Novel Method for Processing the Dynamic Calibration Signal of Pressure Sensor

Abstract

:1. Introduction

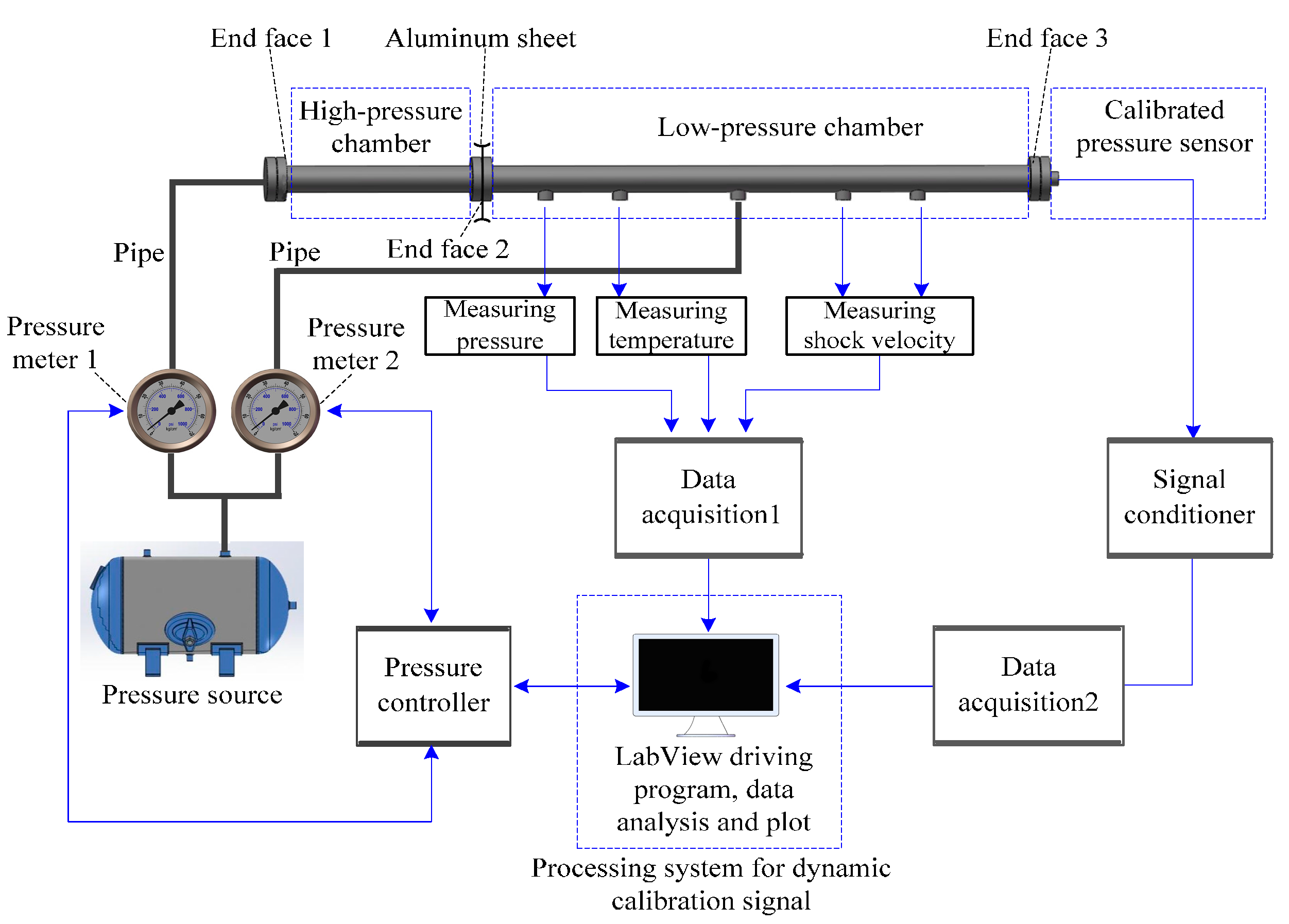

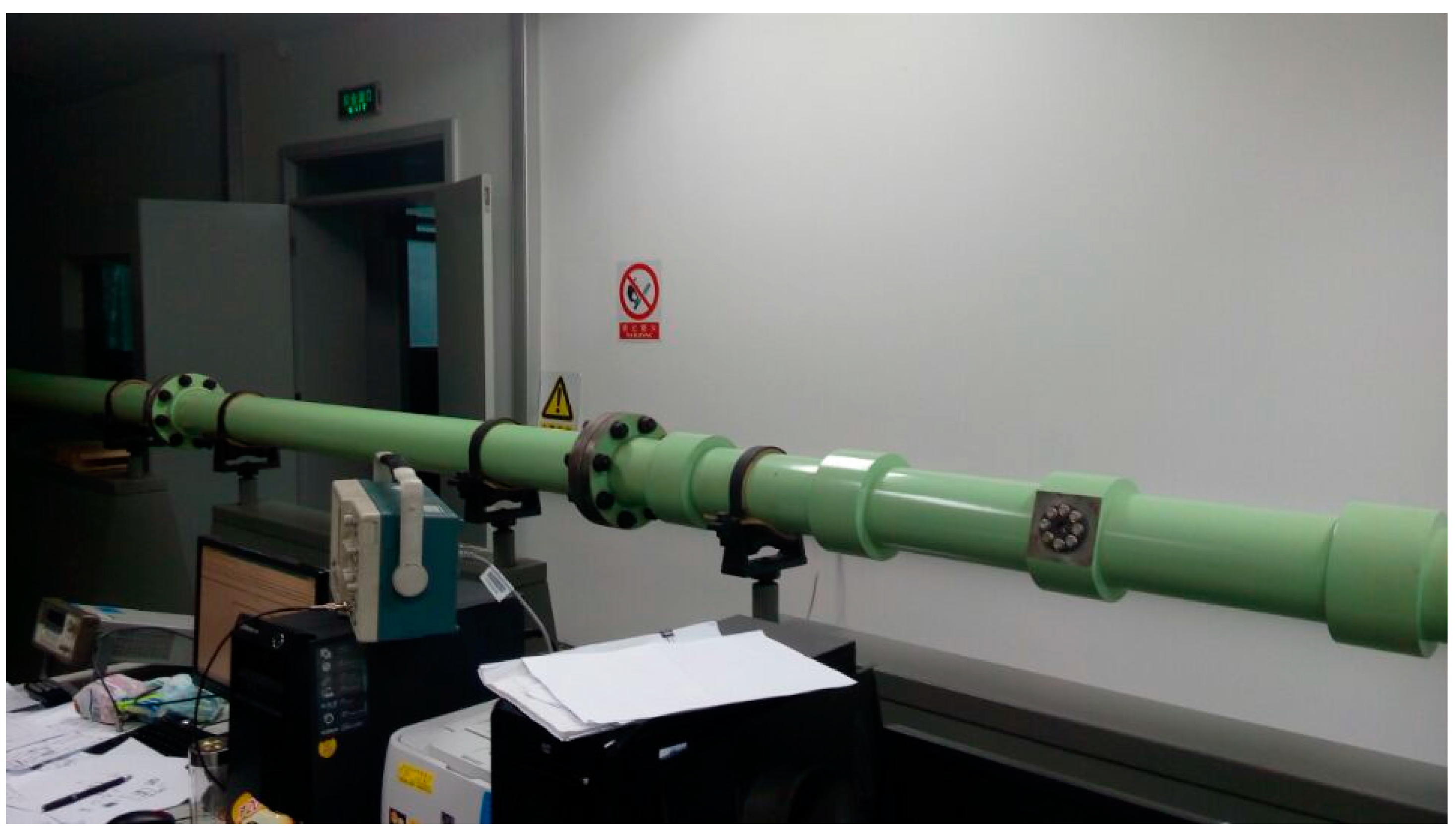

2. Hardware Description of the Shock Tube Calibration System

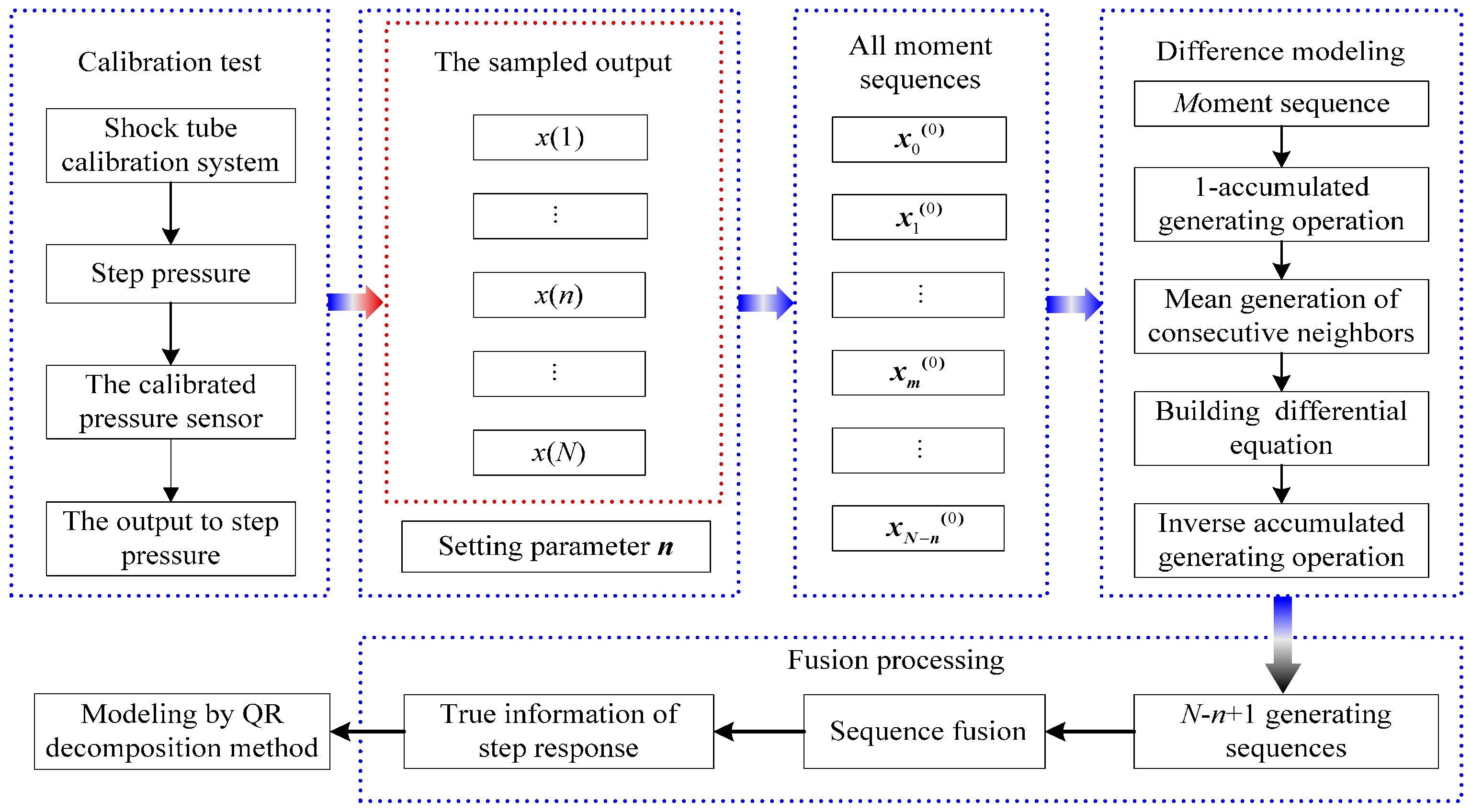

3. Dynamic Calibration Signal Processing

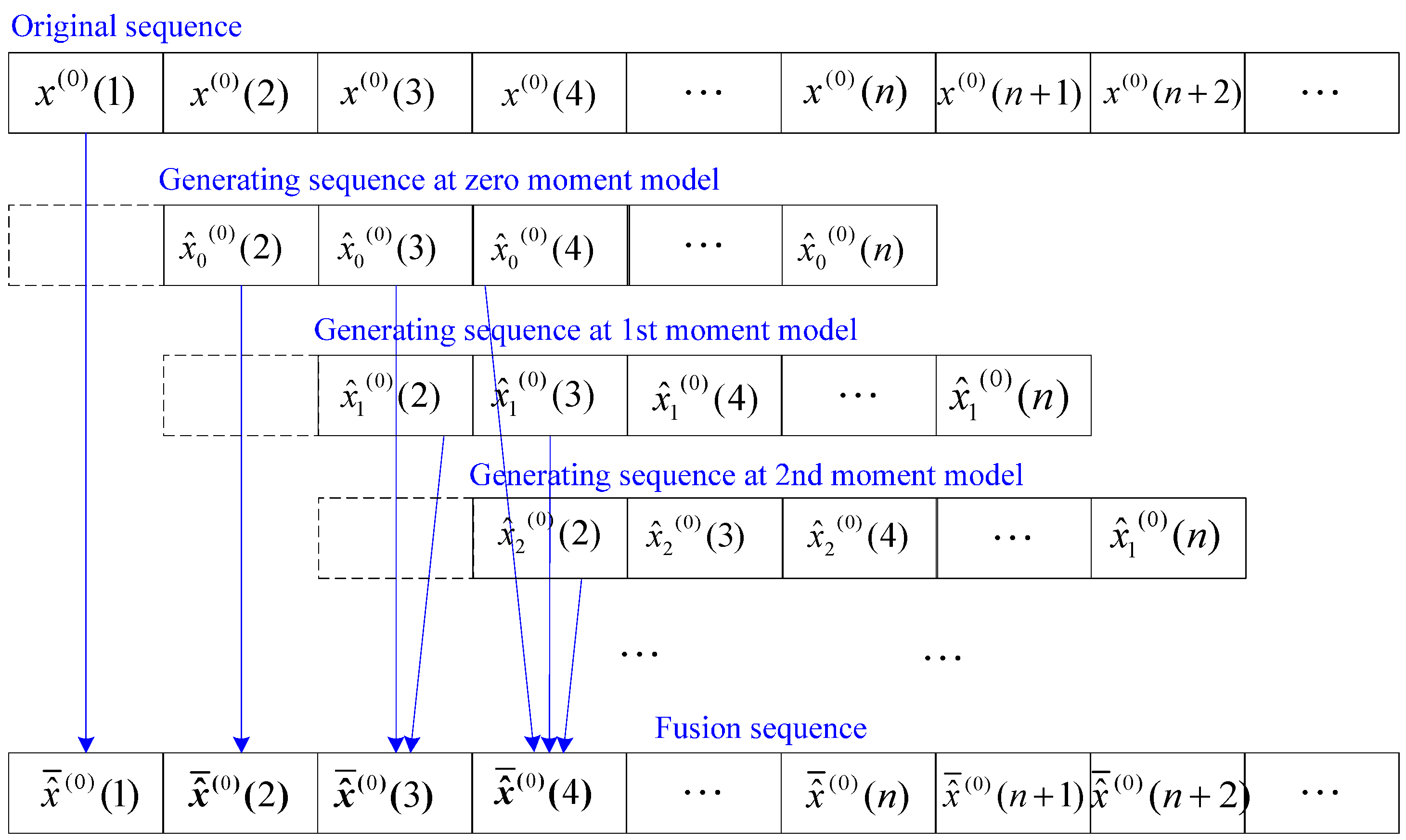

3.1. Method Principle

3.2. Processing Algorithm

4. Experiments

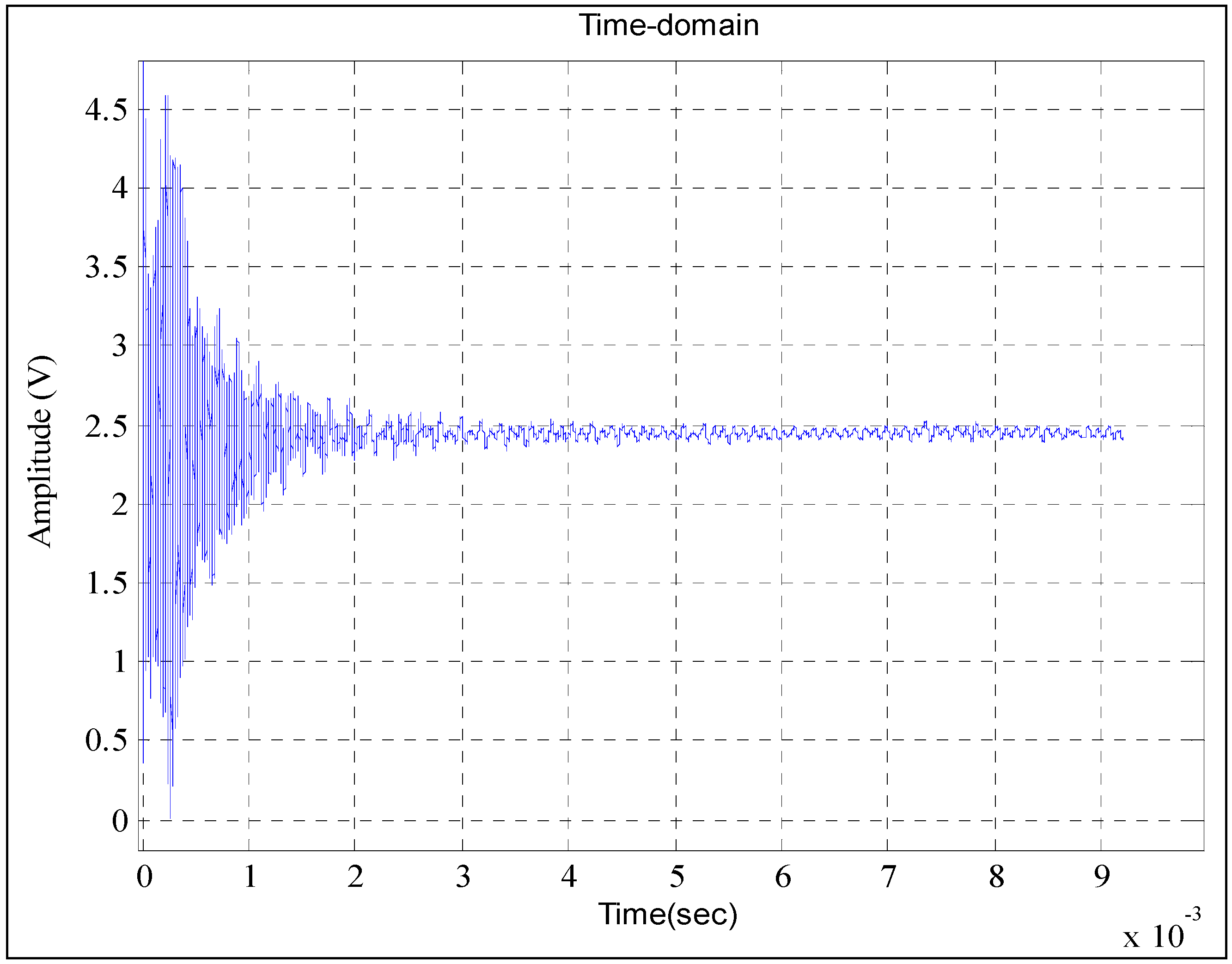

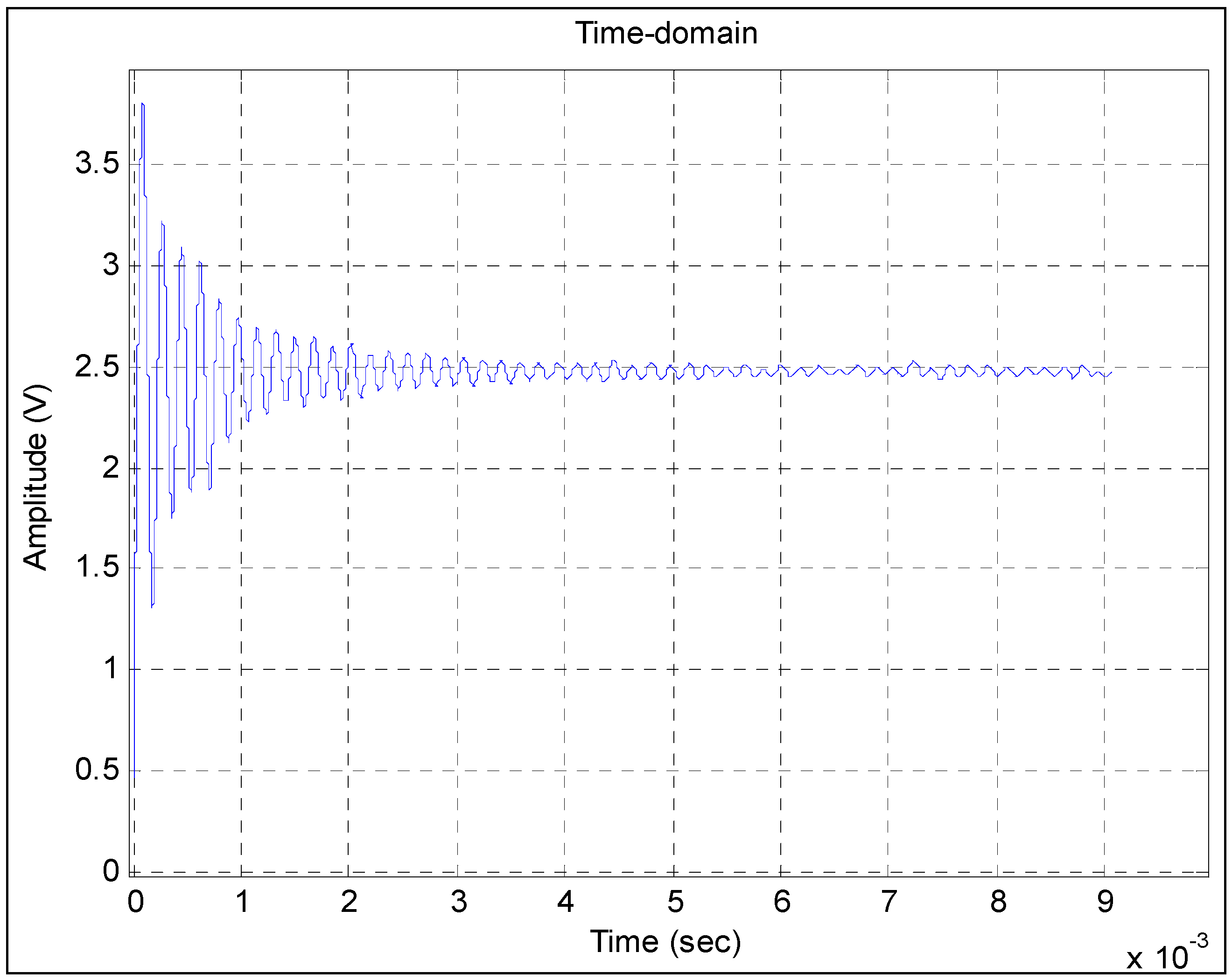

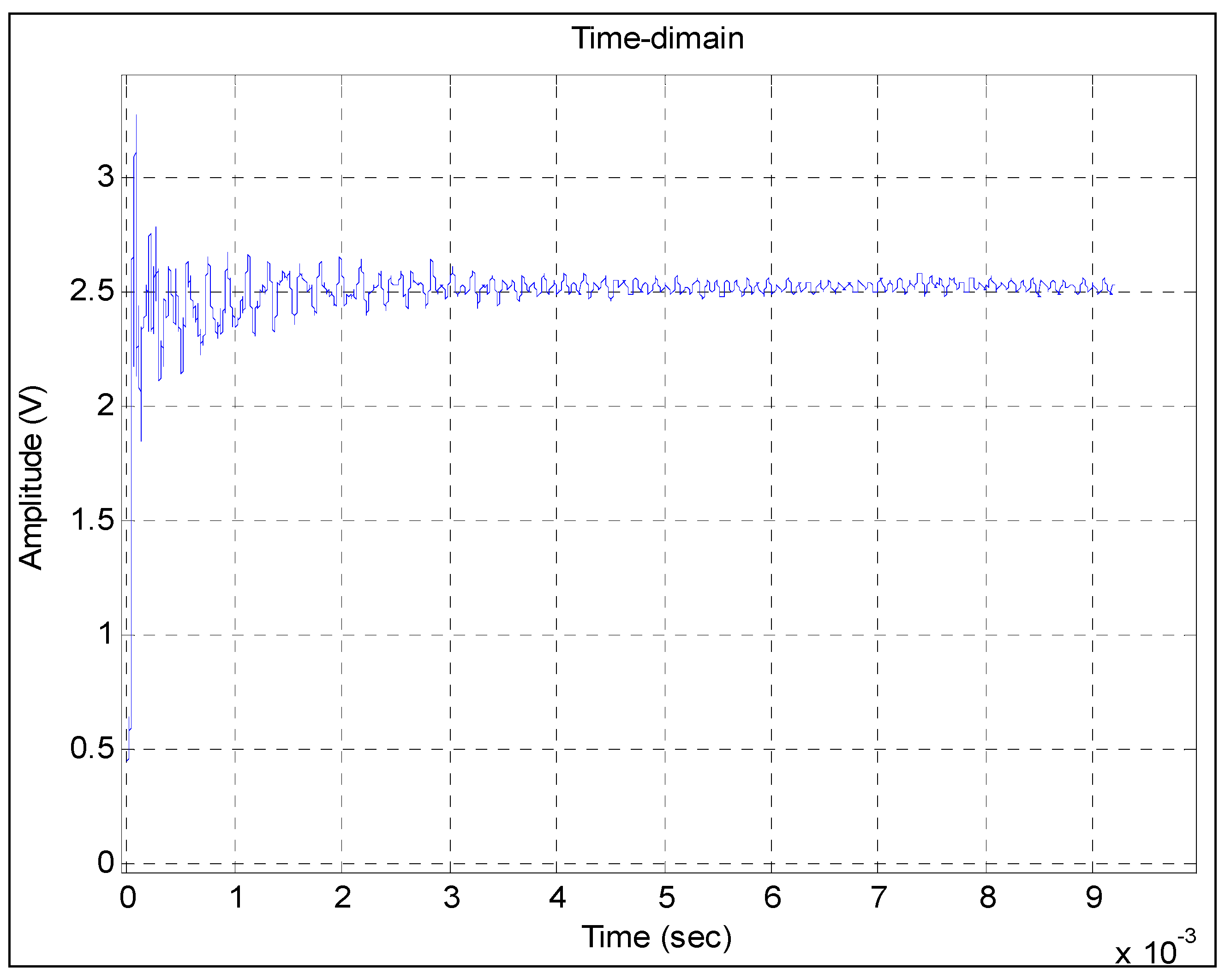

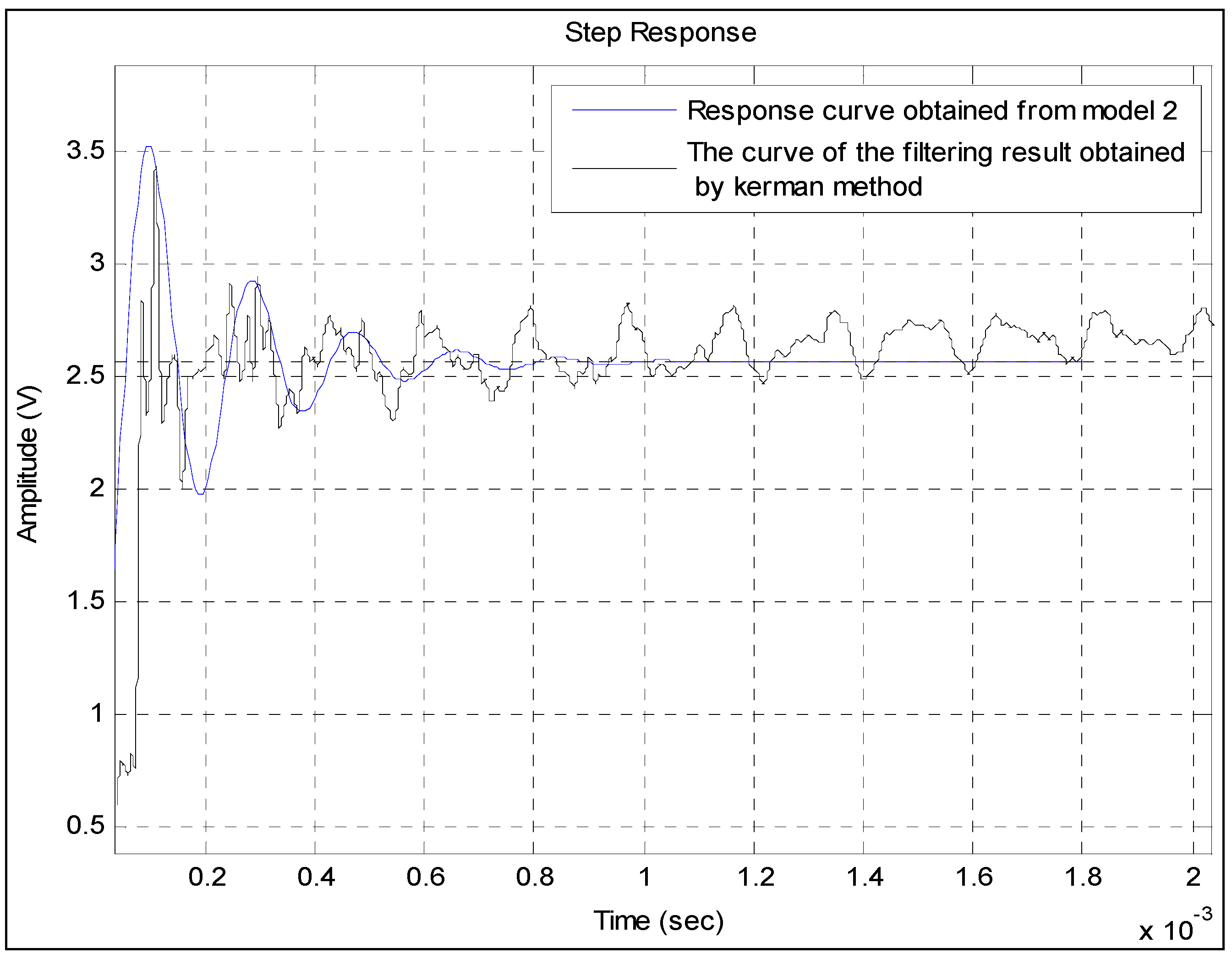

4.1. Experimental Results of the Shock Tube Calibration

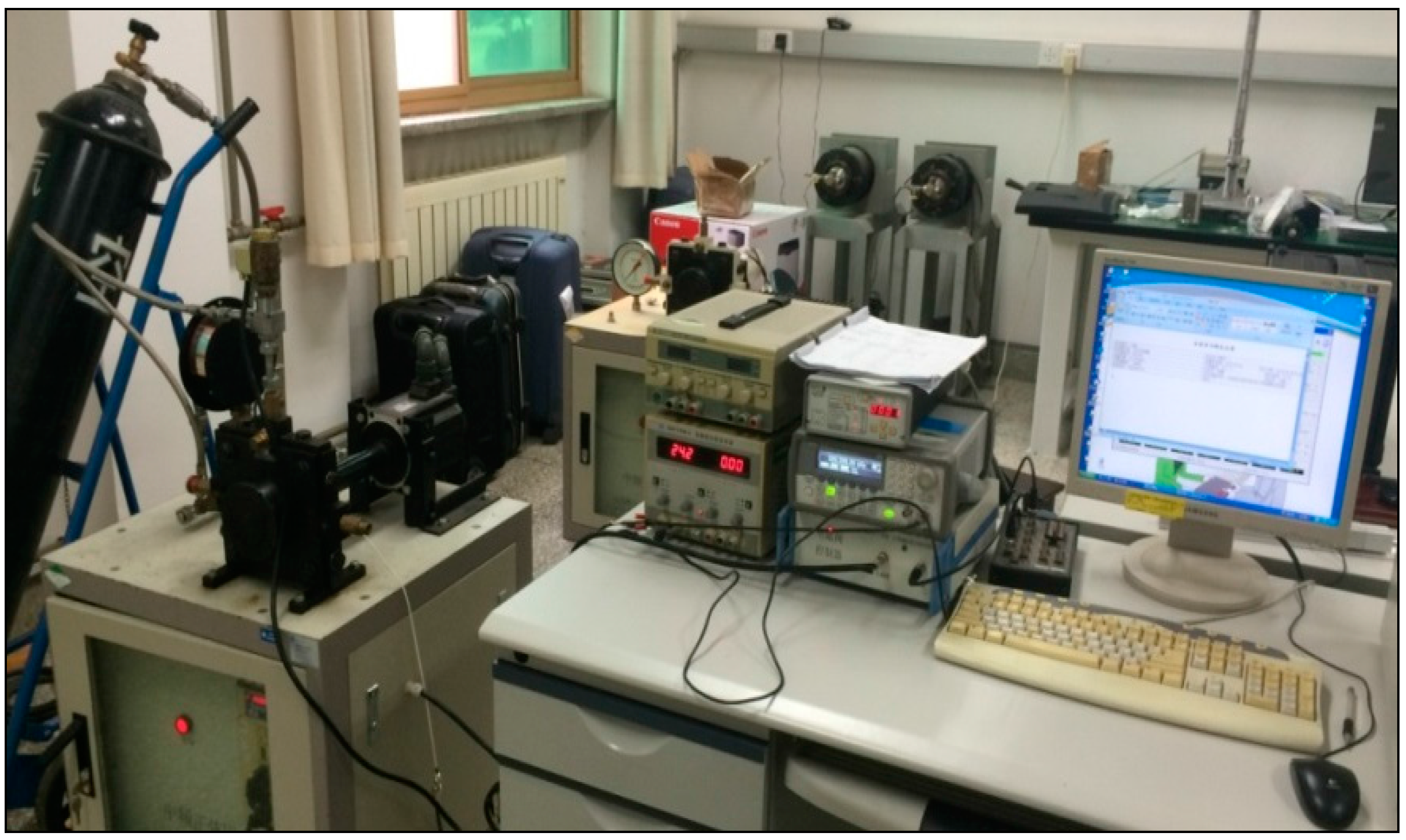

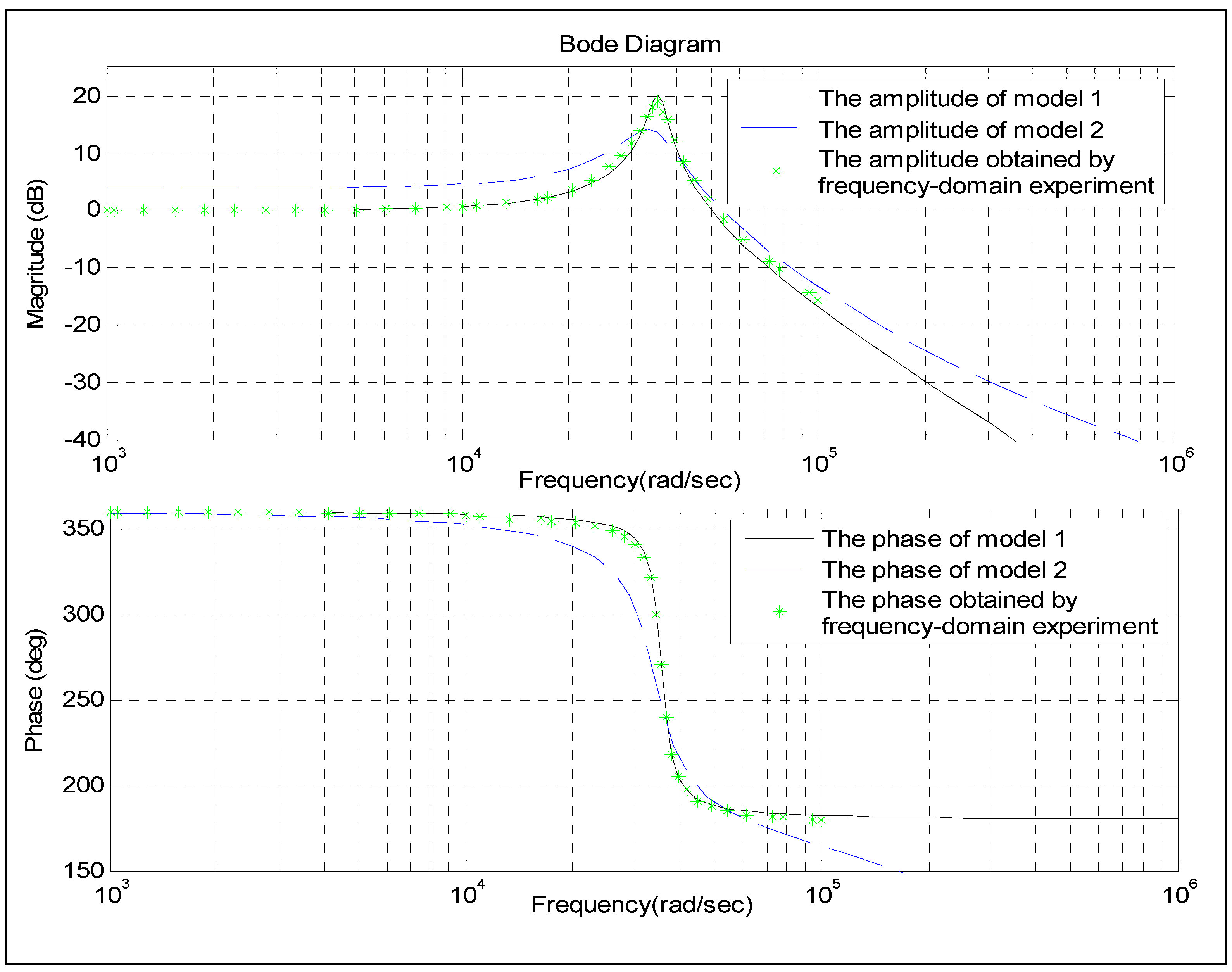

4.2. Experimental Results of the Frequency-Domain Experiment

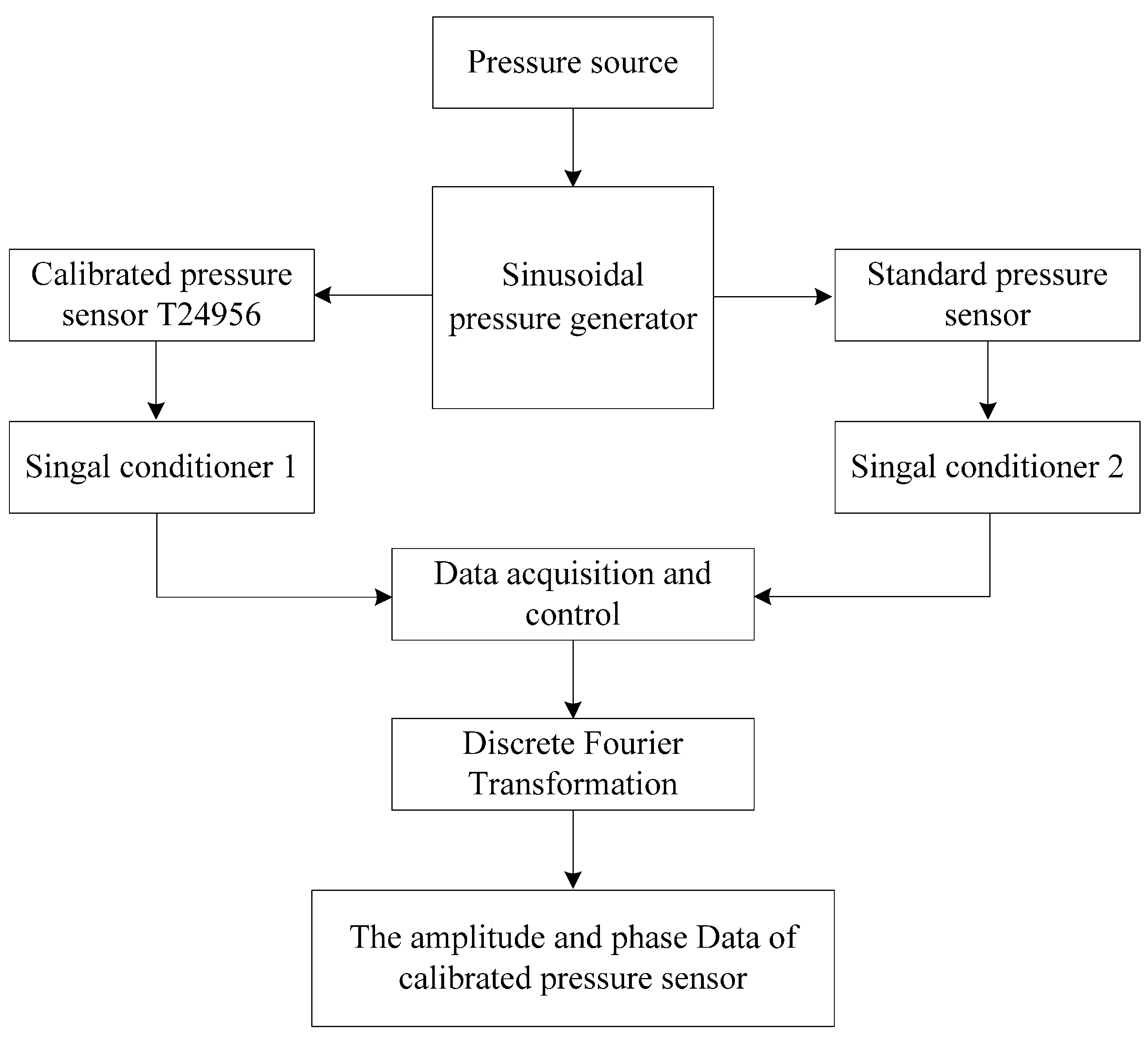

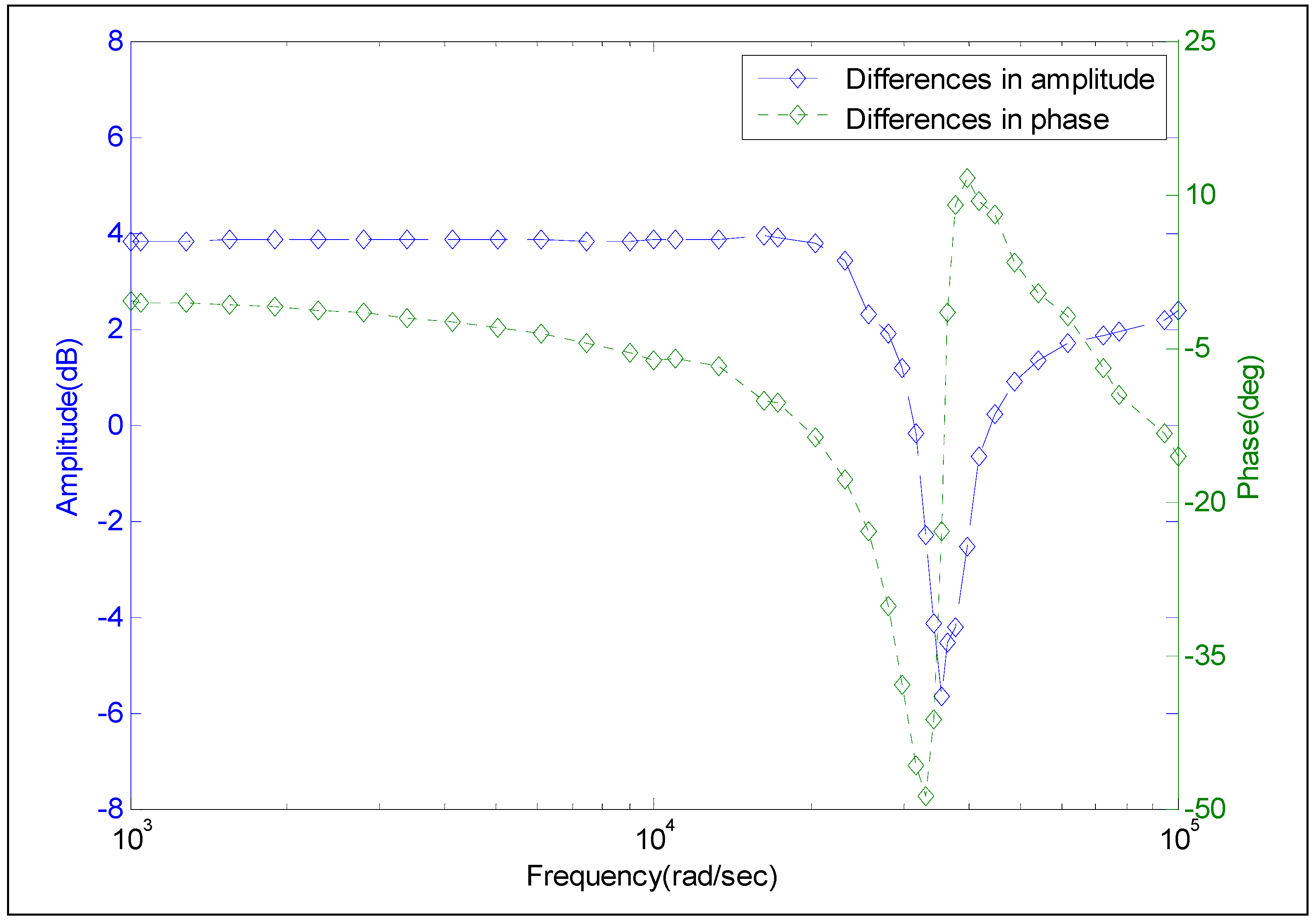

- (1)

- A sinusoidal pressure generator is recognized to simultaneously excite two pressure sensors at frequency fi (i = 1, 2,…, n). Meanwhile, the outputs of the two pressure sensors are separately processed by signal conditioners, with the output of the standard pressure sensor as the true information of the generated sinusoidal pressure. The processed signals are then collected by data acquisition, acquiring two discrete voltage sequences.

- (2)

- Discrete Fourier Transformation is applied to separately handle the two voltage sequences, and the amplitude Afi1 (i = 1, 2,…, n) of the sinusoidal pressure produced in the experiment and the corresponding phase θfi1 (i = 1, 2,…, n) are found. Similarly, the amplitude Afi2 (i = 1, 2,…, n) and the corresponding phase θfi2 (i = 1, 2,…, n) measured using the pressure sensor T24956 for the sinusoidal pressure are obtained.

- (3)

- Comparing the amplitude and phase measured by standard pressure sensor with those measured by the pressure sensor T24956 at frequency fi (i = 1, 2,…, n), the phase shift and amplitude sensitivity error of pressure sensor T24956 are determined. The accurate frequency characteristic of the pressure sensor T24956 is consequently found.

| Indices of Sinusoidal Pressure Generator | Parameters | Indices of the Standard Pressure Sensor | Parameters | |

|---|---|---|---|---|

| Calibrated pressure range | 0–5 MPa | Amplitude sensitivity error [6] | ±2 dB | |

| Operating frequency range | 0.1–120,000 Hz | Measurement uncertainty of phase angle [6] | ±0.5° | |

| Degree of waveform distortion [3] | 0.1–10,000 Hz | 0.5%–1% | Measurement uncertainty of amplitude sensitivity [6] | <1% |

| 10,000–30,000 Hz | 1%–2% | |||

| 30,000–70,000 Hz | 2%–4% | Static accuracy level [6] | 1 grades | |

| 70,000–120,000 Hz | 4%–7% | |||

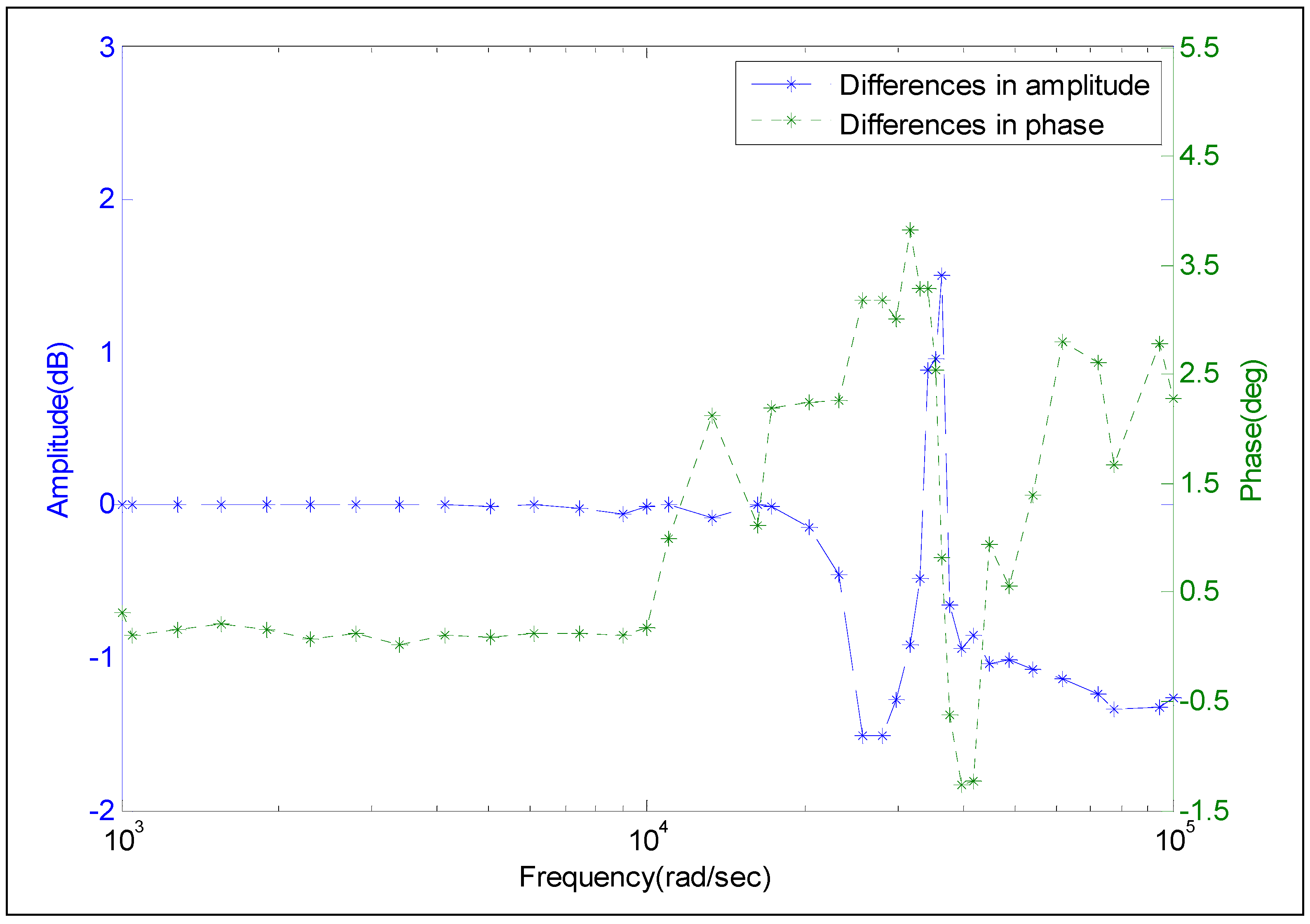

4.3. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Revel, G.M.; Pandarese, G.; Cavuto, A. The development of a shock-tube based characterization technique for air-coupled ultrasonic probes. Ultrasonics 2014, 54, 1545–1552. [Google Scholar] [CrossRef] [PubMed]

- ISA. A Guide for the Dynamic Calibration of Pressure Transducers; The Instrumention, Systems, and Automation Society: Research Triangle Park, NC, USA, 2002. [Google Scholar]

- Huang, J. Measurement System Dynamics and Its Application; National Defense Industry Press: Beijing, China, 2013; pp. 76–80. [Google Scholar]

- Yang, W.R.; Wang, F.; Yang, Q.X.; Zhang, W.; Zhang, B.; Wang, Y. A Novel Sinusoidal Pressure Generator Based on Magnetic Liquid. IEEE Trans. Magn. 2012, 48, 575–578. [Google Scholar] [CrossRef]

- Downes, S.; Knott, A.; Robinson, I. Towards a shock tube method for the dynamic calibration of pressure sensors. Philos. Trans. R. Soc. Math. Phys. Eng. Sci. 2014. [Google Scholar] [CrossRef] [PubMed]

- JJG 624-2005. In Verification Regulation of Dynamic Pressure Sensors; China State Bureau of National Defense: Beijing, China, 2005.

- Ansari, A.; Noorzad, A.; Zafarani, H.; Vahidifard, H. Correction of highly noisy strong motion records using a modified wavelet de-noising method. Soil Dyn. Earthq. Eng. 2010, 30, 1168–1181. [Google Scholar] [CrossRef]

- Wu, N.; Li, Y.; Yang, B. Noise attenuation for 2-D seismic data by radial-trace time-frequency peak filtering. IEEE Geosci. Remote Sens. Lett. 2011, 8, 874–878. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, D.; Su, W.; Gu, C.H. A new fuzzy nesting multilevel median filter and its application to seismic data processing. Chin. J. Geophys. Chin. Ed. 2007, 50, 1534–1542. [Google Scholar]

- Chen, Z. Dynamic self-calibration of time grating sensors based on self-adaptive Kalman filter algorithm. In Proceedings of the Sixth International Symposium on Precision Mechanical Measurements, Guiyang, China, 8 August 2013.

- Zhang, J.; Miao, T. A generalized least square method with special whitening filter. Chin. J. Aeronaut. 1985, 6, 572–577. [Google Scholar]

- Wang, Z.; Meng, H.; Fu, J. Separation method for surface comprehensive topography based on grey theory. Measurement. Chin. J. Sci. Instrum. 2008, 29, 1810–1815. [Google Scholar]

- Wang, Q.; Fu, J.; Wang, Z. A seismic intensity estimation method based on the fuzzy-norm theory. Soil Dyn. Earthq. Eng. 2012, 40, 109–117. [Google Scholar] [CrossRef]

- Xu, K.J.; Zhu, Z.H.; Zhou, Y. Applied digital signal processing systems for vortex flowmeter with digital signal processing. Rev. Sci. Instrum. 2009, 80. [Google Scholar] [CrossRef] [PubMed]

- Xu, K.J.; Luo, Q.L.; Wang, G. Frequency-feature based antistrong-disturbance signal processing method and system for vortex flowmeter with single sensor. Rev. Sci. Instrum. 2010, 81, 075104. [Google Scholar] [CrossRef] [PubMed]

- Xu, K.J.; Luo, Q.L.; Fang, M. Anti-strong-disturbance signal processing method of vortex flowmeter with two sensors. Rev. Sci. Instrum. 2011, 82. [Google Scholar] [CrossRef] [PubMed]

- Xu, K.J.; Luo, Q.L.; Zhu, Y.Q.; Liu, S.S.; Zhu, Z.H. Features of amplitude and frequency of vortexflow sensor signal. Acta Metrol. Sin. 2010, 31, 504–508. [Google Scholar]

- Yang, S.L.; Xu, K.J. Frequency-domain correction of sensor dynamic error for step response. Rev. Sci. Instrum. 2012, 83. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Li, Q. Novel Method for Evaluating the Dynamic Calibration Uncertainty of Pressure Transducer by Grey Processing. J. Grey Syst. 2015, 27, 54–67. [Google Scholar]

- Li, Q.; Wang, Z. Novel method for estimating the dynamic characteristics of pressure sensor in shock tube calibration test. Rev. Sci. Instrum. 2015, 86. [Google Scholar] [CrossRef] [PubMed]

- Kalman, R.H. New Methods in Wiener Filtering Theory; John Wiley & Sons Inc.: New York, NY, USA, 1963. [Google Scholar]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Li, Q.; Wang, Z.; Yan, H. Novel Method for Processing the Dynamic Calibration Signal of Pressure Sensor. Sensors 2015, 15, 17748-17766. https://doi.org/10.3390/s150717748

Wang Z, Li Q, Wang Z, Yan H. Novel Method for Processing the Dynamic Calibration Signal of Pressure Sensor. Sensors. 2015; 15(7):17748-17766. https://doi.org/10.3390/s150717748

Chicago/Turabian StyleWang, Zhongyu, Qiang Li, Zhuoran Wang, and Hu Yan. 2015. "Novel Method for Processing the Dynamic Calibration Signal of Pressure Sensor" Sensors 15, no. 7: 17748-17766. https://doi.org/10.3390/s150717748