1. Introduction

Extremely high pointing stability is required in high-resolution Earth observation satellites, which are equipped with many sensitive payloads [

1]. However, the pointing stability is severely affected by undesirable harmonic vibrations of rapidly spinning rigid rotors in momentum exchange devices, such as flywheels and control moment gyros [

2,

3]. These harmonic vibrations are mainly caused by the rotor mass imbalance and imperfect bearing properties [

4]. If conventional ball bearings are adopted to support the rotor, the bearing stiffness varies periodically, and then multiple vibrations will be induced and be transferred to the spacecraft directly [

5]. To suppress these undesirable harmonic vibrations, additional special isolation devices are usually designed [

6]. Active magnetic bearings (AMBs) offer many advantages of contact-free levitation, small noise emission and, especially, active controlability [

7,

8]. In contrast with the conventional ball bearings, AMBs can employ field balancing and vibration suppression methods without adding any hardware. Hence, the AMBs are preferred in micro-vibration applications [

9].

The rotor imbalances, which result from lack of alignment between the inertial axis of the rotor and its geometric axis, are the dominant causes of synchronous vibrations. Balancing is a process of improving the mass distribution of the rotor, so that the inertial axis coincides with the geometric axis. The main balancing methods can be divided into three categories: balancing with a special machine, automatic balancing with a self-compensating device, and field balancing. The first method is usually employed by manufacturers with a balancing machine before installation [

10]. Only a mediocre level of balancing accuracy can be achieved due to measurement precision, limited rotational speed, structural resonance, and various disturbances. The widely-used self-compensation balancing device is a ball balancer [

11,

12]. The main advantage of this method is its ability of compensating variable imbalances during operation. However, it is acceptable to add a balancing device for control moment gyros with an inner rotor structure and limited space. Field balancing is a method of balancing a rotor in its own supporting structure rather than in a balancing machine. The imbalances can be reduced to a relatively low level because the balancing process can be completed in the actual working condition of the rotor. The influence coefficient method is effective [

13], yet too many trials will prolong the balancing process. The number of the trials can be reduced if the unknown imbalances are identified through vibration responses and precise modeling of the rotor-bearing system [

14]. However, if a direct identification is performed without effective control of the AMB-rotor system, the identification precision is highly dependent on the accuracy of the system model. As one of the most important features, AMBs can modulate the dynamic behaviors of the rotor by supplying active real-time control. A more accurate identification can be realized if the rotation axis of the rotor can be properly controlled in a certain position [

15]. The field balancing can be achieved by adding discrete weights, once the rotor imbalance identification is completed. It is suitable for rigid rotors because the rotor imbalances change little over the full range of the rotor speed.

To control the rotation axis of the rotor, traditional methods fall into two categories. In the former one, synchronous control force and torque are provided for forcing the rotor to rotate around its geometric axis. The imbalances can be identified through on-line estimations or well-established dynamic knowledge from the control force and torque to the rotor imbalances [

16]. However, the control effect is limited by the bandwidth of the AMB-rotor system and the synchronous control voltage that can be supplied, so it is not suitable for a high-speed rotor driven by a low-voltage power source [

17]. An approach for solving this problem is the latter one, which controls the rotor to spin around its inertial axis [

18]. The imbalance compensator method in the AMB system is firstly proposed by Habermann, a so-called automatic balancing system is proposed to eliminate the synchronous current and to reduce the housing vibration in [

19]. In fact, precise control current should be generated to compensate the vibration caused by the displacement stiffness [

20]. However, the precision of this approach mainly depends on the parameter accuracy of the controlled object [

21], especially the voltage-source power amplifiers, whose performances vary greatly with many parameters, such as temperature and the inductance of the AMB coil [

22]. The precision of rotation around the inertial axis will inevitably decrease due to the inaccurate control current caused by the errors and variations of the power amplifiers [

23]. Instead, a synchronous current reduction approach is practically preferred because of low copper loss and, especially, structural stability [

21]. To reduce the synchronous current, a notch filter is widely used and studied owing to its advantages of low computation effort and easy analysis of closed-loop stability [

24,

25]. However, residual synchronous currents, which are generated by the motion induced voltage, will still remain if the synchronous control voltage is merely cleaned in the AMB-rotor system with voltage-source power amplifiers [

26].

Position of the rotation axis is dependent on the rotor speed when the synchronous current reduction is achieved and then further identification of the imbalances, according to the measured synchronous displacements, can be performed. However, the sensor runout, which originates from nonuniform electrical and magnetic properties around the sensing surface of the rotor, brings noise at first and multiple harmonics of the rotor speed to the measured displacements [

27]. Furthermore, the first harmonic of the sensor runout is mixed with the rotor imbalances. Hence, errors will occur if the synchronous measured displacements are directly employed to estimate the rotor imbalances [

28]. For the control moment gyro in high-resolution Earth observation satellites, the undesirable harmonic vibrations induced by the rotor imbalances and the sensor runout have to be effectively suppressed. Setiawan

et al. did comprehensive research on an adaptive compensation approach whose stability is guaranteed by a Lyapunov function [

29,

30]. However, a higher robustness of the controller needs complex design and extensive computational effort. To solve this problem, Xu proposed a harmonic disturbance rejection method with a repetitive controller [

31]. However, the repetitive control method did not separate the rotor imbalance from the sensor runout, but just reduced all the harmonic currents. Unlike sensor runout, which is essentially sensor noise and only generates vibration through the current stiffness of the AMB, the rotor imbalances are due to uneven mass distribution and can cause vibrations through both the current stiffness and the displacement stiffness [

31]. Hence, the synchronous vibrations caused by the rotor imbalance and the displacement stiffness still remain, if only the repetitive control method is employed without balancing the rotor.

In this study, the rotor imbalances are identified through a synchronous current reduction method with a variable-phase notch feedback. Next, the static and dynamic imbalances are presented as two imbalanced masses located in two prescribed balancing planes of the rotor, and add-on discrete weights with the masses’ values calculated in the vector form are used to compensate the rotor imbalances. Then, the residual harmonic vibrations induced by the sensor runout and the current stiffness are suppressed by only reducing the harmonic currents with a repetitive control algorithm. Finally, the effectiveness of the field balancing and harmonic vibration suppression strategies are demonstrated by simulations and experiments performed on a control moment gyro test rig with a high-speed rigid AMB-rotor system.

2. Modeling of the AMB-Rotor System

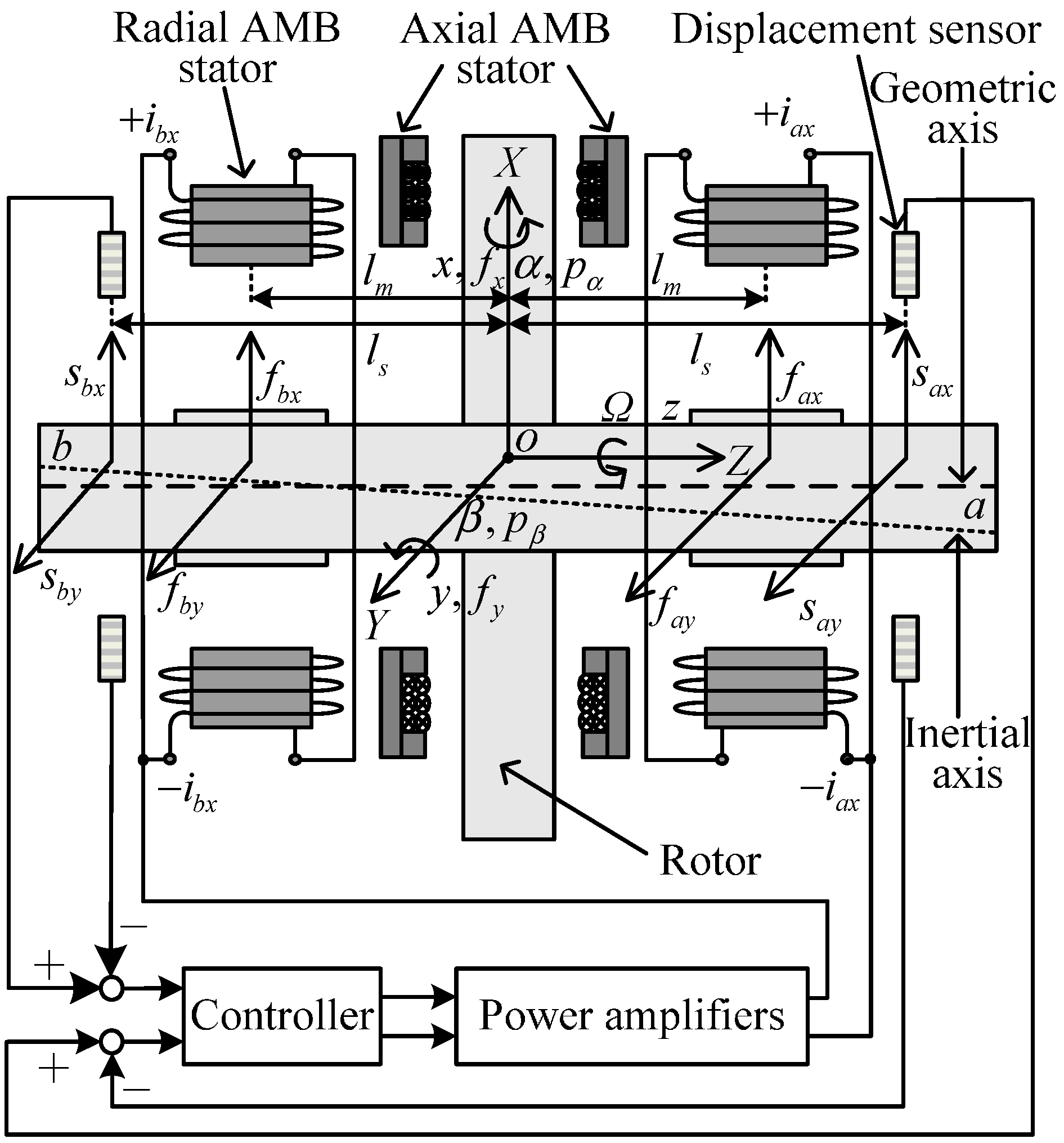

The AMB-rotor system, whose block diagram in the

x-

z plane is shown in

Figure 1, consists of an imbalanced rotor, radial AMB stators, axial AMB stators, displacement sensors, controller, and power amplifiers.

o is the center of the AMB stators and the origin of the coordinate

XYZ.

lm and

ls are the distances from

o to the centers of a radial AMB stator and a displacement sensor, respectively. The rotor has six degrees-of-freedom (DOF): three translational motions with displacements of

x,

y,

z, and three rotational motions with two radial displacements of

α,

β, and one axial rotor speed of

Ω.

Ω is driven by a rotor motor and is independent of the AMB-rotor system. Moreover,

z is controlled by the axial AMBs, which have little coupling with the radial AMBs and the imbalances.

Figure 1.

Diagram of the AMB-rotor system in the x-z plane.

Figure 1.

Diagram of the AMB-rotor system in the x-z plane.

Consequently, we only focus on the radial 4-DOF directions (

x,

y,

α,

β) controlled by the radial AMBs. Only two pairs of radial AMBs are shown in

Figure 1, as the other two pairs are oriented orthogonal to the paper plane.

a and

b denote the two terminals of the rotor. Signals of the AMB-rotor system are defined in three coordinates: the sensor coordinate, the stator coordinate, and the generalized coordinate. According to the measured displacements (

sax,

sbx,

say, and

sby in the four decentralized sensor directions of

ax,

bx,

ay, and

by, respectively) of the geometric axis by the displacement sensors, the controller drives the power amplifiers to generate four coil currents

iax,

ibx,

iay, and

iby (only

iax and

ibx of the shown radial AMB stators are visible in

Figure 1). Finally, control forces of

fax,

fbx,

fay, and

fby in the four decentralized stator directions are produced to levitate the rotor in the radial 4-DOF directions. The generalized displacement and force vectors are defined as [

x β y −α]

T and [

fx pβ fy −pα]

T in the generalized coordinate. Then, the displacements of the geometric and inertial axes can be expressed as

qG = [

xG βG yG −αG]

T and

qI = [

xI βI yI −αI]

T, respectively. Since the static and dynamic imbalances are the eccentricity and inclination angle of

qG and

qI, the imbalance vector Δ

q is defined in the generalized coordinate:

where

ε and

χ are the amplitude and the initial phase of the static imbalance, respectively;

σ and

δ are the amplitude and the initial phases of the dynamic imbalance, respectively.

The sensor runout is the noise of the displacement sensor, and its vector

qsr is defined in the sensor coordinate:

where

srax,

srbx,

sray, and

srby are the sensor runout in the

ax,

bx,

ay, and

by channels of the sensor coordinate,

n is the harmonic number,

sasi and

sbsi are the harmonic Fourier coefficients, and

αsi and

βsi are the harmonic initial phases.

Assuming that the parameters among the four decentralized directions have identical values and the gravity is acting in the

Z direction, the dynamics of the rotor in the radial 4-DOF directions can be given based on earlier work [

30]:

where

M is the mass matrix,

G is the gyroscopic matrix,

ki is the current stiffness,

Gw(

s) is the transfer function of the power amplifier,

kv is a coefficient related to the motion induced voltage,

Tfs,

Ts, and

Tft are coordinate transfer matrices,

Gs(

s) is the displacement controller matrix designed in the generalized coordinate, and

kx is the displacement stiffness:

where

m is the rotor mass,

Jr and

Jz are the transverse and polar moments of inertia of the rotor, respectively,

ks is the coefficient of the displacement sensor,

kP and

kD are the coefficients of the typical proportional-derivative controller, a pseudo integrator is used to avoid over-restriction,

kI and

kIM are its parameters,

I4 is a 4 × 4 unit matrix,

krh and

krl are gains of the cross feedback control,

ωrh and

ωrl are the cutoff angular frequencies of the high-pass and low-pass filters, respectively,

ϕ and

φ are the cross phases,

kw and

ωw are the gain and the cutoff angular frequency of the simplified low-pass power amplifier model. The PID controller is employed to stabilize the AMB system with a negative stiffness, while the cross feedback controller is designed to suppress the gyroscopic effect [

26].

The AMB-rotor model can be divided into two uncoupled subsystems: one is related to the translational motions which are also uncoupled in the

X and

Y directions, and the other is related to the two coupled rotational motions:

where:

As shown in Equations (3)–(5), the measured displacements of the geometric axis expressed in the generalized coordinate is (defined as ), according to which Gs(s) controls the rotor. The static and dynamic imbalances induce synchronous vibration force and torque through Ct(s), kv, and kx in the translational and rotational motions, respectively, whereas the sensor runout causes first and multiple harmonic vibration force and torque only through Ct(s) due to its nature of the displacement sensor noises. To achieve field balancing and harmonic vibration suppression, identification of Δq from qGM is primary.

The output force and torque from AMB are functions of the coil current and the geometric displacement respectively related to

ki and

kx [

30]. If a reduction of the synchronous currents can be achieved, only the force and torque related to

kx remain, and Equation (3) will be given by:

The synchronous displacement relationship of Δq and qG can be easily determined. Then, a method of identifying Δq from the noisy qGM is designed.

3. Design of the Synchronous Current Reduction Controller

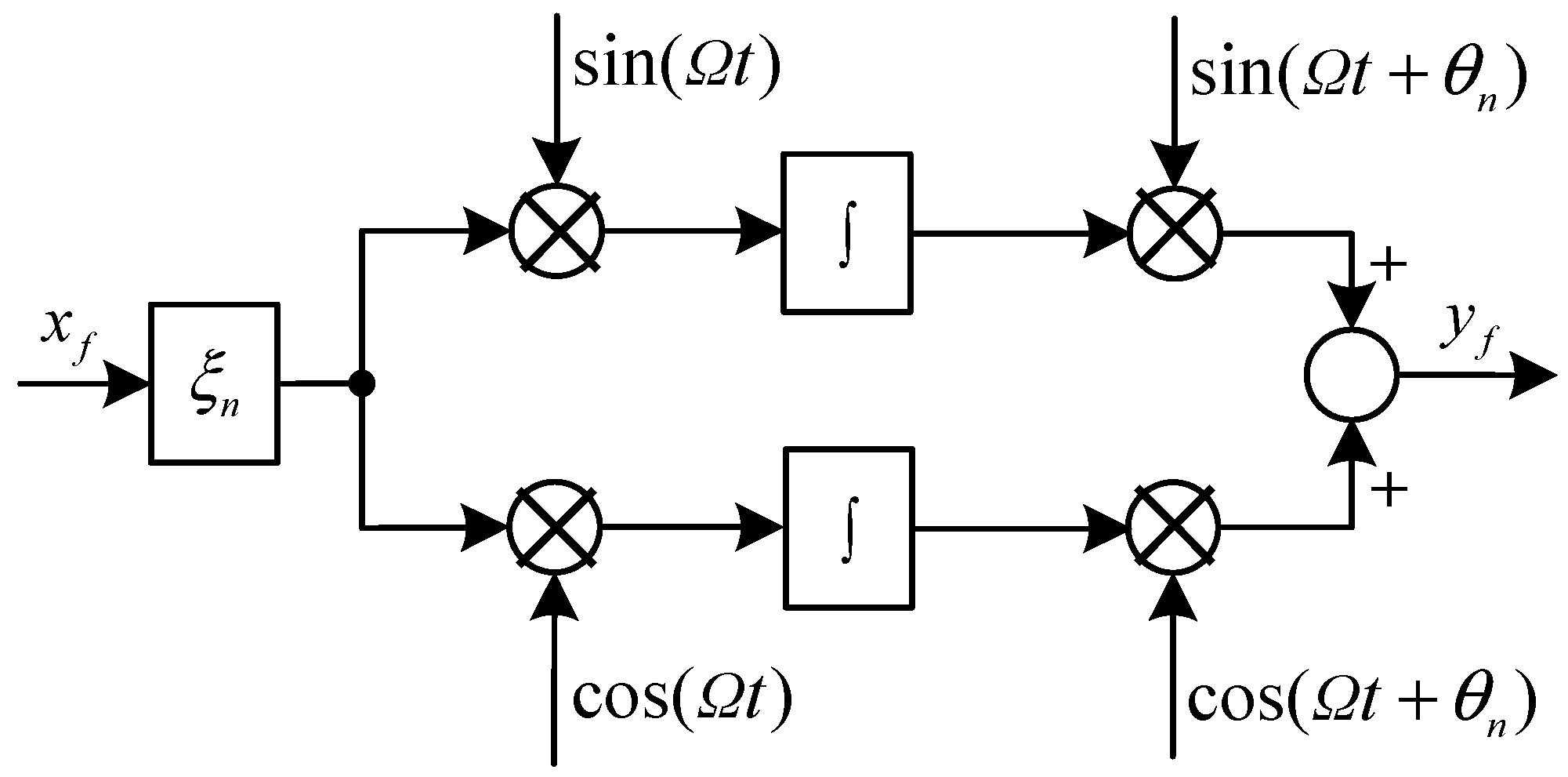

A notch feedback block [

32], which has an infinite gain at the synchronous frequency, is designed to reduce the synchronous current. The diagram of the notch feedback block is shown in

Figure 2, where

xf is the input signal with a component at the frequency of

Ω to be separated,

ξn is the damping coefficient,

θn is the phase shift,

yf is the output signal. The dynamic equation of the internal feedback block can be expressed as:

We can easily verify the following differential equation:

Consequently, the transfer function of the developed notch feedback block can be obtained as:

Figure 2.

Diagram of the improved notch feedback block.

Figure 2.

Diagram of the improved notch feedback block.

Figure 3.

Bode diagrams of the improved notch feedback block: (a) magnitude; (b) phase.

Figure 3.

Bode diagrams of the improved notch feedback block: (a) magnitude; (b) phase.

Bode diagrams of

Cnf(

s) are shown in

Figure 3, where

Ω = 400

π rad/s,

ξn = 1, and values of

θn are chosen as 0 and π/4 to make comparisons. As can be seen, the magnitude at the notch frequency of

Ω is infinite, and this can also be verified by using Equation (9). Therefore, a notch filter with a notch frequency of

Ω can be formed if

Cnf(

s) is used as a feedback element [

23]. Furthermore, the phase at the notch frequency is

θn. Hence, design and stability analysis of

Cnf(

s) can be simplified, because the synchronous phase shift can be easily set.

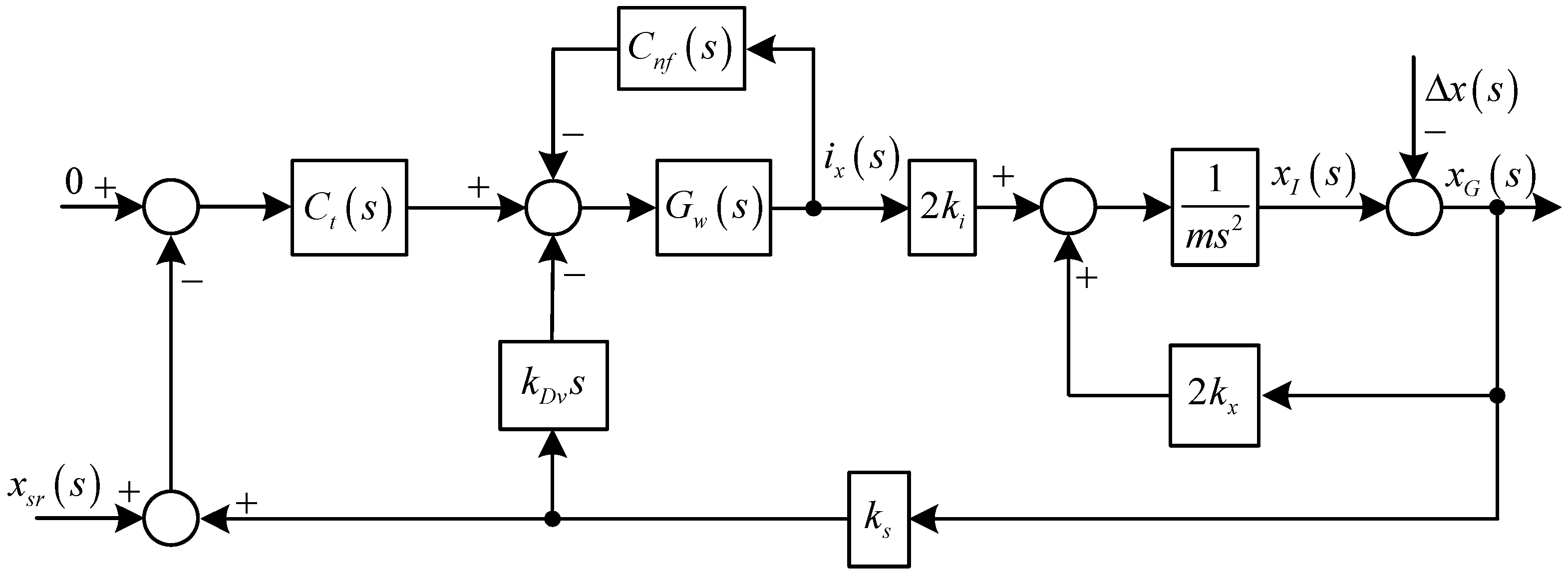

Figure 4.

Diagram of the translational subsystem in the X direction with the notch feedback.

Figure 4.

Diagram of the translational subsystem in the X direction with the notch feedback.

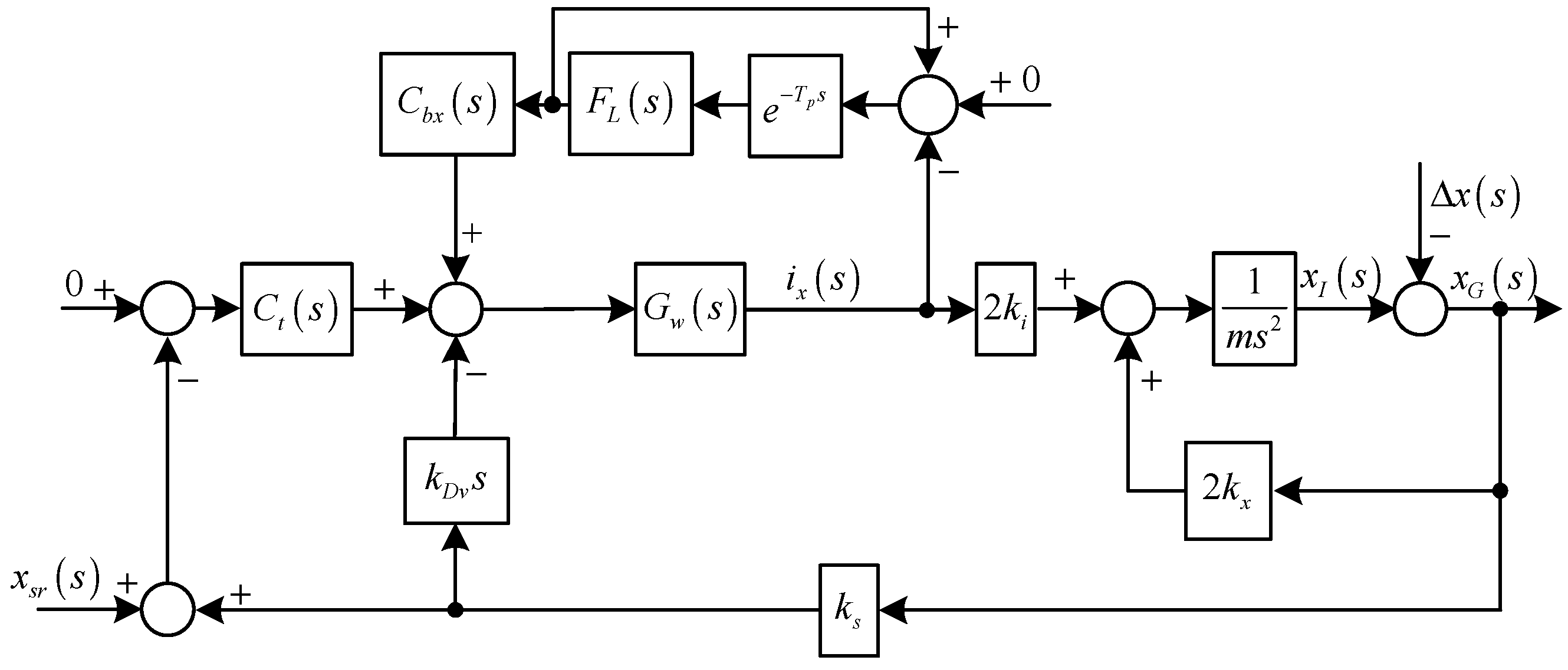

A generalized current vector

i is defined as [

30]:

The variable-phase notch feedback block is incorporated into the AMB-rotor control system to achieve a synchronous infinite-gain feedback of

i. Since the translational motions in the

X and

Y directions are symmetrical, only the controller design in the

X direction is introduced, and the diagram is shown in

Figure 4.

From

Figure 4, we have the expression of

ix(

s) as:

where:

It is easy to verify the following equation:

Hence, the synchronous

ix(

s) will be cleaned, only if the stability can be guaranteed. The poles of the closed-loop system in

Figure 4 are the roots of the following equation:

Cnf(

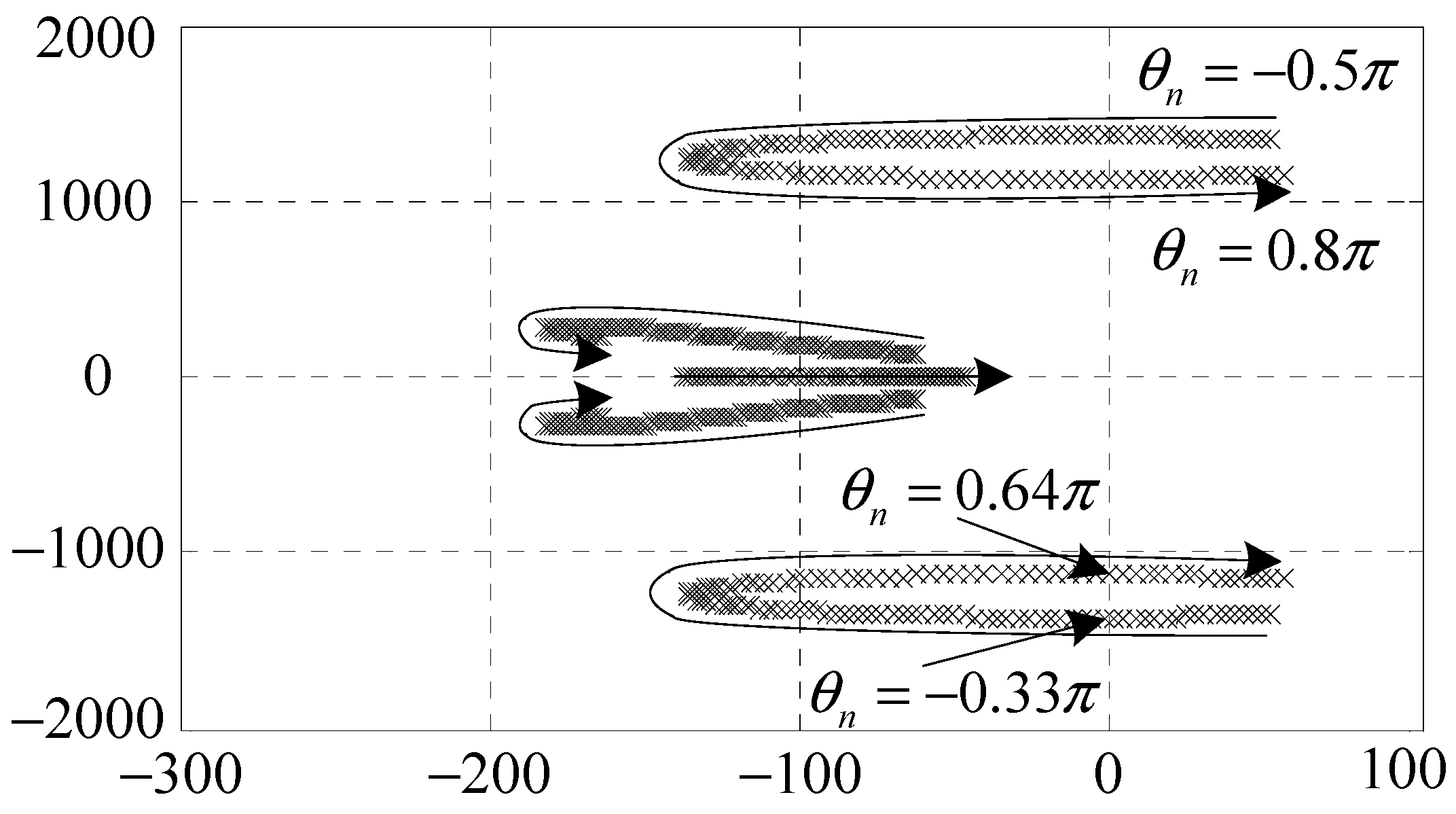

s) may endanger the stability of the AMB system. A root locus method is employed to analyze the stability and determine the values of the parameters in

Cnf(

s). As shown in

Figure 5 and

Figure 6, the stable value ranges of

ξn and

θn are [0, 6.2 × 10

6] and [−0.33

π, 0.64

π], respectively.

Figure 5.

Root locus of the clean synchronous ix control subsystem when θn = 0.3π, ξn ∈ [10, 1 × 107].

Figure 5.

Root locus of the clean synchronous ix control subsystem when θn = 0.3π, ξn ∈ [10, 1 × 107].

Figure 6.

Root locus of the clean synchronous ix control subsystem when ξn = 2 × 106, θn ∈ [−0.5π, 0.8π].

Figure 6.

Root locus of the clean synchronous ix control subsystem when ξn = 2 × 106, θn ∈ [−0.5π, 0.8π].

Figure 7.

Diagram of the rotational subsystem with two variable-phase notch feedback blocks.

Figure 7.

Diagram of the rotational subsystem with two variable-phase notch feedback blocks.

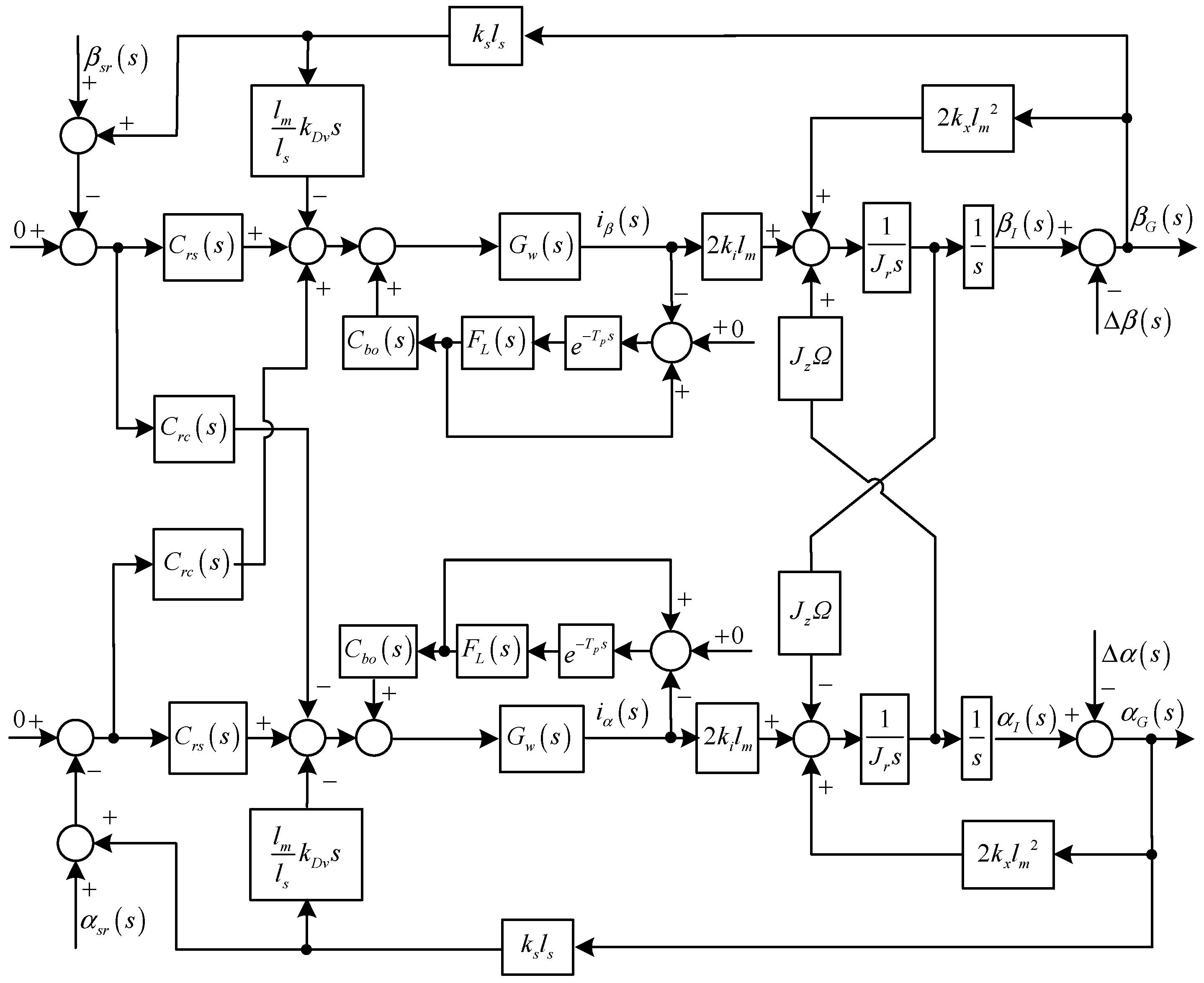

A similar control and analysis method can be utilized to achieve the synchronous current reduction in the rotational subsystem. However, the rotational motions in the

α and

β directions are coupled due to the gyroscopic effect, so two notch feedback blocks are designed in the rotational subsystem, whose diagram is shown in

Figure 7.

4. Identification of the Rotor Imbalances and Field Balancing

To analyze the dynamics of the AMB-rotor system upon reduction of the synchronous currents, let:

where

j is the complex unit. Then Equation (6) can be simplified as follows:

where:

From Equation (14), the synchronous displacements of the geometric axis can be formulated as:

The synchronous displacement relationships of the geometric, inertial, and rotational axes of the rotor are shown in

Figure 8, where

CG,

CI, and

CR are the centers of the geometric, inertial, and rotational axes,

RG,

RI, and

RR are the angles of the geometric, inertial, and rotational axes, respectively. Then we have:

It is noted that the rotor of the control moment gyro is designed to be flat () for a large moment of inertia. It can be regarded as peer rigid because the first bending-critical speed (887 Hz) is far beyond the nominal speed (200 Hz).

Figure 8.

The synchronous displacement relationships of the geometric, inertial, and rotational axes: (a) translation; (b) rotation.

Figure 8.

The synchronous displacement relationships of the geometric, inertial, and rotational axes: (a) translation; (b) rotation.

Figure 9.

The schematic diagram of the double-plane balancing method.

Figure 9.

The schematic diagram of the double-plane balancing method.

The synchronous

qGM consists of the synchronous

qG and the first harmonic of

qsr. From Equations (2) and (16), the amplitude of the synchronous

qG is related to

Ω, whereas the amplitude and the initial phase is not related to

Ω. Hence, a two-speed separation method can be used to identify Δ

q. The displacement sensors and the angular-position sensor are used to measure a rotor revolution of

qGM and its relative phase to the reference point. Then

qsr can be cancelled with the difference of

qGM at two varied speeds of

Ω1 and

Ω2, which leads to:

ε and σ can be calculated from Equation (17) by using the displacement sensors to measure , and the angular-position sensor to measure Ω1, Ω2, the phases of the rotor imbalances, respectively.

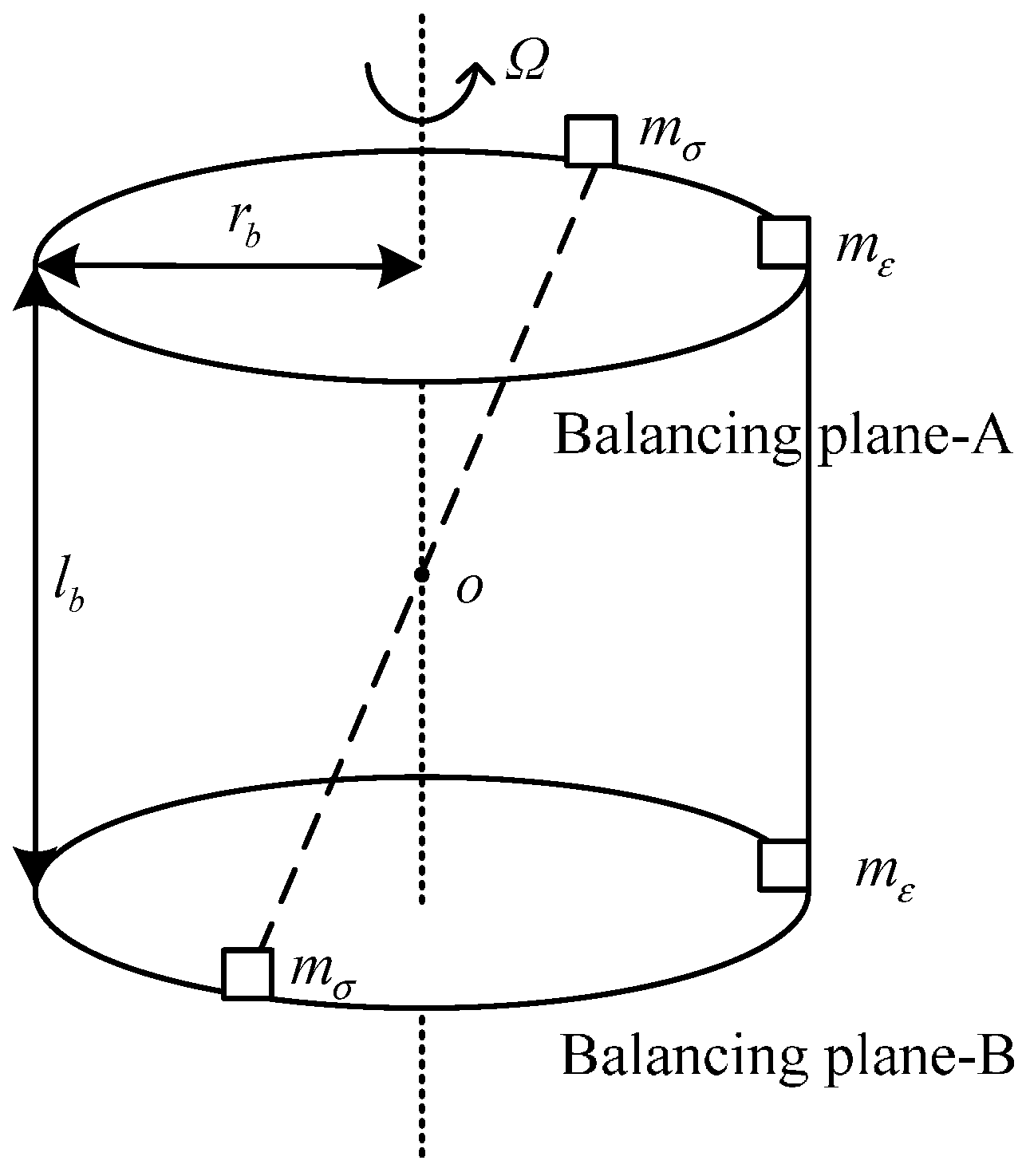

A rigid rotor can be balanced in two different planes [

8]. The schematic diagram of the two-plane balancing method is shown in

Figure 9, where

rb is the radius of the balancing plane,

lb is the distance between the balancing planes,

mε and

mσ are the correction masses to compensate the static and dynamic imbalances, respectively.

According to the equivalent formula, the correction masses are given by:

Two or four screws with values, which match

mε and

mσ and can be added or resolved in the vector form are fixed in the balancing holes to balance the rotor [

28].

5. Suppression of the Harmonic Vibrations Induce by the Sensor Runout

Theoretically, only the sensor runout remains if the field balancing is well achieved. Then the harmonic vibrations (torque and force) can be suppressed by reducing harmonic currents, which are induced by the sensor runout only related to

ki. A plug-in repetitive control method is employed owing to its ability to reduce all the harmonic currents simultaneously with a light computational load. The repetitive controller is utilized in a feedback form, because

Gw(

s) is voltage-sourced. The diagram of the translational subsystem in the

X direction with the repetitive controller is shown in

Figure 10, where

Tp is the dead time,

FL(

s) is a fist-order low-pass filter,

Cbx(

s) is a lead element to compensate the phase lad due to the power amplifiers and to improve the system bandwidth, and:

where

ωL is the cut-off frequency,

kcx and

kwx are positive parameters to be chosen.

The suppression factor of the sensitivity function due to the repetitive controller is given by [

33]:

Figure 10.

Diagram of the translational subsystem in the X direction with the repetitive controller.

Figure 10.

Diagram of the translational subsystem in the X direction with the repetitive controller.

To suppress the harmonic currents, let:

To satisfy the gain and phase requirements,

,

nm is the largest number of the harmonic to be suppressed.

Tp is set with:

To compensate the phase lag of all the suppressed harmonics due to the power amplifiers, . If kcx = 0, the repetitive controllers will be closed. kcx is closely related with the system characteristics. It can be chosen according to the stability analysis and the performances of the repetitive controllers in simulations and experiments with the increase of the value from 0.

The characteristic equation of the translational subsystem with a single time delay

Tp can be expressed by:

where:

The regeneration spectrum for this system is defined as:

The absolute stability can be guaranteed if:

Similarly, repetitive controllers are designed in the rotational subsystem, as shown in

Figure 11, where:

where

kco is the gain, and

kco ≥ 0.

Figure 11.

Diagram of the rotational system with the repetitive controllers.

Figure 11.

Diagram of the rotational system with the repetitive controllers.

6. Simulations and Experiments

To demonstrate the effectiveness of the proposed control methods, comparative simulations and experiments have been developed.

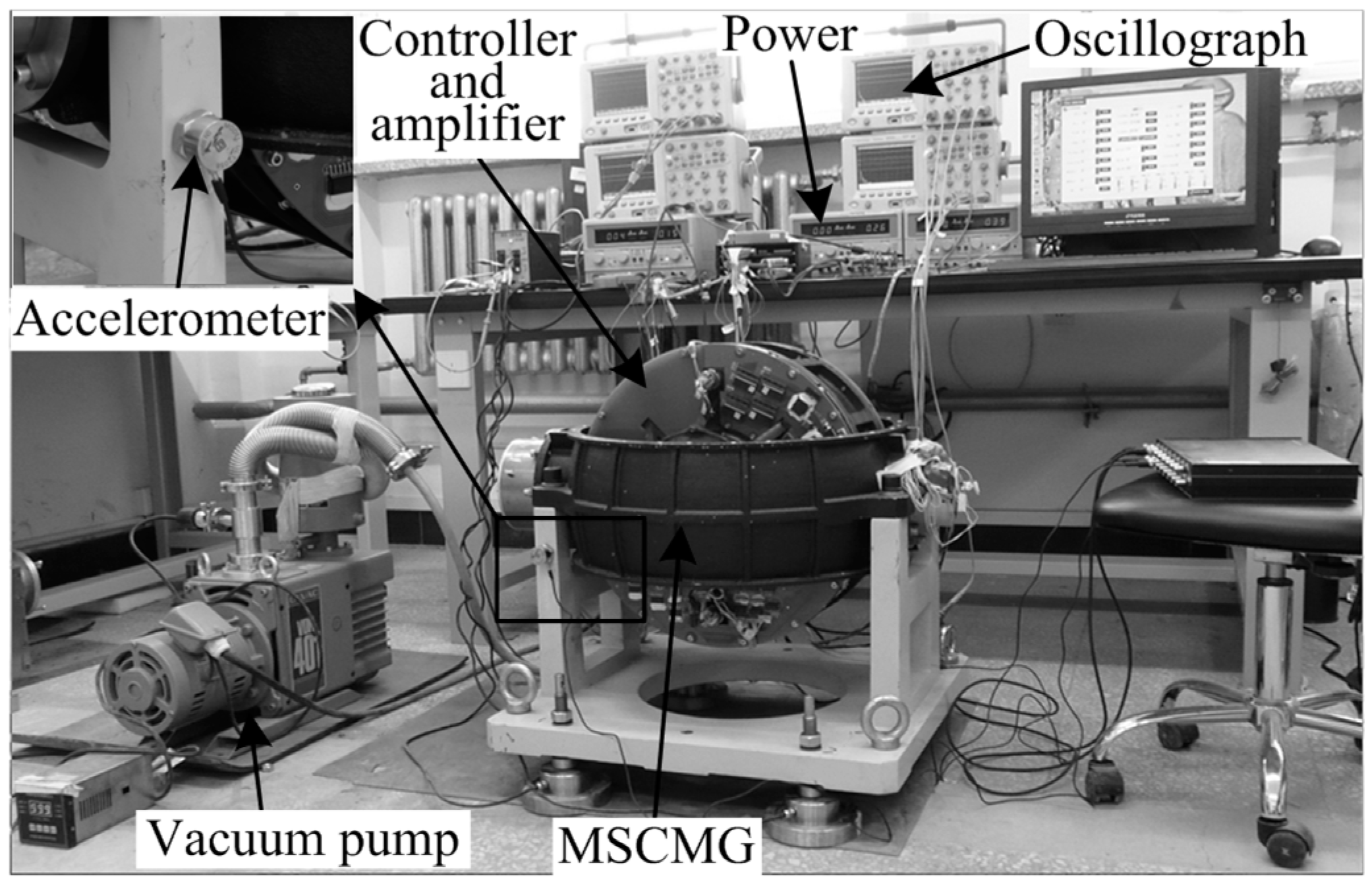

Figure 12 shows the experimental rig of the magnetically-suspended control moment gyro (MSCMG), which consists of a gimbal system and a high-speed rotor system with AMBs. The high-speed rotor system with AMBs is very suitable to verify the proposed field balancing and harmonic vibration suppression methods. The experiment setup is composed of vacuum pump, power, controller and amplifier, accelerometer, oscillographs, and MSCMG. A high-speed rigid and flat AMB-rotor is inside the MSCMG room. The vacuum pump is employed to create a nearly vacuous environment (the air pressure is about 2 Pa) in the MSCMG room, in which the magnetically-suspended rotor is driven by the controller and amplifier. The proposed control algorithm is implemented in a digital signal processor-based controller with a sampling and control period of 150 μs. Eight eddy-current sensors and one Hall sensor are employed to measure the displacements of the geometric axis and the relative angular positions to the reference point, respectively. An accelerometer is employed to measure the harmonic vibration acceleration transmitted to the support bracket, which is fixed on the spacecraft in space. The measured signals of the harmonic displacements, currents, and vibrations are shown on the oscillographs. The nominal speed of the AMB-rotor system is 200 Hz. It is noted that the first, third, and fifth harmonics are dominant components in actual experiments; therefore, the harmonic frequencies are 200, 600, and 1000 Hz.

The parameters of the AMB system are chosen to match those in the experimental rig, presented in

Table 1. The rotor is designed to be flat (As shown in

Table 1,

) for a large moment of inertia. To simulate the actual current noises and to test the performance of the proposed control methods at all the frequencies, a random noise with the mean and variance values of 0 and 3 × 10

−4, respectively, is injected into the currents in simulations.

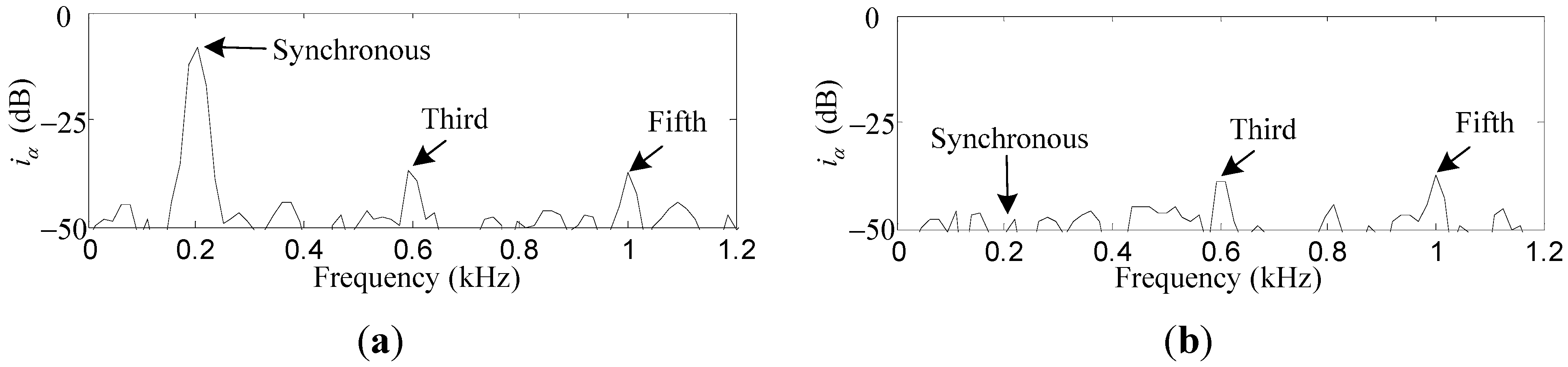

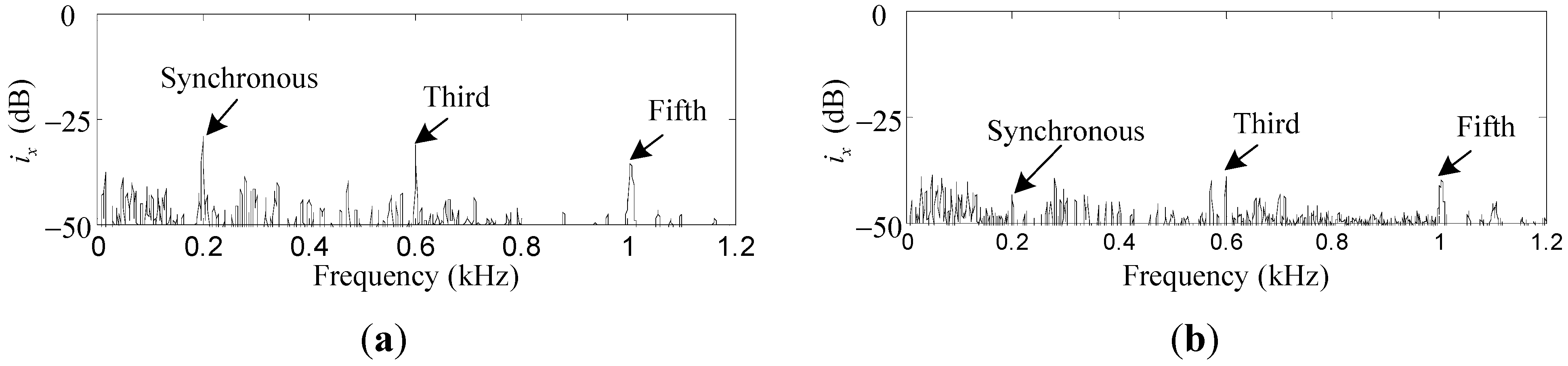

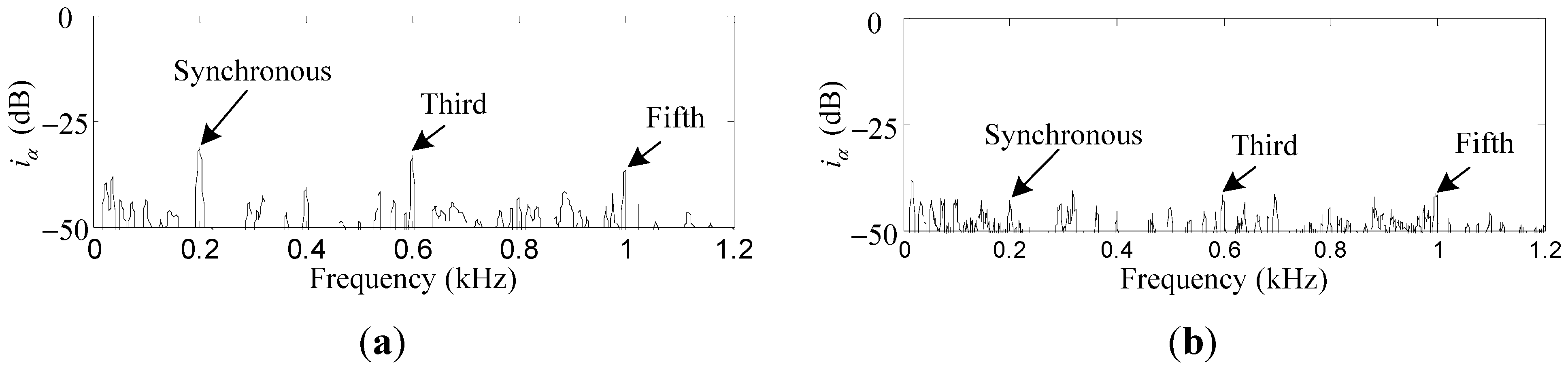

Comparative simulation results of

ix and

iα before and after the synchronous current reduction are presented. As shown in

Figure 13 and

Figure 14, the synchronous

ix and

iα are reduced by 41.2 dB and 40.7 dB, respectively, if the variable-phase notch feedback block is activated.

Figure 12.

The photograph of the magnetically-suspended control moment gyro experimental rig.

Figure 12.

The photograph of the magnetically-suspended control moment gyro experimental rig.

Table 1.

Parameters of the AMB system with the proposed control approach.

Table 1.

Parameters of the AMB system with the proposed control approach.

| Parameters | Values | Parameters | Values |

|---|

| m | 57 kg | θn | 0.94 rad |

| Jr | 0.62 kg∙m2 | ωL | 104 rad/s |

| Jz | 0.82 kg∙m2 | Tp | 0.0049 s |

| lm | 0.113 m | kcx | 960 |

| ls | 0.178 m | kωx | 0.1 |

| ki | 450 N/A | kco | 1100 |

| kx | 2.5 × 106 N/m | ε | 5 × 10−6 m |

| ks | 1.5 × 107 V/m | χ | π/3 rad |

| ωw | 1683 rad/s | σ | 2.8 × 10−5 rad |

| kw | 1.23 × 10−4 A/V | δ | −π/3 rad |

| rb | 0.21 m | sas1 | 10 |

| lb | 0.07 m | αs1 | π/4 rad |

| kP | 5 | sas3 | 4 |

| kI | 40 | αs3 | 4π/3 rad |

| kIM | 0.05 | sas5 | 1 |

| kD | 0.01 | αs5 | 9π/5 rad |

| krh | 0.01 | sbs1 | 12 |

| krl | 0.001 | βs1 | 5π/3 rad |

| ωrh | 1256.6 rad/s | sbs3 | 5 |

| ωrl | 314.2 rad/s | βs3 | 11π/6 rad |

| ϕ | 2.5 rad | sbs5 | 2 |

| φ | 0.9 rad | βs5 | π/5 rad |

| ξn | 2 × 106 | | |

Figure 13.

Simulation results of ix: (a) before synchronous current reduction; (b) after synchronous current reduction.

Figure 13.

Simulation results of ix: (a) before synchronous current reduction; (b) after synchronous current reduction.

Figure 14.

Simulation results of iα: (a) before synchronous current reduction; (b) after synchronous current reduction.

Figure 14.

Simulation results of iα: (a) before synchronous current reduction; (b) after synchronous current reduction.

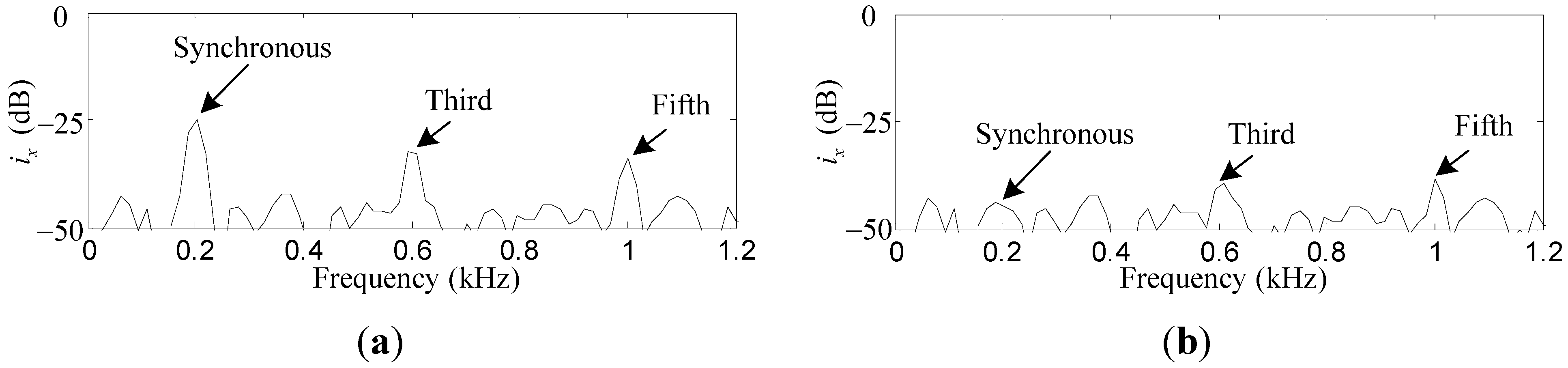

Figure 15.

Simulation results of ix: (a) before harmonic current suppression; (b) after harmonic current suppression.

Figure 15.

Simulation results of ix: (a) before harmonic current suppression; (b) after harmonic current suppression.

Figure 16.

Simulation results of iα: (a) before harmonic current suppression; (b) after harmonic current suppression.

Figure 16.

Simulation results of iα: (a) before harmonic current suppression; (b) after harmonic current suppression.

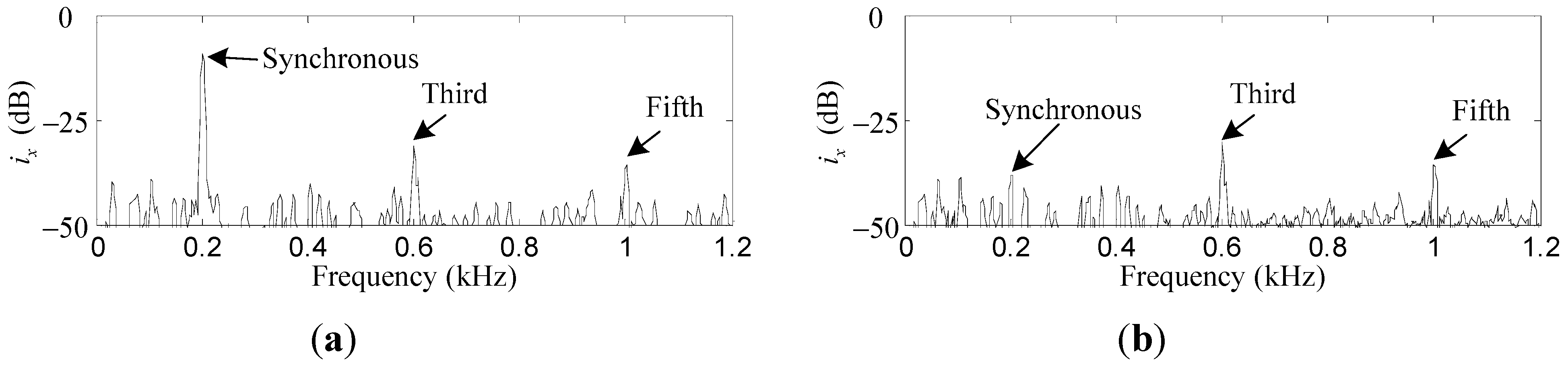

Figure 17.

Experiment results of ix: (a) before synchronous current reduction; (b) after synchronous current reduction.

Figure 17.

Experiment results of ix: (a) before synchronous current reduction; (b) after synchronous current reduction.

To verify the suppression effect of the harmonic

ix and

iα induced by the sensor runout, the repetitive controller is enabled. As can be seen in

Figures 15a,b, the first, third, and fifth harmonics of

ix are suppressed by 18.8 dB, 7.3 dB and 4.7 dB, respectively. Similar results can be found in

Figures 16a,b, where the first, third, and fifth harmonics of

iα are suppressed by 12.7 dB, 8.9 dB, and 4.5 dB, respectively. The harmonics of

ix and

iα are suppressed by a considerable amount, although the attenuation degree decreases with the increase of the harmonic number due to the low-pass

FL(

s).

Experiments of the synchronous currents reduction at varied speeds of 180 and 200 Hz were carried out for field balancing. Only the experimental results of 200 Hz are shown in accord with those of the simulations. As shown in

Figure 17 and

Figure 18, the synchronous

ix and

iα were reduced by 26.2 dB and 27.1 dB, respectively. The correction masses were calculated as

g and

g.

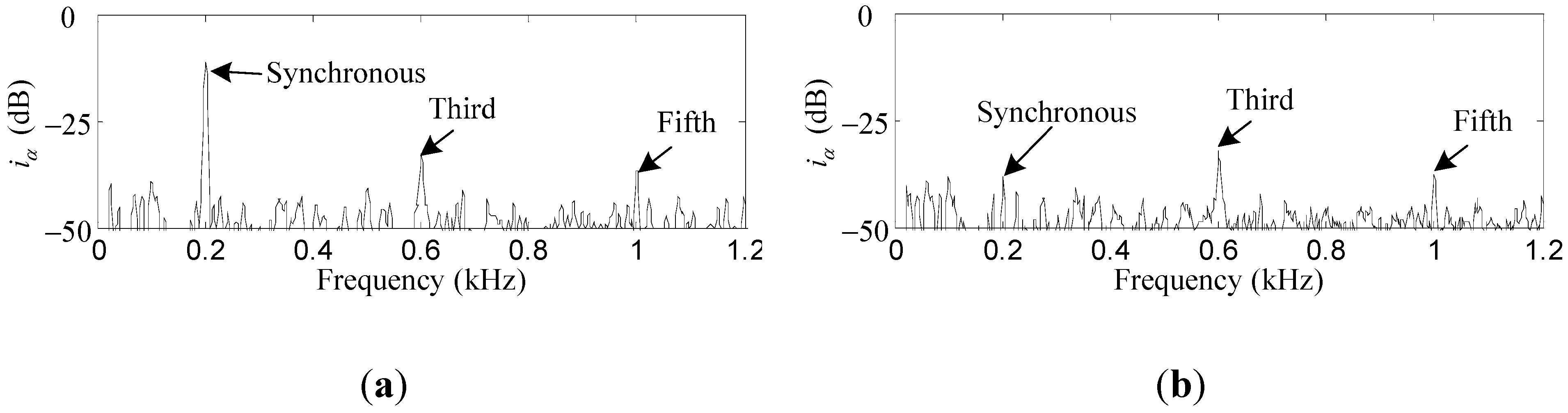

Compared

Figure 19a and

Figure 20a with

Figure 17a and

Figure 18a, the synchronous currents are much smaller after the field balancing. Hence, the rotor imbalances are well compensated. To further suppress the harmonic vibrations, the harmonic currents induced by the sensor runout were attenuated by the repetitive controllers. As shown in

Figure 19 and

Figure 20, the first, third, and fifth harmonic currents of

ix (

iα) were suppressed by 12.0 dB, 6.9 dB, and 3.6 dB (11.1 dB, 8.5 dB, and 4.3 dB), respectively. Good matching between the experiment results and the simulation results was achieved.

Figure 18.

Experiment results of iα: (a) before synchronous current reduction; (b) after synchronous current reduction.

Figure 18.

Experiment results of iα: (a) before synchronous current reduction; (b) after synchronous current reduction.

Figure 19.

Experiment results of ix: (a) before harmonic current suppression; (b) after harmonic current suppression.

Figure 19.

Experiment results of ix: (a) before harmonic current suppression; (b) after harmonic current suppression.

Figure 20.

Experiment results of iα: (a) before harmonic current suppression. (b) after harmonic current suppression.

Figure 20.

Experiment results of iα: (a) before harmonic current suppression. (b) after harmonic current suppression.

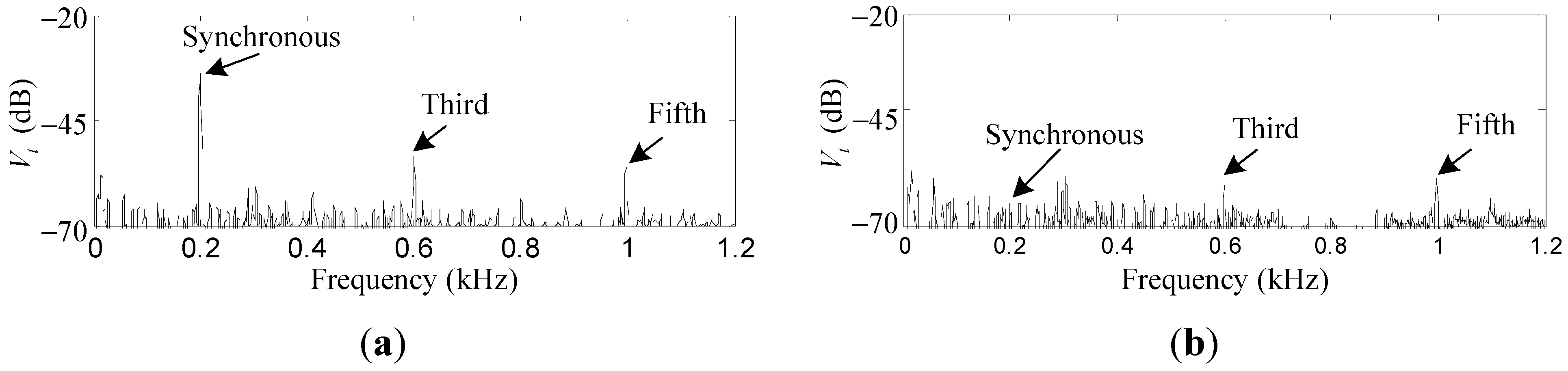

Figure 21.

Experiment results of Vt: (a) before field balancing and harmonic vibration suppression; (b) after field balancing and harmonic vibration suppression.

Figure 21.

Experiment results of Vt: (a) before field balancing and harmonic vibration suppression; (b) after field balancing and harmonic vibration suppression.

The measured acceleration

Vt by the accelerometer is used to demonstrate the overall effects of the proposed field balancing and harmonic vibration suppression methods.

Figure 21 shows the values of first, third, and fifth harmonic vibrations are reduced by 31.1 dB, 6.8 dB, and 3.9 dB, to similar sizes to those of noises (mainly caused by the gyroscopic effects and structural resonance), which means the rotor imbalance is well compensated and the harmonic vibrations are significantly suppressed.