Detection of Lettuce Discoloration Using Hyperspectral Reflectance Imaging

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials

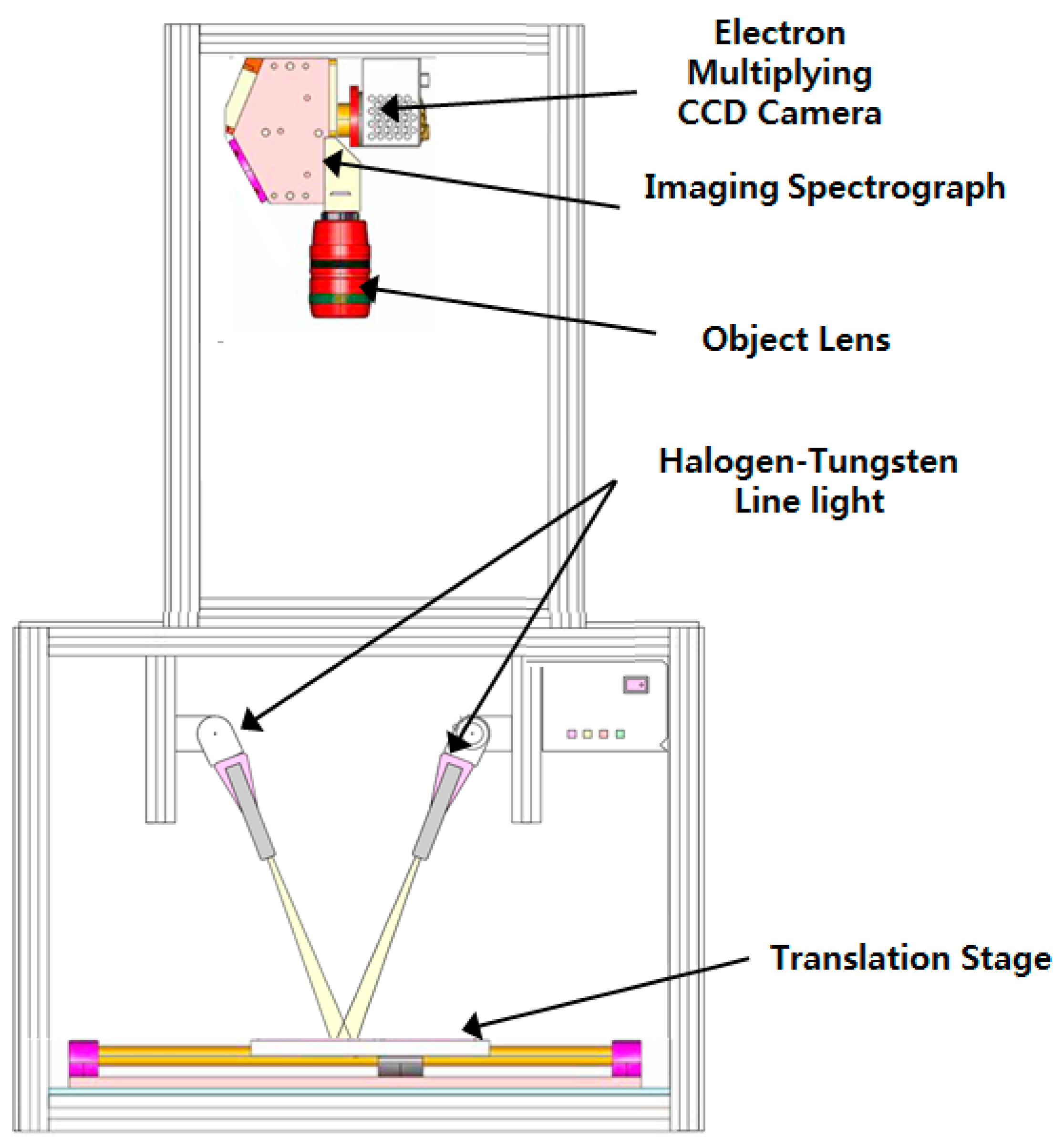

2.2. Hyperspectral Imaging System

2.3. Hyperspectral Image Spectra Acquisition

3. Results and Discussion

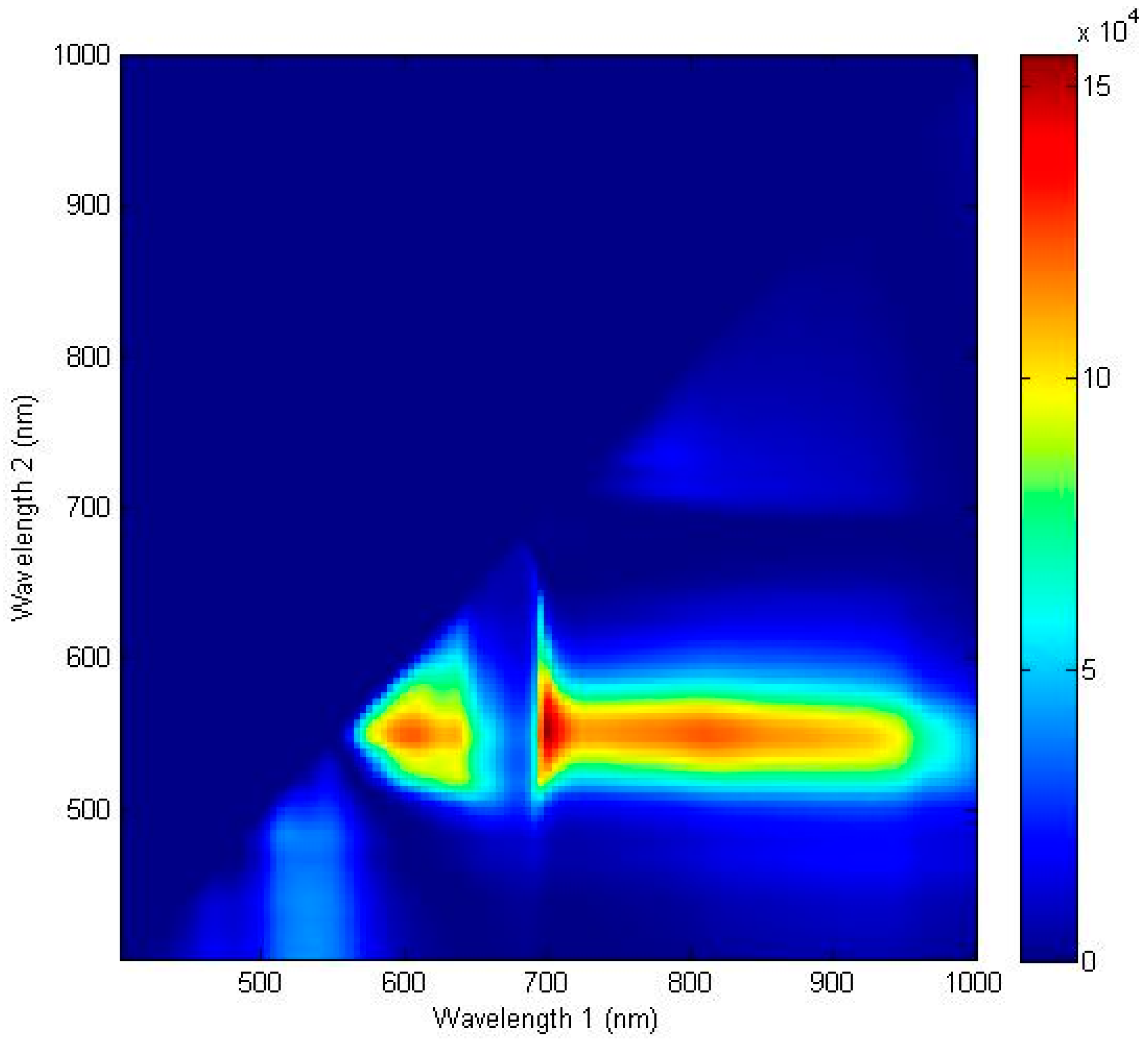

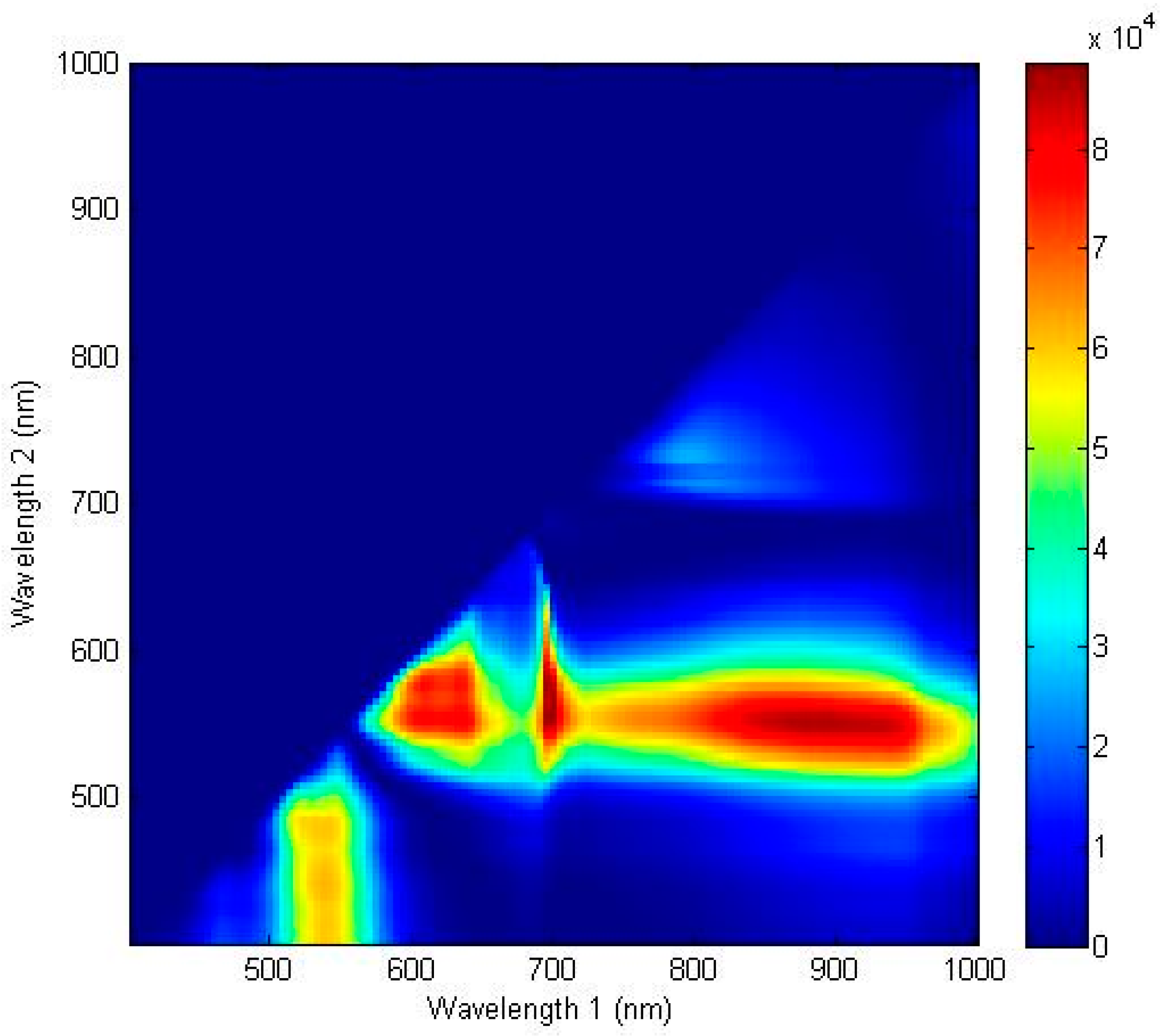

3.1. Spectral Characteristics of Sound and Discolored Lettuce

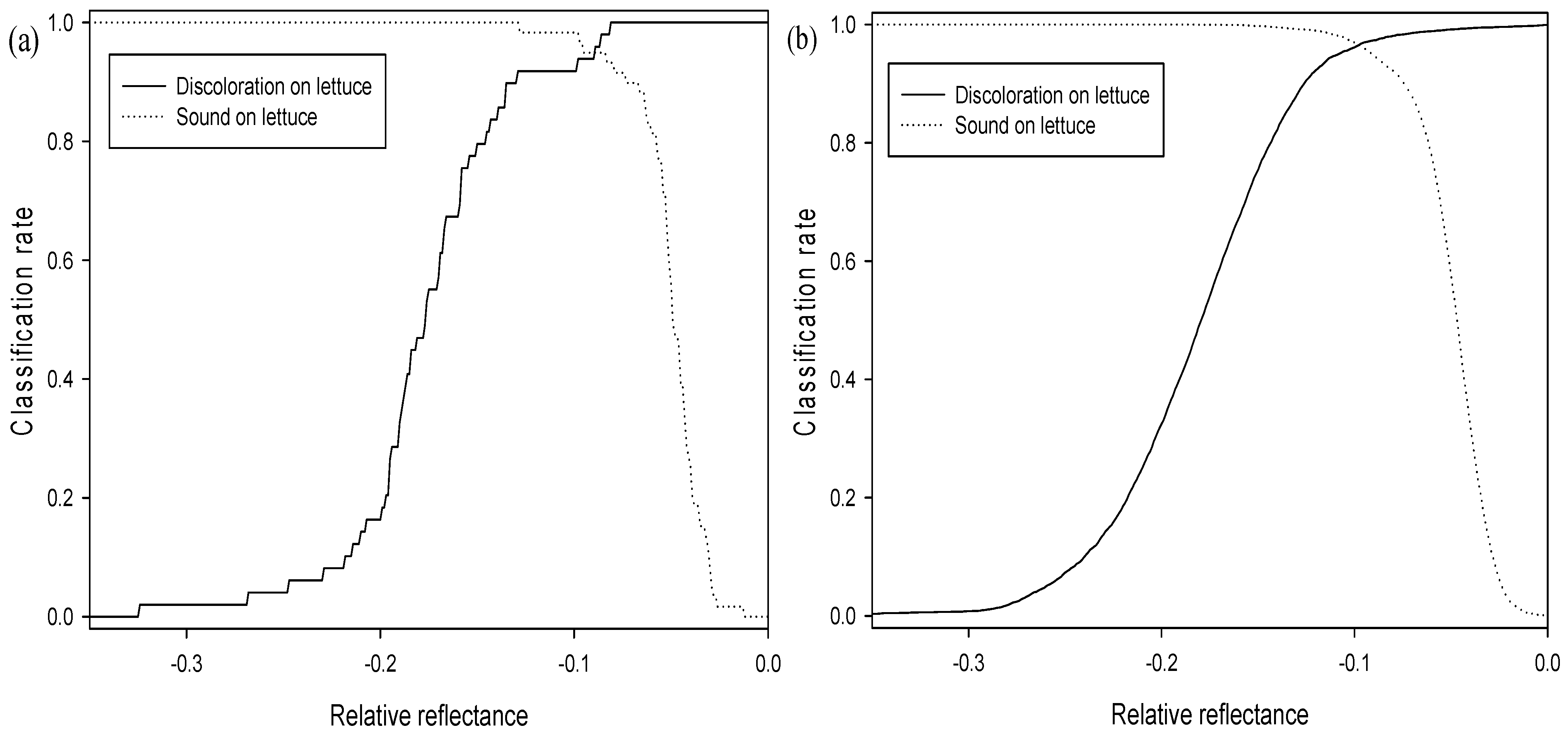

3.2. Algorithm for Distinguishing Discoloration on Lettuce Using Spectra

| Type of Surface | Calibration (Set A) | Validation (Set B) | ||||||

|---|---|---|---|---|---|---|---|---|

| Single Waveband | Two-Waveband Ratio | Two-Waveband Subtraction | Single Waveband | Two-Waveband Ratio | Two-Waveband Subtraction | |||

| Optimal Wavebands | 547 nm | 552 nm, 701 nm | 557 nm, 701 nm | 547 nm | 552 nm, 701 nm | 557 nm, 701 nm | ||

| No. of total sample | Adaxial | Discoloration | 23 | 26 | ||||

| Sound | 30 | 30 | ||||||

| Abaxial | Discoloration | 26 | 29 | |||||

| Sound | 29 | 30 | ||||||

| 1) CA (%) | Adaxial | 2) CV | 0.44~0.45 | 0.85–0.89 | −0.086 ~ −0.074 | 0.44 | 0.85 | −0.086 ~ −0.084 |

| Discoloration | 95.7 | >99.9 | >99.9 | >99.9 | >99.9 | >99.9 | ||

| Sound | 93.3 | 96.7 | 96.7 | 66.7 | 96.7 | >99.9 | ||

| Abaxial | 2) CV | 0.44 | 0.79–0.85 | −0.098 | 0.44 | 0.85 | −0.086 ~ −0.084 | |

| Discoloration | 84.6 | 96.2 | 96.2 | 72.4 | >99.9 | >99.9 | ||

| Sound | 89.7 | >99.9 | >99.9 | 60.0 | >99.9 | >99.9 | ||

| Both | 2) CV | 0.44 | 0.85 | −0.086 ~ −0.084 | 0.44 | 0.85 | −0.086 ~ −0.084 | |

| Discoloration | 89.8 | 98.0 | 98.0 | 85.5 | >99.9 | >99.9 | ||

| Sound | 91.5 | 98.3 | 94.9 | 63.3 | 98.3 | >99.9 | ||

| Type of Surface | Calibration (Set A) | Validation (Set B) | ||||||

|---|---|---|---|---|---|---|---|---|

| Single Waveband | Two-Waveband Ratio | Two-Waveband Subtraction | Single Waveband | Two-Waveband Ratio | Two-Waveband Subtraction | |||

| Optimal Wavebands | 547 nm | 552 nm, 701 nm | 557 nm, 701 nm | 547 nm | 552 nm, 701 nm | 557 nm, 701 nm | ||

| No. of total pixels | Adaxial | Discoloration | 2694 | 1213 | ||||

| Sound | 6919 | 16,917 | ||||||

| Abaxial | Discoloration | 3882 | 2836 | |||||

| Sound | 10,147 | 4854 | ||||||

| 1) CA (%) | Adaxial | 2) CV | 0.44 | 0.78 | −0.089 | 0.43 | 0.81 | −0.106 |

| Discoloration | 83.1 | 98.8 | 98.1 | 86.0 | 99.7 | 90.0 | ||

| Sound | 84.1 | 97.8 | 96.3 | 63.6 | 99.9 | 99.6 | ||

| Abaxial | 2) CV | 0.41 | 0.81 | −0.106 | 0.43 | 0.81 | −0.106 | |

| Discoloration | 72.0 | 99.1 | 95.1 | 58.2 | 99.4 | 96.2 | ||

| Sound | 87.7 | 99.9 | 98.4 | 64.2 | >99.9 | >99.9 | ||

| Both | 2) CV | 0.43 | 0.81 | −0.106 | 0.43 | 0.81 | −0.106 | |

| Discoloration | 78.4 | 99.1 | 95.4 | 66.5 | 99.5 | 94.4 | ||

| Sound | 83.4 | 98.7 | 97.8 | 63.7 | 99.9 | 99.7 | ||

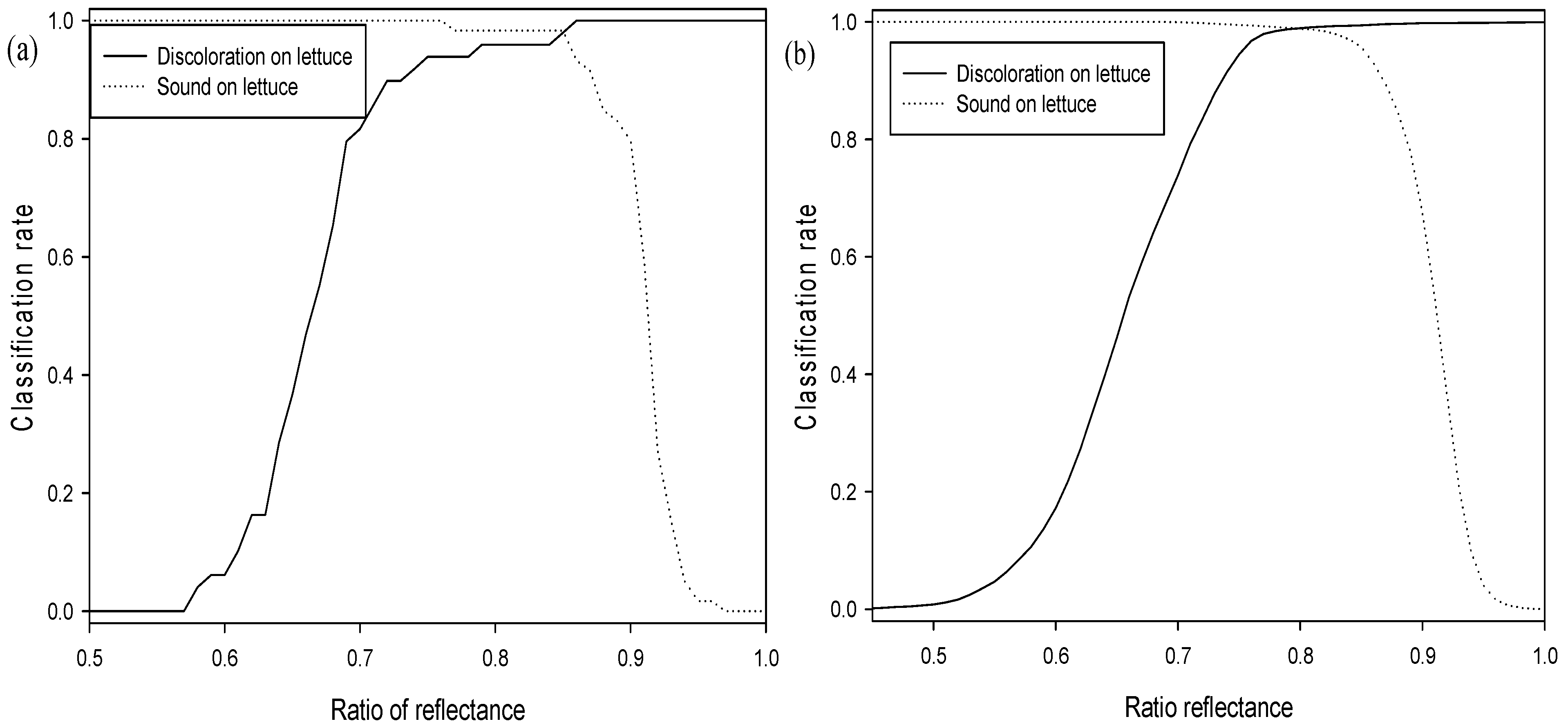

3.2.1. Single Waveband Algorithm

3.2.2. Two-Waveband Ratio Algorithm

3.2.3. Two-Waveband Subtraction Algorithm

3.3. Development of Imaging Algorithms for Discoloration Discrimination

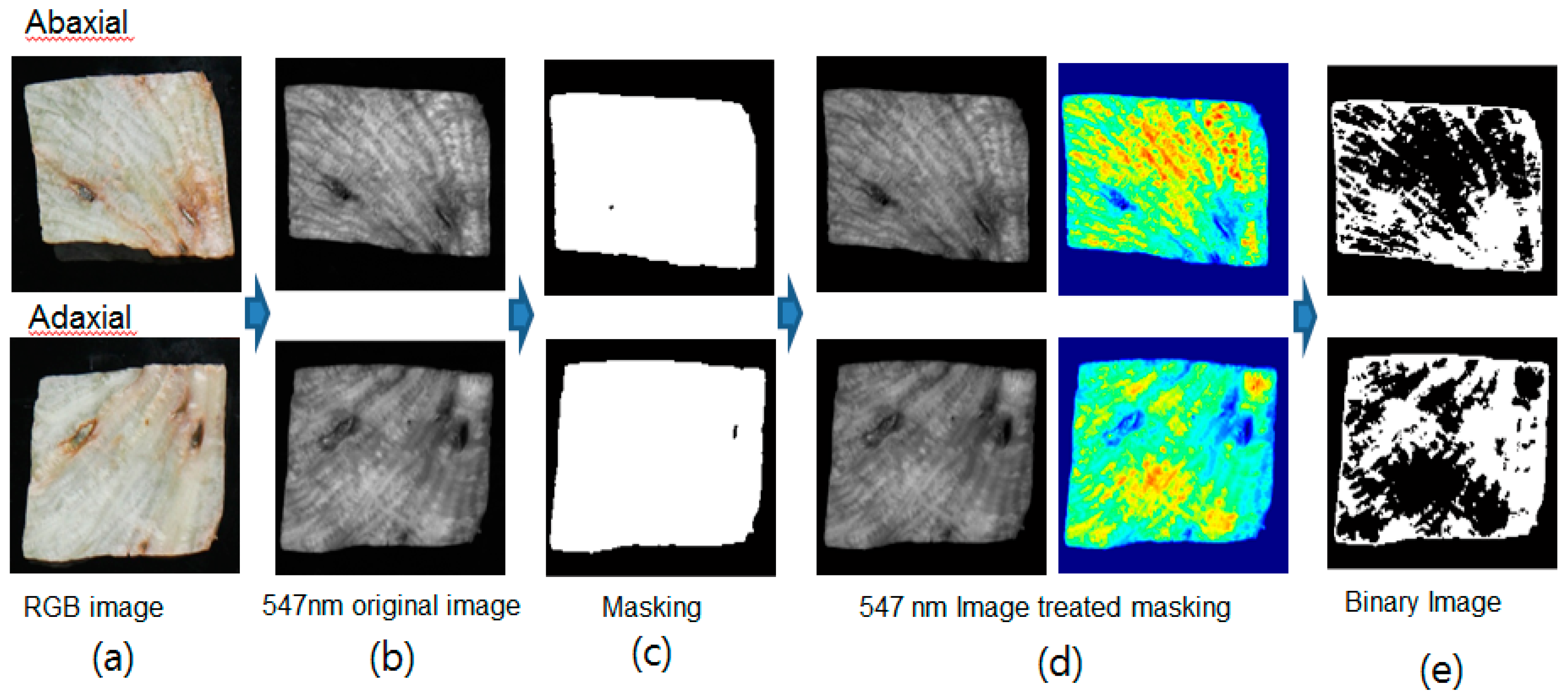

3.3.1. Single Waveband Imaging (SWI) Algorithm

3.3.2. Ratio Imaging (RI) Algorithm

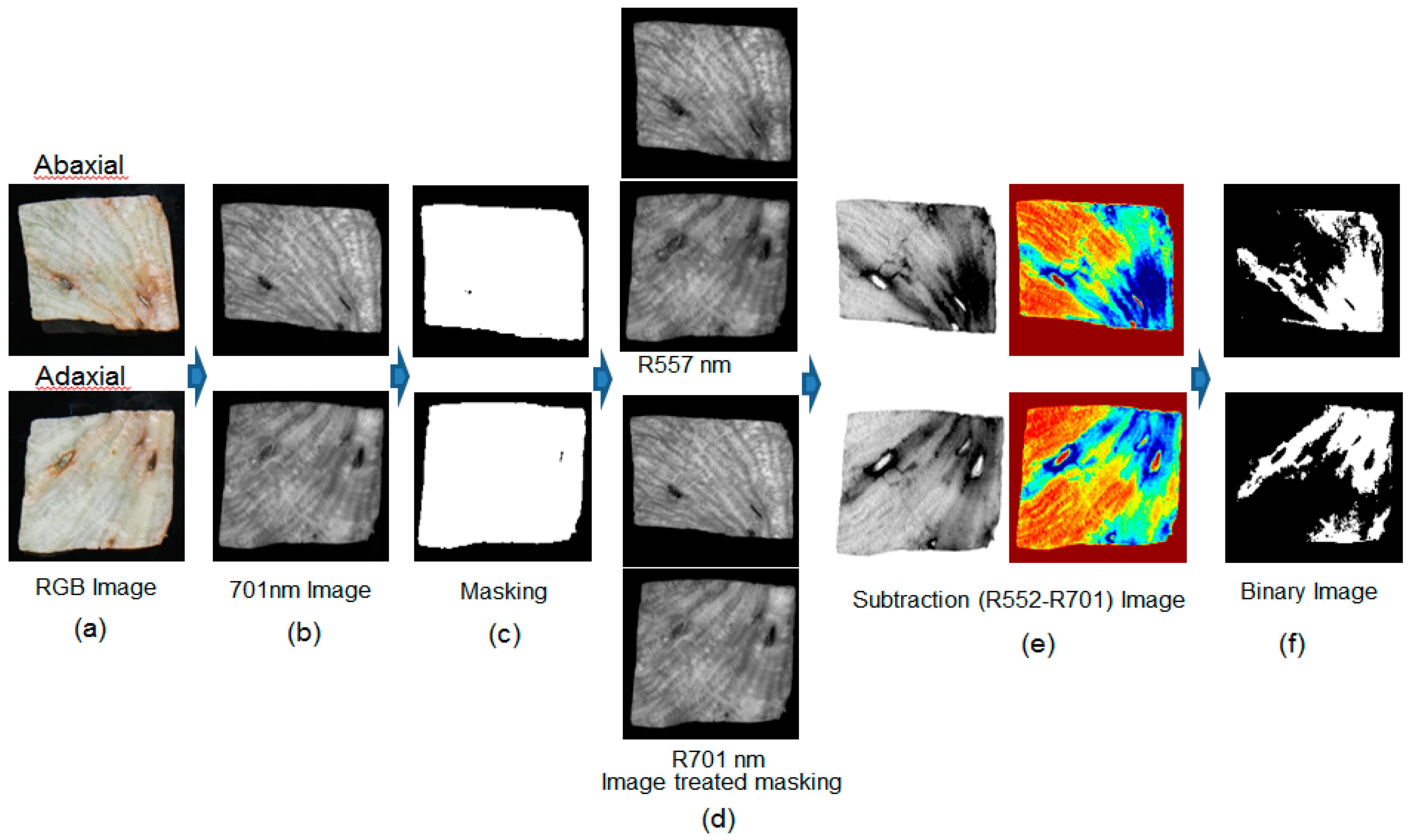

3.3.3. Two-Band Subtraction Imaging (SI) Algorithm

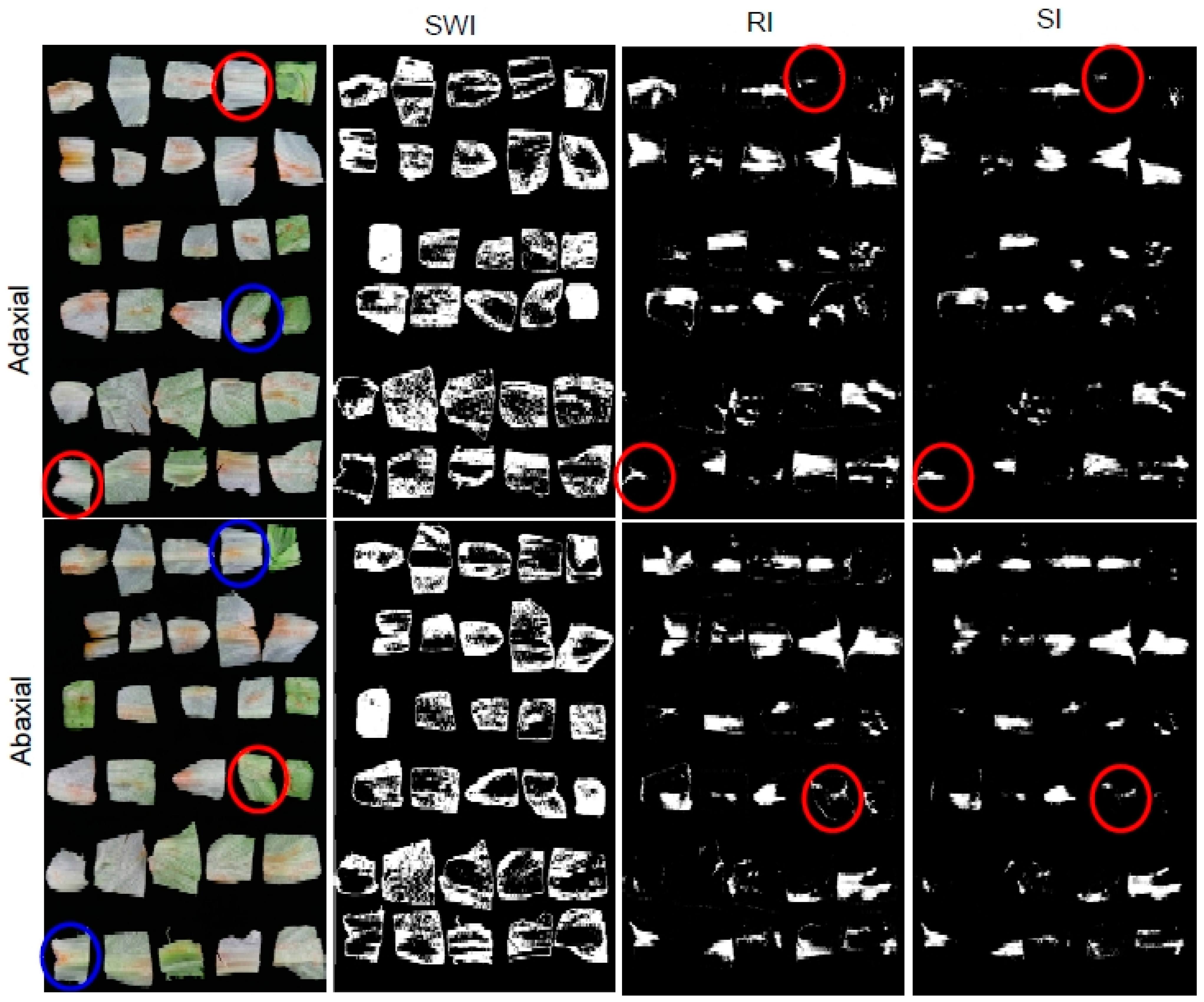

3.3.4. Classification Results for the Three Imaging Algorithms

| No. of Samples | CA 1) (%) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| SWI 2) | RI 3) | SI 4) | |||||||||

| Discoloration | Sound | SE 5) | SP 6) | PA 7) | SE 5) | SP 6) | PA 7) | SE 5) | SP 6) | PA 7) | |

| Adaxial surface | 26 | 30 | >99.9 | 0 | 46.4 | >99.9 | >99.9 | >99.9 | >99.9 | >99.9 | >99.9 |

| Abaxial surface | 29 | 30 | 86.2 | 0 | 42.4 | >99.9 | >99.9 | >99.9 | >99.9 | >99.9 | >99.9 |

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Couture, R.; Cantwell, M.I.; Ke, D.; Saltveit, M.E., Jr. Physiological attributes and storage life of minimally processed lettuce. Hortscience 1993, 28, 723–725. [Google Scholar]

- Mateos, M.; Ke, D.; Cantwell, M.; Kader, A.A. Phenolic metabolism and ethanolic fermentation of intact and cut lettuce exposed to CO2-enriched atmospheres. Postharvest Biol. Technol. 1993, 3, 225–233. [Google Scholar] [CrossRef]

- Hisaminato, H.; Murata, M.; Homma, S. Relationship between enzymatic browning of cut lettuce and phenylalanine ammonia-lyase activity, and prevention of browning by inhibitors of polyphenol biosynthesis. Biosci. Biotech. Biochem. 2001, 65, 1016–1021. [Google Scholar] [CrossRef]

- Ke, D.; Saltveit, M.E. Wound-induced ethylene production, phenolic metabolism and susceptibility to russet spotting in Iceberg lettuce. Physiol. Plant. 1989, 76, 412–418. [Google Scholar] [CrossRef]

- Dixon, R.A.; Paiva, N.L. Stress-lnduced Phenylpropanoid Metabolism. Plant Cell 1995, 7, 1085–1097. [Google Scholar] [CrossRef] [PubMed]

- Tomás-Barberán, F.A.; Gil, M.I.; Castaner, M.; Artés, F.; Saltveit, M.E. Effect of selected browning inhibitors on phenolic metabolism in stem tissue of harvested lettuce. J. Agric. Food Chem. 1997, 45, 583–589. [Google Scholar] [CrossRef]

- Mayer, A.M. Polyphenol oxidases in plants—Recent progress. Phytochemistry 1987, 26, 11–20. [Google Scholar] [CrossRef]

- Ferrante, A.; Incrocci, L.; Maggini, R.; Serra, G.; Tognoni, F. Colour changes of fresh-cut leafy vegetables during storage. J. Food Agric. Environ. 2004, 2, 40–44. [Google Scholar]

- Lim, J.; Mo, C.; Kim, G.; Kim, M.S.; Lee, H. Development of models for the prediction of domestic red pepper (capsicum annuum L.) powder capsaicinoid content using visible and near-infrared spectroscopy. J. Biosyst. Eng. 2015, 40, 47–60. [Google Scholar] [CrossRef]

- Moons, E.; Dardenne, P.; Dubois, A.; Sindic, M. Nondestructive visible and NIR spectroscopy measurement for the determination of apple internal quality. Acta Hortic. 1997, 517, 441–448. [Google Scholar]

- Blasco, J.; Aleixos, N.; Molto, E. Computer vision detection of peel defects in citrus by means of a region oriented segmentation algorithm. J. Food Eng. 2007, 81, 535–543. [Google Scholar] [CrossRef]

- Lee, K.J.; Kang, S.W.; Delwiche, S.R.; Kim, M.S.; Noh, S.H. Correlation analysis of hyperspectral imagery for multispectral wavelength selection for detection of defects on apples. Sens. Instrum. Food Qual. Saf. 2008, 2, 90–96. [Google Scholar] [CrossRef]

- Cho, B.K.; Beak, I.S.; Lee, N.G.; Mo, C.H. Study on bruise detection of “Fuji” apple using hyperspectral reflectance imagery. J. Biosyst. Eng. 2011, 36, 484–490. [Google Scholar] [CrossRef]

- Wu, D.; Sun, D.W. Advanced applications of hyperspectral imaging technology for food quality and safety analysis and assessment: A review—Part I: Fundamentals. Innov. Food Sci. Emerg. Technol. 2013, 19, 1–14. [Google Scholar] [CrossRef]

- Kim, M.S.; Chen, Y.R.; Mehl, P.M. Hyperspectral reflectance and fluorescence imaging system for food quality and safety. Trans. ASAE 2001, 44, 721–729. [Google Scholar]

- Kim, M.S.; Lefcourt, A.M.; Chao, K.; Chen, Y.R.; Kim, I.; Chan, D.E. Multispectral detection of fecal contamination on apples based on hyperspectral imagery: Part I. Application of visible and near-infrared reflectance imaging. Trans. ASAE 2002, 45, 2027–2037. [Google Scholar]

- Mo, C.; Lim, J.; Lee, K.; Kang, S.; Kim, M.S.; Kim, G.; Cho, B.K. Determination of germination quality of cucumber (cucumis sativus) seed by led-induced hyperspectral reflectance imaging. J. Biosyst. Eng. 2013, 38, 318–326. [Google Scholar] [CrossRef]

- Lee, H.; Yang, C.C.; Kim, M.S.; Lim, J.; Cho, B.K.; Lefcourt, A.; Chao, K.; Everard, C.D. A simple multispectral imaging algorithm for detection of defects on red delicious apples. J. Biosyst. Eng. 2014, 39, 142–149. [Google Scholar] [CrossRef]

- Jeong, D.H.; Kim, M.S.; Lee, H.; Lee, H.; Cho, B.K. Detection algorithm for cracks on the surface of tomatoes using multispectral VIS/NIR reflectance imagery. J. Biosyst. Eng. 2013, 38, 199–207. [Google Scholar] [CrossRef]

- Jun, W.; Kim, M.S.; Lee, K.; Millner, P.; Chao, K. Assessment of bacterial biofilm on stainless steel by hyperspectral fluorescence imaging. Sens. Instrum. Food Qual. Saf. 2009, 3, 41–48. [Google Scholar] [CrossRef]

- Luo, Y.; Tao, Y. Determining tissue damage of fresh-cut vegetables using image technology. Acta Hortic. 2003, 628, 97–102. [Google Scholar] [CrossRef]

- Lee, H.Y.; Everard, C.; Kang, S.; Cho, B.K.; Chao, K.; Chan, D.; Kim, M.S. Multispectral fluorescence imaging for detection of bovine feces on Romaine lettuce and baby spinach leaves. Biosyst. Eng. 2014, 127, 125–134. [Google Scholar] [CrossRef]

- Hardenburg, R.E.; Watada, A.E.; Wang, C.Y. The Commercial Storage of Fruits, Vegetables, and Florist and Nursery Stocks; USDA Handbook No. 66; U.S. Department of Agriculture, Agricultural Research Service: Beltsville, MA, USA, 1986. [Google Scholar]

- De Rigal, D.; Gauillard, F.; Richard-Forget, F. Changes in the carotenoid content of apricot (Prunus armeniaca, var Bergeron) during enzymatic browning: B-carotene inhibition of chlorogenic acid degradation. J. Sci. Food Agric. 2000, 80, 763–768. [Google Scholar] [CrossRef]

- Tian, S.P.; Li, B.Q.; Xu, Y. Effects of O2 and CO2 concentrations on physiology and quality of litchi fruit in storage. Food Chem. 2005, 91, 659–663. [Google Scholar] [CrossRef]

- Gross, J. Pigments in Vegetables: Chlorophylls and Carotenoids; Van Nostrand Reinhold: New York, NY, USA, 1991. [Google Scholar]

- Wesche-Ebeling, P.; Montgomery, M.W. Strawberry polyphenoloxidadase: Its role in anthocyanin degradation. J. Food Sci. 1990, 55, 731–734. [Google Scholar] [CrossRef]

- Merzlyak, M.N.; Solovchenko, A.E.; Gitelson, A.A. Reflectance spectral features and non-destructive estimation of chlorophyll, carotenoid and anthocyanin content in apple fruit. Postharvest Biol. Technol. 2003, 27, 197–211. [Google Scholar] [CrossRef]

- Viña, A.; Gitelson, A.A. Sensitivity to foliar anthocyanin content of vegetation indices using green reflectance. IEEE Geosci. Remote Sens. Lett. 2011, 8, 464–468. [Google Scholar] [CrossRef]

- Gitelson, A.A.; Merzlyak, M.N. Spectral reflectance changes associate with autumn senescence of Aesculus hippocastanum L. and Acer platanoides L. leaves. Spectral features and relation to chlorophyll estimation. J. Plant Physiol. 1994, 143, 286–292. [Google Scholar] [CrossRef]

- Gitelson, A.A.; Merzlyak, M.N.; Lichtenthaler, H.K. Detection of red edge position and chlorophyll content by reflectance measurements near 700 nm. J. Plant Physiol. 1996, 148, 501–508. [Google Scholar] [CrossRef]

- Loredana, L.; Pamela, G.; Belén, D.; Lourdes, L.; Luis, R.-G. A multispectral vision system to evaluate enzymatic browning in fresh-cut apple slices. Postharvest Biol. Technol. 2011, 60, 225–234. [Google Scholar] [CrossRef] [Green Version]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mo, C.; Kim, G.; Lim, J.; Kim, M.S.; Cho, H.; Cho, B.-K. Detection of Lettuce Discoloration Using Hyperspectral Reflectance Imaging. Sensors 2015, 15, 29511-29534. https://doi.org/10.3390/s151129511

Mo C, Kim G, Lim J, Kim MS, Cho H, Cho B-K. Detection of Lettuce Discoloration Using Hyperspectral Reflectance Imaging. Sensors. 2015; 15(11):29511-29534. https://doi.org/10.3390/s151129511

Chicago/Turabian StyleMo, Changyeun, Giyoung Kim, Jongguk Lim, Moon S. Kim, Hyunjeong Cho, and Byoung-Kwan Cho. 2015. "Detection of Lettuce Discoloration Using Hyperspectral Reflectance Imaging" Sensors 15, no. 11: 29511-29534. https://doi.org/10.3390/s151129511