1. Introduction

Rice plays a significantly important role in people’s daily life, therefore, detection of the rice quality has received progressively increasing attention. However, currently, the evaluation of rice quality lacks a uniform standard and the evaluation method depends on the test aim of the rice. Rice quality has attracted significant attention and it has become the most important target in rice improvement. Therefore, the quality of rice is evaluated in terms of its sensory quality, processing quality, eating quality, and nutritional quality. The assessment indexes of sensory quality of rice are mainly based on the color, appearance, smell, taste and other features which are identified by the examiner’s sense organs and practical experience. Rice processing quality mainly reflects the characteristics of rice processing. The main evaluation index includes milled rice rate and machining accuracy. The main assessment indexes of eating quality of rice include the gelatinization temperature, amylose content, and gel consistency. Evaluation of the nutritional quality of rice is mainly embodied in the detection of the content of rice starch, fat, protein, vitamins, and microelements which are beneficial to the human body. However, in some of these methods, the influence of the examiner’s subjective consciousness in the evaluation process is strong, and the validity and reliability of the corresponding evaluation results cannot be guaranteed. What’s more, pretreatment procedures, while highly desirable in order to obtain reliable evaluation results, are complex and time-consuming. With an increasing need for field rice harvest season and rice manufacture testing, it is necessary to study the discrimination and recognition of different varieties of rice and further to evaluate its quality control. Nowadays, modern analytical techniques are applied for the discrimination and identification of damaged rice plants. Furthermore, these techniques are also used for the discrimination of rice varieties based on volatile compounds released by the plant, and for rice detection by gas chromatography-mass spectrometry (GC-MC) or electronic noses [

1,

2,

3,

4,

5,

6].

Recently, electronic tongues have started to play an important role in the food industry as intelligent analytical systems. According to the IUPAC definition [

7], an electronic tongue is “a multisensor system, which consists of a number of low-selective sensors and uses advanced mathematical procedures for signal processing based on pattern recognition (PARC) and/or multivariate data analysis artificial neural networks (ANNs), principal component analysis (PCA),

et al.”. Therefore, an electronic tongue represents a new way to interpret chemical signals and provide qualitative and quantitative assessment of multispecies solutions. The two emerging analytical technologies of electronic tongues with electrochemical sensors and bioelectronic tongues involving biosensor arrays are studied in food applications [

8,

9,

10].

When an electronic tongue is employed, there are two key parameters that determine the detection of information,

i.e., the modeling tool and the type of sensors used [

11]. Voltammetric electronic tongues with voltammetric sensors are used extensively in electronic tongue systems. They have been applied for the qualitative/quantitative analysis of natural samples, wine, milk, tea, oil, or other liquid solutions [

12,

13,

14,

15,

16,

17,

18,

19,

20,

21,

22,

23,

24]. An array of noble metal working electrodes has been used in voltammetric electronic tongues to analyze different foodstuffs, tea, juices, and milk [

12,

13,

14,

15,

16]. Moreover, various materials such as polymers and epoxy-graphite have been used as coating membranes for sensor design. For example, Cetó

et al., developed a novel voltammetric electronic tongue containing modified epoxy-graphite electrodes for the qualitative and quantitative analysis of wine and beer [

17,

18,

19,

20,

21,

22,

23,

24].

Advanced data processing and pattern recognition methods are the fundamental part in any voltammetric electronic tongue system [

11]. Among previously reported studies on qualitative modelling and various data processing methods implemented, PCA has been mostly used as a qualitative visualization tool; and partial least squares Discriminant Analysis (PLS-DA), Linear Discriminant Analysis (LDA), cluster algorithm (CA), Support Vector Machine (SVM), and ANNs have been employed as qualitative modeling [

11,

25,

26,

27,

28,

29,

30,

31,

32] methods. However, Multiple Linear Regression (MLR), Principle Components Regression (PCR), PLS, or ANN are usually quantitative analysis tools [

33,

34,

35,

36,

37,

38,

39]. Despite the significant advantages provided by the reported data processing methods, the high complexity of the obtained data matrix makes the model building very difficult for the use of voltammetric sensors, therefore, some feature extraction and preprocessing methods for data compression and reduction must be applied to reduce input data dimensionality, training time, and to obtain better model ability. The data preprocessing may be achieved by the use of PCA, fast Fourier transform (FFT), or discrete wavelet transform (DWT) [

11,

20,

39].

The abovementioned discussion indicates that the voltammetric electronic tongue has several advantages and convenient features in the detection of liquid samples; however, the effect of taste detection in a solid food such as rice is unknown. Rice solutions which are dissolved in water contain certain water-soluble vitamins, inorganic salts, minerals, and rice bran oil containing a rich vitamin B and E composition. Different varieties of rice contain different quantitative water-soluble contents. Discrimination and recognition of the rice samples, with different quantities of this content, have seldom been evaluated using an electronic tongue taste sensor array. Consequently, it was necessary to develop an initial study to investigate whether the voltammetric array of sensors based on basic metal electrodes could detect these differences to output response signals of different samples under the excitation potential and then reflect the individual differences among sample solutions of different varieties of rice with proper data processing. Furthermore, in this study, an attempt was made to select a rice solution pretreatment method and to determine whether the rice needs to be crushed or not.

Thus, the main objective of this study was to construct a basis for the future use of a voltammetry-based electronic tongue, employing an array of metallic sensors for discrimination and prediction of different varieties of rice during rice harvest, storage, and processing. Moreover, a better and simpler rice sample pretreatment method was also proposed by comparing two such pretreatment methods. Specifically, an array of metallic working electrodes was applied as the sensing part. Cyclic voltammetry was set as excitation potential to obtain electrochemical response signals. The collected taste response signal data were first compressed by FFT. Discriminant Factorial Analysis (DFA) and radial basis function (RBF) artificial neural network were used as the discrimination and prediction modeling tools, respectively. Thus, this study provides a new perspective to the understanding of the discrimination and prediction of different varieties of rice by DFA and RBF artificial neural network by using an electronic tongue.

3. Results and Discussion

3.1. Voltammetry Characteristics of the Test Samples

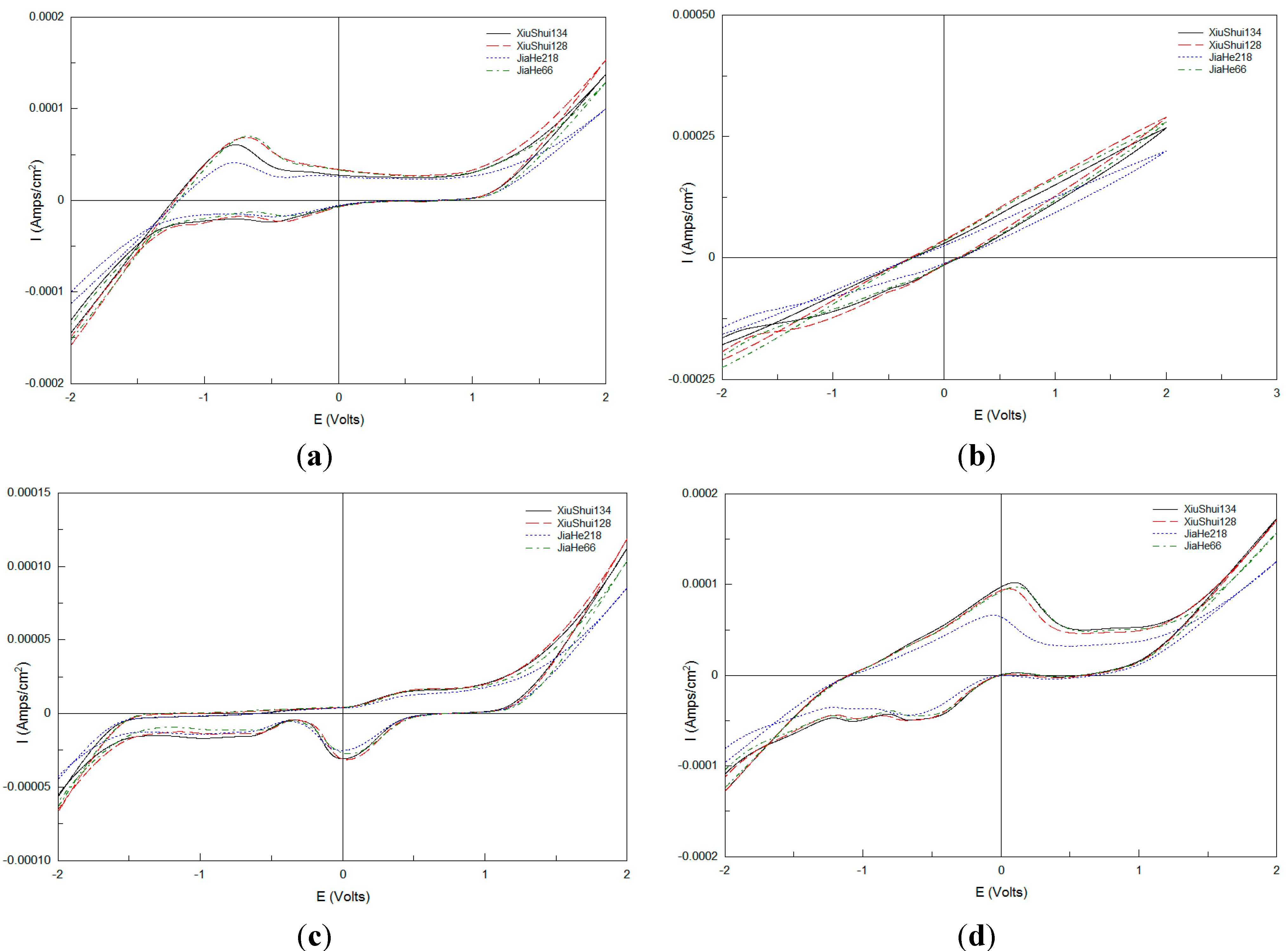

Figure 1 shows the voltammograms of four varieties of rice sample solution, obtained by the crushed rice pretreatment method, using four electrodes in the scanning potential range −2 to 2 V, at scan rate 200 mV∙s

−1 under a linear change of potential. The upper half curve is the reduction wave which is called the cathodic branch, while the lower half part is the oxidation wave, known as the anode branch. Response current values reached their peak and trough under +2 V and −2 V.

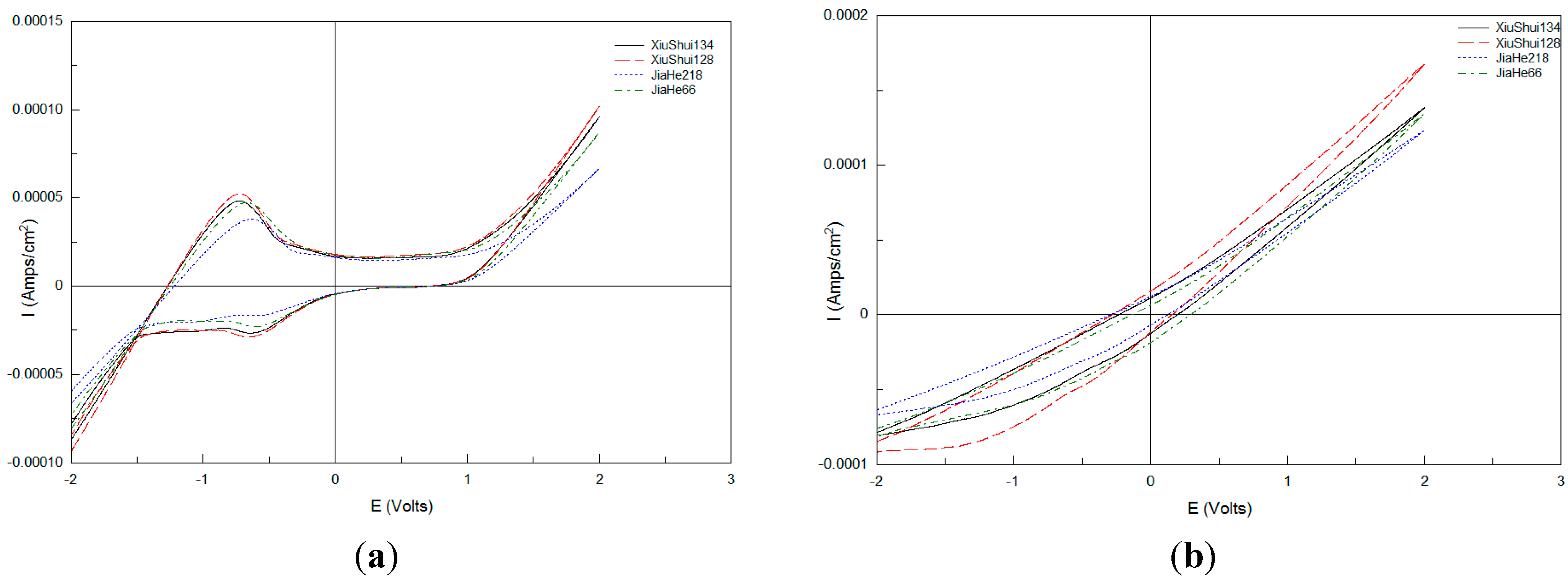

Figure 2 exhibits the voltammograms of four varieties of rice sample solution with the non-crushed rice pretreatment method obtained under the same condition.

Figure 1 and

Figure 2 show that both the four varieties of crushed and non-crushed rice sample solutions have a wide electrochemical window in which electrochemical reaction tests can be done and different cyclic voltammetry response curves under different electrodes were obtained with different varieties of rice tested.

Figure 1.

Voltammograms of four crushed rice sample solutions obtained using four electrodes. (a) Pt electrode; (b) Ag electrode; (c) Au electrode; (d) Pd electrode.

Figure 1.

Voltammograms of four crushed rice sample solutions obtained using four electrodes. (a) Pt electrode; (b) Ag electrode; (c) Au electrode; (d) Pd electrode.

Figure 2.

Voltammograms of four non-crushed rice sample solutions obtained using four electrodes. (a) Pt electrode; (b) Ag electrode; (c) Au electrode; (d) Pd electrode.

Figure 2.

Voltammograms of four non-crushed rice sample solutions obtained using four electrodes. (a) Pt electrode; (b) Ag electrode; (c) Au electrode; (d) Pd electrode.

3.2. Comparison of Current-Time Charts

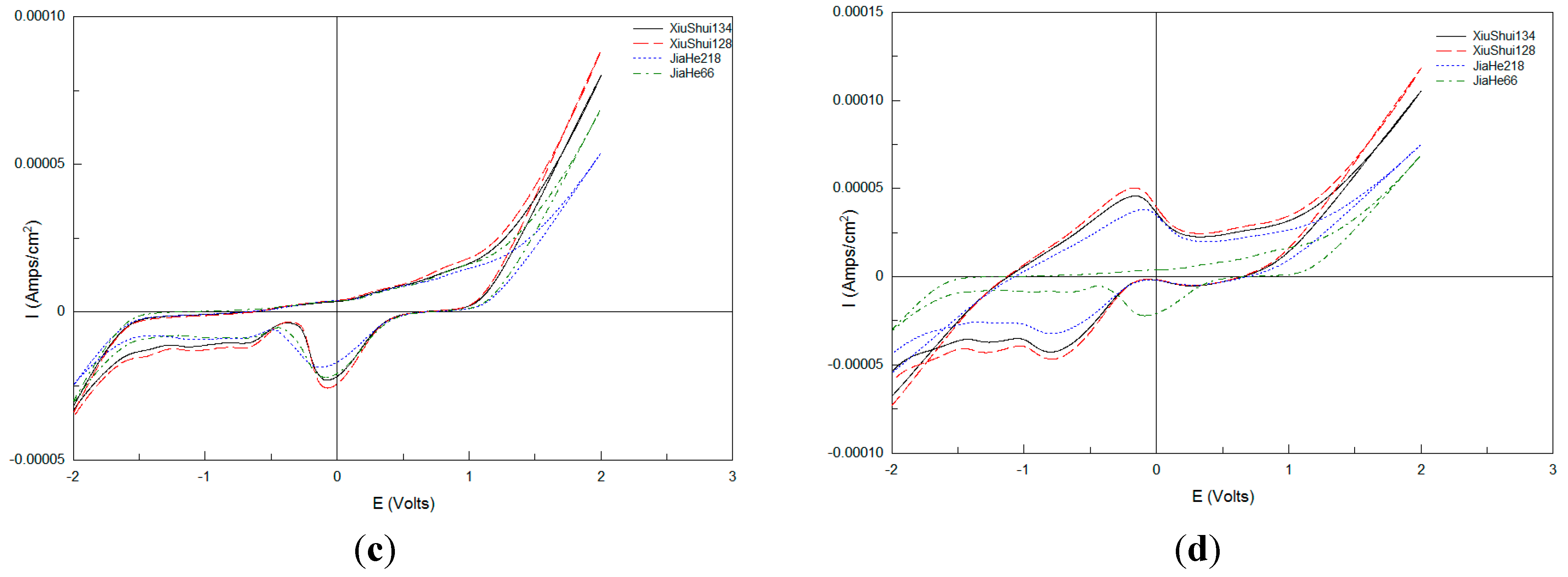

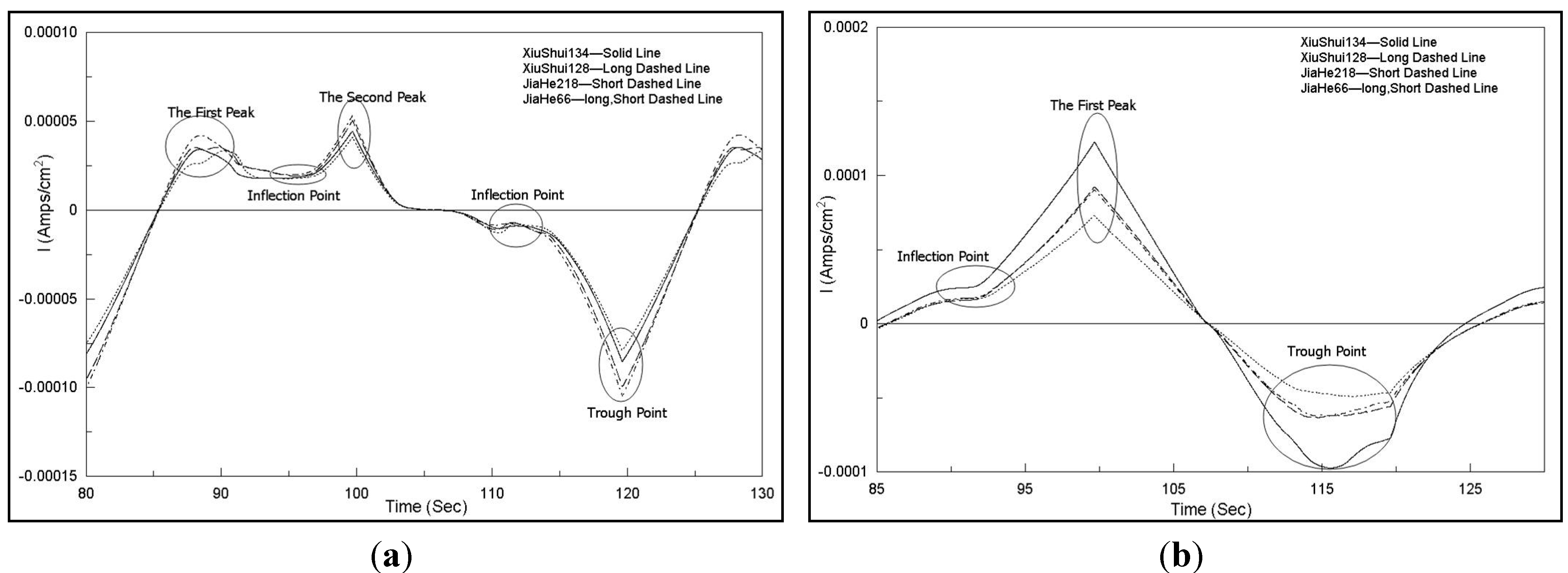

Current-time amplifying charts of all the four working electrodes obtained with one time data collection for four crushed rice sample solutions are shown in

Figure 3, which exhibits similar response curves for different crushed rice sample solutions, except for different details, especially in the peaks, troughs, and the inflection point with the same working electrode. Obvious differences in the cyclic voltammetry response curves with different working electrodes are observed. The differences in details, especially in the peaks, troughs, and the inflection points are also circled in

Figure 3. Different peaks, troughs, and the inflection points appeared by using different working electrodes. Five special data points are obtained with Pt electrodes (

Figure 3a); however, three, five, and five special data points are obtained with Ag, Au, and Pd electrodes, respectively.

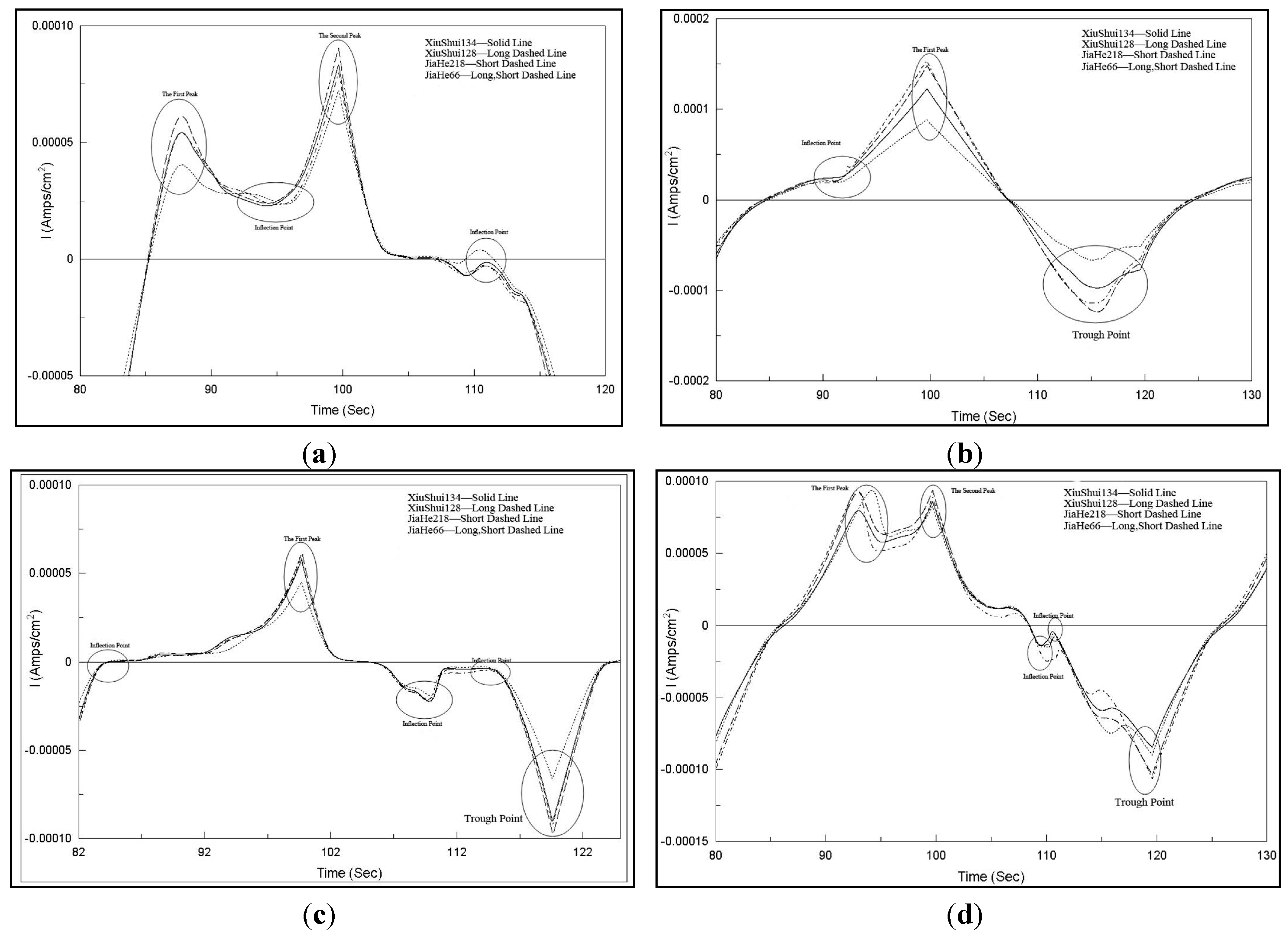

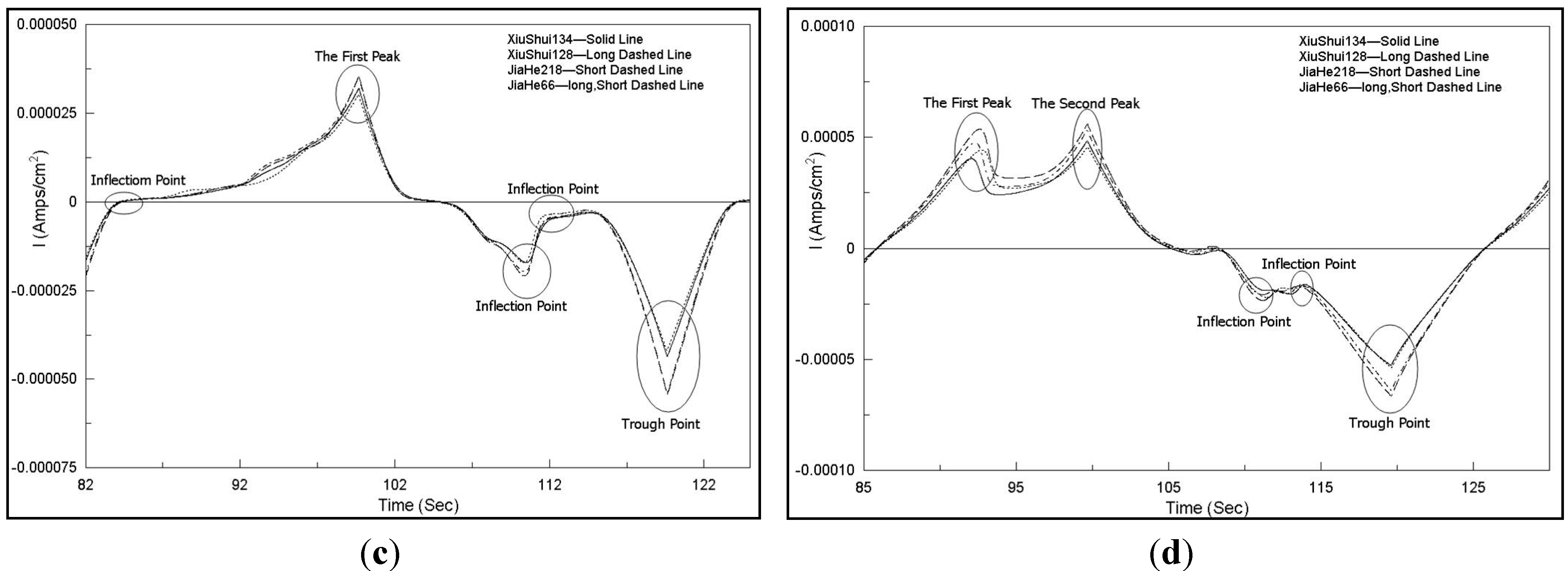

Similarly, the current-time charts for four non-crushed rice sample solutions are shown in

Figure 4. Similar to the abovementioned descriptions, good response current-time characteristics were obtained with different sensors. Different peaks, troughs, and the inflection points also appeared by using different working electrodes. Similar special data points could be obtained in the same electrode voltammograms. However, comparison of

Figure 3a and

Figure 4a to

Figure 3d and

Figure 4d, corresponding to the same electrode voltammograms obtained after using different rice sample pretreatment methods, indicates that the total current response values with the crushed rice grain pretreatment method are higher than that with non-crushed pretreatment method. Consequently, more information could be obtained with crushed rice samples, which caused the sensor array of the electronic tongue to generate higher response current signals.

Figure 3.

Current-time amplified charts of four working electrodes obtained with one time data collection for four crushed rice sample solutions. (a) Pt electrode; (b) Ag electrode; (c) Au electrode; (d) Pd electrode.

Figure 3.

Current-time amplified charts of four working electrodes obtained with one time data collection for four crushed rice sample solutions. (a) Pt electrode; (b) Ag electrode; (c) Au electrode; (d) Pd electrode.

Figure 4.

Current-time amplified charts of four working electrodes obtained with one time data collection for four non-crushed rice sample solutions. (a) Pt electrode; (b) Ag electrode; (c) Au electrode; (d) Pd electrode.

Figure 4.

Current-time amplified charts of four working electrodes obtained with one time data collection for four non-crushed rice sample solutions. (a) Pt electrode; (b) Ag electrode; (c) Au electrode; (d) Pd electrode.

3.3. Discrimination of Different Rice Samples Using DFA

3.3.1. Discrimination of Crushed Rice Sample Solutions

In order to compress the original data set and confirm the differentiated behavior, the original voltammetric responses data were compressed by using 16 FFT with the selected 64 FFT coefficients (each sensor response data corresponding to 16 FFT coefficients), and the obtained coefficients were analyzed by employing DFA.

Using the classical discriminant analysis method eigenvalues and accumulated contribution rate were obtained, which are listed in

Table 3. The values listed in

Table 3 indicate that the first discriminant function explains 86.8% of the original data information, the second function explains 12.9%, and the third function explains 0.4%. Notably, with just the first two discriminant functions, the accumulated contribution rate was up to 99.7%. Significantly large value indicated that most original data information could be represented by only these two new coordinates, leading to the determination of the differences in rice samples. Discrimination Index (DI) value was 96.

Figure 5a displays the discrimination effect plot obtained after DFA analysis of the four varieties of crushed rice sample solutions.

Figure 5a clearly shows the separation of all the samples into four distinct clusters. The DFA plot shows that the sample solutions belonging to the same category are group in clusters around each group centroid, respectively. The same variety was nearby; however, the distance among the different groups was large. The above mentioned analysis showed that DFA could be a supervised method to distinguish different varieties of rice and the effect of discrimination was better.

Figure 5.

Discrimination of rice sample solutions by employing DFA analysis. (a) Crushed rice; (b) Non-crushed rice. (Ο) XiuShui134, (*) XiuShui128, (⊿) JiaHe218, and (Δ) JiaHe66, also the centroid of each class is plotted (+).

Figure 5.

Discrimination of rice sample solutions by employing DFA analysis. (a) Crushed rice; (b) Non-crushed rice. (Ο) XiuShui134, (*) XiuShui128, (⊿) JiaHe218, and (Δ) JiaHe66, also the centroid of each class is plotted (+).

Table 3.

Classical discriminant analysis results for rice solutions.

Table 3.

Classical discriminant analysis results for rice solutions.

| Function | Crushed | Non-Crushed |

|---|

| Eigenvalue | Contribution | Correlation | Eigenvalue | Contribution | Correlation |

|---|

| D1 | 177.630 | 86.8% | 0.997 | 1743.571 | 94.1% | 1.000 |

| D2 | 32.034 | 99.7% | 0.985 | 13.982 | 98.5% | 0.996 |

| D3 | 0.041 | 100.0% | 0.198 | 0.541 | 100.0% | 0.593 |

3.3.2. Discrimination of Non-Crushed Rice Sample Solutions

In order to compare the discrimination effect of the crushed rice sample solutions, the same voltammetric data preprocessed method using FFT and DFA analysis were used for the discrimination of non-crushed rice sample solutions.

Eigenvalues and accumulated contribution rate for the non-crushed rice sample solutions are also listed in

Table 3. The values listed in

Table 3 indicate that the first discriminant function explains 94.1% of the data information and the second function explains 4.4%. Thus, the total accumulated contribution rate of the first two discriminant functions is 98.5%, indicating that the first two discriminant functions can explain majority of the original data information without any significant loss in the information. Discrimination Index (DI) value is 98.

The discrimination plot of the rice sample solutions employing DFA analysis is shown in

Figure 5b, revealing that different varieties of non-crushed rice sample solutions are distributed away from each other. The space within the same variety is less; however, the distance among the different groups was large, indicating good data repeatability and a clear distinction between different samples. Thus, the rice sample solutions with non-crushed pretreatment method can also be efficiently discriminated by DFA analysis.

The abovementioned analysis of the rice sample solutions through two different pretreatment methods showed that DFA could efficiently discriminate different rice samples obtained by both pretreatment methods, except that the current response values with non-crushed pretreatment were lower. The results of the crushed pretreatment method indicated that the four varieties of rice could be well distinguished with DI value of 96. Interestingly, the discrimination effect was also perfect for non-crushed pretreatment methods with DI value of 98. The pretreatment of crushed rice was more complex because it involved crushing, dissolving, centrifuging, and filtering prior to the test; therefore, non- crushed pretreatment methods could be considered as a better choice to perform discrimination and later recognition modeling of electronic tongue to simplify the rice pretreatment process and pretreatment time. The total DFA analysis results provided the basis for the optimization and selection of the rice pretreatment method.

3.4. Prediction of Different Unknown Samples of Rice Using RBF Neural Network

To further assess the ability of the electronic tongue for the identification of unknown rice samples, a RBF neural network prediction model was attempted. Good discrimination results were observed, which indicated that different varieties of rice could be distinguished by using the non-crushed sample solutions; therefore, further tests and analysis were performed on the four varieties of non-crushed rice samples. The test samples were obtained by the steps described in

Section 2.2.3.

The recognition and prediction of the unknown variety of rice were modeled by using RBF neural network from the voltammetric responses data, previously compressed with FFT. The final structure of the RBF neural network was designed as 64-32-1 after a systematic study to optimize its topology. The number of input neurons was 64, and they were corresponding to the FFT coefficients of the four metallic sensors, and 16 separate coefficients for each sensor as before. Thirty two neurons were set in the hidden layer and one neuron in the output layer. The output values 1, 2, 3, and 4 correspond to “JiaHe218”, “JiaHe66”, “XiuShui128”, and “XiuShui134”, respectively.

The recognition and prediction effect of RBF neural network with leave-one-out cross-validation approach was studied. The recognition and prediction results are listed in

Table 4. Rows indicated expected rice class and columns predicted ones. All the varieties of rice samples with four concentration gradients were measured and predicted. The values listed in

Table 4 indicate that at 0 dilution, the recognition success rate of the four types of rice samples reached 95% of accuracy. As aforementioned, the obtained recognition efficiency of the RBF neural network also evaluated specificity and sensitivity. The value of specificity, averaged for the four classes considered was 98.3% and that of sensitivity was 95%. When recognizing rice samples with 5 times dilution, the correct recognition rate decreased significantly down to 85%, and when diluted 10 times and 100 times, the prediction accuracy of rice samples decreased down to 45% and 7.5%, respectively. The value of specificity also dropped from 95% to 81.7% and finally to 69.2% corresponding to rice sample solutions with dilution of 5 times, 10 times, and 100 times, respectively. Moreover, sensitivity dropped from 85% to 45% and finally to 7.5%. Thus, consequently, when the sample was diluted 100 times, the RBF neural network prediction model was less effective, it could correctly recognize only six out of a total 80 samples.

Table 4.

Prediction results of RBF neural network using leave-one-out cross validation approach.

Table 4.

Prediction results of RBF neural network using leave-one-out cross validation approach.

| Dilution Times | Expected | Predicted | Sensitivity |

|---|

| XiuShui134 | XiuShui128 | JiaHe218 | JiaHe66 | Accuracy | Specificity |

|---|

| 0 | XiuShui134 | 20 | 0 | 0 | 0 | 95% | 98.3% | 95% |

| XiuShui128 | 0 | 18 | 0 | 2 |

| JiaHe218 | 1 | 0 | 19 | 0 |

| JiaHe66 | 0 | 1 | 0 | 19 |

| 5 | XiuShui134 | 18 | 0 | 2 | 0 | 85% | 95% | 85% |

| XiuShui128 | 1 | 16 | 0 | 3 |

| JiaHe218 | 2 | 0 | 17 | 1 |

| JiaHe66 | 0 | 2 | 1 | 17 |

| 10 | XiuShui134 | 10 | 3 | 7 | 0 | 45% | 81.7% | 45% |

| XiuShui128 | 0 | 7 | 6 | 7 |

| JiaHe218 | 6 | 0 | 10 | 4 |

| JiaHe66 | 0 | 8 | 3 | 9 |

| 100 | XiuShui134 | 3 | 4 | 8 | 5 | 7.5% | 69.2% | 7.5% |

| XiuShui128 | 4 | 1 | 5 | 10 |

| JiaHe218 | 11 | 3 | 1 | 5 |

| JiaHe66 | 3 | 12 | 4 | 1 |

In all, the RBF neural network could be used effectively to distinguish different varieties of rice; however, at different concentrations, the ability of RBF neural network to identify rice samples was markedly different. When the sample dilution ratio was more than 10 times, RBF exhibited worse rice variety identification performance.

Finally, in order to confirm the effectiveness of the FFT data preprocessing or compressing method, other original voltammetric data preprocessing methods were attempted to compare the performance of the prediction model with different preprocessing methods. As stated in

Section 3.2, different rice sample solutions exhibited different details especially in the peaks, troughs, and the inflection point circled in

Figure 3 and

Figure 4. The ability to recognize the rice variety using only these data details was observed. Response current peak value, the inflection point value, and trough value of each sensor for all 80 samples at each concentration were selected as the eigenvalues for model input. Concretely, five eigenvalues were extracted from Pt electrode, Au electrode, and Pd electrode, respectively. However, three eigenvalues were extracted from Ag electrode.

Therefore, the structure of the RBF neural network was designed as 18-13-1 after model optimization. The number of input neurons was 18, and they corresponded to the eigenvalues of the four metallic sensors, separately number 5, 5, 5, and 3 for each sensor, 13 neurons in the hidden layer and one neuron in the output layer. Consequently, the prediction accuracy was demoted to 91.25%, 77.5%, 40%, and 3.75% respectively corresponding to rice sample solutions with different dilution. Therefore, it was confirmed that in contrast to the preprocessing method of feature value extraction, the best RBF neural network performance was obtained by using FFT.

4. Conclusions

A voltammetric electronic tongue, based on the combination of metallic sensors, was researched in order to create a suitable tool for discrimination and prediction of different varieties of rice. The sensor array coupled with data compression method, statistical method, and pattern recognition method, namely, FFT, DFA, and RBF artificial neural network, respectively, were employed to discriminate and predict different types of rice. DFA was established for selecting the rice pretreatment methods and discrimination of different varieties. A RBF neural network with leave-one-out cross validation approach realized recognition and prediction. According to the RBF neural network model, 95% of rice sample solutions with no dilution were correctly recognized. The results of this study showed that the voltammetric electronic tongue was a useful tool for qualitative analysis of rice. This study undertook a preliminary exploration of taste assessment in solid food using voltammetric electronic tongue technology. However, the variety and quantity of samples were not sufficient for further research and the application effect of experimental results needs further study and in-depth discussion of practical applications. Further, different data preprocessing methods and more modeling are necessary to confirm the validity of this system for qualitative analysis of rice. Undeniably, a lot more systematic explorations are demanded for the detection of specific rice gustatory or non-volatile substances information by employing the electronic tongue.