A Fixed-Pattern Noise Correction Method Based on Gray Value Compensation for TDI CMOS Image Sensor

Abstract

:1. Introduction

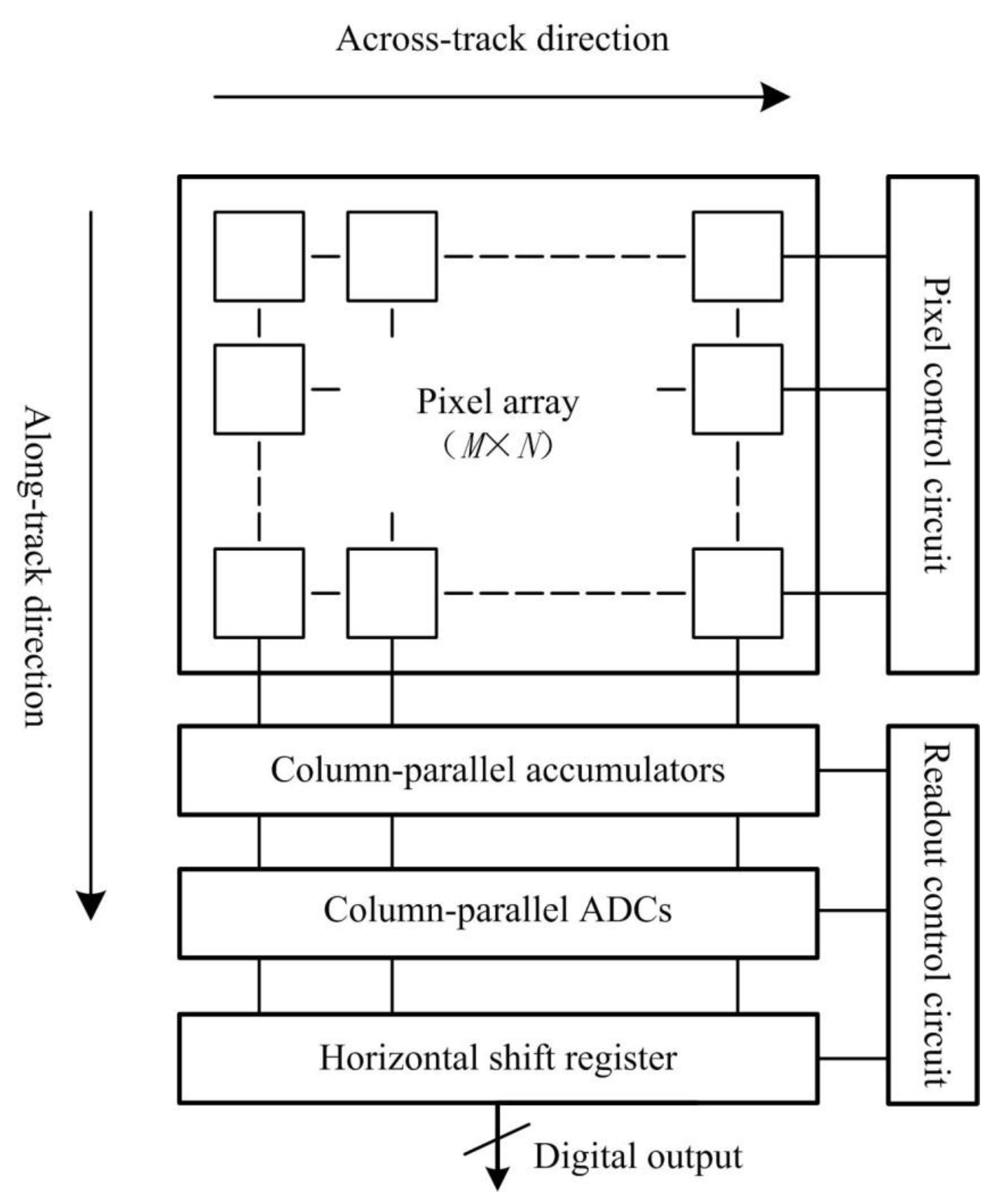

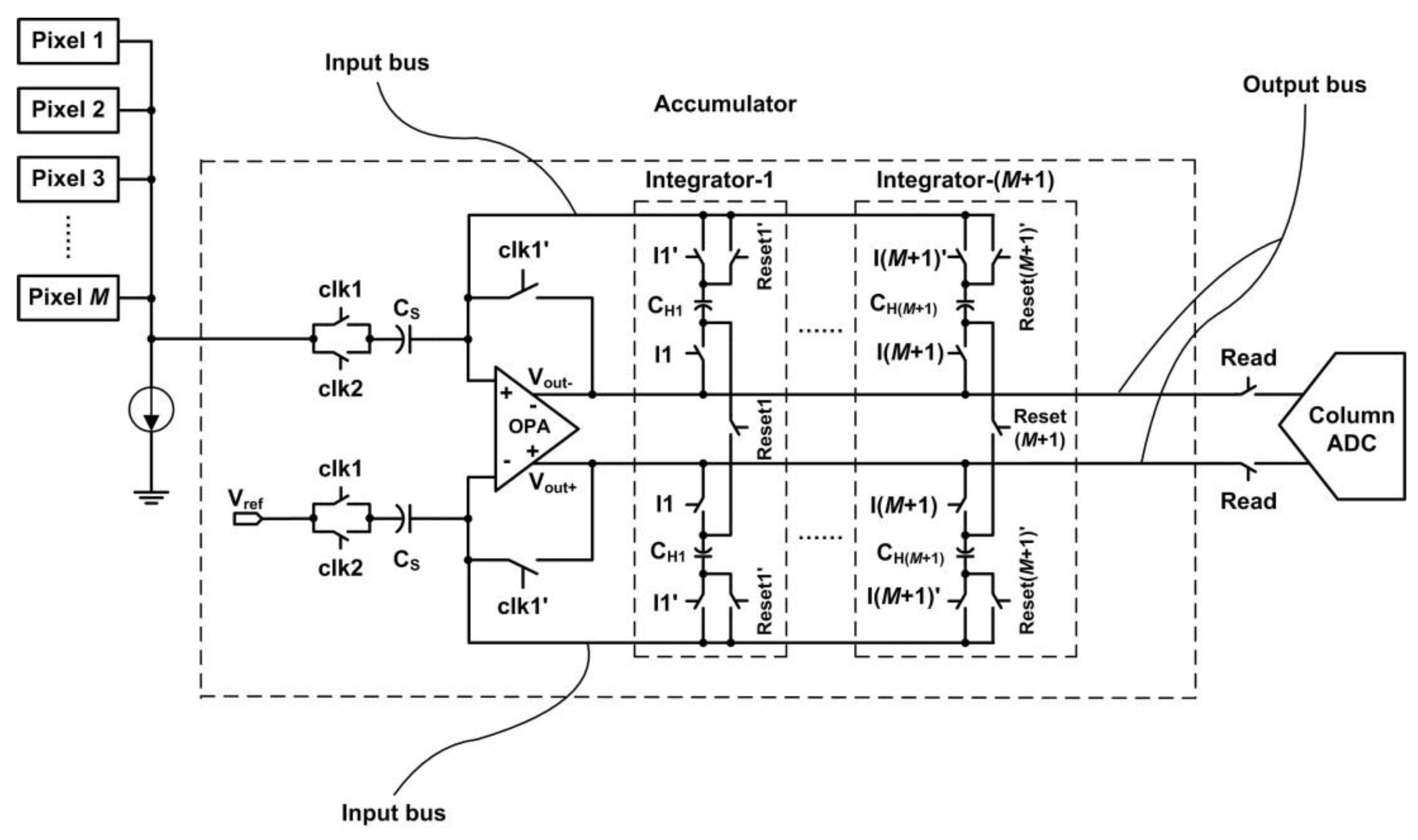

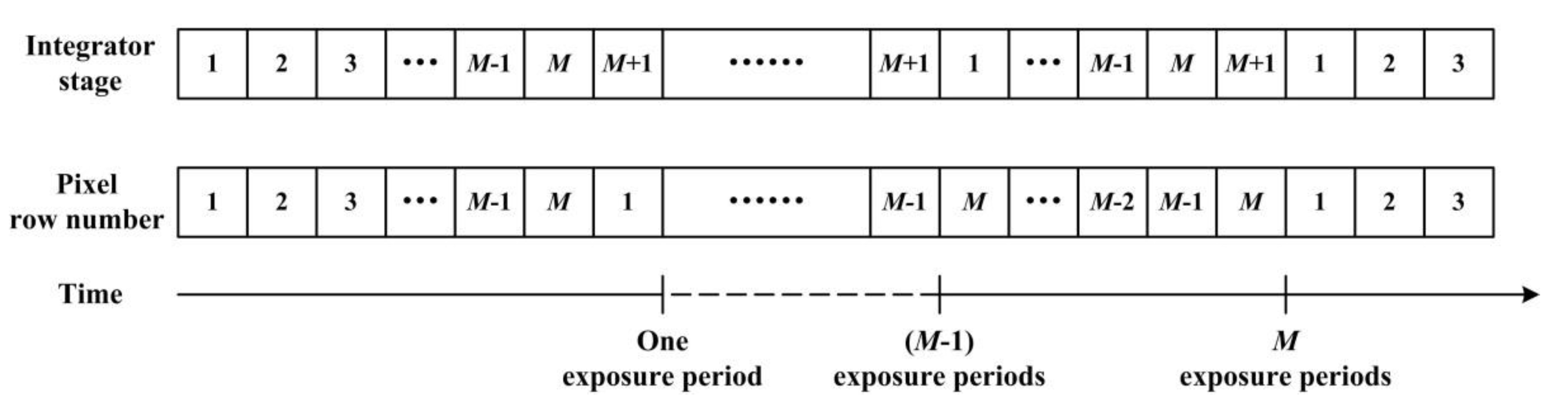

2. Analysis and Modeling of Sensor Noise

2.1. Source and Analysis of RFPN

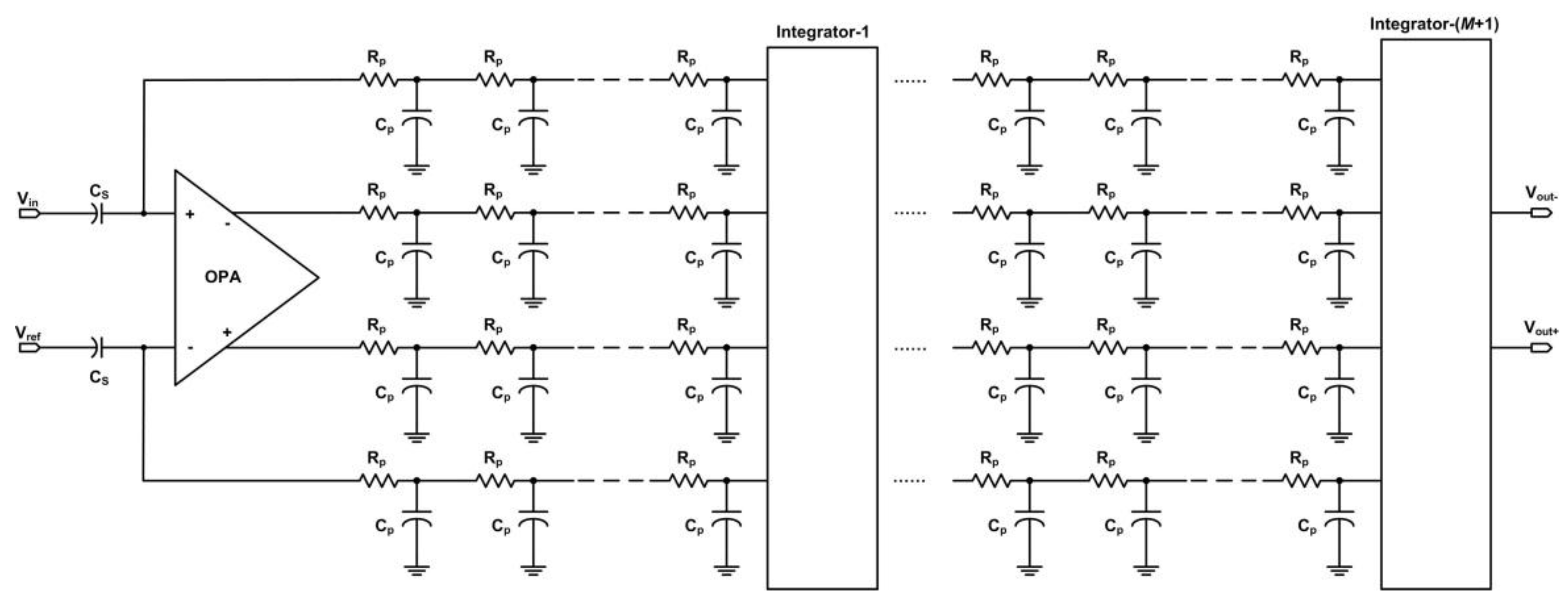

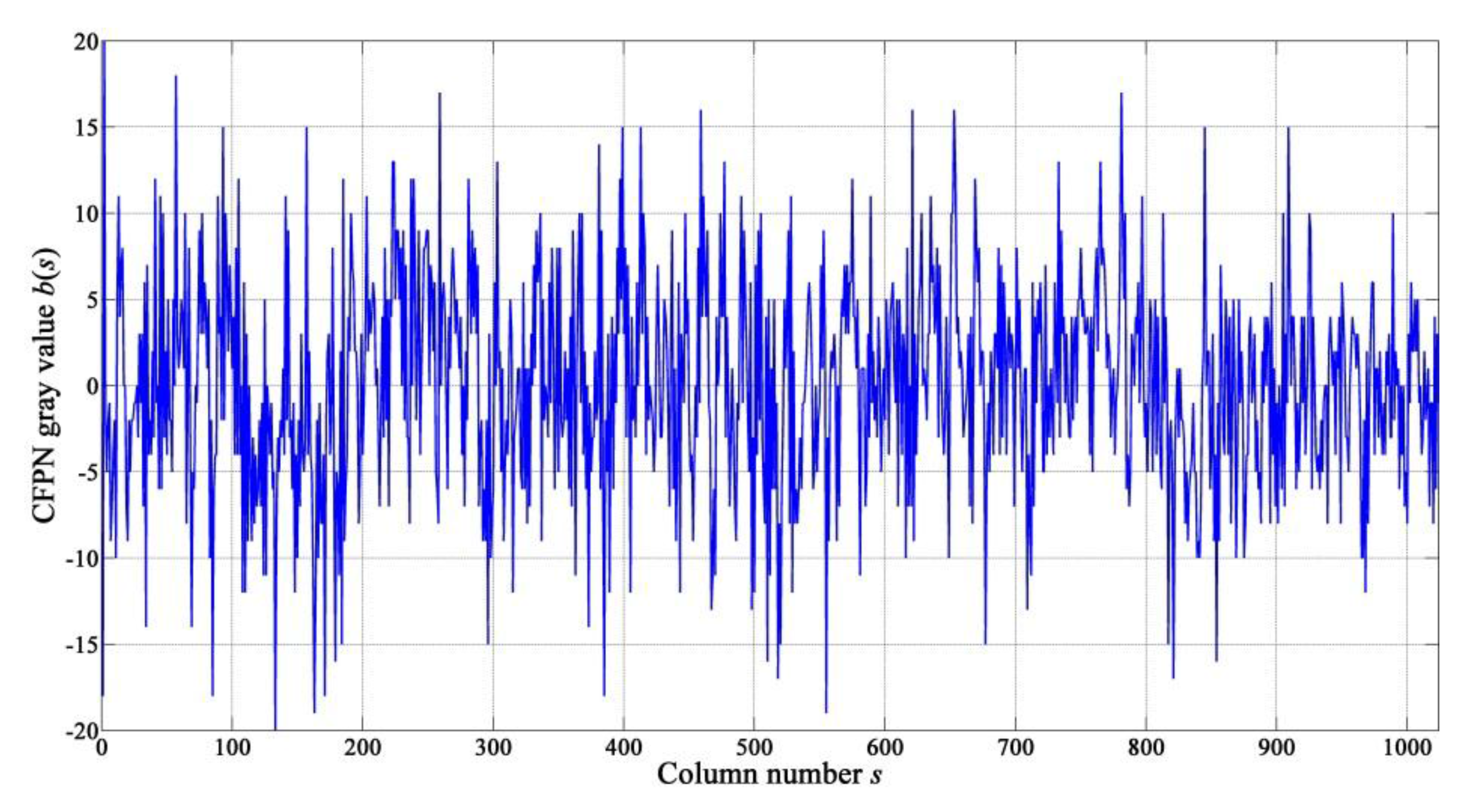

2.2. Source and Analysis of CFPN

2.3. Noise Model of TDI-CIS

3. Method Description

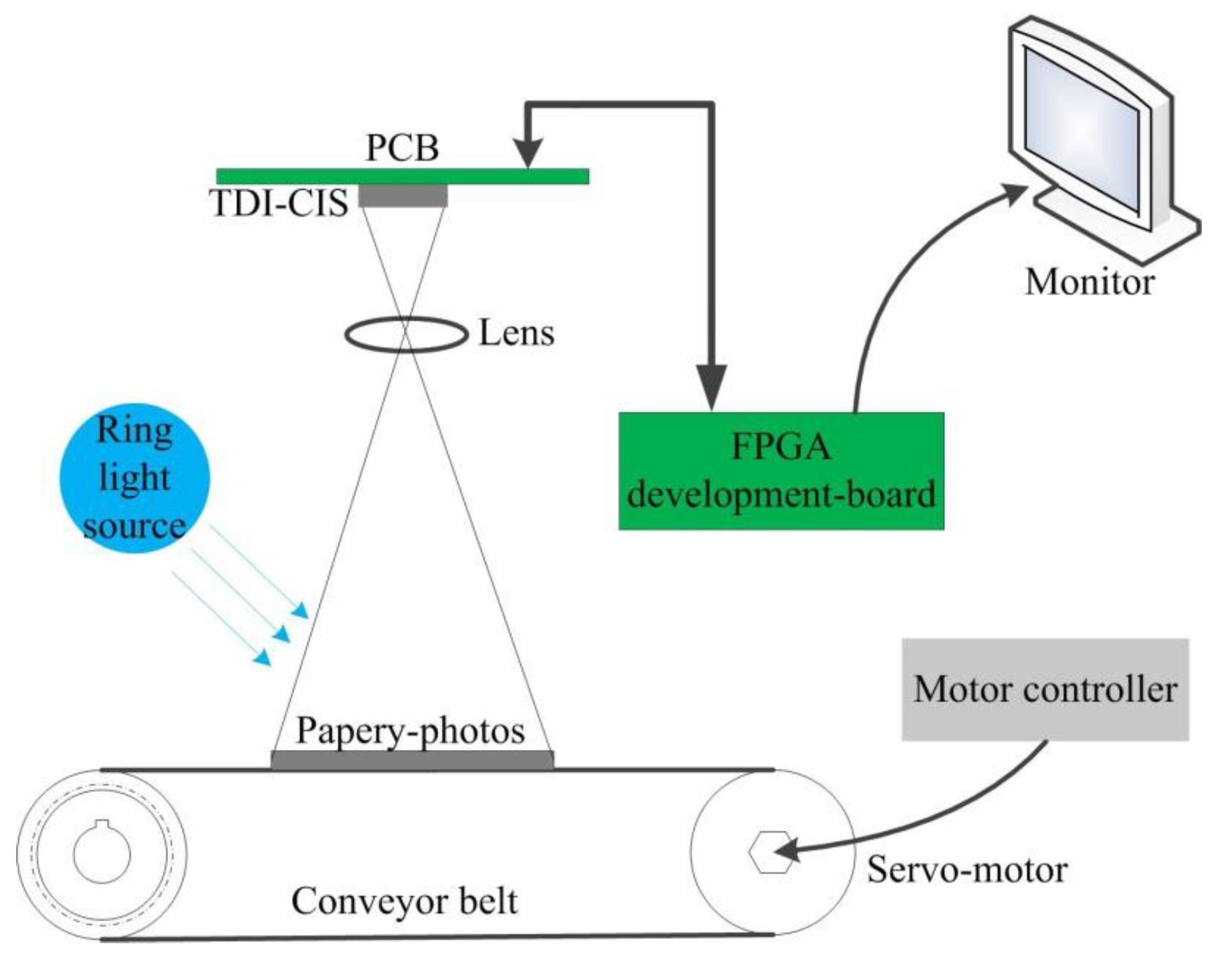

3.1. Sample Data Acquisition

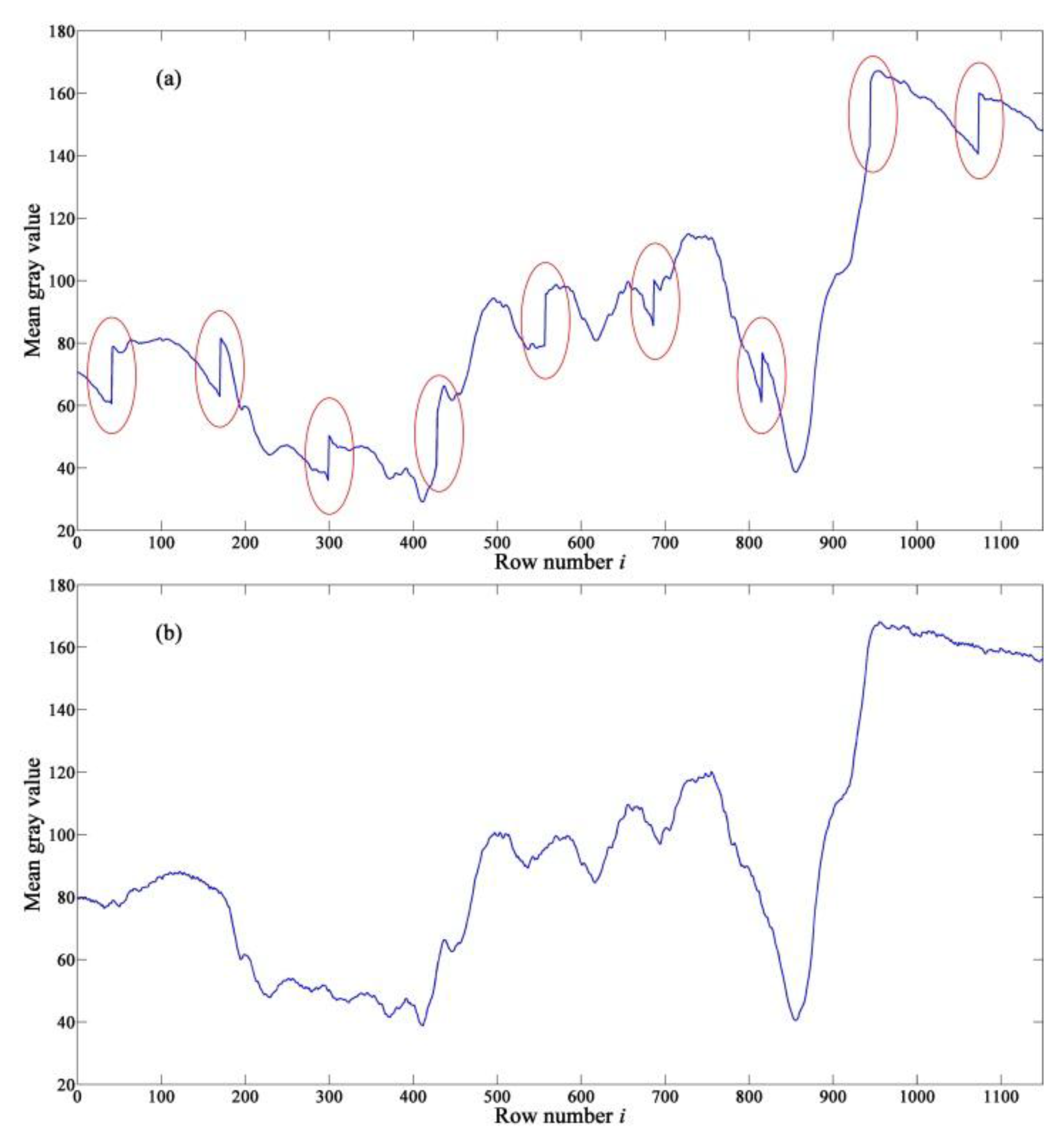

3.2. Estimation and Correction of RFPN

3.3. Estimation and Correction of CFPN

4. Experimental Results

| Item | Description |

|---|---|

| Technology | 0.18 µm CMOS |

| Power supply | 1.8 V (Digital)/3.3 V (Analog) |

| Pixel array size | 1024 columns × 128 rows |

| Pixel size | 15 µm × 15 µm |

| Column ADC resolution | 10-bit |

| Column ADC input range | 1.6 V |

| Maximum line rate | 3875 lines/s |

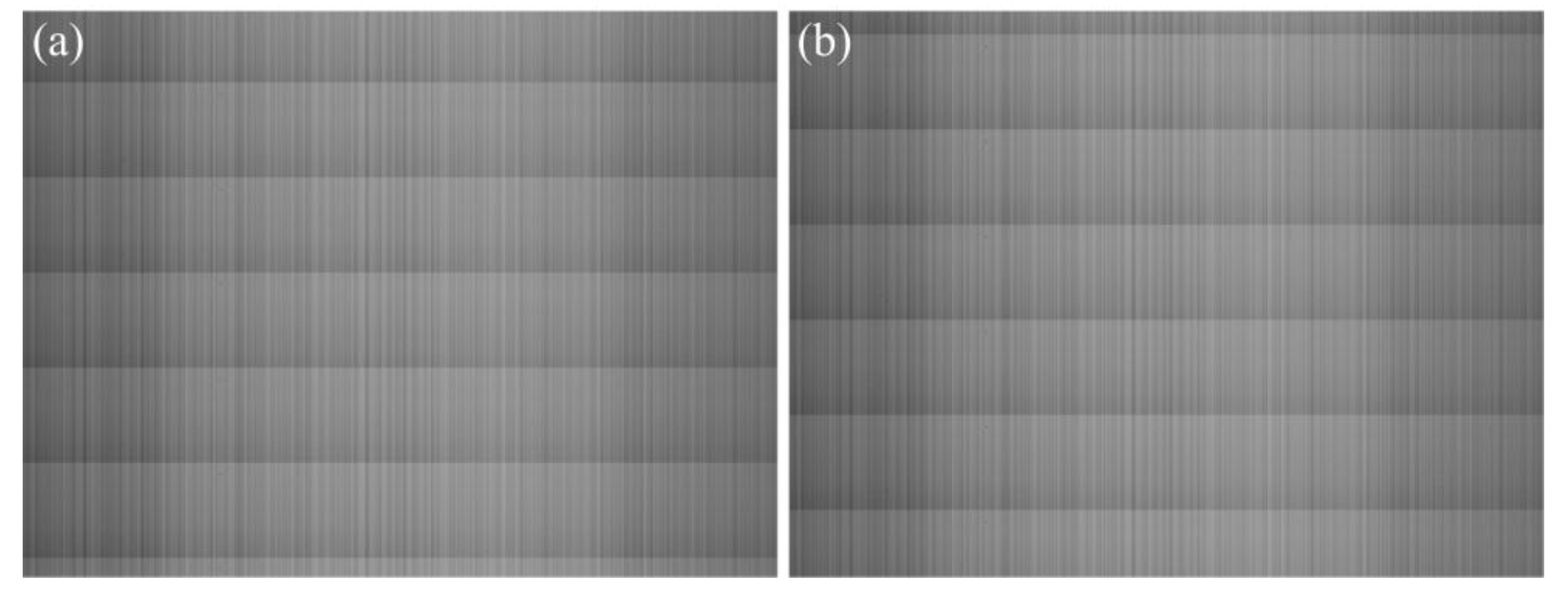

4.1. FPN Correction for Uniform-Light Image

| Image | SDRMV (LSB) | SDCMV (LSB) |

|---|---|---|

| Original image | 5.6798 | 15.2080 |

| Corrected image | 0.4214 | 13.4623 |

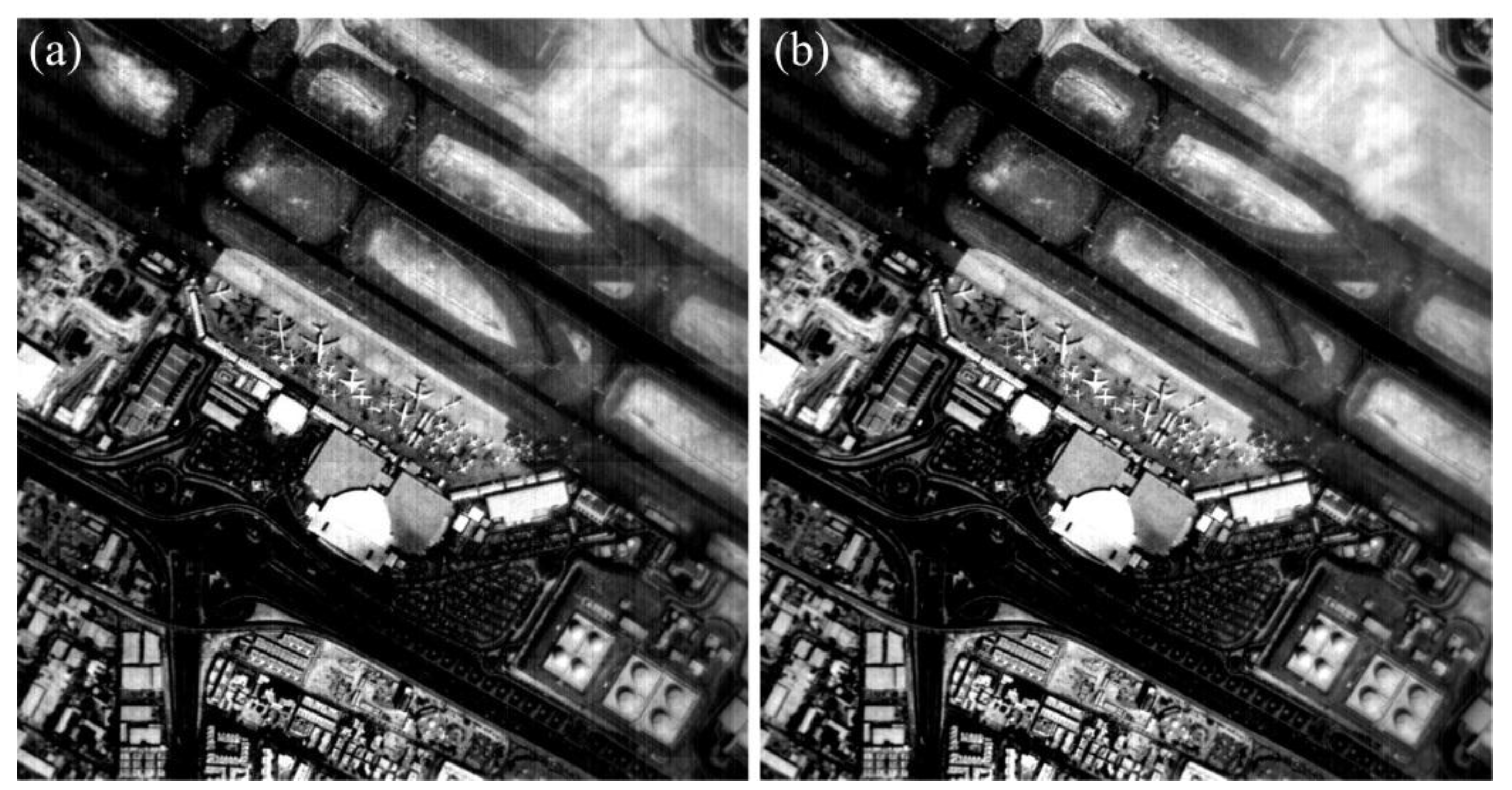

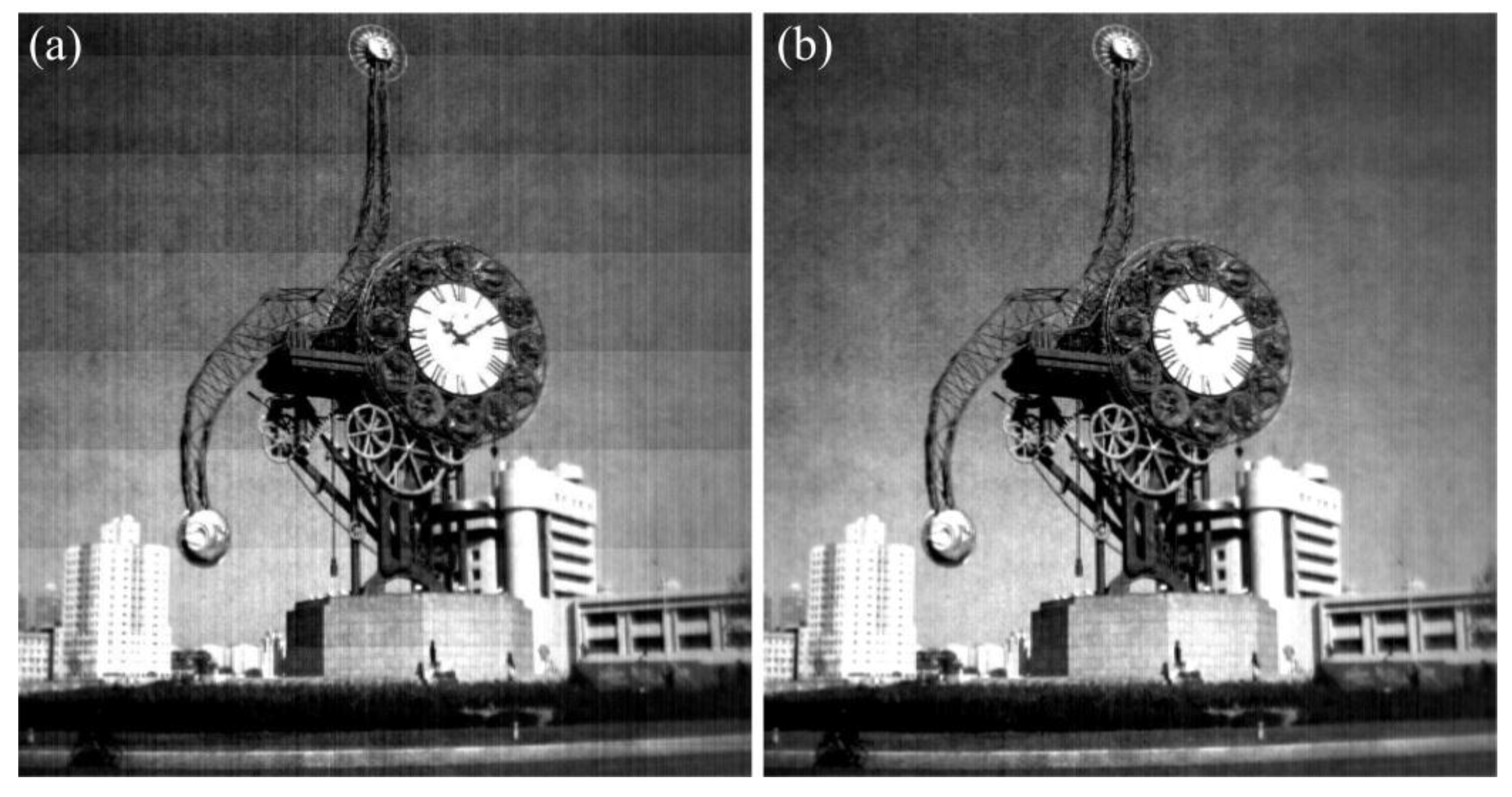

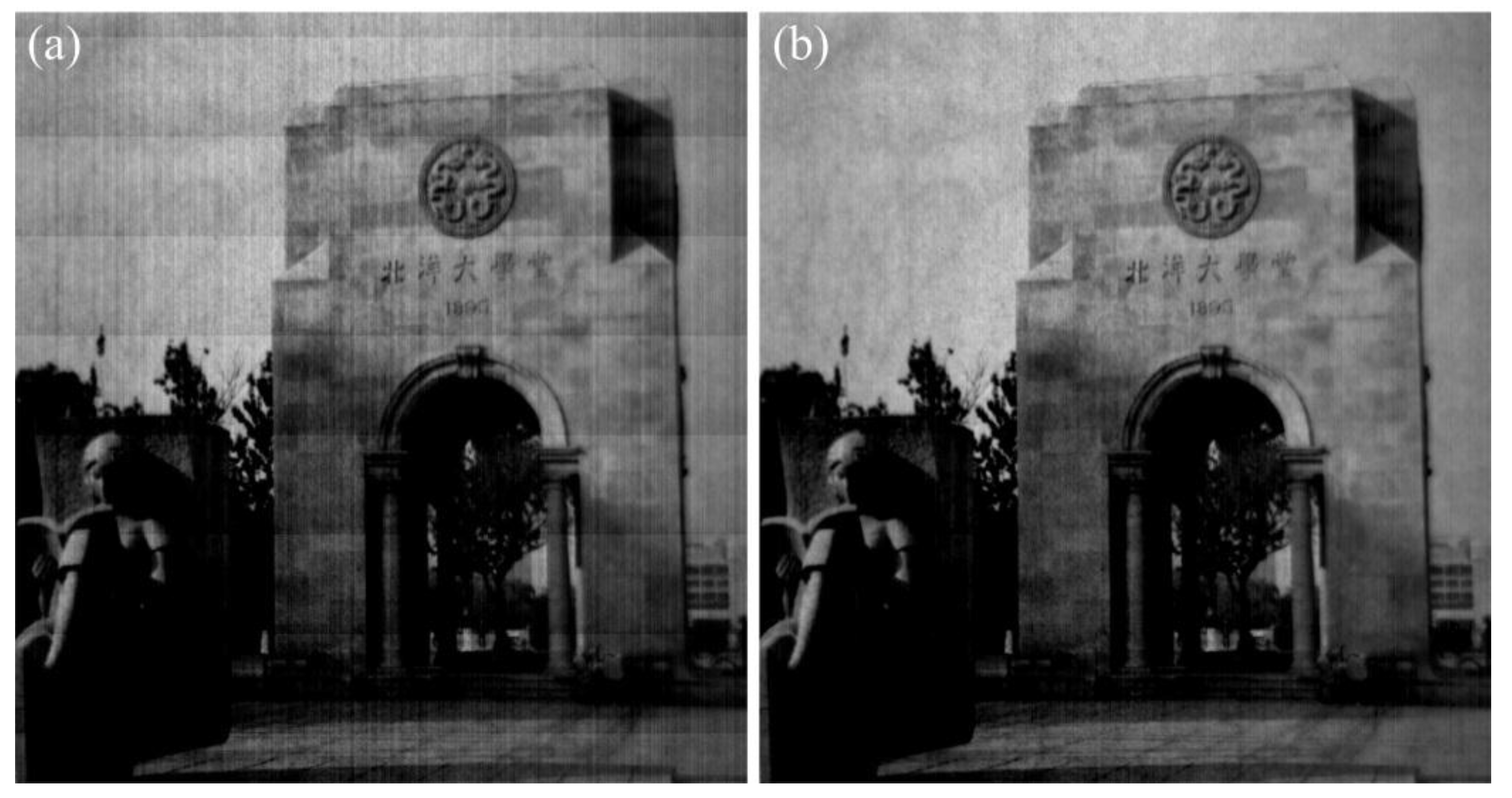

4.2. FPN Correction for Real-Test Image

4.3. Running Time

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Farrier, M.G.; Dyck, R.H. A Large Area TDI Image Sensor for Low Light Level Imaging. IEEE J. Solid-State Circuits 1980, 15, 753–758. [Google Scholar] [CrossRef]

- Wong, H.-S.; Yao, Y.L.; Schlig, E.S. TDI charge-coupled devices: Design and applications. IBM J. Res. Dev. 1992, 36, 83–106. [Google Scholar] [CrossRef]

- El Gamal, A.; Eltoukhy, H. CMOS image sensors. IEEE Circuits Devices Mag. 2005, 21, 6–20. [Google Scholar]

- Lepage, G.; Dantes, D.; Diels, W. CMOS long linear array for space application. In Proceedings of the SPIE Sensors, Cameras, and Systems for Scientific/Industrial Applications VII, San Jose, CA, USA, 15–19 January 2006.

- Kim, C.B.; Kim, B.-H.; Lee, Y.S.; Jung, H.; Lee, H.C. Smart CMOS Charge Transfer Readout Circuit for Time Delay and Integration Arrays. In Proceedings of the IEEE 2006 Custom Integrated Circuits Conference (CICC), San Jose, CA, USA, 10–13 September 2006; pp. 651–654.

- Yu, H.; Qian, X.; Chen, S.; Low, K.S. A Time-Delay-Integration CMOS image sensor with pipelined charge transfer architecture. In Proceedings of the 2012 IEEE International Symposium Circuits and Systems (ISCAS), Seoul, Korea, 20–23 May 2012; pp. 1624–1627.

- Chang, J.-H.; Cheng, K.-W.; Hsieh, C.-C.; Chang, W.-H.; Tsai, H.-H.; Chiu, C.-F. Linear CMOS image sensor with time-delay integration and interlaced super-resolution pixel. In Proceedings of the 2012 IEEE Sensors, Taipei, China, 28–31 October 2012; pp. 1–4.

- Nie, K.; Yao, S.; Xu, J.; Gao, J. Thirty Two-Stage CMOS TDI Image Sensor With On-Chip Analog Accumulator. IEEE Trans. Very Larg. Scale Integr. (VLSI) Syst. 2014, 22, 951–956. [Google Scholar] [CrossRef]

- Nie, K.; Yao, S.; Xu, J.; Gao, J.; Xia, Y. A 128-Stage Analog Accumulator for CMOS TDI Image Sensor. IEEE Trans. Circuits Syst. I. 2014, 61, 1952–1961. [Google Scholar] [CrossRef]

- Snoeij, M.F.; Theuwissen, A.J.P.; Makinwa, K.A.A.; Huijsing, J.H. A CMOS Imager with Column-Level ADC Using Dynamic Column Fixed-Pattern Noise Reduction. IEEE J. Solid-State Circuits 2006, 41, 3007–3015. [Google Scholar] [CrossRef]

- Sui, X.; Chen, Q.; Gu, G. Adaptive grayscale adjustment-based stripe noise removal method of single image. Infrared Phys. Technol. 2013, 60, 121–128. [Google Scholar] [CrossRef]

- Rogass, C.; Mielke, C.; Scheffler, D.; Boesche, N.K.; Lausch, A.; Lubitz, C.; Brell, M.; Spengler, D.; Eisele, A.; Segl, K.; et al. Reduction of Uncorrelated Striping Noise–Applications for Hyperspectral Pushbroom Acquisitions. Remote Sens. 2014, 6, 11082–11106. [Google Scholar] [CrossRef]

- Chang, Y.; Yan, L.; Fang, H.; Luo, C. Anisotropic Spectral-Spatial Total Variation Model for Multispectral Remote Sensing Image Destriping. IEEE Trans. Image Process. 2015, 24, 1852–1866. [Google Scholar] [CrossRef] [PubMed]

- Rakwatin, P.; Takeuchi, W.; Yasuoka, Y. Stripe Noise Reduction in MODIS Data by Combining Histogram Matching With Facet Filter. IEEE Trans. Geosci. Remote Sens. 2007, 45, 1844–1856. [Google Scholar] [CrossRef]

- Bouali, M.; Ladjal, S. Toward Optimal Destriping of MODIS Data Using a Unidirectional Variational Model. IEEE Trans. Geosci. Remote Sens. 2011, 49, 2924–2935. [Google Scholar] [CrossRef]

- Nie, K.; Li, L.; Yao, S.; Xu, J. Scanning Modulation Transfer Function Model of TDI CMOS Image Sensor. J. Signal Process. Syst. 2015. [Google Scholar] [CrossRef]

- Lepage, G.; Bogaerts, J.; Meynants, G. Time-Delay-Integration Architectures in CMOS Image Sensors. IEEE Trans. Electron Devices 2009, 56, 2524–2533. [Google Scholar] [CrossRef]

- EMVA Standard 1288 release 3.1. Available online: http://www.emva.org/cms/upload/Standards/Stadard_1288/EMVA1288-3.1rc.pdf (accessed on 14 August 2015).

- Nakamura, J. Image Sensors and Signal Processing for Digital Still Cameras; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Z.; Xu, J.; Wang, X.; Nie, K.; Jin, W. A Fixed-Pattern Noise Correction Method Based on Gray Value Compensation for TDI CMOS Image Sensor. Sensors 2015, 15, 23496-23513. https://doi.org/10.3390/s150923496

Liu Z, Xu J, Wang X, Nie K, Jin W. A Fixed-Pattern Noise Correction Method Based on Gray Value Compensation for TDI CMOS Image Sensor. Sensors. 2015; 15(9):23496-23513. https://doi.org/10.3390/s150923496

Chicago/Turabian StyleLiu, Zhenwang, Jiangtao Xu, Xinlei Wang, Kaiming Nie, and Weimin Jin. 2015. "A Fixed-Pattern Noise Correction Method Based on Gray Value Compensation for TDI CMOS Image Sensor" Sensors 15, no. 9: 23496-23513. https://doi.org/10.3390/s150923496