Top-Down CMOS-NEMS Polysilicon Nanowire with Piezoresistive Transduction

Abstract

:1. Introduction

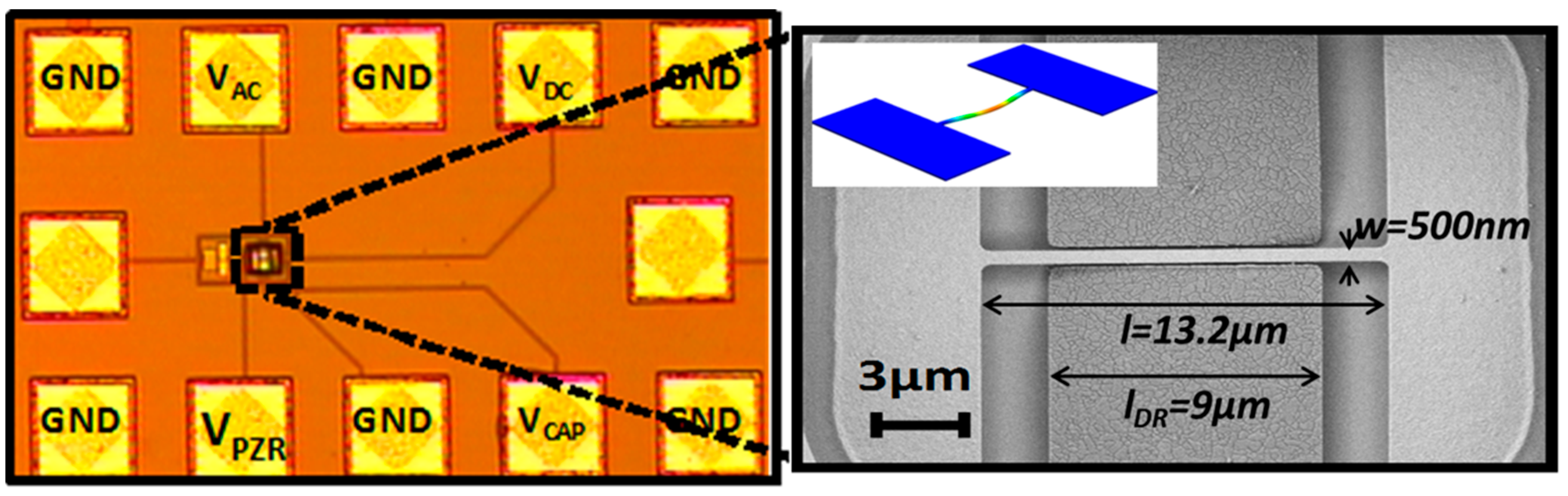

2. Experimental Section

2.1. Capacitive Sensing

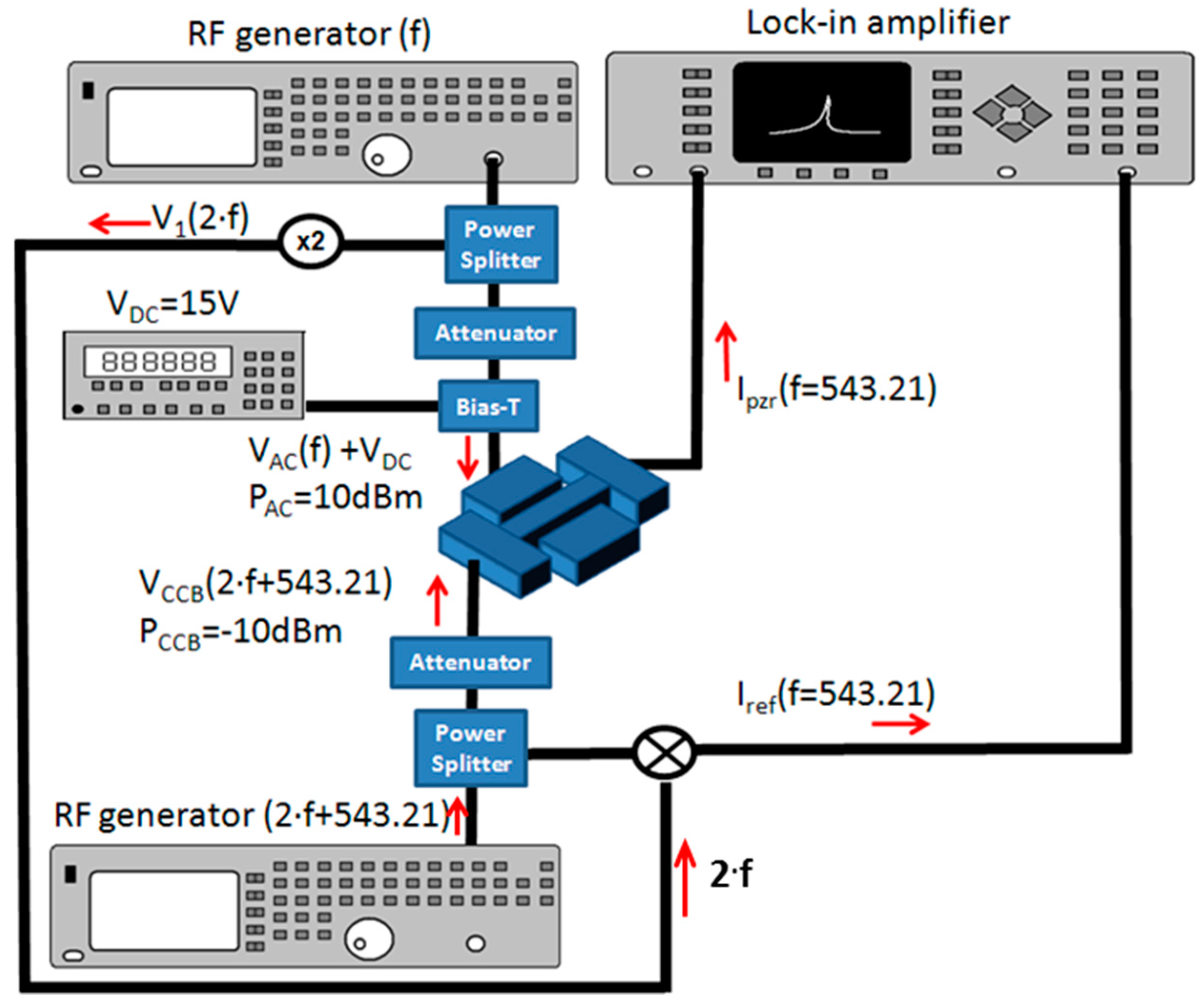

2.2. Piezoresistive Sensing

3. Results and Discussion

3.1. Capacitive Transduction

3.2. Piezoresistive Transduction

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Arlett, J.L.; Myers, E.B.; Roukes, M.L. Comparative advantages of mechanical biosensors. Nat. Nanotechnol. 2011, 6, 203–215. [Google Scholar] [CrossRef] [PubMed]

- Boisen, A.; Dohn, S.; Keller, S.S.; Schmid, S.; Tenje, M. Cantilever-like micromechanical sensors. Rep. Prog. Phys. 2011, 74, 036101. [Google Scholar] [CrossRef]

- Fanget, S.; Hentz, S.; Puget, P.; Arcamone, J.; Matheron, M.; Colinet, E.; Andreucci, P.; Duraffourg, L.; Myers, E.; Roukes, M.L. Gas sensors based on gravimetric detection. Sens. Actuators B Chem. 2011, 160, 804–821. [Google Scholar] [CrossRef]

- Hanay, M.S.; Kelber, S.; Naik, A.K.; Chi, D.; Hentz, S.; Bullard, E.C.; Duraffourg, L. Single-protein nanomechanical mass spectrometry in real time. Nat. Nanotechnol. 2012, 7, 602–608. [Google Scholar] [CrossRef] [PubMed]

- Lassagne, B.; Garcia-Sanchez, D.; Aguasca, A.; Bachtold, A. Ultrasensitive mass sensing with a nanotube electromechanical resonator. Nano Lett. 2008, 8, 3735–3738. [Google Scholar] [CrossRef] [PubMed]

- Bargatin, I.; Myers, E.B.; Aldridge, J.S.; Marcoux, C.; Brieanceau, P.; Duraffourg, L.; Colinet, E.; Hentz, S.; Andreucci, P.; Roukes, M.L. Large-scale integration of nanoelectromechanical systems for gas sensing applications. Nano Lett. 2012, 12, 1269–1274. [Google Scholar] [CrossRef] [PubMed]

- International Technology Roadmap of Semiconductors. Available online: www.itrs.net (accessed on 13 July 2015).

- Van Beek, J.T.M.; Puers, R. A review of MEMS oscillators for frequency reference and timing applications. J. Micromech. Microeng. 2012, 22, 013001. [Google Scholar] [CrossRef]

- Verd, J.; Uranga, A.; Abadal, G.; Teva, J.; Torres, F.; Pérez-Murano, F.; Esteve, J.; Barniol, N. Monolithic CMOS MEMS Oscillator Circuit for Sensing in the Attogram Range. IEEE Electron. Device Lett. 2008, 29, 146–148. [Google Scholar] [CrossRef]

- Huang, W.L.; Ren, Z.; Lin, Y.-W.; Chen, H.-Y.; Lahann, J.; Nguyen, C.T.C. Fully monolithic CMOS nickel micromechanical resonator oscillator. In Proceedings of the IEEE 21th International Conference on Micro Electro. Mechanical Systems, Tucson, AZ, USA, 13–17 January 2008.

- Lo, C.C.; Fedder, G.K. On-chip high quality factor CMOS-MEMS silicon-fin resonators. In Proceedings of the International Solid-State Sensors, Actuators and Microsystems Conference, Lyon, France, 10–14 June 2007.

- Zalalutdinov, M.K.; Cross, J.D.; Baldwin, J.W.; Ilic, B.R.; Zhou, W.; Houston, B.H.; Parpia, J.M. CMOS integrated RF MEMS resonators. J. Microelectromech. Syst. 2010, 19, 807–815. [Google Scholar] [CrossRef]

- Chen, W.C.; Fang, W.; Li, S.S. A generalized CMOS-MEMS platform for micromechanical resonators monolithically integrated with circuits. J. Micromech. Microeng. 2011, 21, 065012. [Google Scholar] [CrossRef]

- Chen, W.C.; Fang, W.; Li, S.S. VHF CMOS-MEMS oxide resonators with Q > 10000. In Proceedings of the IEEE International Frequency Control Symposium, Baltimore, MD, USA, 21–24 May 2012.

- Van Beek, J.T.M.; Verheijden, G.J.A.; Koops, G.E.J.; Phan, K.L.; van der Avoort, C.; van Wingerden, J.; Badaroglu, D.E.; Bontemps, J.J.M. Scalable 1.1 GHz fundamental mode piezo-resistive silicon MEMS resonator. In Proceedings of the IEEE International Electron, Device Meeting, Washington, DC, USA, 10–12 December 2007.

- Van Beek, J.T.M.; Steeneken, P.G.; Giesbers, B. A 10MHz piezoresistive MEMS resonator with high Q. In Proceedings of the IEEE International Frequency Control Symposium and Exposition, Miami, FL, USA, 4–7 June 2006.

- Lee, J.E.-Y.; Seshia, A.A. Parasitic feedthrough cancellation techniques for enhanced electrical characterisation of electrostatic microresonators. Sens. Actuators A Phys. 2009, 146, 36–42. [Google Scholar] [CrossRef]

- Cheng-Syun, Li.; Chi-Hang, C.; Yu-Chia, L.; Sheng-Shian, Li. Capacitively-driven and piezoresistively sensed CMOS-MEMS resonators. In Proceedings of the IEEE 25th International Conference on Micro Electro Mechanical Systems (MEMS), Paris, France, 29 January–2 February 2012.

- Arcamone, J.; Niel, A.; Gouttenoire, V.; Petitjean, M.; David, N.; Barattin, R.; Matheron, M.; Ricoul, F.; Bordy, T.; Blanc, H.; Ruellan, J.; et al. VLSI silicon multigas analyzer coupling gas cromathography and NEMS detectors. In Proceedings of the IEEE International Electron Devices Meeting, Washington, DC, USA, 5–7 December 2011.

- Lopez, J.L.; Verd, J.; Teva, J.; Murillo, G.; Giner, J.; Torres, F.; Uranga, A.; Abadal, G.; Barniol, N. Integration of RF-MEMS resonators on submicrometric commercial CMOS technologies. J. Micromech. Microeng. 2009, 19, 0150:02–0150:12. [Google Scholar] [CrossRef]

- Uranga, A.; Verd, J.; Marigó, E.; Giner, J.; Muñoz-Gamarra, J.L.; Barniol, N. Exploitation of non-linearities in CMOS-NEMS electrostatic resonators for mechanical memories. Sens. Actuators A Phys. 2013, 197, 88–95. [Google Scholar] [CrossRef]

- He, R.; Feng, X.L.; Roukes, M.L.; Yang, P.D. Self-transducing silicon nanowire electromechanical systems at room temperature. Nano Lett. 2008, 8, 1756–1761. [Google Scholar] [CrossRef] [PubMed]

- Sansa, M.; Fernández-Regúlez, M.; Llobet, J.; San, P.A.; Pérez-Murano, F. High-sensitivity linear piezoresistive transduction for nanomechanical beam resonators. Nat. Commun. 2014, 5, 4313. [Google Scholar] [CrossRef] [PubMed]

- Reck, K.; Richter, J.; Hansen, O.; Thomsen, E.V. Piezoresistive effect in top-down fabricated silicon nanowires. In Proceedings of the IEEE 22th International Conference on Micro Electro Mechanical Systems, Tucson, AZ, USA, 13–17 January 2008.

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marigó, E.; Sansa, M.; Pérez-Murano, F.; Uranga, A.; Barniol, N. Top-Down CMOS-NEMS Polysilicon Nanowire with Piezoresistive Transduction. Sensors 2015, 15, 17036-17047. https://doi.org/10.3390/s150717036

Marigó E, Sansa M, Pérez-Murano F, Uranga A, Barniol N. Top-Down CMOS-NEMS Polysilicon Nanowire with Piezoresistive Transduction. Sensors. 2015; 15(7):17036-17047. https://doi.org/10.3390/s150717036

Chicago/Turabian StyleMarigó, Eloi, Marc Sansa, Francesc Pérez-Murano, Arantxa Uranga, and Núria Barniol. 2015. "Top-Down CMOS-NEMS Polysilicon Nanowire with Piezoresistive Transduction" Sensors 15, no. 7: 17036-17047. https://doi.org/10.3390/s150717036