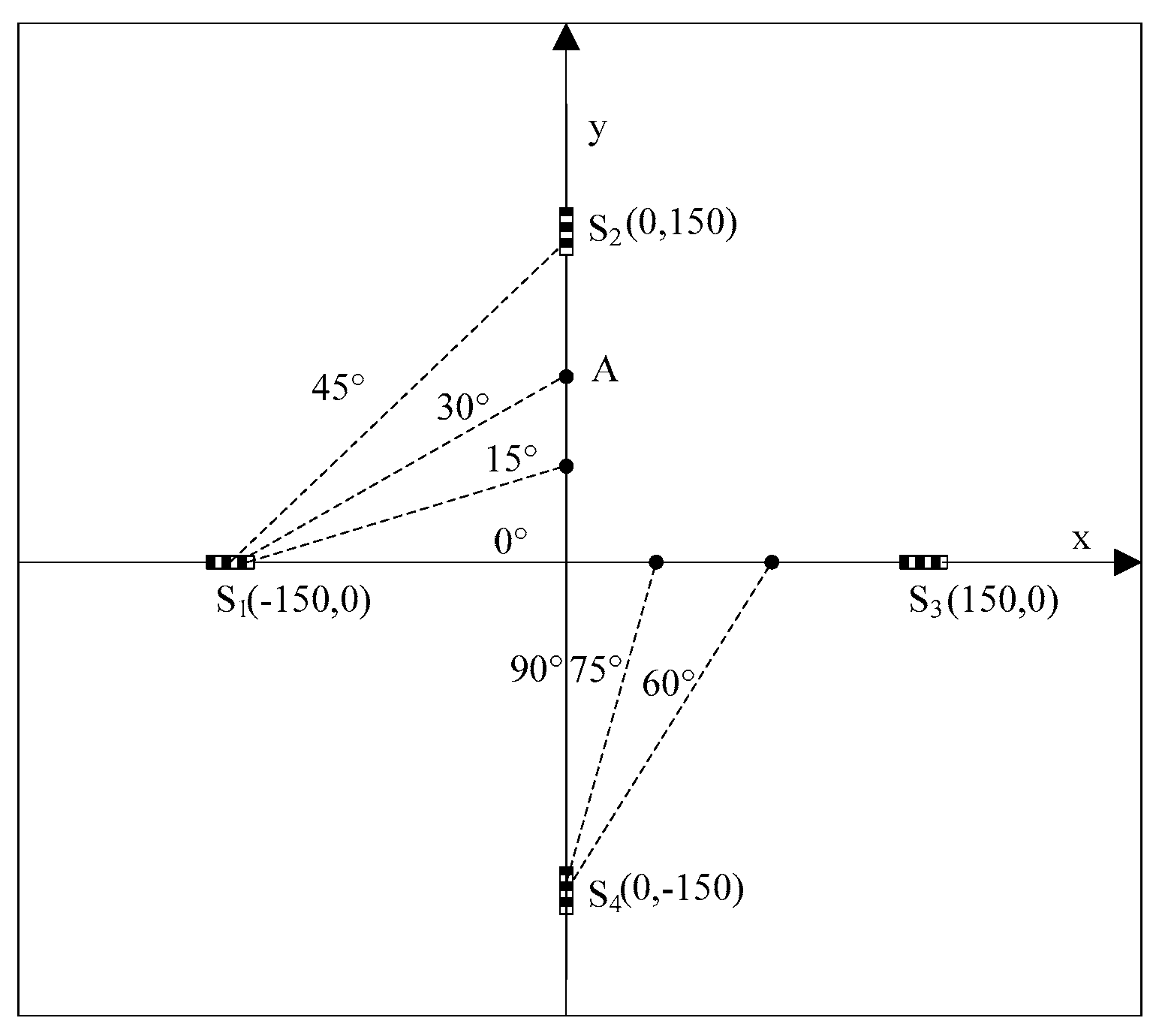

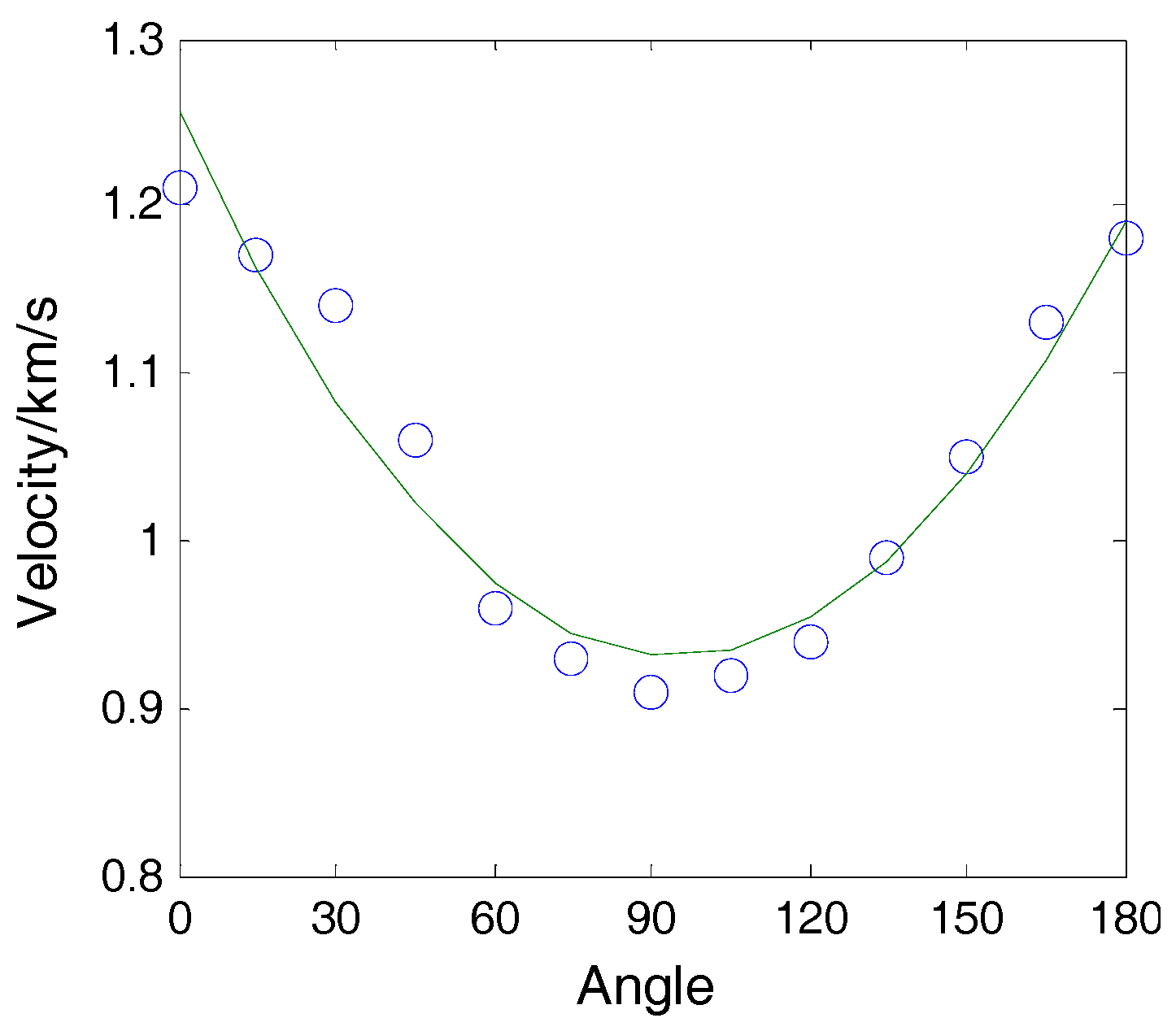

3.1. Wave Velocities Measurement

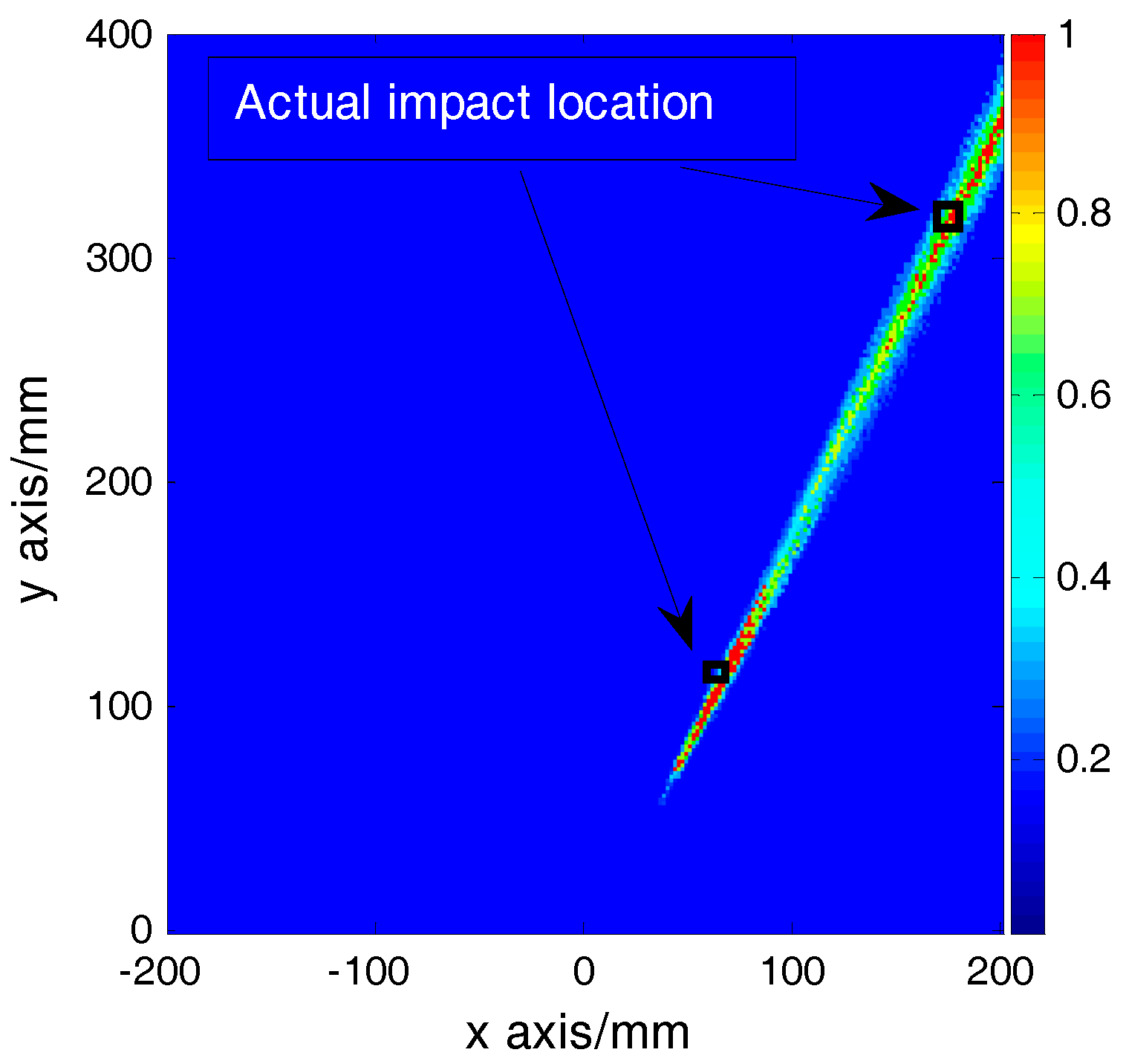

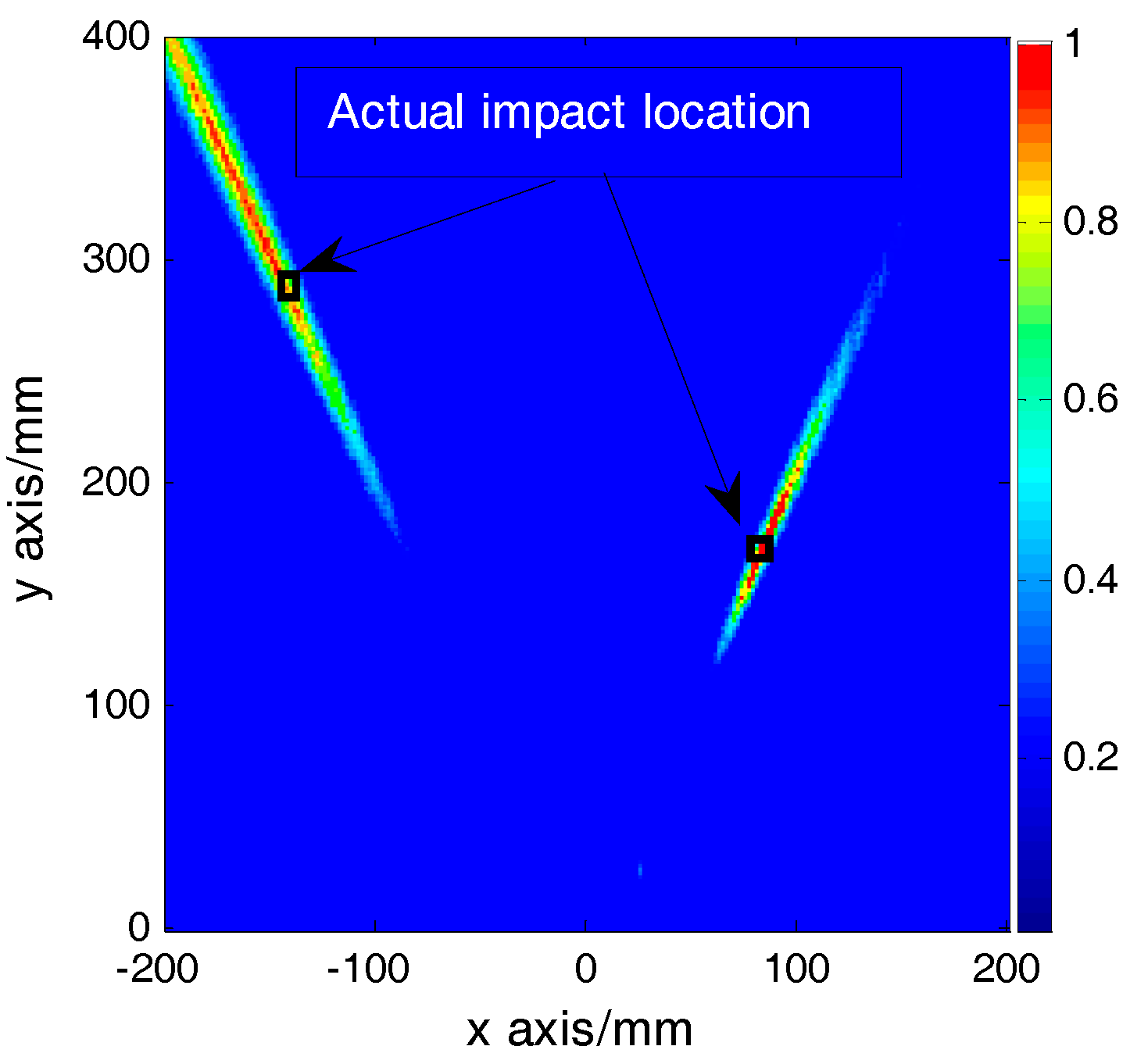

3.2. Localization of Multiple Impacts

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Park, H.; Kong, C. Experimental study on barely visible impact damage and visible impact damage for repair of small aircraft composite structure. Aerosp. Sci. Technol. 2013, 29, 363–372. [Google Scholar] [CrossRef]

- Katunin, A. Stone impact damage identification in composite plates using modal data and quincunx wavelet analysis. Arch. Civ. Mech. Eng. 2015, 15, 251–261. [Google Scholar] [CrossRef]

- Pérez, M.A.; Gil, L.; Oller, S. Impact damage identification in composite laminates using vibration testing. Compos. Struct. 2014, 108, 267–276. [Google Scholar] [CrossRef]

- Dang, X. Statistic Strategy of Damage Detection for Composite Structure Using the Correlation Function Amplitude Vector. Procedia Eng. 2015, 99, 1395–1406. [Google Scholar] [CrossRef]

- Hafizi, Z.M.; Epaarachchi, J.; Lau, K.T. Impact location determination on thin laminated composite plates using an NIR-FBG sensor system. Measurement 2015, 61, 51–57. [Google Scholar] [CrossRef]

- Kirikera, G.R.; Balogun, O.; Krishnaswamy, S. Adaptive Fiber Bragg Grating Sensor Network for Structural Health Monitoring: Applications to Impact Monitoring. Struct. Health Monit. 2011, 10, 5–16. [Google Scholar] [CrossRef]

- Shin, C.S.; Chen, B.L.; Cheng, J.R.; Liaw, S.K. Impact Response of a Wind Turbine Blade Measured by Distributed FBG Sensors. Mater. Manuf. Process. 2010, 25, 268–271. [Google Scholar] [CrossRef]

- Kirkby, E.; de Oliveira, R.; Michaud, V.; Manson, J.A. Impact localisation with FBG for a self-healing carbon fibre composite structure. Compos. Struct. 2011, 94, 8–14. [Google Scholar] [CrossRef]

- Fu, T.; Liu, Y.; Lau, K.; Leng, J. Impact source identification in a carbon fiber reinforced polymer plate by using embedded fiber optic acoustic emission sensors. Compos. Part B Eng. 2014, 66, 420–429. [Google Scholar] [CrossRef]

- Ribeiro, F.; Possetti, G.R.C.; Fabris, J.L.; Muller, M. Smart optical fiber sensor for impact localization on planar structures. In Proceedings of the 2013 SBMO/IEEE MTT-S International Microwave & Optoelectronics Conference (IMOC), Rio de Janeiro, Brazil, 4–7 August 2013.

- Lu, J.; Wang, B.; Liang, D. Wavelet packet energy characterization of low velocity impacts and load localization by optical fiber Bragg grating sensor technique. Appl. Opt. 2013, 52, 2346–2352. [Google Scholar] [CrossRef] [PubMed]

- Moon, Y.S.; Lee, S.K.; Shin, K.; Lee, Y.S. Identification of Multiple Impacts on a Plate Using the Time-Frequency Analysis and the Kalman Filter. J. Intell. Mater. Syst. Struct. 2011, 22, 1283–1291. [Google Scholar] [CrossRef]

- Lee, S.K.; Park, J.H. Source Localization for Multiple Impacts Based on Elastodynamics and Wavelet Analysis. Appl. Mech. Mater. 2011, 52–54, 424–429. [Google Scholar] [CrossRef]

- Qiu, L.; Yuan, S.; Su, Y.; Zhang, X. Multiple Impact Source Imaging and Localization on Composite Structure Based on Shannon Complex Wavelet and Time Reversal Focusing. Acta Aeronaut. Astronaut. Sin. 2010, 31, 2417–2424. [Google Scholar]

- Lu, S.; Jiang, M.; Sui, Q.; Sai, Y.; Jia, L. Low velocity impact localization system of CFRP using fiber Bragg grating sensors. Opt. Fiber Technol. 2015, 21, 13–19. [Google Scholar] [CrossRef]

- Jiang, M.; Lu, S.; Sui, Q.; Dong, H.; Sai, Y.; Jia, L. Low velocity impact localization on CFRP based on FBG sensors and ELM algorithm. IEEE Sens. J. 2015, 15, 4451–4456. [Google Scholar] [CrossRef]

- Wu, H.T.; Yang, J.F.; Chen, F.K. Source number estimators using transformed Gerschgorin radii. IEEE Trans. Signal Process. 1995, 43, 1325–1333. [Google Scholar]

- Qiu, L.; Yuan, S.; Zhang, X.; Wang, Y. A time reversal focusing based impact imaging method and its evaluation on complex composite structures. Smart Mater. Struct. 2011, 20, 105014. [Google Scholar] [CrossRef]

- Hongo, A.; Kojima, S.; Komatsuzaki, S. Applications of fiber Bragg grating sensors and high-speed interrogation techniques. Struct. Control Health Monit. 2005, 12, 269–282. [Google Scholar] [CrossRef]

| Impact Event | GDE Coefficients | ||||

|---|---|---|---|---|---|

| GDE(1) | GDE(2) | GDE(3) | GDE(4) | GDE(5) | |

| 1 | 38.1901 | 10.8721 | −5.6729 | −11.0569 | −20.6672 |

| 2 | 29.1176 | 8.2952 | −4.8572 | −10.2598 | −20.2149 |

| 3 | 43.5331 | 13.6286 | −8.7215 | −15.6943 | −23.2517 |

| 4 | 51.4519 | 16.8921 | −10.3996 | −18.9185 | −26.2364 |

| 5 | 39.2379 | 11.9012 | −8.1339 | −14.8913 | −22.7269 |

| Number | Actual Coordinate (mm) | Predicted Coordinate (mm) | Error (mm) | |||

|---|---|---|---|---|---|---|

| 1 | (−171,58) | (−127,138) | (−176,65) | (−133,144) | 8.6 | 8.4 |

| 2 | (−119,216) | (57,268) | (−112,210) | (53,260) | 9.2 | 8.9 |

| 3 | (−52,157) | (132,96) | (−59,156) | (137,98) | 7.7 | 5.3 |

| 4 | (86,117) | (92,279) | (89,121) | (96,283) | 5 | 5.6 |

| 5 | (159,107) | (78,193) | (163,111) | (83,198) | 8 | 7 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, M.; Sai, Y.; Geng, X.; Sui, Q.; Liu, X.; Jia, L. Development of an FBG Sensor Array for Multi-Impact Source Localization on CFRP Structures. Sensors 2016, 16, 1770. https://doi.org/10.3390/s16101770

Jiang M, Sai Y, Geng X, Sui Q, Liu X, Jia L. Development of an FBG Sensor Array for Multi-Impact Source Localization on CFRP Structures. Sensors. 2016; 16(10):1770. https://doi.org/10.3390/s16101770

Chicago/Turabian StyleJiang, Mingshun, Yaozhang Sai, Xiangyi Geng, Qingmei Sui, Xiaohui Liu, and Lei Jia. 2016. "Development of an FBG Sensor Array for Multi-Impact Source Localization on CFRP Structures" Sensors 16, no. 10: 1770. https://doi.org/10.3390/s16101770