Segmentation of a Vibro-Shock Cantilever-Type Piezoelectric Energy Harvester Operating in Higher Transverse Vibration Modes

Abstract

:1. Introduction

2. FEM Modelling of PVEH Segmentation in Higher Vibration Modes

| Parameter | Constant Cross-Section Area Cantilever | Optimal Shape |

|---|---|---|

| 86 | 66 | |

| 541 | 534 | |

| Density, kg/m3 | 7850 | |

| Elastic modulus, N/m2 | 2 × | |

| Poisson’s ratio | 0.33 | |

| Length, m | 0.1 | |

| Width a, m | 0.01 | |

| Thickness b, m | 1 × 10−3 | Varying from 4 × 10−4 to 1 × 10−3 |

| Parameter | Name | PVDF | Units |

|---|---|---|---|

| d31 | Piezoelectric strain constant | 23 | (pC/N) |

| g31 | Piezoelectric stress constant | 216 | (10−3 Vm/N) |

| kt | Electromechanical coupling factor | 12% | |

| C | Capacitance | 1.4–2.8 | nF |

| Y | Young’s modulus | 4 | 109 N/m2 |

| ε | Permittivity | 110 | 10−12 F/m |

| ρ | Mass Density | 1780 | kg/m3 |

| t | Thickness | 64 | µm |

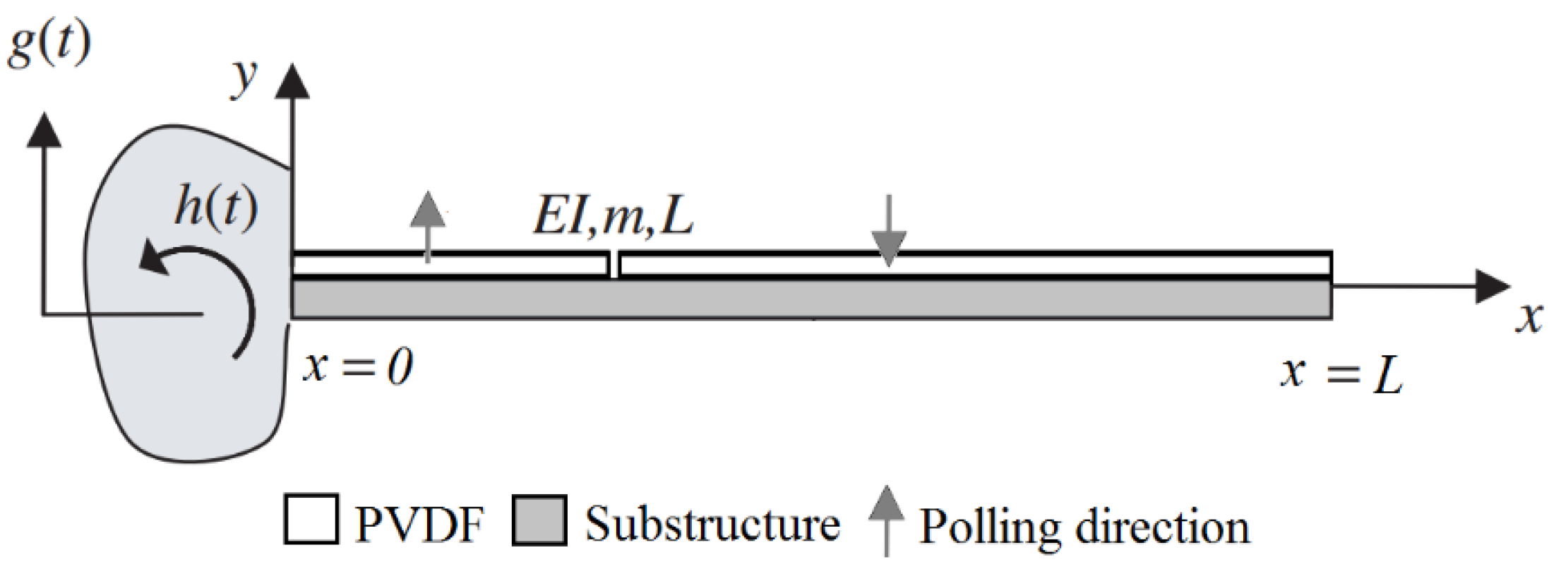

2.1. Finite Element Model

2.2. Constitutive Equations for Substructure and Piezoelectric Layers

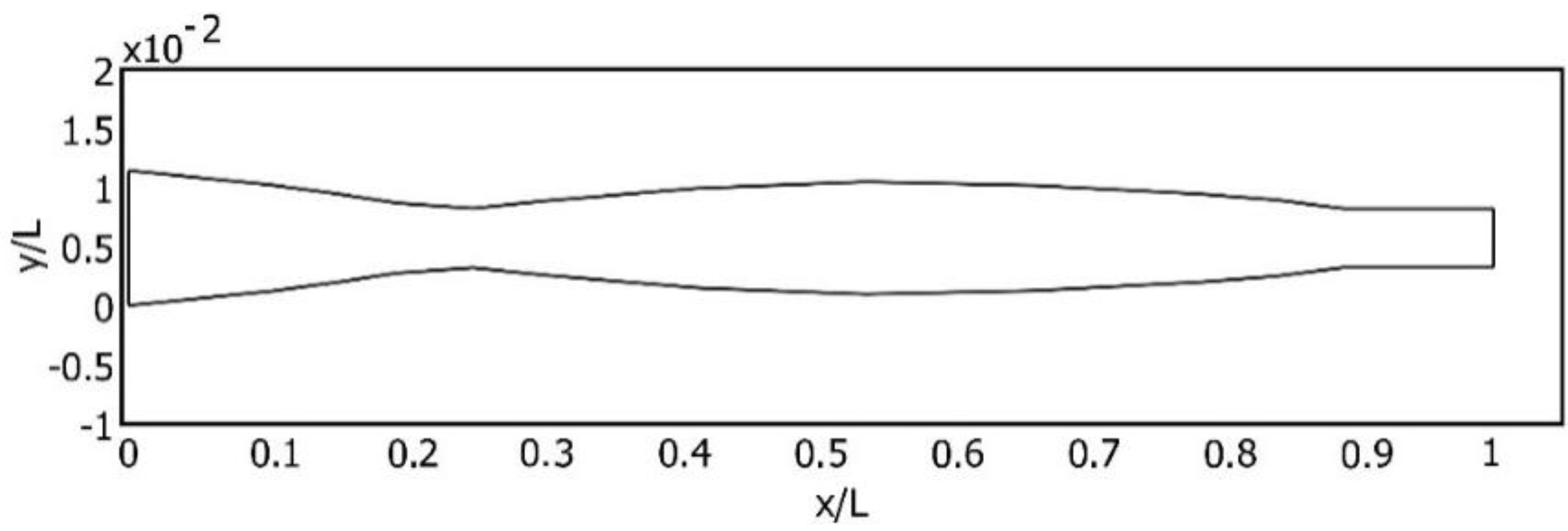

2.3. Procedure for Cantilever Shape Optimization

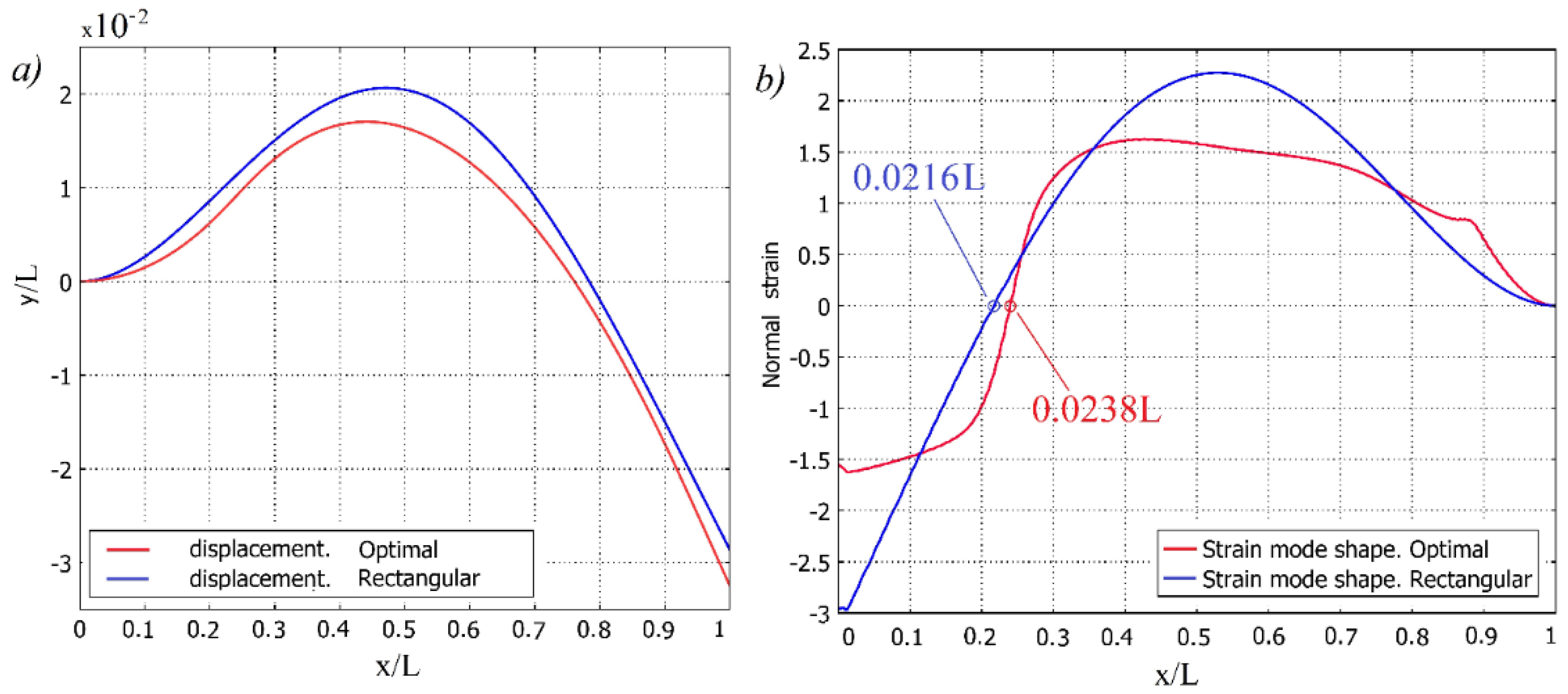

2.4. Determination of Strain Node Position for the Second Vibration Mode via Modal Analysis

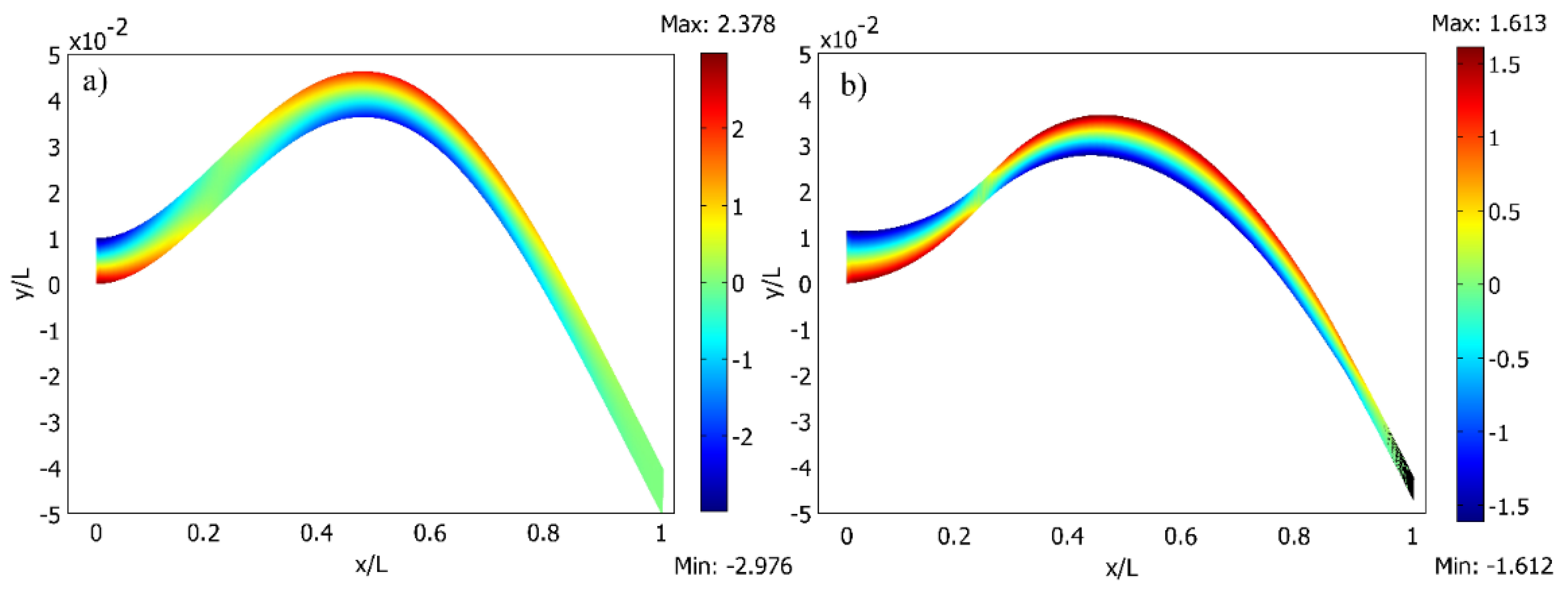

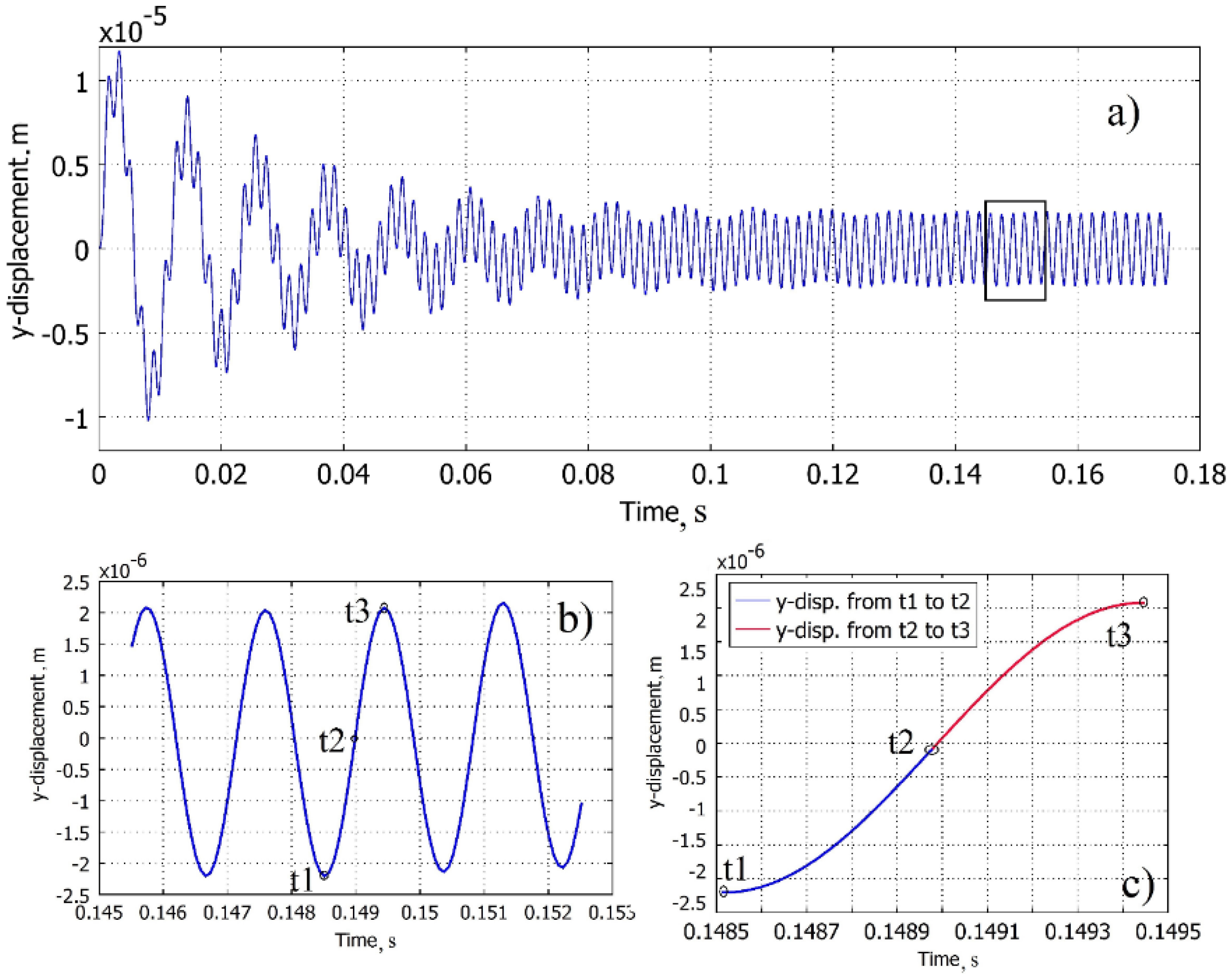

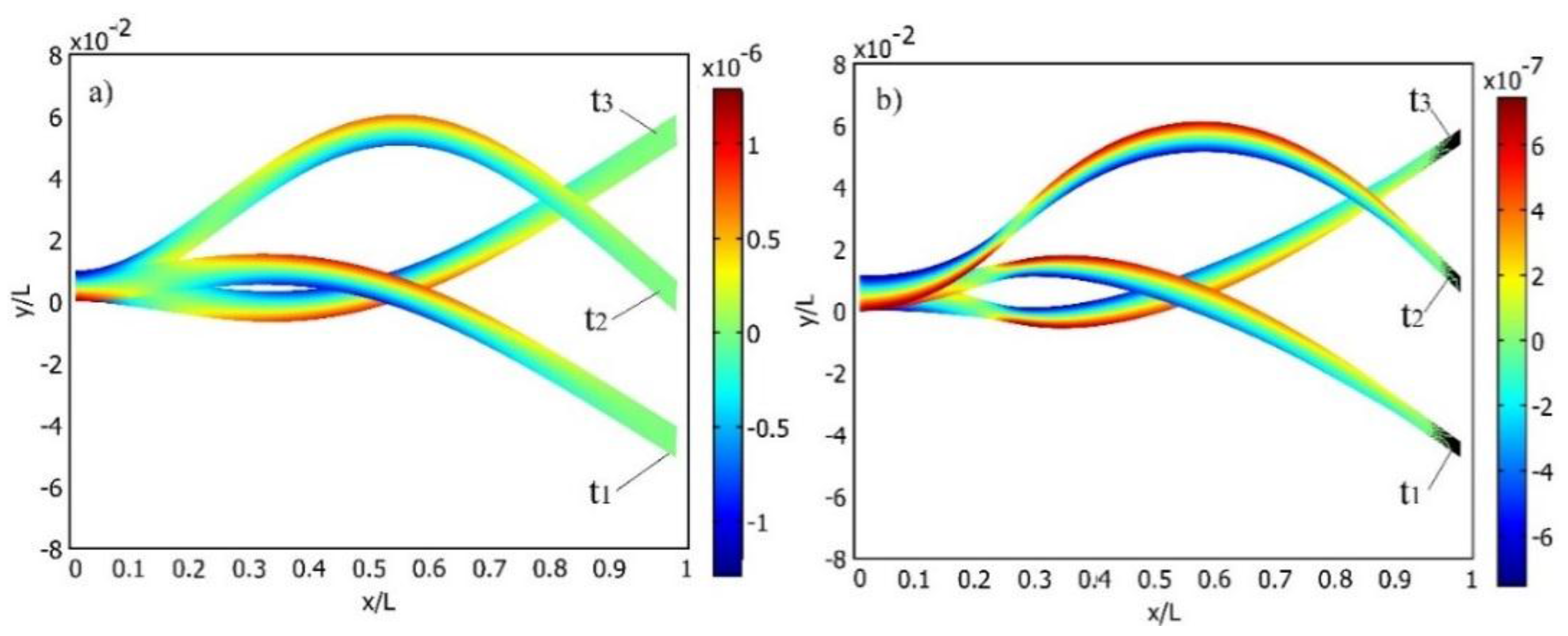

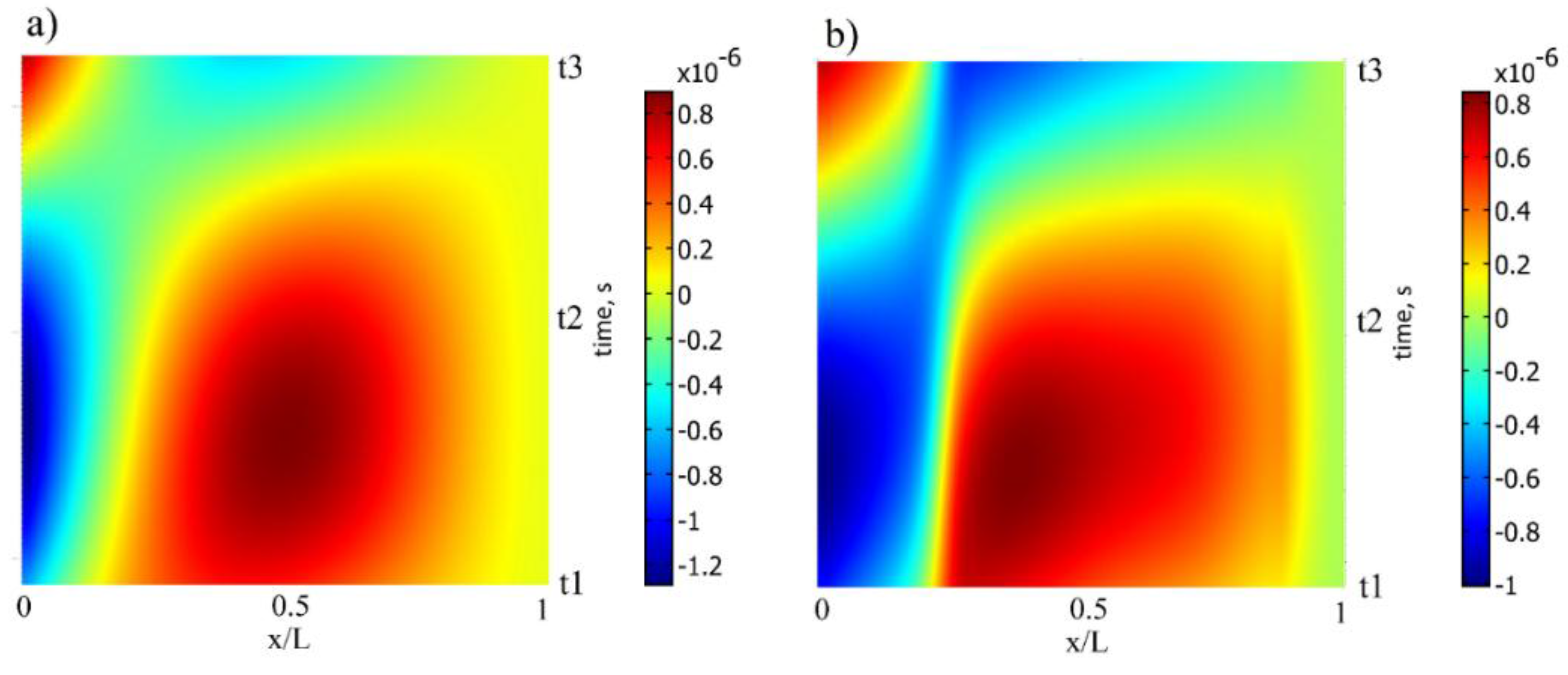

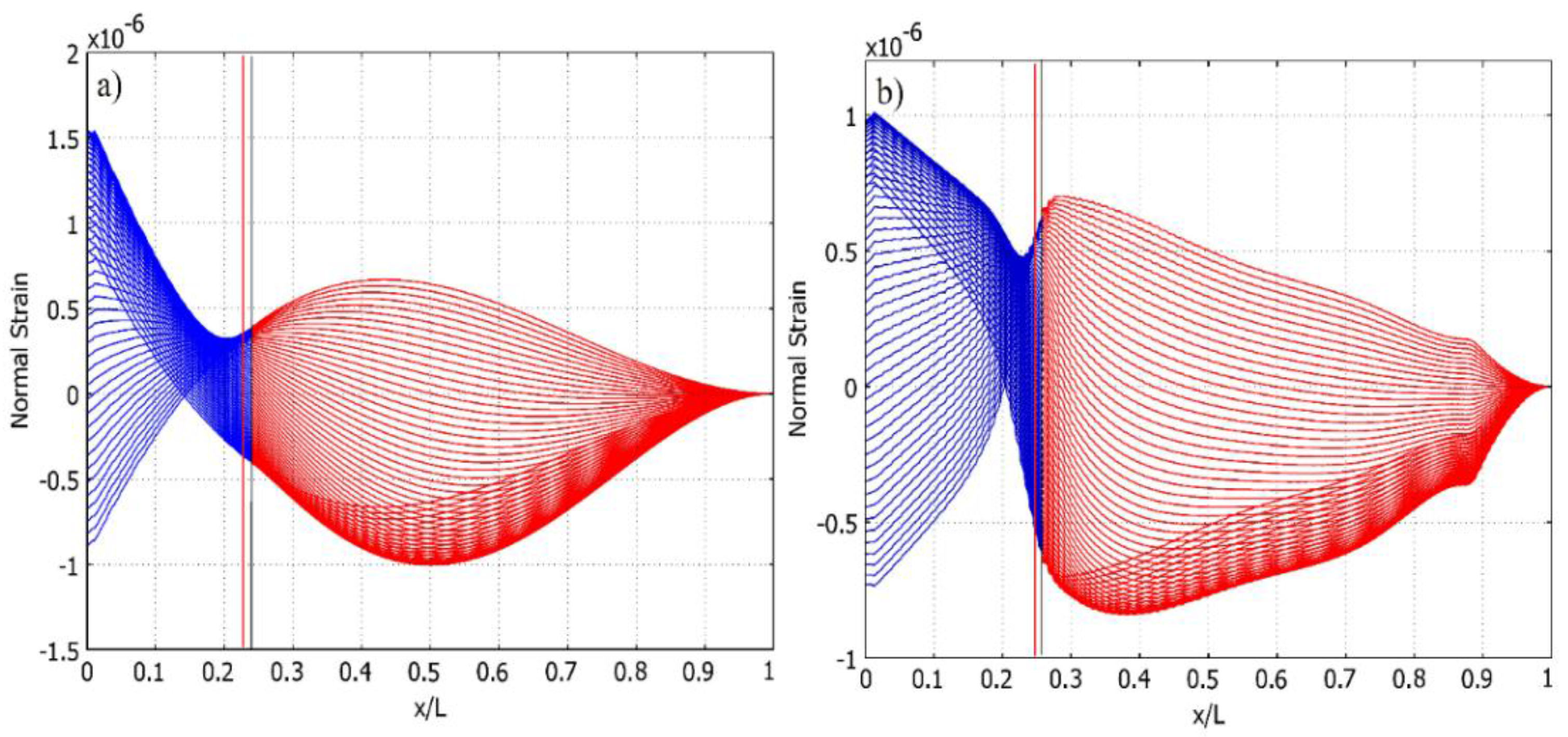

2.5. Determination of Strain Node Position for the Second Vibration Mode via Transient Analysis

| Strain Node | Amount of Normal Strain-Left (Dimensionless) | Amount of Normal Strain-Right (Dimensionless) | Gain, % | |

|---|---|---|---|---|

| Cantilever of a constant cross-section | ||||

| Modal solution | 0.216 | 6.53 × 10−10 | −9.7 × 10−10 | |

| Transient solution | 0.238 | 6.73 × 10−10 | −9.9 × 10−10 | +5.5% |

| Optimally-shaped cantilever | ||||

| Modal solution | 0.239 | 6.3 × 10−10 | −9.6 × 10−10 | |

| Transient solution | 0.259 | 6.5 × 10−10 | −9.85 × 10−10 | +5.2% |

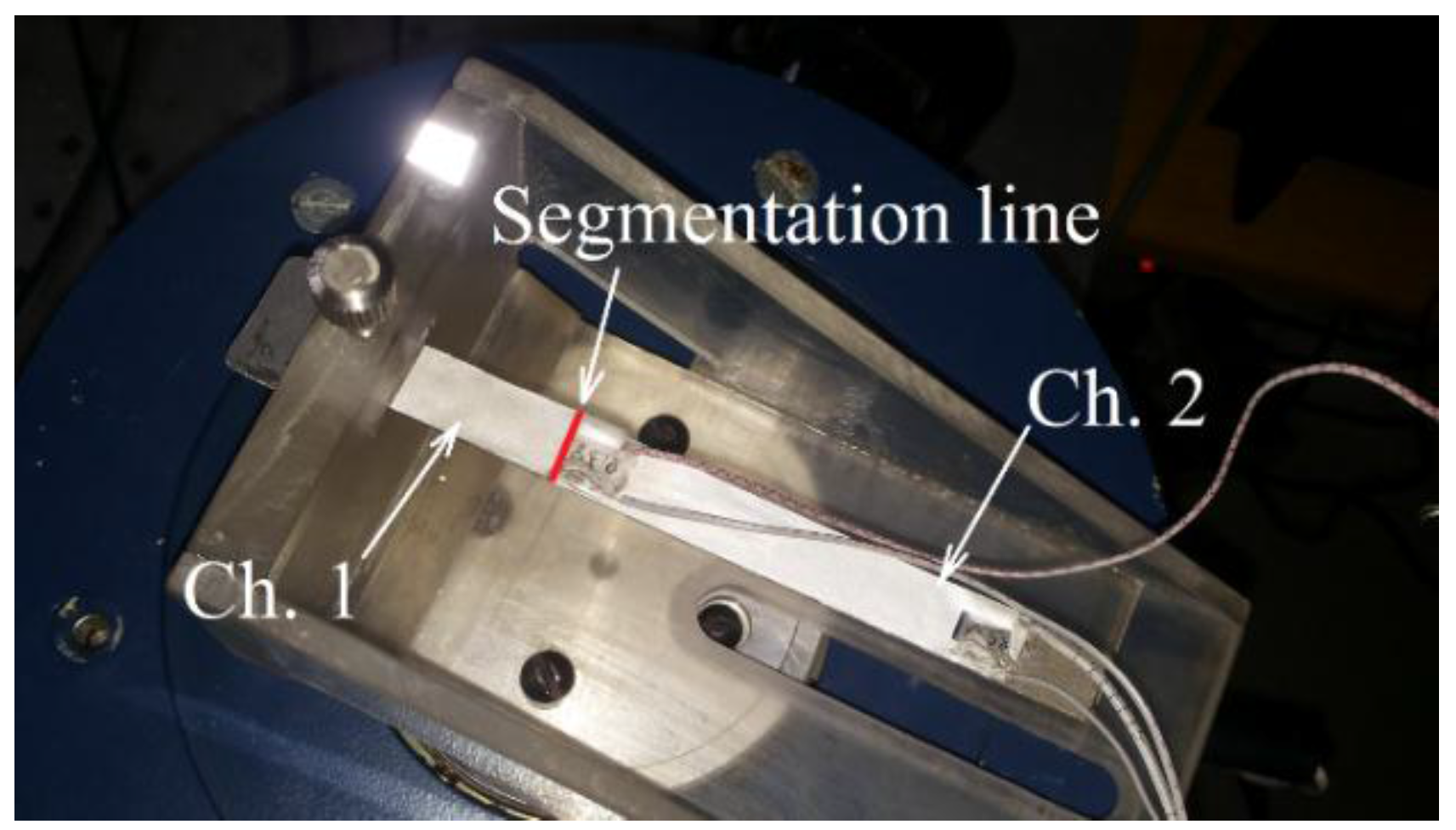

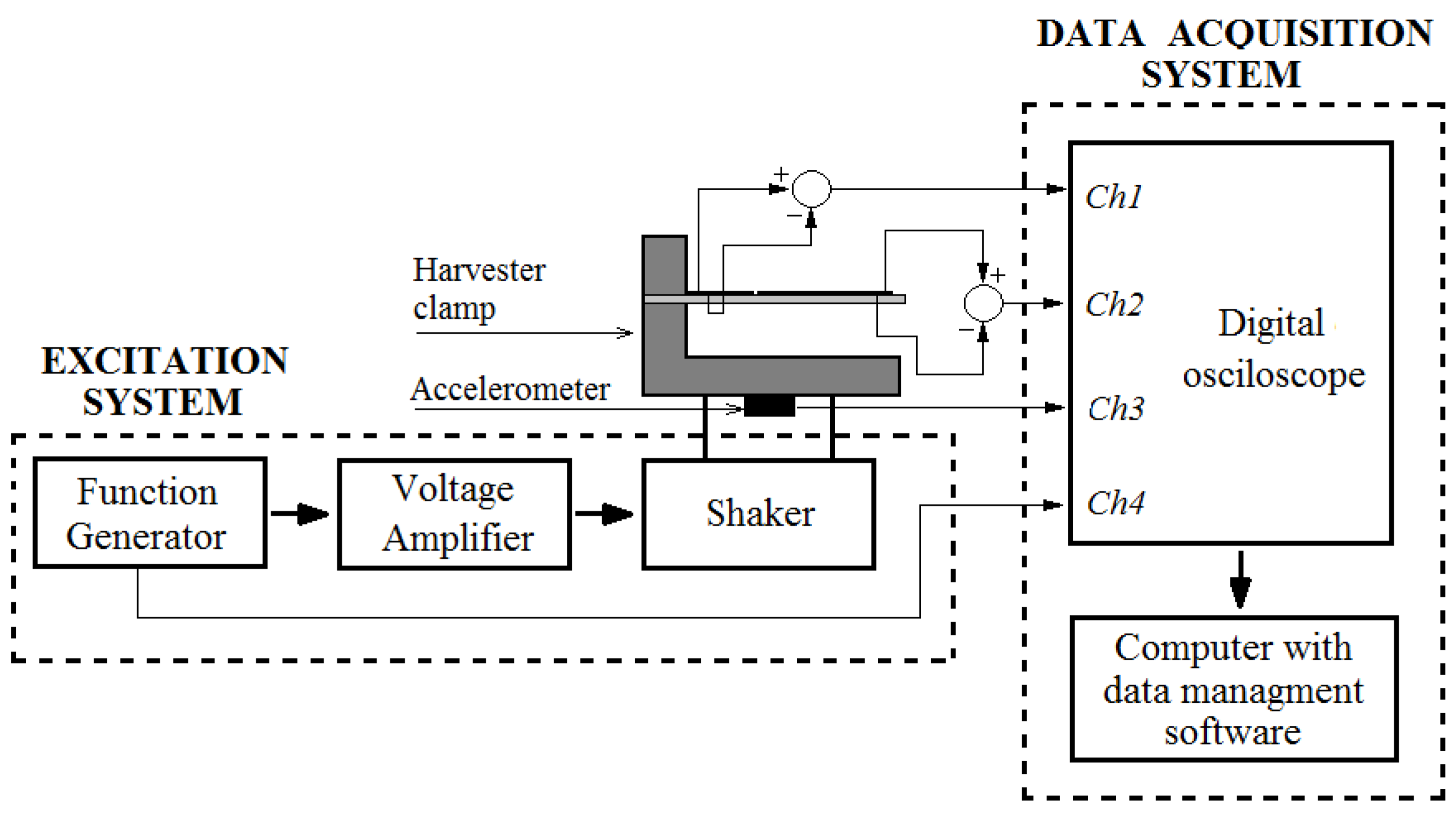

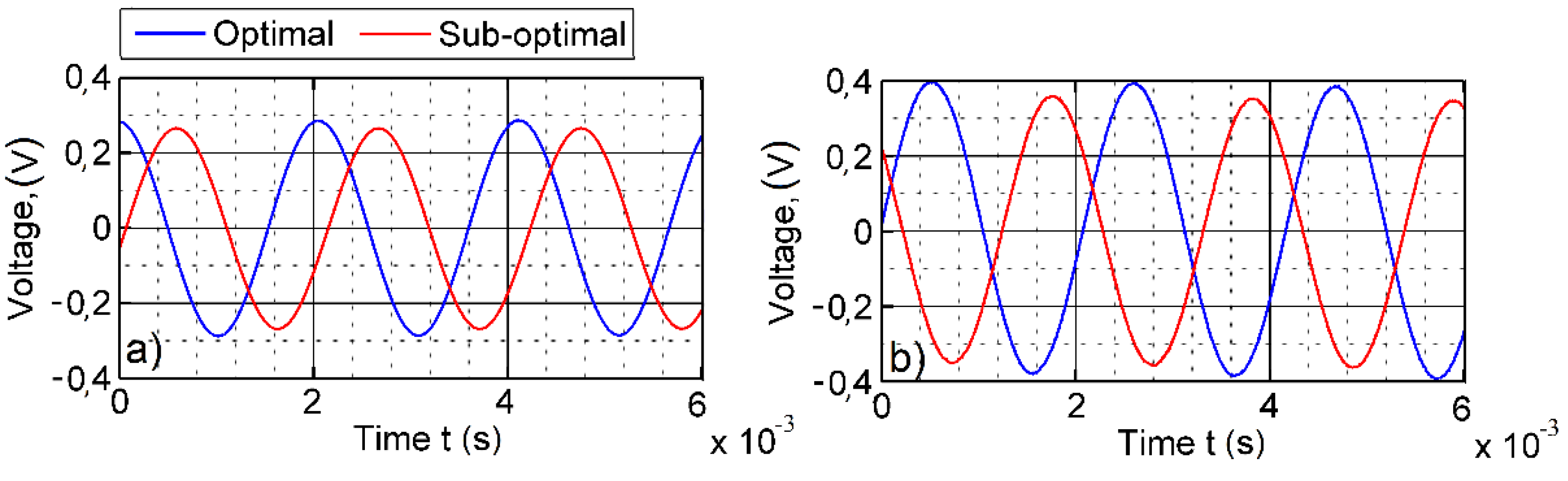

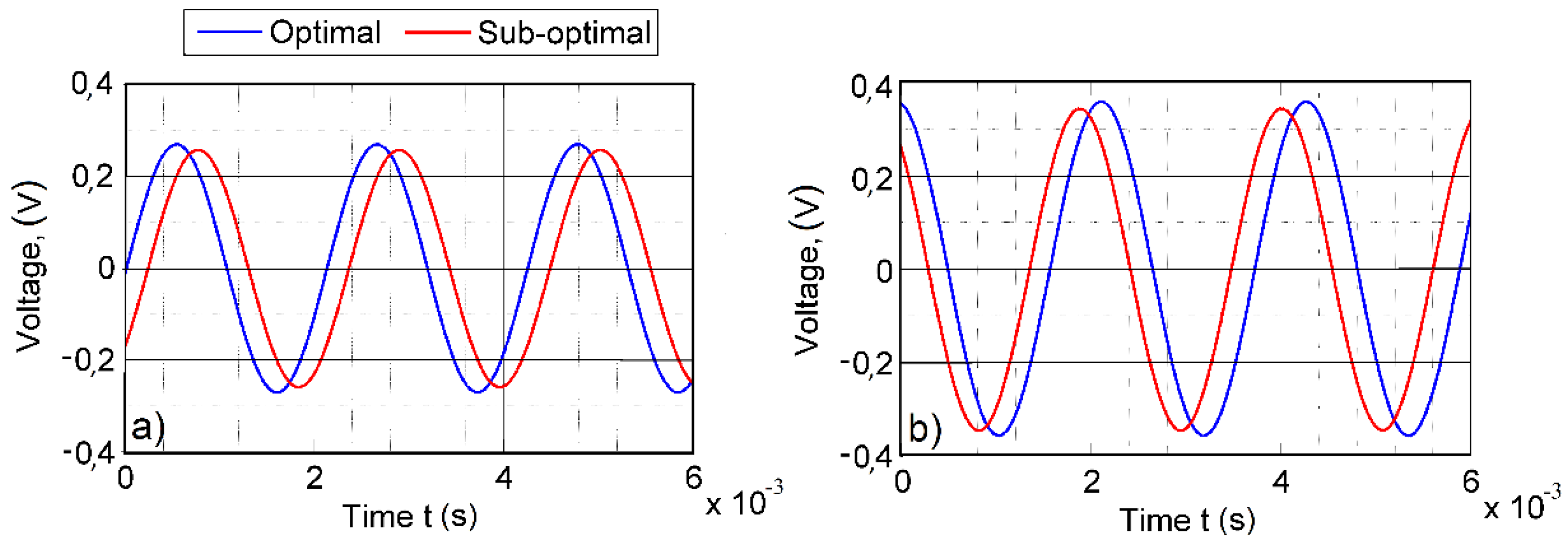

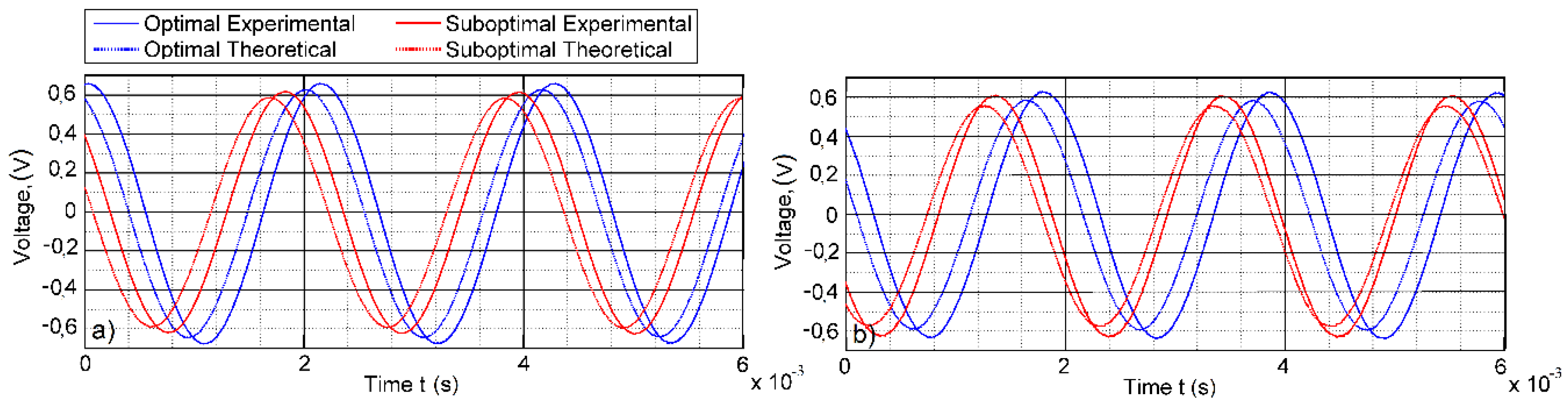

3. Theoretical and Experimental Results: Open Circuit Voltage Outputs

4. Conclusions

- The optimal segmentation point was determined by means of transient analysis for the two setups of the harvesters, the cantilever of a constant cross-section and the optimally-shaped, cantilever by integrating the strain distribution along the face of the cantilever during the ½ T period and then comparing to the total normal strain amount obtained from the cantilevers segmented at the strain node obtained from modal analysis.

- Theoretically-obtained results indicating the superiority of the transient analysis versus modal analysis for finding the strain node for segmentation were verified experimentally.

- The adjusted segmentation line increased the generated open-circuit voltage output per period of vibration by 7.2% for the optimally-shaped cantilever and 6% for the cantilever of a constant cross-section.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Le, C.P.; Halvorsen, E.; Søråsen, O.; Yeatman, E.M. Wideband excitation of an electrostatic vibration energy harvester with power-extracting endstops. Smart Mater. Struct. 2013, 22, 50–62. [Google Scholar] [CrossRef]

- Roundy, S.; Wright, P.K. A piezoelectric vibration based generator for wireless electronics. Smart Mater. Struct. 2004, 13, 1131–1142. [Google Scholar] [CrossRef]

- Beeby, S.P.; Tudor, M.J.; White, N.M. Energy harvesting vibration sources for microsystems applications. Meas. Sci. Technol. 2006, 17, 175–195. [Google Scholar] [CrossRef]

- Sirohi, J.; Chopra, I. Fundamental Understanding of Piezoelectric Strain Sensors. J. Intell. Mater. Syst. Struct. 2000, 11, 246–257. [Google Scholar] [CrossRef]

- Sodano, H.A.; Park, G.; Inman, D.J. Estimation of Electric Charge Output for Piezoelectric Energy Harvesting. Integr. Ferroelectr. Int. J. 2004, 40, 49–58. [Google Scholar] [CrossRef]

- Erturk, A.; Inman, D.J. Electromechanical Modeling of Cantilevered Piezoelectric Energy Harvesters. In Energy Harvesting Technologies; Springer: Berlin, Germany, 2009; pp. 41–77. [Google Scholar]

- Mello, L.A.M.; Kiyono, C.Y.; Nakasone, P.H.; Silva, E.C.N. Design of quasi-static piezoelectric plate based transducer by using topology optimization. Smart Mater. Struct. 2014, 23. [Google Scholar] [CrossRef]

- Nakasone, P.H.; Silva, N. Dynamic design of piezoelectric laminated sensors and actuators using topology optimization. J. Intell. Mater. Syst. Struct. 2010, 21, 1627–1652. [Google Scholar] [CrossRef]

- Lefeuvre, E.; Badel, A.; Richard, C.; Petit, L.; Guyomar, D. Optimization of Piezoelectric Electrical Generators Powered by Random Vibrations. Available online: http://arxiv.org/abs/0711.3309 (accessed on 10 December 2015).

- Ashraf, K.; Khir, M.H.M.; Dennis, J.O.; Baharudin, Z. A wideband, frequency up-converting bounded vibration energy harvester for a low-frequency environment. J. Smart Mater. Struct. 2013, 22. [Google Scholar] [CrossRef]

- Li, W.G.; He, S.; Yu, S. Improving Power Density of a Cantilever Piezoelectric Power Harvester Through a Curved L-Shaped Proof Mass. IEEE Trans. Ind. Electron. 2010, 57, 868–876. [Google Scholar] [CrossRef]

- El-Hebeary, M.M.R.; Arafa, M.H.; Megahed, S.M. Modeling and experimental verification of multi-modal vibration energy harvesting from plate structures. Sens. Actuators 2013, 193, 35–47. [Google Scholar] [CrossRef]

- Bai, X.; Wen, Y.; Li, P.; Yang, J.; Peng, X.; Yue, X. Multi-modal vibration energy harvesting utilizing spiral cantilever with magnetic coupling. Sens. Actuators 2014, 2009, 78–86. [Google Scholar] [CrossRef]

- Rezaeisaray, M.; El Gowini, M.; Sameoto, D.; Raboud, D.; Moussa, W. Low frequency piezoelectric energy harvesting at multi vibration mode shapes. Sens. Actuators 2015, 228, 104–111. [Google Scholar] [CrossRef]

- Bucciarelli, L.L. Chapter 8. In Engineering Mechanics for Structures; Dover Publications: Mineola, NY, USA, 2009; p. 306. [Google Scholar]

- Erturk, A.; Inman, D.J. On Mechanical Modeling of Cantilevered Piezoelectric Vibration Energy Harvesters. J. Intel. Mater. Syst. Struct. 2008, 19, 1311–1325. [Google Scholar] [CrossRef]

- Erturk, A.; Tarazaga, P.A.; Farmer, J.R.; Inman, D.J. Effect of Strain Nodes and Electrode Configuration on Piezoelectric Energy Harvesting from Cantilevered Beams. J. Vib. Acoust. 2009, 131, 011010-1–011010-11. [Google Scholar] [CrossRef]

- Kang, Z.; Tong, L. Integrated optimization of material layout and control voltage for piezoelectric laminated plates. J. Intell. Mater. Syst. Struct. 2008. [Google Scholar] [CrossRef]

- Cady, W.G. Piezoelectricity: An Introduction to the Theory and Applications of Electromechanical Phenomena in Crystals; McGraw-Hill: New York, NY, USA, 1946. [Google Scholar]

- Djuguma, R.; Trivailo, P.; Graves, K. A study of energy harvesting from piezoelectrics using impact forces. Eur. Phys. J. Appl. Phys. 2009, 48. [Google Scholar] [CrossRef]

- Renaud, M.; Fiorini, P.; van Hoof, C. Optimization of a piezoelectric unimorph for shock and impact energy harvesting. Smart Mater. Struct. 2007, 16, 1125–1135. [Google Scholar] [CrossRef]

- Gilardi, G.; Sharf, I. Literature survey of contact dynamics modelling. Mech. Mach. Theory 2002, 37, 1213–1239. [Google Scholar] [CrossRef]

- Impact test on cantilever Modal analysis. Available online: http://coep.vlab.co.in/?sub=34&brch=101&sim=957&cnt=2 (accessed on 23 September 2015).

- Ostaševičius, V.; Janušas, G. Pecularities of The Third Natural Frequency Vibrations of a Cantilever for the Improvement of Energy Harvesting. Sensors 2015, 15, 12594–12612. [Google Scholar] [CrossRef] [PubMed]

- Ferrari, M.; Cerini, F.; Ferrari, V. Autonomous Sensor Module Powered By Impact-Enchanced Energy Harvester From Broadband Low-Frequency Vibrations. In Proceedings of the 17th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS & EUROSENSORS XXVII), Barcelona, Spain, 16–20 June 2013; pp. 2249–2252.

- Edwards, B.; Xie, M.; Aw, K.C.; Hu, A.P.; Gao, W. An Impact Based Frequency Up-Conversion Mechanism for Low Frequency Vibration Energy. In Proceedings of the 17th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS & EUROSENSORS XXVII), Barcelona, Spain, 16–20 June 2013; pp. 1344–1347.

- Zhang, X.; Kang, Z. Dynamic topology optimization of piezoelectric structures with active control for reducing transient response. Comput. Methods Appl. Mech. Eng. 2014, 281, 200–219. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zizys, D.; Gaidys, R.; Dauksevicius, R.; Ostasevicius, V.; Daniulaitis, V. Segmentation of a Vibro-Shock Cantilever-Type Piezoelectric Energy Harvester Operating in Higher Transverse Vibration Modes. Sensors 2016, 16, 11. https://doi.org/10.3390/s16010011

Zizys D, Gaidys R, Dauksevicius R, Ostasevicius V, Daniulaitis V. Segmentation of a Vibro-Shock Cantilever-Type Piezoelectric Energy Harvester Operating in Higher Transverse Vibration Modes. Sensors. 2016; 16(1):11. https://doi.org/10.3390/s16010011

Chicago/Turabian StyleZizys, Darius, Rimvydas Gaidys, Rolanas Dauksevicius, Vytautas Ostasevicius, and Vytautas Daniulaitis. 2016. "Segmentation of a Vibro-Shock Cantilever-Type Piezoelectric Energy Harvester Operating in Higher Transverse Vibration Modes" Sensors 16, no. 1: 11. https://doi.org/10.3390/s16010011