Processing and Characterization of a Novel Distributed Strain Sensor Using Carbon Nanotube-Based Nonwoven Composites

Abstract

:1. Introduction

2. Sensor Manufacturing and Characterization

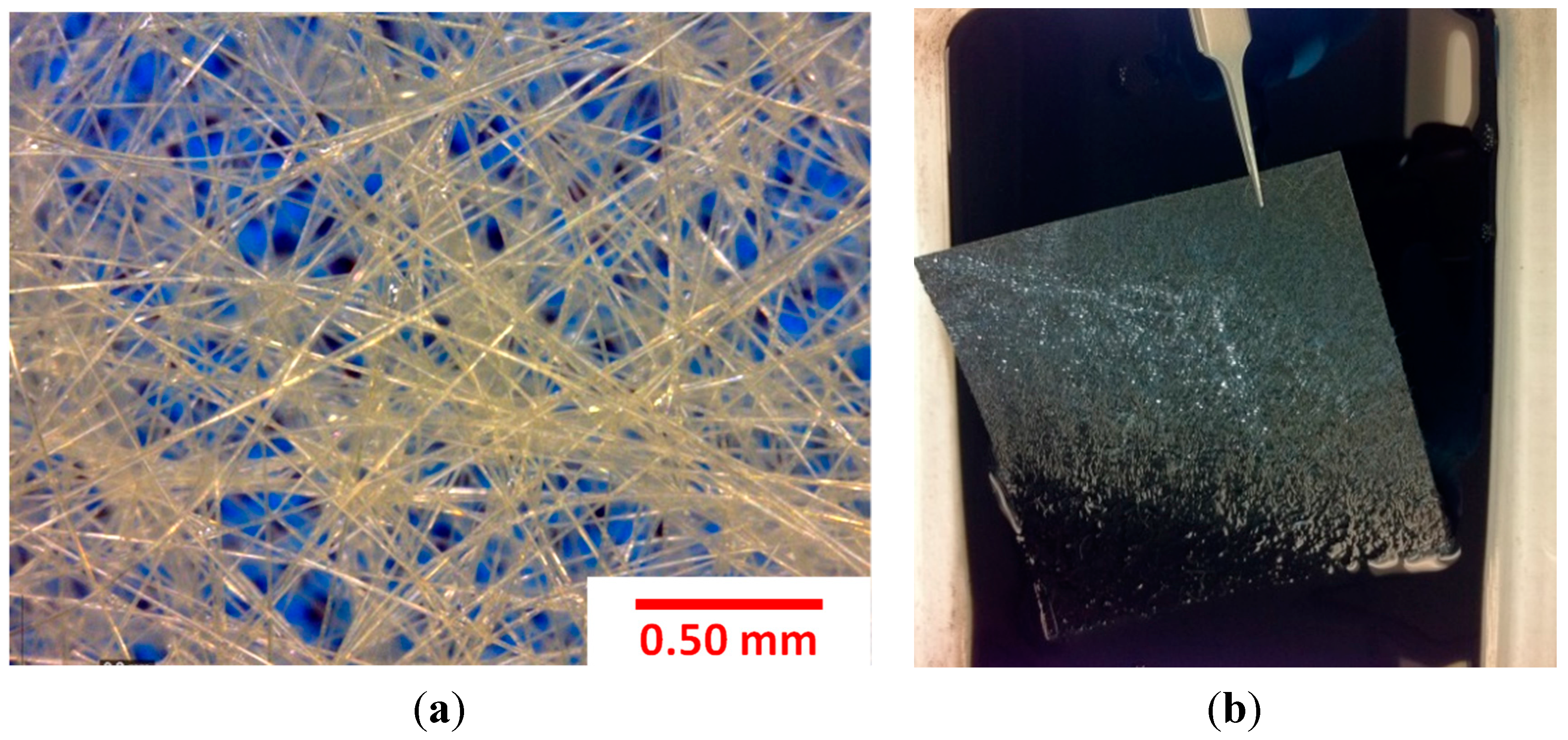

2.1. Materials and CNT Composite Sensor Manufacturing

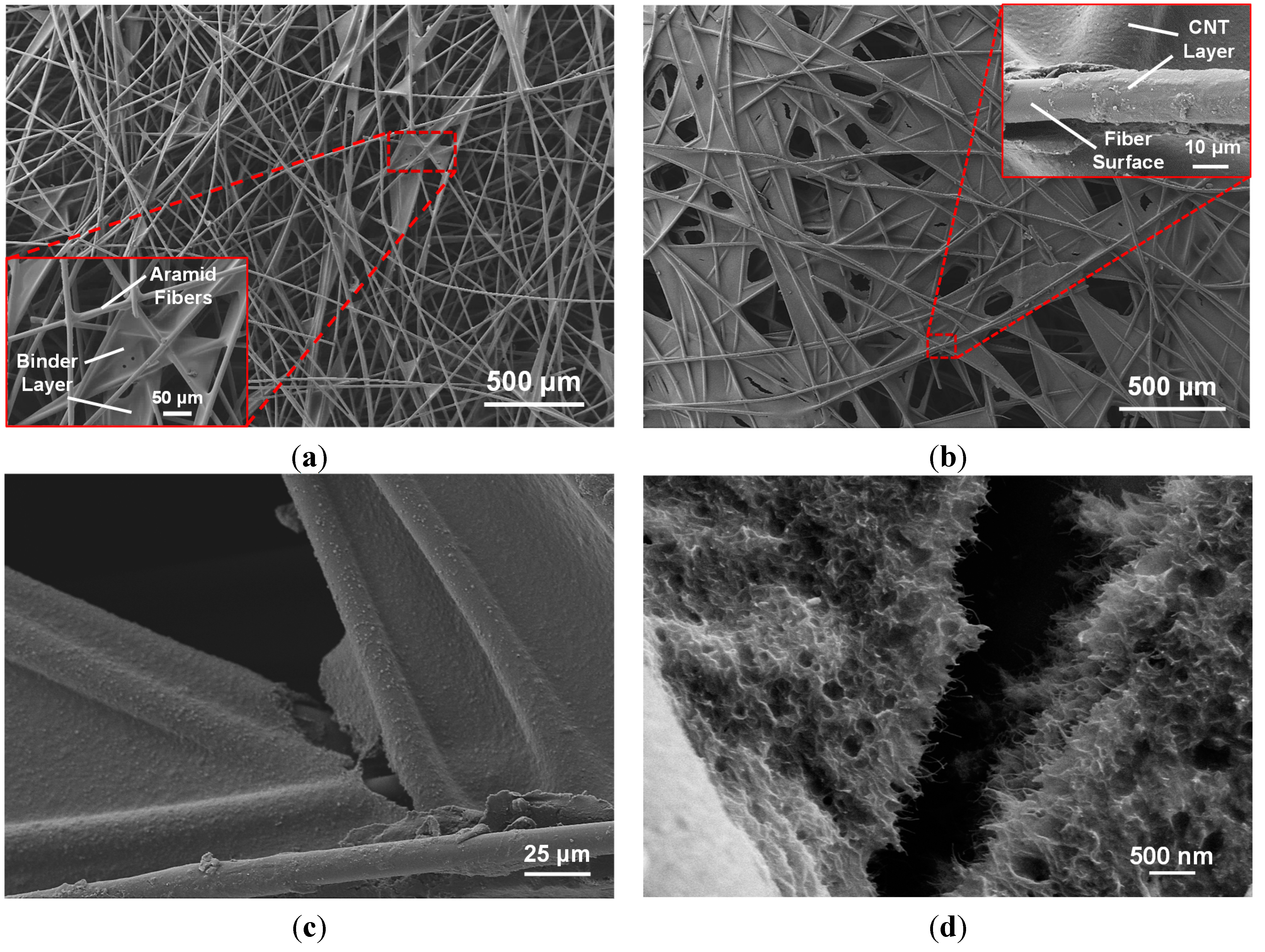

2.2. Sensor Microstructure Characterization

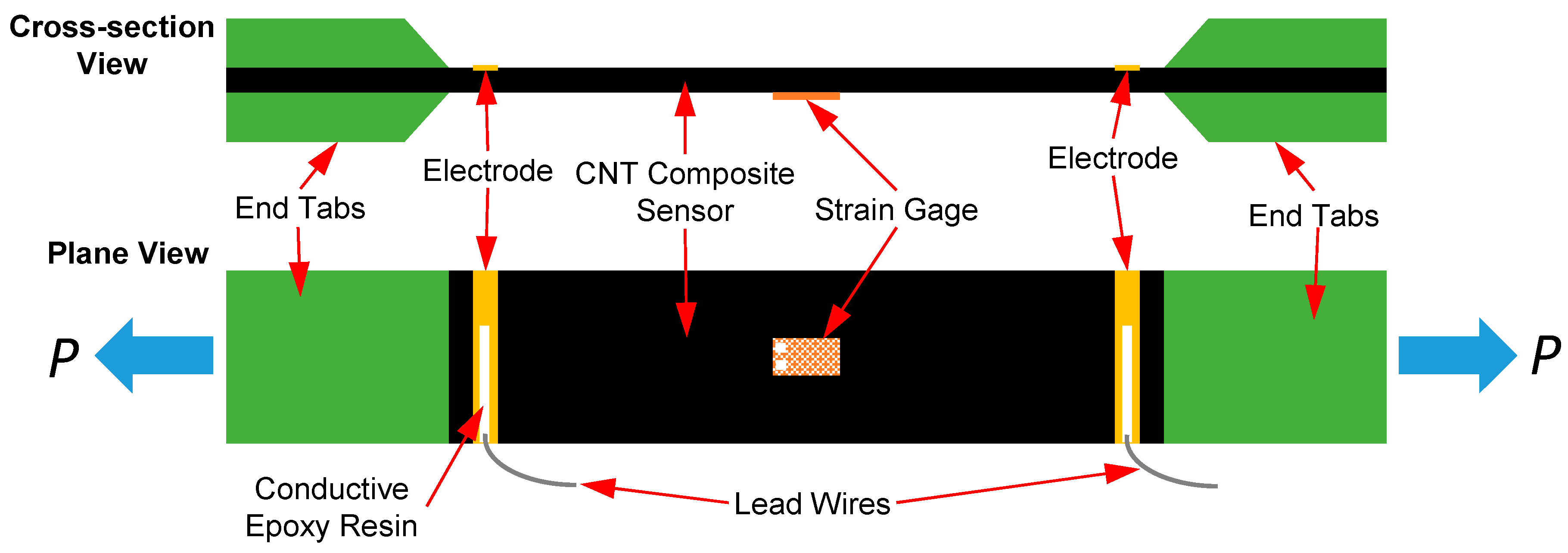

2.3. Mechanical and Electrical Characterization

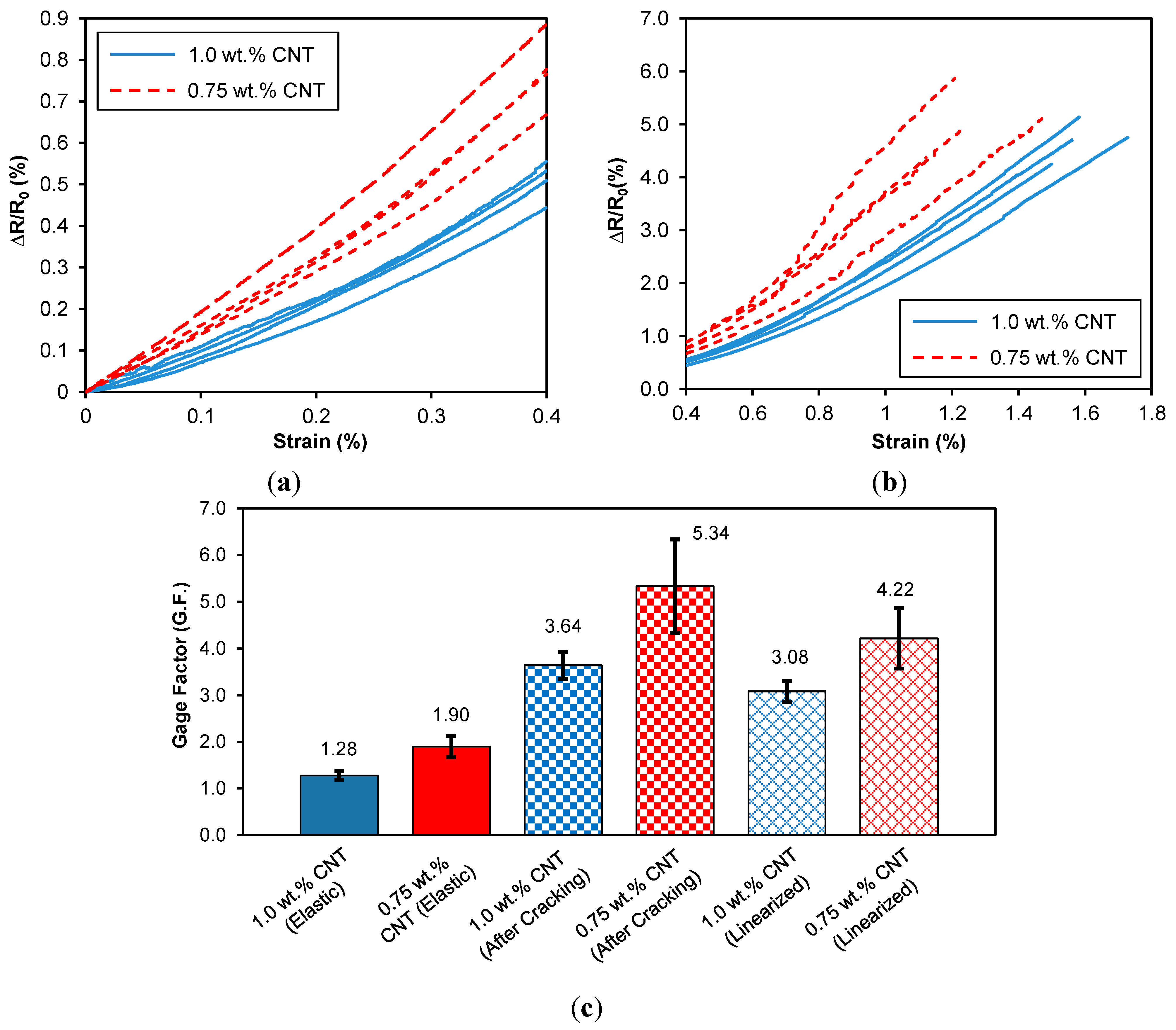

2.3.1. Mechanical/Electrical Response of the CNT Composite Sensors

2.3.2. Strain Monitoring of CNT Composite Sensors on Metallic Substrates

3. Results and Discussion

3.1. Sensing Composite Microstructure Characterization

3.2. Mechanical and Electrical Characterization of CNT Composite Sensors

3.3. Strain Monitoring of CNT Composite Sensors on Metallic Substrates

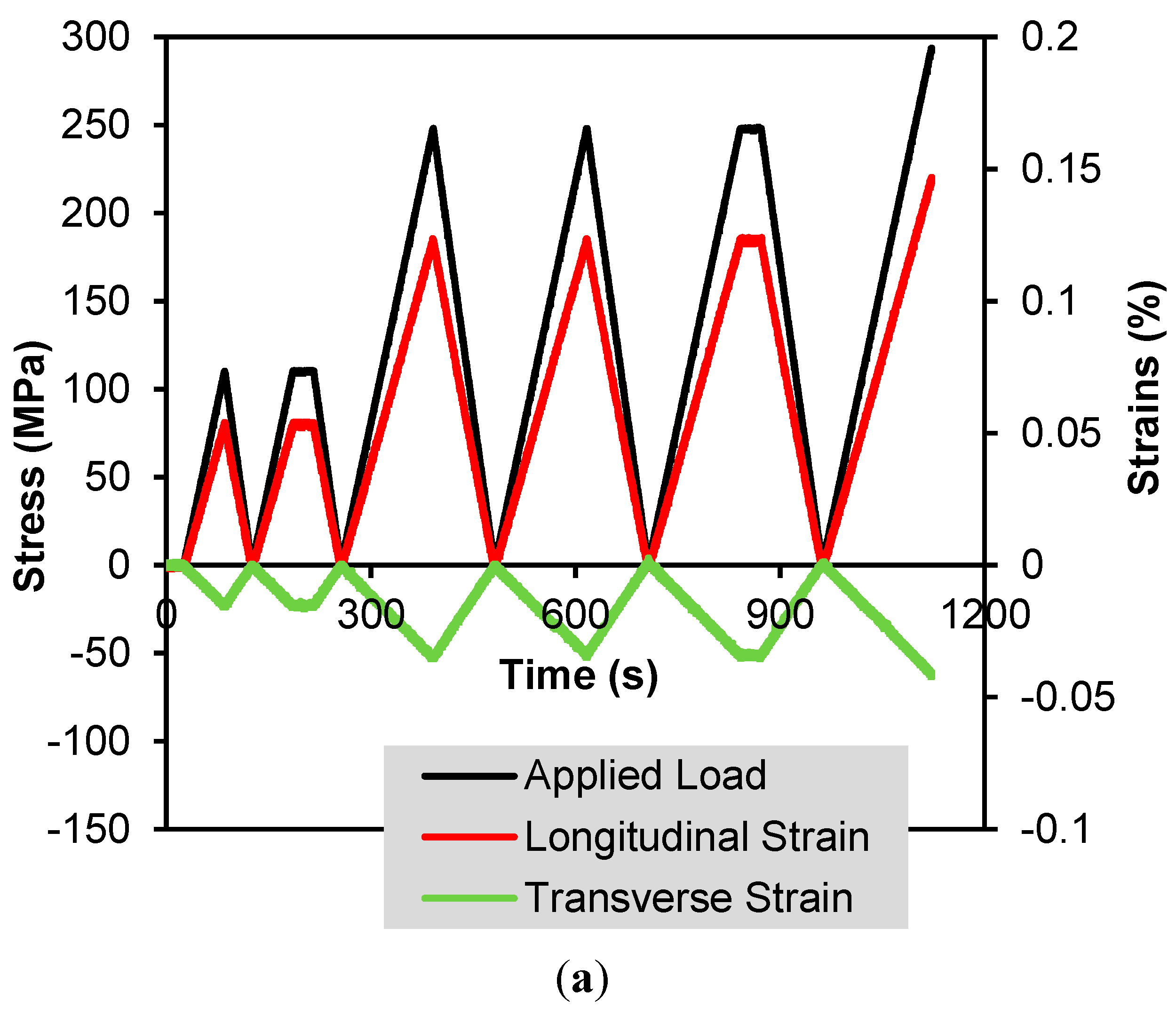

3.3.1. Case Study 1: Longitudinal and Transverse Strain Sensing on a Steel Substrate

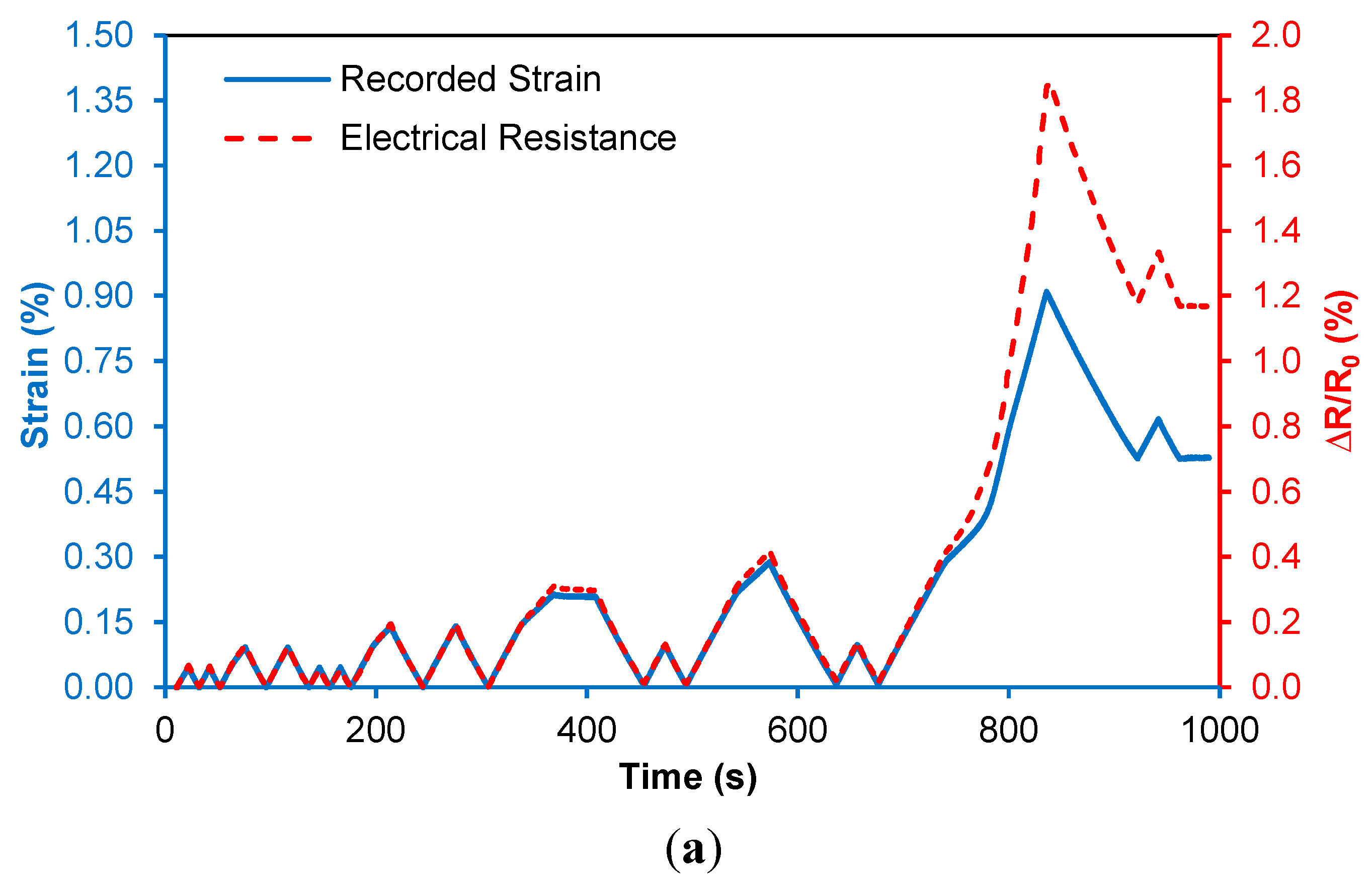

3.3.2. Case Study 2: Uniaxial Strain Monitoring on Aluminum Substrates

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Huston, D. Point Sensors. In Structural Sensing, Health Monitoring, and Performance Evaluation; CRC Press: Boca Raton, FL, USA, 2010; pp. 19–61. [Google Scholar]

- Schumacher, T.; Thostenson, E.T. Development of Structural Carbon Nanotube–Based Sensing Composites for Concrete Structures. J. Intell. Mater. Syst. Struct. 2014, 25, 1331–1339. [Google Scholar] [CrossRef]

- Ettouney, M.M.; Alampalli, S. Sensors and Infrastructure Health. In Infrastructure Health in Civil Engineering: Theory and Components; CRC Press: Boca Raton, FL, USA, 2012; pp. 175–276. [Google Scholar]

- Thostenson, E.T.; Li, C.; Chou, T. Nanocomposites in Context. Compos. Sci. Technol. 2005, 65, 491–516. [Google Scholar] [CrossRef]

- Thostenson, E.T.; Ren, Z.; Chou, T. Advances in the Science and Technology of Carbon Nanotubes and their Composites: A Review. Compos. Sci. Technol. 2001, 61, 1899–1912. [Google Scholar] [CrossRef]

- Pandey, G.; Thostenson, E.T. Carbon Nanotube-Based Multifunctional Polymer Nanocomposites. Polym. Rev. 2012, 52, 355–416. [Google Scholar] [CrossRef]

- Thostenson, E.T.; Chou, T. Aligned Multi-Walled Carbon Nanotube-Reinforced Composites: Processing and Mechanical Characterization. J. Phys. D 2002, 35. [Google Scholar] [CrossRef]

- Breton, Y.; Désarmot, G.; Salvetat, J.P.; Delpeux, S.; Sinturel, C.; Béguin, F.; Bonnamy, S. Mechanical Properties of Multiwall Carbon Nanotubes/Epoxy Composites: Influence of Network Morphology. Carbon 2004, 42, 1027–1030. [Google Scholar] [CrossRef]

- Gojny, F.H.; Wichmann, M.H.G.; Fiedler, B.; Schulte, K. Influence of Different Carbon Nanotubes on the Mechanical Properties of Epoxy Matrix Composites—A Comparative Study. Compos. Sci. Technol. 2005, 65, 2300–2313. [Google Scholar] [CrossRef]

- Yu, N.; Zhang, Z.H.; He, S.Y. Fracture Toughness and Fatigue Life of MWCNT/Epoxy Composites. Mater. Sci. Eng. A 2008, 494, 380–384. [Google Scholar] [CrossRef]

- Bhatia, R.; Prasad, V.; Menon, R. Characterization, Electrical Percolation and Magnetization Studies of Polystyrene/Multiwall Carbon Nanotube Composite Films. Mater. Sci. Eng. B 2010, 175, 189–194. [Google Scholar] [CrossRef]

- Guadagno, L.; de Vivo, B.; Di Bartolomeo, A.; Lamberti, P.; Sorrentino, A.; Tucci, V.; Vertuccio, L.; Vittoria, V. Effect of Functionalization on the Thermo-Mechanical and Electrical Behavior of Multi-Wall Carbon Nanotube/Epoxy Composites. Carbon 2011, 49, 1919–1930. [Google Scholar] [CrossRef]

- Thostenson, E.T.; Ziaee, S.; Chou, T. Processing and Electrical Properties of Carbon Nanotube/Vinyl Ester Nanocomposites. Compos. Sci. Technol. 2009, 69, 801–804. [Google Scholar] [CrossRef]

- Guthy, C.; Du, F.; Brand, S.; Fischer, J.E.; Winey, K.I. Thermal Conductivity of Single-Walled Carbon Nanotube/PMMA Nanocomposites. MRS Proc. 2004, 858. [Google Scholar] [CrossRef]

- Thostenson, E.T.; Chou, T. Processing-Structure-Multi-Functional Property Relationship in Carbon Nanotube/Epoxy Composites. Carbon 2006, 44, 3022–3029. [Google Scholar] [CrossRef]

- Yang, Y.; Gupta, M.C.; Zalameda, J.N.; Winfree, W.P. Dispersion Behaviour, Thermal and Electrical Conductivities of Carbon Nanotube-Polystyrene Nanocomposites. Micro Nano Lett. IET 2008, 3, 35–40. [Google Scholar] [CrossRef]

- Li, C.; Thostenson, E.T.; Chou, T. Sensors and Actuators Based on Carbon Nanotubes and their Composites: A Review. Compos. Sci. Technol. 2008, 68, 1227–1249. [Google Scholar] [CrossRef]

- Thostenson, E.T.; Chou, T. Carbon Nanotube Networks: Sensing of Distributed Strain and Damage for Life Prediction and Self Healing. Adv. Mater. 2006, 18, 2837–2841. [Google Scholar] [CrossRef]

- Park, M.; Kim, H.; Youngblood, J.P. Strain-Dependent Electrical Resistance of Multi-Walled Carbon Nanotube/Polymer Composite Films. Nanotechnology 2008, 19, 055705. [Google Scholar] [CrossRef] [PubMed]

- Chang, F.; Wang, R.; Yang, H.; Lin, Y.; Chen, T.; Huang, S. Flexible Strain Sensors Fabricated with Carbon Nano-Tube and Carbon Nano-Fiber Composite Thin Films. Thin Solid Films 2010, 518, 7343–7347. [Google Scholar] [CrossRef]

- Dharap, P.; Li, Z.; Nagarajaiah, S.; Barrera, E.V. Nanotube Film Based on Single-Wall Carbon Nanotubes for Strain Sensing. Nanotechnology 2004, 15, 379–382. [Google Scholar] [CrossRef]

- Li, Z.; Dharap, P.; Nagarajaiah, S.; Barrera, E.V.; Kim, J.D. Carbon Nanotube Film Sensors. Adv. Mater. 2004, 16, 640–643. [Google Scholar] [CrossRef]

- Kang, I.; Schulz, M.J.; Kim, J.H.; Shanov, V.; Shi, D. A Carbon Nanotube Strain Sensor for Structural Health Monitoring. Smart Mater. Struct. 2006, 15. [Google Scholar] [CrossRef]

- Wichmann, M.H.G.; Buschhorn, S.T.; Böger, L.; Adelung, R.; Schulte, K. Direction Sensitive Bending Sensors Based on Multi-Wall Carbon Nanotube/Epoxy Nanocomposites. Nanotechnology 2008, 19, 475503. [Google Scholar] [CrossRef] [PubMed]

- Loh, K.J.; Lynch, J.P.; Shim, B.; Kotov, N. Tailoring Piezoresistive Sensitivity of Multilayer Carbon Nanotube Composite Strain Sensors. J. Intell. Mater. Syst. Struct. 2008, 19, 747–764. [Google Scholar] [CrossRef]

- Theodosiou, T.C.; Saravanos, D.A. Numerical Investigation of Mechanisms Affecting the Piezoresistive Properties of CNT-Doped Polymers Using Multi-Scale Models. Compos. Sci. Technol. 2010, 70, 1312–1320. [Google Scholar] [CrossRef]

- Yasuoka, T.; Shimamura, Y.; Todoroki, A. Electrical Resistance Change under Strain of CNF/Flexible-Epoxy Composite. Adv. Compos. Mater. 2010, 19, 123–138. [Google Scholar] [CrossRef]

- Alamusi, L.Y.; Hu, N. Numerical Simulations on Piezoresistivity of CNT/Polymer Based Nanocomposites. Comput. Mater. Contin. 2010, 20, 101–117. [Google Scholar]

- Hu, N.; Karube, Y.; Yan, C.; Masuda, Z.; Fukunaga, H. Tunneling Effect in a Polymer/Carbon Nanotube Nanocomposite Strain Sensor. Acta Mater. 2008, 56, 2929–2936. [Google Scholar] [CrossRef] [Green Version]

- Li, C.; Thostenson, E.T.; Chou, T. Dominant Role of Tunneling Resistance in the Electrical Conductivity of Carbon Nanotube–Based Composites. Appl. Phys. Lett. 2007, 91, 223114. [Google Scholar] [CrossRef]

- Hu, N.; Fukunaga, H.; Atobe, S.; Liu, Y.; Li, J. Piezoresistive Strain Sensors made from Carbon Nanotubes Based Polymer Nanocomposites. Sensors 2011, 11, 10691–10723. [Google Scholar]

- Hu, N.; Karube, Y.; Arai, M.; Watanabe, T.; Yan, C.; Li, Y.; Liu, Y.; Fukunaga, H. Investigation on Sensitivity of a Polymer/Carbon Nanotube Composite Strain Sensor. Carbon 2010, 48, 680–687. [Google Scholar] [CrossRef]

- Zhang, W.; Suhr, J.; Koratkar, N. Carbon Nanotube/Polycarbonate Composites as Multifunctional Strain Sensors. J. Nanosci. Nanotechnol. 2006, 6, 960–964. [Google Scholar] [CrossRef] [PubMed]

- Gao, L.; Thostenson, E.T.; Zhang, Z.; Chou, T. Coupled Carbon Nanotube Network and Acoustic Emission Monitoring for Sensing of Damage Development in Composites. Carbon 2009, 47, 1381–1388. [Google Scholar] [CrossRef]

- Gao, L.; Thostenson, E.T.; Zhang, Z.; Chou, T. Sensing of Damage Mechanisms in Fiber-Reinforced Composites under Cyclic Loading Using Carbon Nanotubes. Adv. Funct. Mater. 2009, 19, 123–130. [Google Scholar] [CrossRef]

- Gao, L.; Thostenson, E.T.; Zhang, Z.; Byun, J.; Chou, T. Damage Monitoring in Fiber-Reinforced Composites under Fatigue Loading Using Carbon Nanotube Networks. Philos. Mag. 2010, 90, 4085–4099. [Google Scholar] [CrossRef]

- Gao, L.; Chou, T.; Thostenson, E.T.; Zhang, Z.; Coulaud, M. In Situ Sensing of Impact Damage in Epoxy/Glass Fiber Composites Using Percolating Carbon Nanotube Networks. Carbon 2011, 49, 3382–3385. [Google Scholar] [CrossRef]

- Loh, K.J.; Kim, J.; Lynch, J.P.; Kam, N.W.S.; Nicholas, A.K. Multifunctional Layer-by-Layer Carbon Nanotube–Polyelectrolyte Thin Films for Strain and Corrosion Sensing. Smart Mater. Struct. 2007, 16. [Google Scholar] [CrossRef]

- Anand, S.V.; Mahapatra, D.R. Quasi-Static and Dynamic Strain Sensing Using Carbon Nanotube/Epoxy Nanocomposite Thin Films. Smart Mater. Struct. 2009, 18. [Google Scholar] [CrossRef]

- Srivastava, R.K.; Vemuru, V.S.M.; Zeng, Y.; Vajtai, R.; Nagarajaiah, S.; Ajayan, P.M.; Srivastava, A. The Strain Sensing and Thermal–Mechanical Behavior of Flexible Multi-Walled Carbon Nanotube/Polystyrene Composite Films. Carbon 2011, 49, 3928–3936. [Google Scholar] [CrossRef]

- Thostenson, E.T.; Chou, T. Carbon Nanotube-Based Health Monitoring of Mechanically Fastened Composite Joints. Compos. Sci. Technol. 2008, 68, 2557–2561. [Google Scholar] [CrossRef]

- Lim, A.S.; Melrose, Z.R.; Thostenson, E.T.; Chou, T. Damage Sensing of Adhesively-Bonded Hybrid Composite/Steel Joints Using Carbon Nanotubes. Compos. Sci. Technol. 2011, 71, 1183–1189. [Google Scholar] [CrossRef]

- Cai, L.; Song, L.; Luan, P.; Zhang, Q.; Zhang, N.; Gao, Q.; Zhao, D.; Zhang, X.; Tu, M.; Yang, F. Super-Stretchable, Transparent Carbon Nanotube-Based Capacitive Strain Sensors for Human Motion Detection. Sci. Rep. 2013, 3. [Google Scholar] [CrossRef] [PubMed]

- Yamada, T.; Hayamizu, Y.; Yamamoto, Y.; Yomogida, Y.; Izadi-Najafabadi, A.; Futaba, D.N.; Hata, K. A Stretchable Carbon Nanotube Strain Sensor for Human-Motion Detection. Nat. Nano 2011, 6, 296–301. [Google Scholar] [CrossRef] [PubMed]

- Dharap, P.; Li, Z.; Nagarajaiah, S.; Barrera, E.V. Flexural Strain Sensing Using Carbon Nanotube Film. Sens. Rev. 2004, 24, 271–273. [Google Scholar] [CrossRef]

- Ubertini, F.; Laflamme, S.; Ceylan, H.; Materazzi, A.L.; Cerni, G.; Saleem, H.; D’Alessandro, A.; Corradini, A. Novel Nanocomposite Technologies for Dynamic Monitoring of Structures: A Comparison between Cement-Based Embeddable and Soft Elastomeric Surface Sensors. Smart Mater. Struct. 2014, 23, 045023. [Google Scholar] [CrossRef]

- Saafi, M. Wireless and Embedded Carbon Nanotube Networks for Damage Detection in Concrete Structures. Nanotechnology 2009, 20, 395502. [Google Scholar] [CrossRef] [PubMed]

- Dai, H.; Schumacher, T.; Thostenson, E. Carbon Nanotube-Based Sensing Composites for Structural Health Monitoring of Civil Infrastructure Using Non-Woven Fabrics. In Safety, Reliability, Risk and Life-Cycle Performance of Structures and Infrastructures, Proceedings of the 11th International Conference on Structural Safety and Reliability (ICOSSAR), New York, NY, USA, 16–20 June 2013.

- Ci, L.; Bai, J. The Reinforcement Role of Carbon Nanotubes in Epoxy Composites with Different Matrix Stiffness. Compos. Sci. Technol. 2006, 66, 599–603. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dai, H.; Thostenson, E.T.; Schumacher, T. Processing and Characterization of a Novel Distributed Strain Sensor Using Carbon Nanotube-Based Nonwoven Composites. Sensors 2015, 15, 17728-17747. https://doi.org/10.3390/s150717728

Dai H, Thostenson ET, Schumacher T. Processing and Characterization of a Novel Distributed Strain Sensor Using Carbon Nanotube-Based Nonwoven Composites. Sensors. 2015; 15(7):17728-17747. https://doi.org/10.3390/s150717728

Chicago/Turabian StyleDai, Hongbo, Erik T. Thostenson, and Thomas Schumacher. 2015. "Processing and Characterization of a Novel Distributed Strain Sensor Using Carbon Nanotube-Based Nonwoven Composites" Sensors 15, no. 7: 17728-17747. https://doi.org/10.3390/s150717728