Study and Test of a New Bundle-Structure Riser Stress Monitoring Sensor Based on FBG

Abstract

:1. Introduction

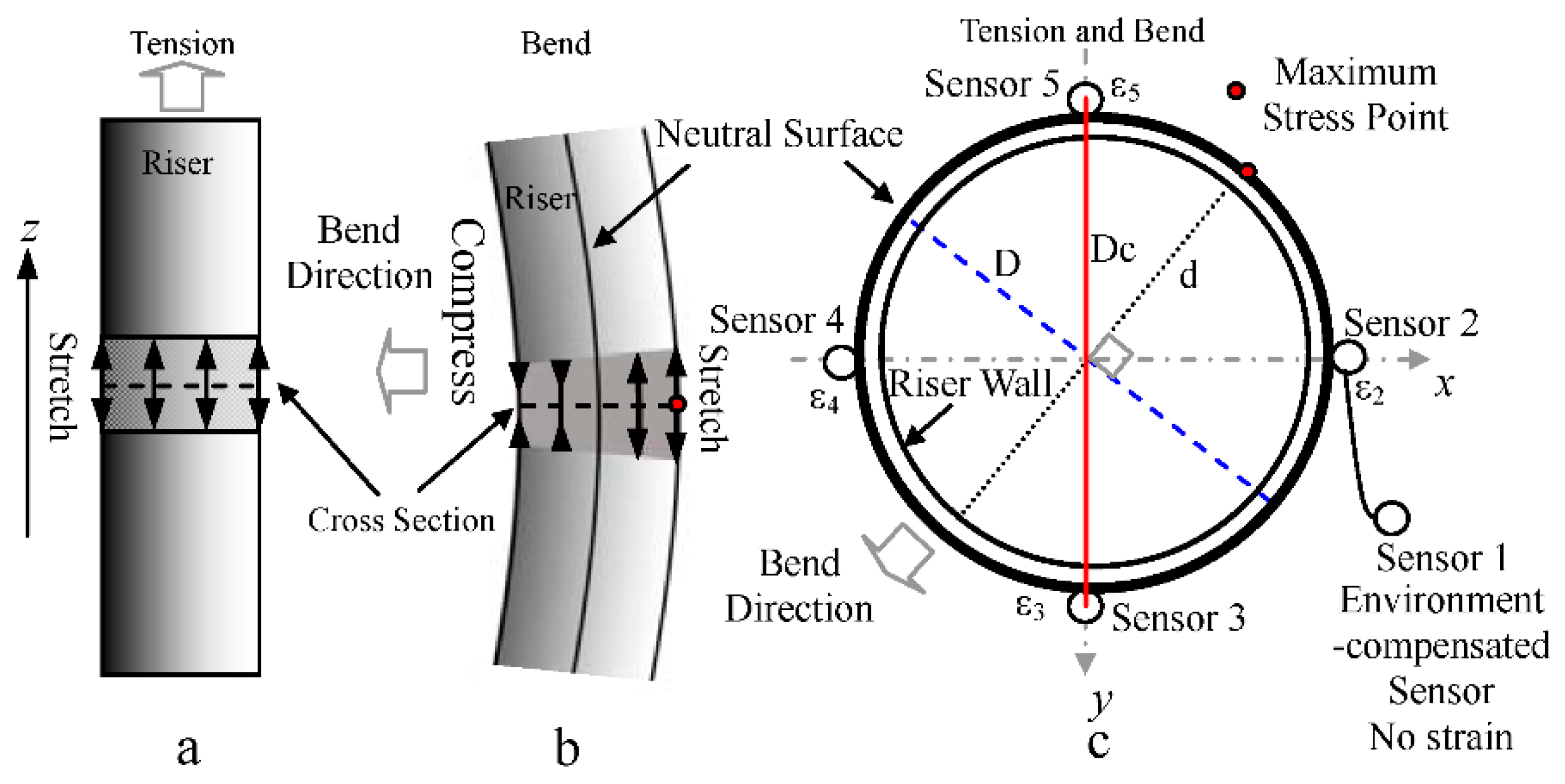

2. Structure and Principle of Sensor

2.1. Structure and Composition

2.2. Sensing Principle

| Parameters | Parameter Meanings | Values |

|---|---|---|

| λ10, λ20, λ30, λ40, λ50 | Initial wavelengths of FBG sensors | -- |

| λ1, λ2, λ3, λ40, λ5 | Measured wavelengths of FBG sensors | -- |

| P, T | Water pressure change, Temperature change | -- |

| σ, ε, M | Stress, Strain, Bending moment | -- |

| η | Sensitivities | -- |

| the subscript “p”, “t”, “z”, “w” | Sensitivity types related to pressure, temperature, tension and bend, respectively | -- |

| the subscript “x”, “y” | Parameter types related to the x axis and the y axis in Figure 2 | -- |

| the subscript “c” | Parameter type related to strain sensors | -- |

| Iz | Inertia moment of riser, Iz = π(D4 − d4)/64 | -- |

| D | Inner diameter of riser | 489 mm |

| D | Outer diameter of riser | 533 mm |

| Dc | Equivalent diameter of the riser stress monitoring sensor | 576 mm |

| E | Elastic modulus of riser metal materials | 2.05 × 1011 Pa |

| ηz | Tension sensitivities of FBG sensors | 1.09 pm/µε |

3. Test Process

3.1. Sensor Installation

3.2. Riser Working Conditions

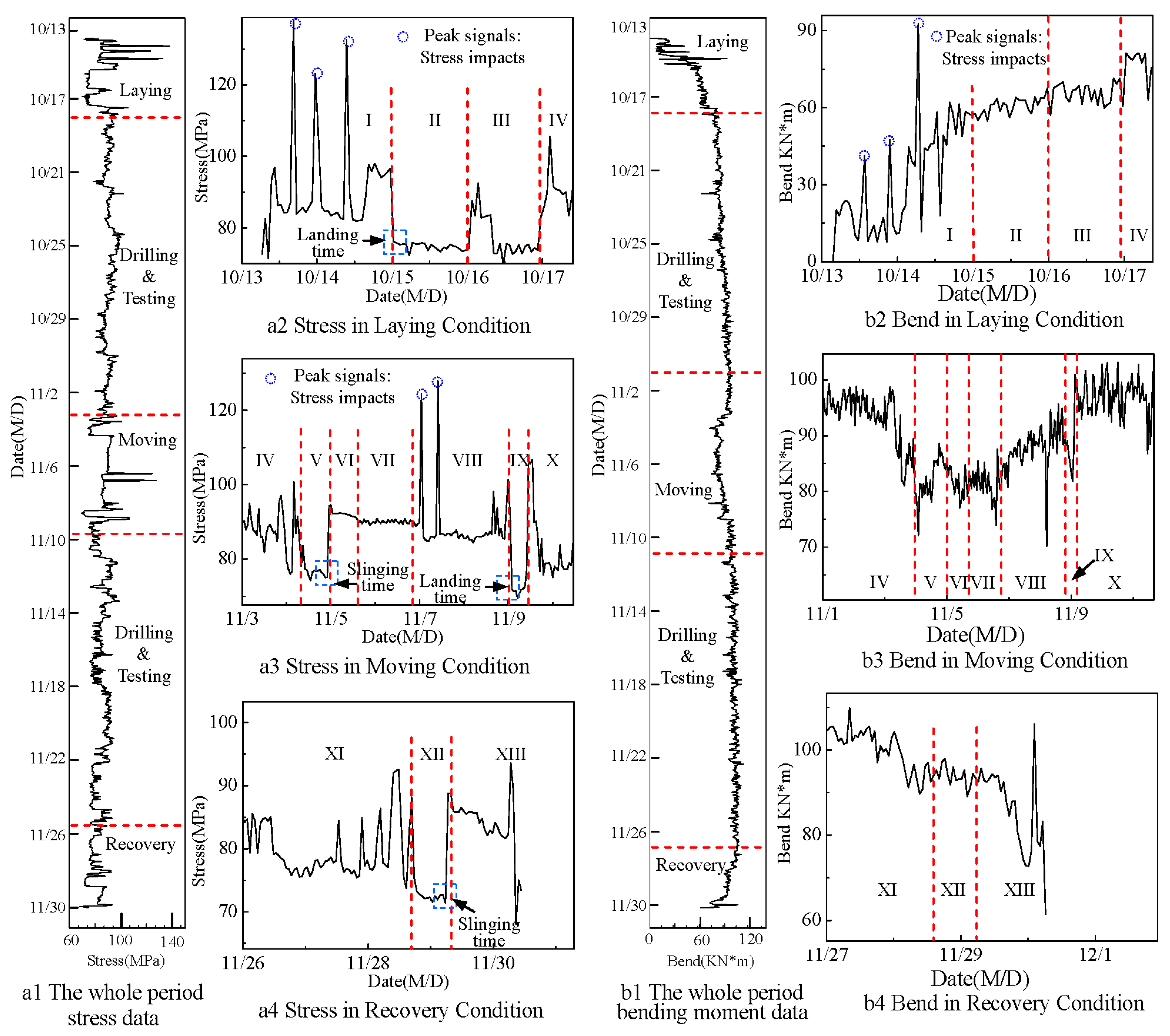

4. Data and Analysis

5. Results and Discussion

5.1. Stress Analysis

| Working Condition | Specific Content | Stress Trends | Main Causes of Changes | |

|---|---|---|---|---|

| Laying | C1 | Riser connecting | High and unstable; With some stress impacts; | Risers were influenced by unstable waves, surges and the gravity of BOP and LMRP; sudden braking of the riser crane produced stress impacts. |

| C2 | BOP pressure test | Low and stable; | There was no BOP and LMRP gravity influence; the platform position was locked right above the well head that straightened the riser string. | |

| C3 | Drilling preparation | High and unstable at the beginning; then stable | Using or changing of tools in drilling caused unstable stresses; risers became stable in testing. | |

| Drilling & Testing | C4 | Drilling & Testing | Sometime high and unstable; sometime low and unstable; | Same as Condition C3 |

| Moving | C5 | Regain preparation | Low and stable; | Same as Condition C2 |

| C6 | Regain risers | High and unstable; | It is the same as Condition C1 except stress impacts. | |

| C7 | Moving drilling platform | Low and unstable; | When the platform was moved to the second well, seven risers were disconnected to avoid the collision between BOP and the seabed. The depth of sensor was decreased. Remaining risers was influenced by unstable waves, surges and the gravity of BOP and LMRP, but the depth had no change in moving. | |

| C8 | Connecting risers | High and unstable; With some stress impacts; | Same as Condition C1 | |

| C9 | BOP pressure test | Low and stable; | Same as Condition C2 | |

| C10 | Drilling preparation | High and unstable at the beginning; then stable | Same as Condition C3 | |

| Drilling & Testing | C11 | Drilling & Testing | Sometime high and unstable; sometime low and unstable; | Same as Condition C3 |

| Recovery | C12 | Recovery preparation | Low and stable; | Same as Condition C2 |

| C13 | Recover risers | High and unstable; | Same as Condition C6 | |

| Special Times | -- | Landing time | much lower in a sudden | BOP and LMRP touched the seabed, no gravity influenced risers. |

| -- | Slinging time | much higher in a sudden | BOP and LMRP left the seabed, the gravity influenced risers. | |

5.2. Bending Moment Analysis

5.3. Results Reliability Analysis

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Constantinides, Y.; Chen, J.-H.; Tran, L.; Enuganti, P.; Campbell, M. Comparison of SCR field response with analytical predictions. In Proceedings of the 30th International Conference on Ocean, Offshore and Arctic Engineering, Rotterdam, The Netherlands, 19–24 June 2011; pp. 883–888.

- Karayaka, M.; Ruf, W.; Natarajan, S. Steel catenary riser response characterization with on-line monitoring devices. In Proceedings of the 28th International Conference on Ocean, Honolulu, HI, USA, 31 May–5 June 2009; pp. 687–698.

- Karayaka, M.; Chen, J.-H.; Blankenshipp, C.; Ruf, W.; Podskarbi, M. SS: Tahiti on-line monitoring system for steel catenary risers and flowlines. In Proceedings of the 2009 Offshore Technology Conference, Houston, TX, USA, 4–7 May 2009.

- Zimmermann, C.; Edwards, R.; de la Cruz, D.; Talmont, P.; Maroju, S. Recent experience with a comprehensive riser tower monitoring system. In Proceedings of the D.O.T International Conference, New Orleans, LA, USA, 3–5 February 2009.

- Inaudi, D.; Glisic, B. Fiber optic sensing for innovative oil and gas production and transport systems. In Proceedings of the 18th International Conference on Optical Fiber Sensors, Cancun, Mexico, 23–27 October 2006. [CrossRef]

- Inaudi, D.; Glisic, B.; Gasparoni, F.; Cenedese, S.; Zecchin, M. Strain sensors for deepwater applications. In Proceedings of the 3rd International Conference on Structural Health Monitoring of Intelligent Infrastructure, Vancouver, BC, Canada, 13–16 November 2007.

- Tuck, J.; Lee, P. Inverse transient analysis for classification of wall thickness variations in pipelines. Sensors 2013, 13, 17057–17066. [Google Scholar] [CrossRef]

- Almazyad, A.S.; Seddiq, Y.M.; Alotaibi, A.M.; Al-Nasheri, A.Y.; BenSaleh, M.S.; Obeid, A.M.; Qasim, S.M. A proposed scalable design and simulation of wireless sensor network-based long-distance water pipeline leakage monitoring system. Sensors 2014, 14, 3557–3577. [Google Scholar] [CrossRef] [PubMed]

- Wan, K.T.; Leung, C.K. Durability tests of a fiber optic corrosion sensor. Sensors 2012, 12, 3656–3668. [Google Scholar] [CrossRef] [PubMed]

- Brower, D.; Hedengren, J.D.; Shishivan, R.A.; Brower, A. Advanced deepwater monitoring system. In Proceedings of the 32nd International Conference on Ocean, Nantes, France, 9–14 June 2013. [CrossRef]

- Qiu, Y.; Wang, Q.-B.; Zhao, H.-T.; Chen, J.-A.; Wang, Y.-Y. Review on composite structural health monitoring based on fiber bragg grating sensing principle. J. Shanghai Jiaotong Univ. (Sci.) 2013, 18, 129–139. [Google Scholar] [CrossRef]

- Baldwin, C.S. Applications for fiber optic sensing in the upstream oil and gas industry. In Proceedings of the Fiber Optic Sensors and Applications XII, Baltimore, MD, USA, 22–23 April 2015.

- Shishavan, R.A.; Brower, D.V.; Hedengren, J.D.; Brower, A.D. New advances in post-installed subsea monitoring systems for structural and flow assurance evaluation. In Proceedings of the 33rd International Conference on Ocean, Offshore and Arctic Engineering, San Francisco, CA, USA, 8–13 June 2014. [CrossRef]

- Brower, D.V.; Prescott, N. Real time subsea monitoring and control smart field solutions. In Proceedings of the Subsea Rio Conference, Rio, Brazil, 3 June 2004.

- Morrison, D.; Dean, J. Apparatuses and Methods for Monitoring Stress in Steel Catenary Risers. U.S. Patent US20060230839 A1, 19 October 2006. [Google Scholar]

- Ren, L.; Jia, Z.; Ho, M.S.C.; Yi, T.; Li, H. Application of fiber bragg grating based strain sensor in pipeline vortex-induced vibration measurement. Sci. China Tech. Sci. 2014, 57, 1714–1720. [Google Scholar] [CrossRef]

- Wang, J.; Fu, S.; Baarholm, R.; Wu, J.; Larsen, C.M. Fatigue damage of a steel catenary riser from vortex-induced vibration caused by vessel motions. Mar. Struct. 2014, 39, 131–156. [Google Scholar] [CrossRef]

- Morikawa, S.R.; Camerini, C.S.; Pipa, D.R.; Santos, J.M.; Pires, G.P.; Braga, A.M.; Llerena, R.W.; Ribeiro, A.S. Monitoring of flexible oil lines using FBG sensors. In Proceedings of the 19th International Conference on Optical Fibre Sensors, Perth, Australia, 14 April 2008. [CrossRef]

- Weppenaar, N.; Andersen, B. Investigation of tension armor wire breaks in flexible risers and a method for detection. In Proceedings of the 33rd International Conference on Ocean, San Francisco, CA, USA, 8–13 June 2014. [CrossRef]

- Dikshit, V.; Seng, O.L.; Maheshwari, M.; Asundi, A. Failure assessment of aluminum liner based filament-wound hybrid riser subjected to internal hydrostatic pressure. In Proceedings of the International Conference on Experimental Mechanics, Singapore, 15 November 2014. [CrossRef]

- Jiang, Y.; Yang, D.; Wang, J.; Xu, J.; Qin, C.; Liao, W.; Zhao, J.; Wang, H.; Jiang, S. Strain monitoring of drilling riser in deepwater based on fiber bragg gratings. In Proceedings of International Conference on Optical Instruments and Technology, Beijing, China, 6 November 2011. [CrossRef]

- Xu, J.; Yang, D.; Jiang, Y.; Wang, M.; Zhai, H.; Bai, Y. Packaged FBG sensors for real-time stress monitoring on deep-water riser. In Proceedings of the International Society for Optics and Photonics, Beijing, China, 9 October 2014. [CrossRef]

- Li, B.; Wang, H.; Shen, X.; Yan, Y.; Yang, F.; Hua, F. Deep-water riser fatigue monitoring systems based on acoustic telemetry. J. Ocean Univ. China 2014, 13, 951–956. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, J.; Yang, D.; Qin, C.; Jiang, Y.; Sheng, L.; Jia, X.; Bai, Y.; Shen, X.; Wang, H.; Deng, X.; et al. Study and Test of a New Bundle-Structure Riser Stress Monitoring Sensor Based on FBG. Sensors 2015, 15, 29648-29660. https://doi.org/10.3390/s151129648

Xu J, Yang D, Qin C, Jiang Y, Sheng L, Jia X, Bai Y, Shen X, Wang H, Deng X, et al. Study and Test of a New Bundle-Structure Riser Stress Monitoring Sensor Based on FBG. Sensors. 2015; 15(11):29648-29660. https://doi.org/10.3390/s151129648

Chicago/Turabian StyleXu, Jian, Dexing Yang, Chuan Qin, Yajun Jiang, Leixiang Sheng, Xiangyun Jia, Yang Bai, Xiaohong Shen, Haiyan Wang, Xin Deng, and et al. 2015. "Study and Test of a New Bundle-Structure Riser Stress Monitoring Sensor Based on FBG" Sensors 15, no. 11: 29648-29660. https://doi.org/10.3390/s151129648