Magnetic Sensors Based on Amorphous Ferromagnetic Materials: A Review

Abstract

:1. Introduction

- (a)

- Variations of magnetic core permeability produced by the parameter to be measured.

- (b)

- Changes in some physical parameters produced by changes of the magnetization direction.

- (c)

- Mutual induction changes between two circuits produced by geometric modifications of the magnetic core positioning.

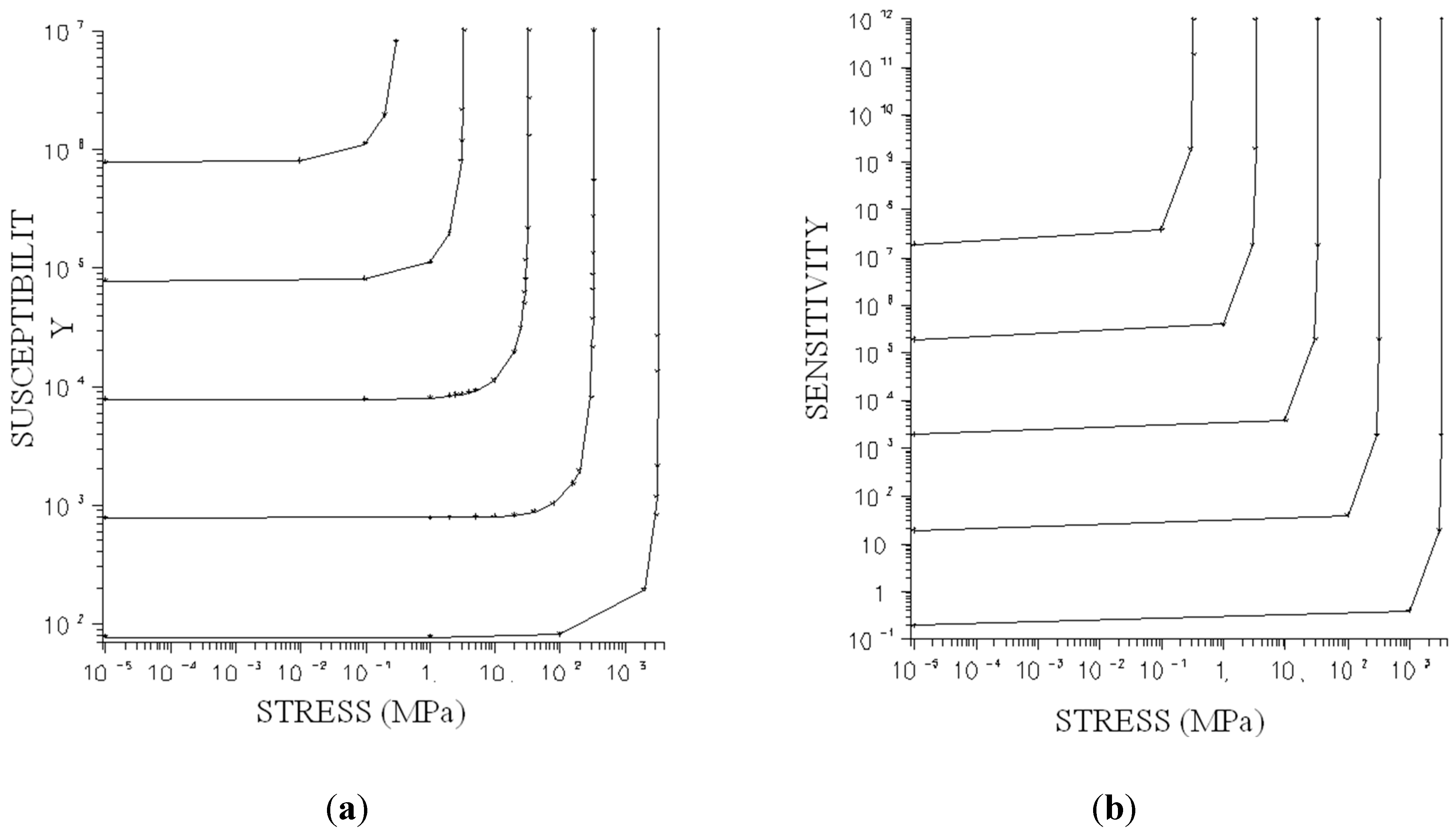

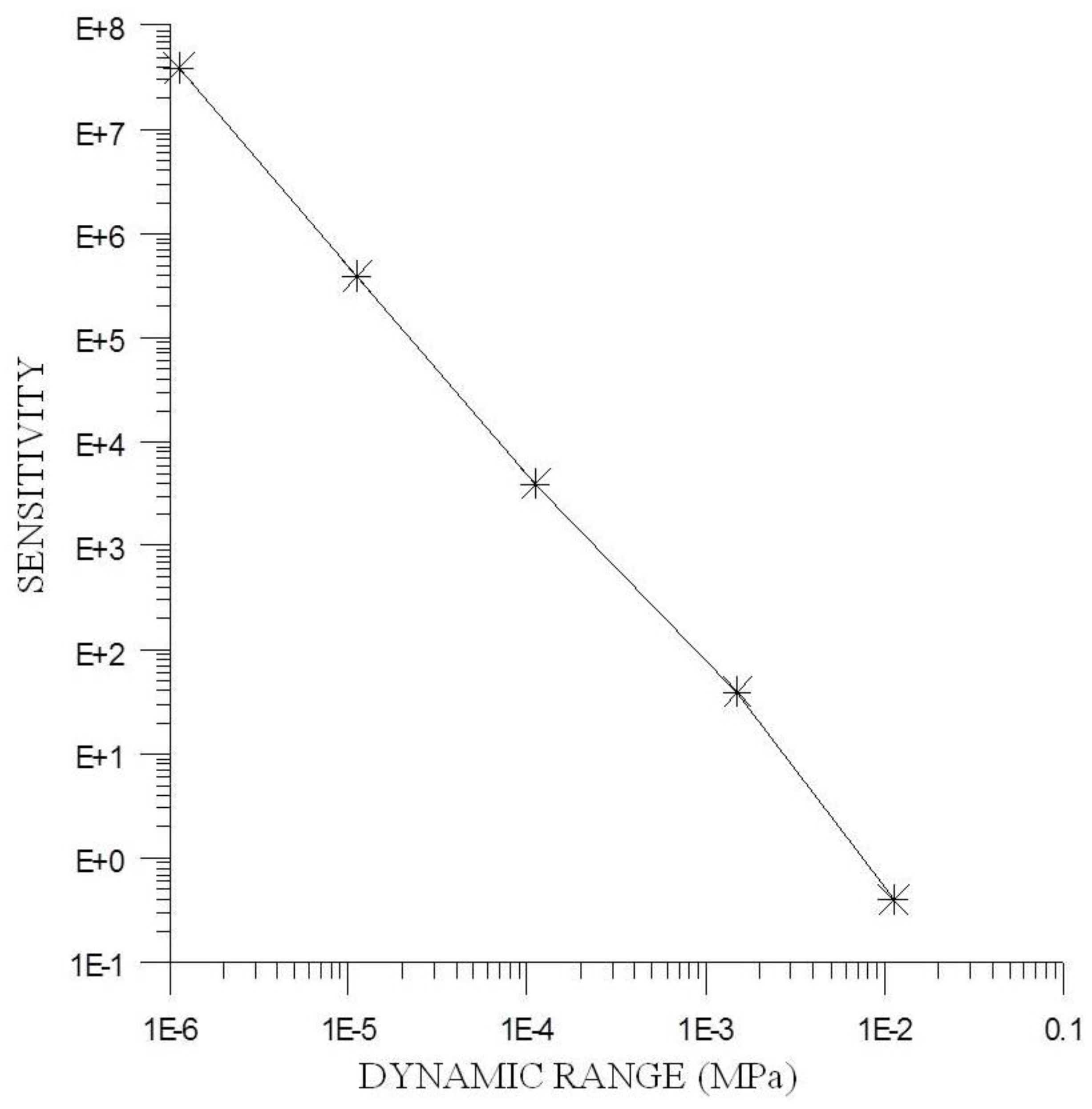

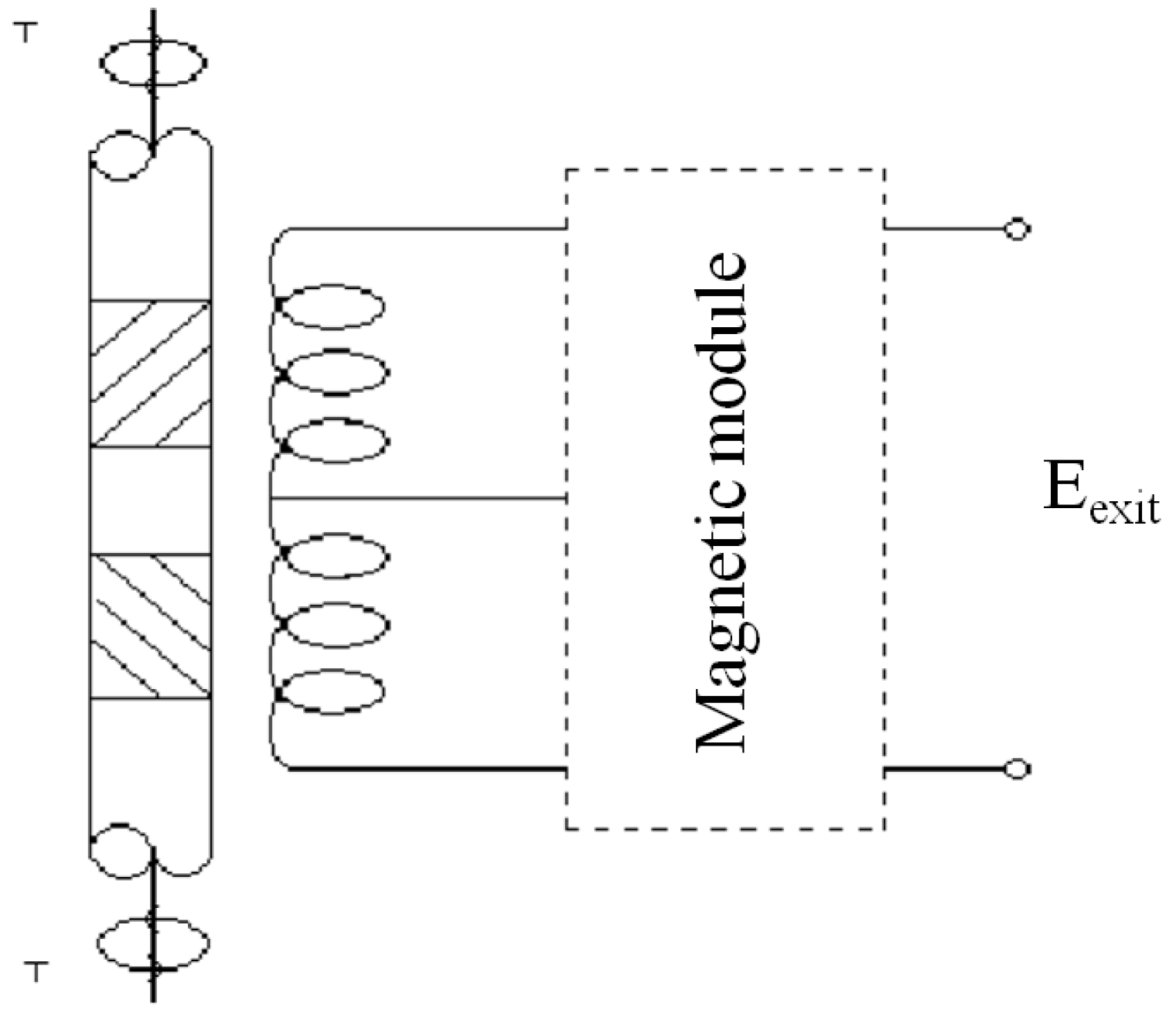

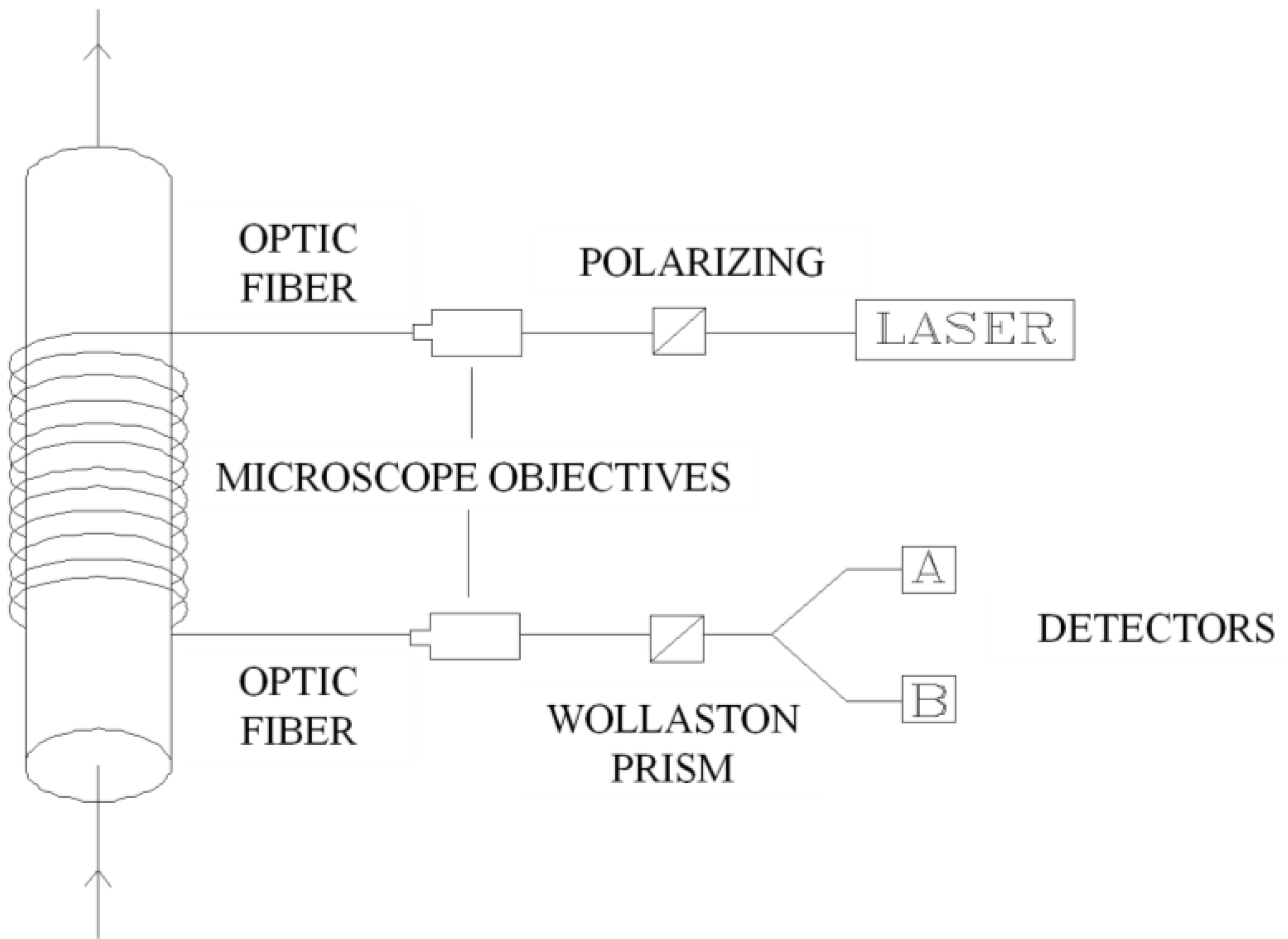

2. Sensors Based on Magnetostrictive Effects

- Variation of magnetic material susceptibility when a mechanical stress is applied.

- Length variation of magnetic materials when the magnetization direction changes.

- Modification of the Young’s modulus of magnetic materials by varying the magnetization state.

2.1. Stress Sensor

2.1.1. Theory

2.1.2. Applications

3. Sensors Based on the Nonlinearity of Magnetization Processes

3.1. Saturated Core Magnetometers

3.1.1. Theory

3.1.2. Double Core Fluxgate

3.1.3. Applications

| Parameters | Values |

|---|---|

| Total mass: | 361 g + 250 g (frame) |

| Sensor mass: | 75 g |

| Sensor volume: | 4 × 4 × 6 cm |

| Energy consumption, Electronic: | 500 mW |

| Energy consumption, Sensor: | 50 mW |

| Range selection: | 1000, 64.000 nT |

| Data rate: | 16 vectors/s |

| Data resolution: | 18 bits (1:range, 1:sign, 16:value) |

| Mission Name | Range (nT) | Cadence (nT) | Mass (g) | Area (in2) |

|---|---|---|---|---|

| ISEE | 8000, 556 | 4, 16 | 500 | 100 |

| Galileo | 16.000, 512, 32 | 0.05, 3, 32 | 500 | 100 |

| Polar | 47.000, 5700, 700 | 8.3, 100 | 400 | 70 |

| FAST | 64.000 | Up to 512 | 350 | 60 |

| FedSat | 60.000 | 10,100 | 200 | 35 |

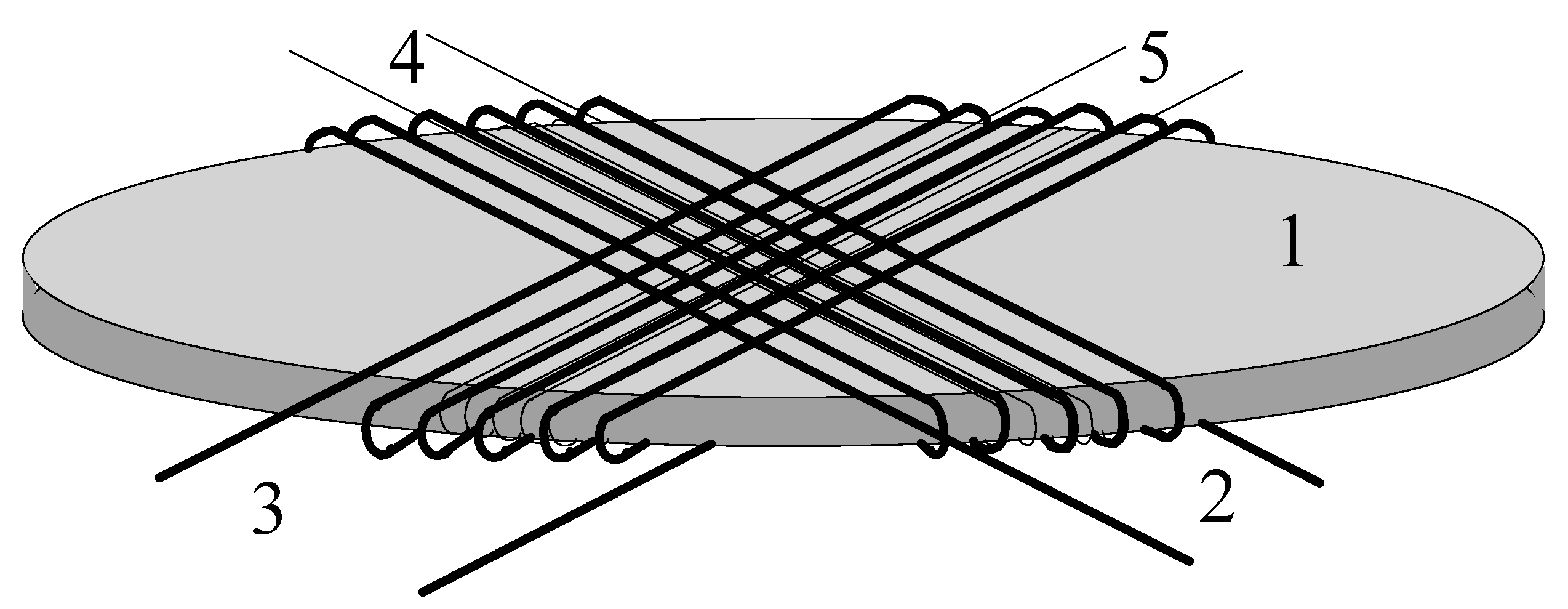

3.1.4. Planar Micro-Fluxgate

- They need little space.

- They provide linear responses for overhead magnetic inductions (there are certainly “conventional” fluxgates that offer a better response, but not in such a reduced area of 50 μT).

- They measure the chip plan (360°) without ambiguity.

- Their production is easy and very cheap using planar technology.

- They have the whole control circuitry integrated.

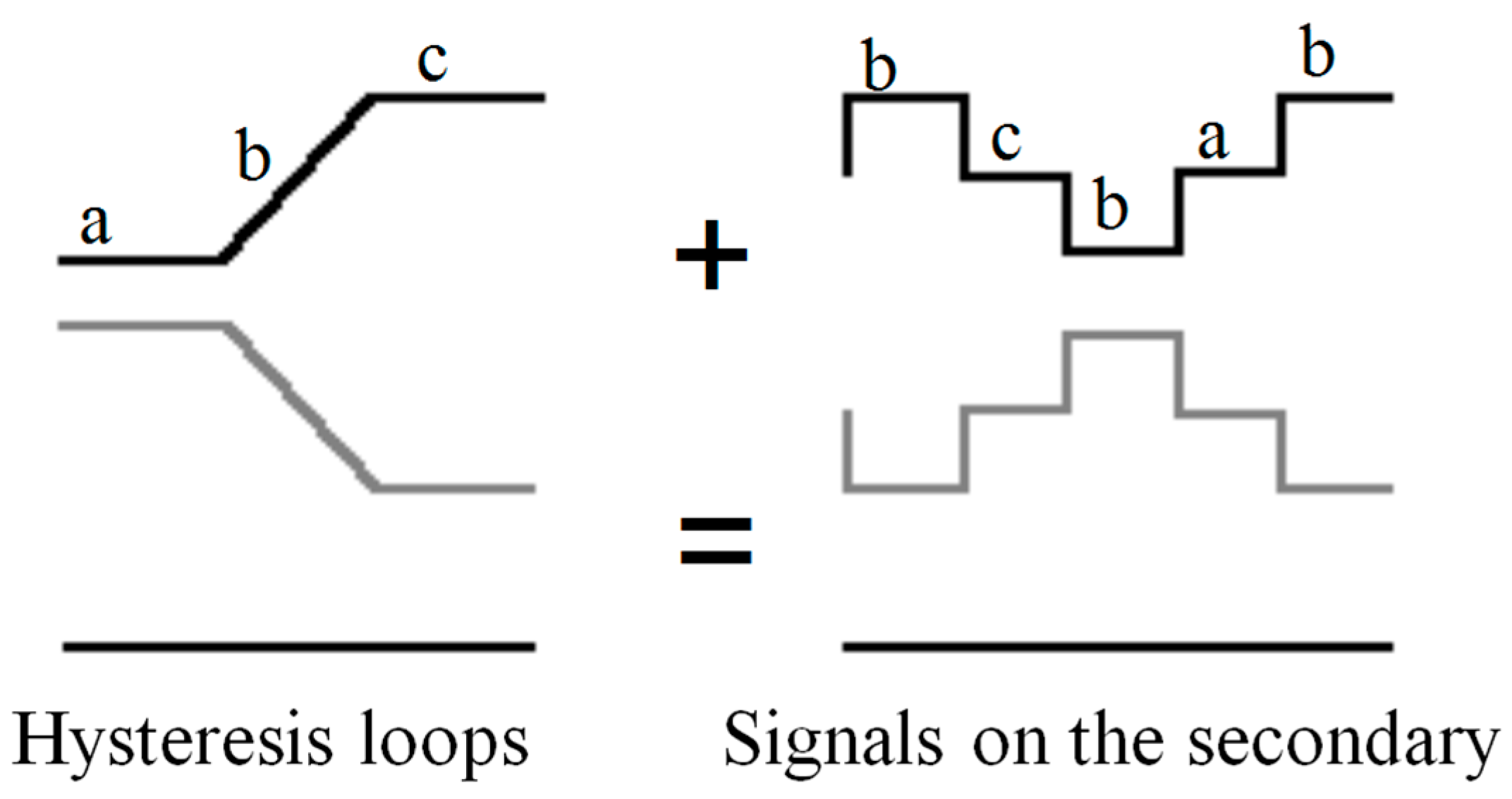

3.2. Bistable Sensors

3.2.1. Theory

3.2.2. Obtaining and Features

3.2.3. Applications

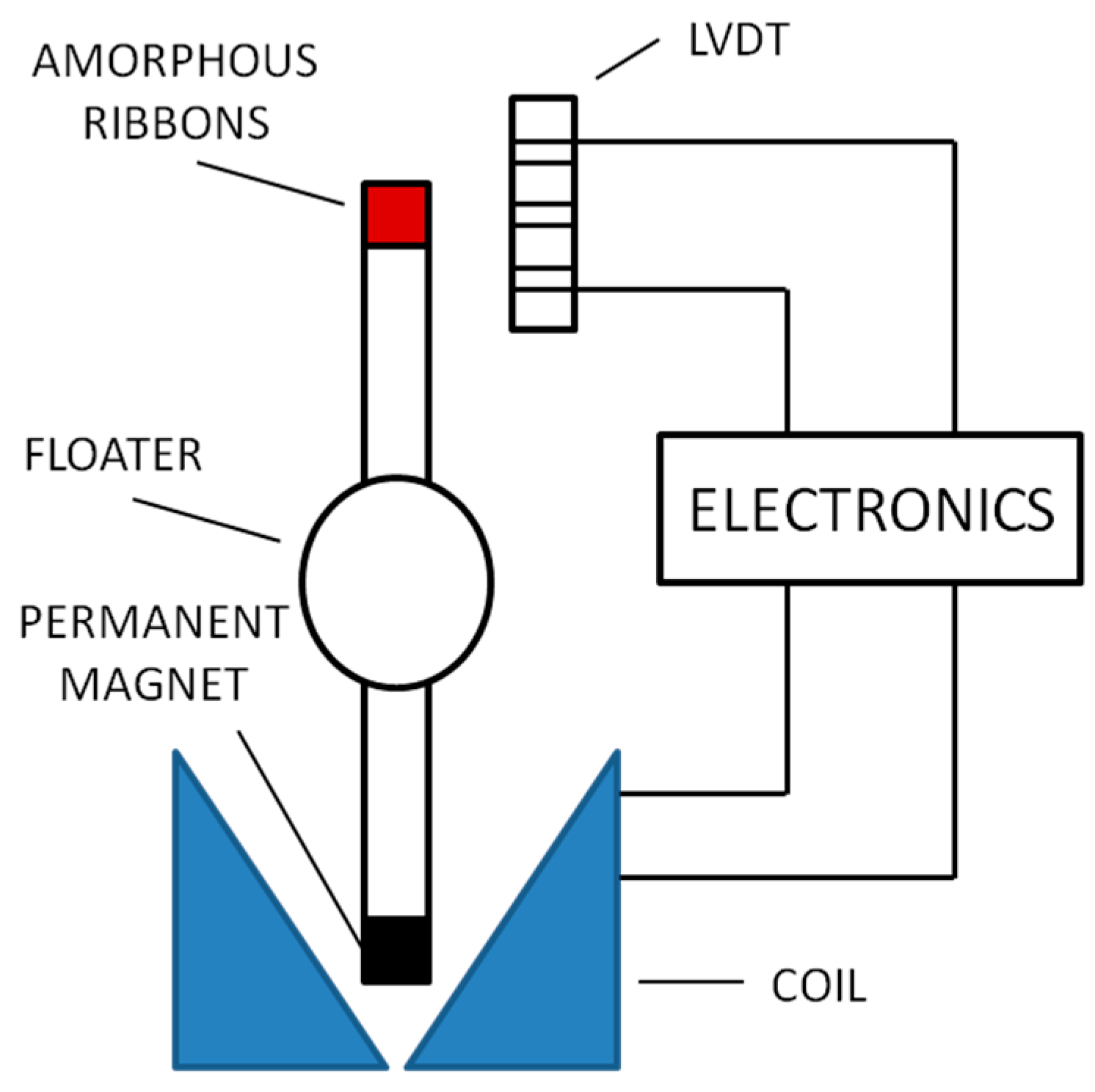

3.3. Magnetostrictive Sensor

3.3.1. Theory

- (1)

- Zeeman Magnetic Energy

- (2)

- Anisotropy Energy

- (3)

- Magnetostatic Energy

3.3.2. Applications

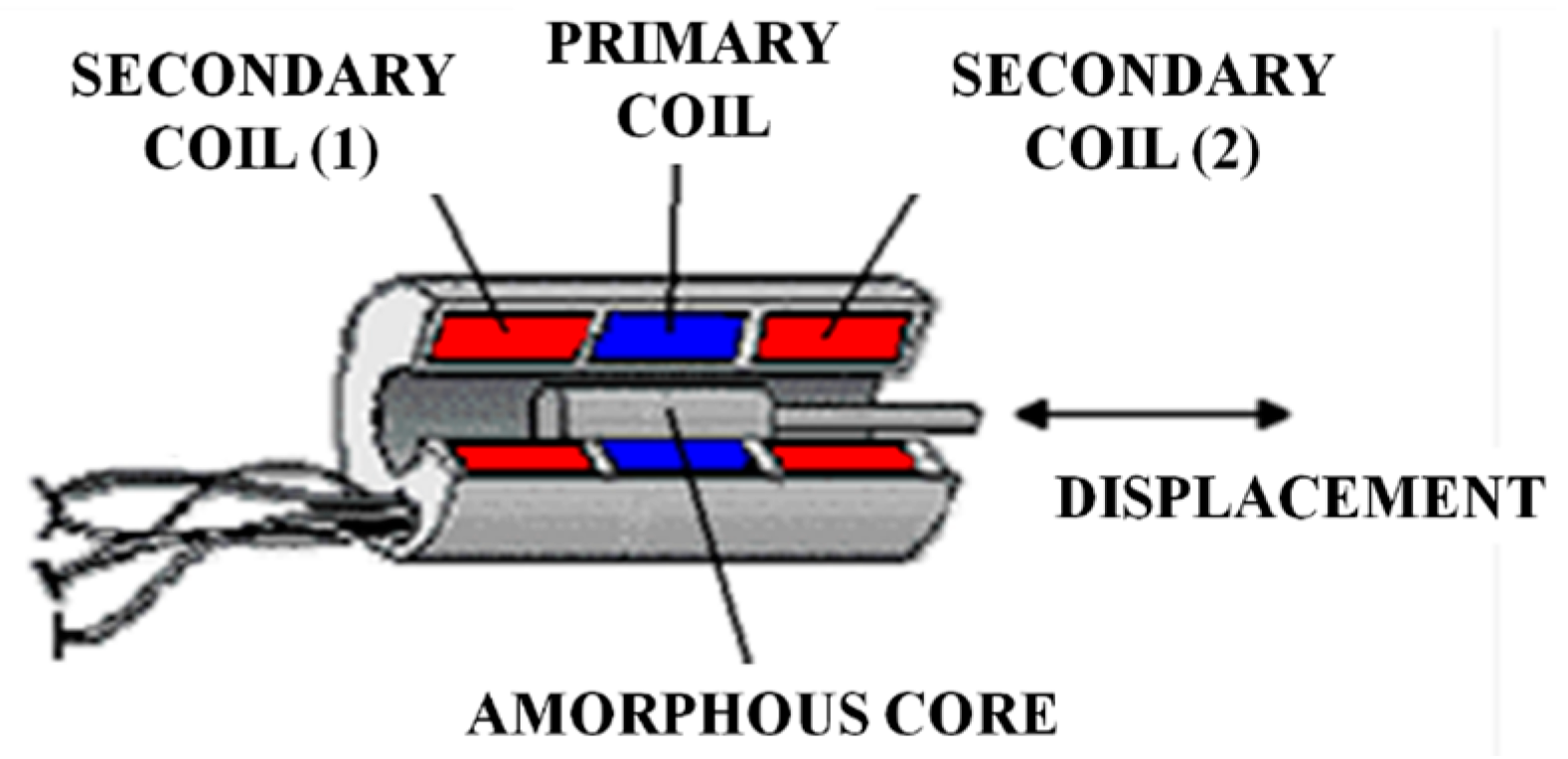

4. Changes on the Inductance

4.1. Linear Variable Differential Transformer

4.1.1. Theory

4.1.2. Applications

4.2. Sensors Based on Giant Magnetoimpedance

4.2.1. Theory

4.2.2. Applications

5. Conclusions

Acknowledgments

Conflicts of Interest

References

- Roy, D. Development of novel magnetic grippers for use in unstructured robotic workspace. Robot. Comput. Integr. Manuf. 2015, 35, 16–41. [Google Scholar] [CrossRef]

- Vähä, P.; Heikkilä, T.; Kilpeläinen, P.; Järviluoma, M.; Gambao, E. Extending automation of building construction—Survey on potential sensor technologies and robotic applications. Autom. Constr. 2013, 36, 168–178. [Google Scholar] [CrossRef]

- Silva, P.; Pinto, P.M.; Postolache, O.; Dias, J.M. Tactile sensors for robotic applications. Measurement 2013, 46, 1257–1271. [Google Scholar] [CrossRef]

- Cullity, B.D. Introduction to Magnetic Materials; Addison-Wesley: Boston, MA, USA, 1972. [Google Scholar]

- Chikazumi, S.; Charap, S.H. Physics of Magnetism; John Wiley: Hoboken, NJ, USA, 1964. [Google Scholar]

- Jiles, D.C.; Lo, C.C.H. The role of new materials in the development of magnetic sensors and actuators. Sens. Actuators A Phys. 2003, 106, 3–7. [Google Scholar] [CrossRef]

- Alloca, J.A.; Stuart, A. Transducers: Theory and Applications; Prentice-Hall: Upper Saddle River, NJ, USA, 1984. [Google Scholar]

- Usher, M.J. Sensors and Transducers; Macmillan Publishers: London, UK, 1985. [Google Scholar]

- Ripka, P.; Závěta, K. Chapter 3—Magnetic Sensors: Principles and Applications. Handb. Magn. Mater. 2009, 18, 347–420. [Google Scholar]

- Harada, K.; Sasada, I.; Kawajiri, T.; Inoue, A. A new torque transducer using stress sensitive amorphous ribbons. IEEE Trans. Magn. 1982, 18, 1767–1772. [Google Scholar] [CrossRef]

- Andreescu, R.; Spellman, B.; Furlani, E.P. Analysis of a non-contact magnetoelastic torque transducer. J. Magn. Magn. Mater. 2008, 320, 1827–1833. [Google Scholar] [CrossRef]

- Morris, A.S.; Langari, R. Mass, Force and Torque Measurement. In Measuerement and Instrumentation: Theory and Application; Academic Press: Waltham, MA, USA; San Diego, CA, USA; London, UK, 2012; pp. 477–496. [Google Scholar]

- Pina, E.; Burgos, E.; Prados, C.; González, J.M.; Hernando, A.; Iglesias, M.C.; Poch, J.; Franco, C. Magnetoelastic sensor as a probe for muscular activity: An in vivo experiment. Sens. Actuators A Phys. 2001, 91, 99–102. [Google Scholar] [CrossRef]

- Meydan, T.; Overshott, K.J. Amorphous force transducers in AC applications. J. Appl. Phys. 1982, 53, 8383–8385. [Google Scholar] [CrossRef]

- Salach, J.; Bieńkowski, A.; Szewczyk, R. The ring-shaped magnetoelastic torque sensors utilizing soft amorphous magnetic materials. J. Magn. Magn. Mater. 2007, 316, e607–e609. [Google Scholar] [CrossRef]

- Mohri, K.; Sudoh, E. Sensitive force transducers using a single amorphous core multivibrator bridge. IEEE Trans. Magn. 1979, 15, 1806–1808. [Google Scholar] [CrossRef]

- Zhang, X.; Chang, M.; Mao, C.; Lu, D.; Kamagara, A. Intrinsic magnetic field sensitivities of sensor head housing for all-fiber optic current sensors. Opt. Commun. 2014, 329, 173–179. [Google Scholar] [CrossRef]

- Chen, F.; Jiang, Y.; Gao, H.; Jiang, L. A high-finesse fiber optic Fabry-Perot interferometer based magnetic-field sensor. Opt. Lasers Eng. 2015, 71, 62–65. [Google Scholar] [CrossRef]

- Hatafuku, H.; Sarudate, C.; Konno, A. Estimation of Residual Stresses in Magnetic Metals by Using Ultrasonic Method. IEEE Trans. Magn. 2002, 38, 3308–3312. [Google Scholar] [CrossRef]

- Primdahl, F. The fluxgate magnetometer. J. Phys. E: Sci. Instrum. 1979, 12, 241–253. [Google Scholar] [CrossRef]

- García, A.; Morón, C. Biaxial Magnetometer Sensor. IEEE Trans. Mag. 2002, 38, 3312–3314. [Google Scholar] [CrossRef]

- Garcia, A.; Morón, C.; Mora, M. Theoretical calculation for a two-axis magnetometer based on magnetization rotation. Sens. Actuators A Phys. 2000, 81, 307–309. [Google Scholar] [CrossRef]

- Cao, Y.; Cao, D. Theory of fluxgate sensor: Stability condition and critical resistance. Sens. Actuators A Phys. 2015, 233, 522–531. [Google Scholar] [CrossRef]

- Ripka, P. Advances in fluxgate sensors. Sens. Actuators A Phys. 2003, 106, 8–14. [Google Scholar] [CrossRef]

- Rühmer, D.; Bögeholz, S.; Ludwig, F.; Schilling, M. Vector fluxgate magnetometer for high operation temperatures up to 250 °C. Sens. Actuators A Phys. 2015, 228, 118–124. [Google Scholar] [CrossRef]

- Baschirotto, A.; Dallago, E.; Ferri, M.; Malcovati, P.; Rossini, A.; Venchi, G. A 2D micro-fluxgate earth magnetic field measurement systems with fully automated acquisition setup. Measurement 2010, 43, 46–53. [Google Scholar] [CrossRef]

- Brauer, P.; Risbo, T.; Merayo, J.M.G.; Nielsen, O.V. Fluxgate sensor for the vector magnetometer on board the “Astrid-2” satellite. Sens. Actuators A Phys. 2000, 81, 184–188. [Google Scholar] [CrossRef]

- Speer, D.; Jackson, G.; Raphael, D. Flight Computer Design for the Space Technology 5 (ST-5) Mission. In Proceedings of the IEEE Aerospace Conference, Big Sky, MT, USA, 9–16 March 2002; Volume 1, pp. 255–269.

- Morón, C.; Maganto, F.; García, A. Technique of magnetic labels production for security systems. Sens. Actuators A Phys. 2003, 106, 333–335. [Google Scholar] [CrossRef]

- Maier, C.; Kawahito, S.; Schneider, M.; Zimmermann, M.; Baltes, H. A 2_D CMOS microfluxgate sensor system for digital detection of weak magnetic fields. IEEE J. Solid State Circuits 1999, 34, 1843–1846. [Google Scholar] [CrossRef]

- Chiesi, L.; Kejik, P.; Janossy, B.; Popovic, R.S. CMOS planar 2D micro-fluxgate sensor. Sens. Actuators A Phys. 2000, 82, 174–180. [Google Scholar] [CrossRef]

- Lu, C.C.; Liu, Y.T.; Jhao, F.Y.; Jeng, J.T. Responsivity and noise of a wire-bonded CMOS micro-fluxgate sensor. Sens. Actuators A Phys. 2012, 179, 39–43. [Google Scholar] [CrossRef]

- Huang, W.S.; Jeng, J.T.; Lu, C.C. Harmonic frequency characterisations of a CMOS micro fluxgate sensor for low magnetic field detection. Proc. Eng. 2010, 5, 993–996. [Google Scholar] [CrossRef]

- Janošek, M.; Ripka, P. PCB sensors in fluxgate magnetometer with controlled excitation. Sens. Actuators A Phys. 2009, 151, 141–144. [Google Scholar] [CrossRef]

- Tipek, A.; O’Donnell, T.; Connell, A.; McCloskey, P.; O’Mathuna, S.C. PCB fluxgate current sensor with saturable inductor. Sens. Actuators A Phys. 2006, 132, 21–24. [Google Scholar] [CrossRef]

- Kejik, P.; Chiesi, L.; Janossy, B.; Popovic, R.S. A new compact 2D planar fluxgate sensor with amorphous metal core. Sens. Actuators A Phys. 2000, 81, 180–183. [Google Scholar] [CrossRef]

- Park, H.S.; Hwang, J.S.; Choi, W.Y.; Shim, D.S.; Na, K.W.; Choi, S.O. Development of micro-fluxgate sensors with electroplated magnetic cores for electronic compass. Sens. Actuators A Phys. 2004, 114, 224–229. [Google Scholar] [CrossRef]

- Dezuari, O.; Belloy, E.; Gilbert, S.E.; Gijs, M.A.M. Printed circuit board integrated fluxgate sensor. Sens. Actuators A Phys. 2000, 81, 300–303. [Google Scholar] [CrossRef]

- Mermelstein, M.D. A magnetoelastic metallic glass low-frequency magnetometer. IEEE Trans. Magn. 1992, 28, 36–56. [Google Scholar] [CrossRef]

- Burdin, D.A.; Chashin, D.V.; Ekonomov, N.A.; Fetisov, L.Y.; Fetisov, Y.K.; Sreenivasulu, G.; Srinivasan, G. Nonlinear magneto-electric effects in ferromagnetic-piezoelectric composites. J. Magn. Magn. Mater. 2014, 358–359, 98–104. [Google Scholar] [CrossRef]

- Ausanioa, G.; Iannottia, V.; Ricciardib, E.; Lanottec, L.; Lanotte, L. Magneto-piezoresistance in Magnetorheological elastomers for magnetic induction gradient or position sensors. Sens. Actuators A Phys. 2014, 205, 235–239. [Google Scholar] [CrossRef]

- Mietta, J.L.; Jorge, G.; Perez, O.E.; Maeder, T.; Negri, R.M. Superparamagnetic anisotropic elastomer connectors exhibiting reversible magneto-piezoresistivity. Sens. Actuators A Phys. 2013, 192, 34–41. [Google Scholar] [CrossRef]

- Marauska, S.; Jahns, R.; Kirchhof, C.; Claus, M.; Quandt, E.; Knöchel, R.; Wagner, B. Highly sensitive wafer-level packaged MEMS magnetic field sensor based on magnetoelectric composites. Sens. Actuators A Phys. 2013, 189, 321–327. [Google Scholar] [CrossRef]

- Greve, H.; Woltermann, E.; Jahns, R.; Marauska, S.; Wagner, B.; Knöchel, R.; Wuttig, M.; Quandt, E. Low damping resonant magnetoelectric sensors. Appl. Phys. Lett. 2010, 97, 152503. [Google Scholar] [CrossRef]

- Garcia, A.; Morón, C.; Maganto, F.; Carracedo, M.T. Induction of bistability in amorphous ribbons. Sens. Actuators A Phys. 2003, 106, 340–343. [Google Scholar] [CrossRef]

- Kurlyandskaya, G.V.; Garcia-Miquel, H.; Vazquez, M.; Svalov, A.V.; Vas’kovskiy, V.O. Longitudinal magnetic bistability of electroplated wires. J. Magn. Magn. Mater. 2002, 249, 34–38. [Google Scholar] [CrossRef]

- Komová, E.; Varga, M.; Varga, R.; Vojtaník, P. Magnetic properties of nanocrystalline bistable FeNiMoB microwires. Acta Electrotech. Inform. 2010, 10, 63–65. [Google Scholar]

- Chizhik, A.; Gonzalez, J.; Zhukov, A.; Blanco, J.M. Circular magnetic bistability in Co-rich amorphous microwires. J. Phys. D 2003, 36, 419–422. [Google Scholar] [CrossRef]

- García, A.; Morón, C.; Maganto, F. Magnetization processes in bistable amorphous ribbons with induced helical anisotropy. J. Magn. Magn. Mater. 2003, 254–255, 161–163. [Google Scholar] [CrossRef]

- Vázquez, M. Soft magnetic wires. Phys. B 2001, 299, 302–313. [Google Scholar] [CrossRef]

- García-Miquel, H.; Chen, D.X.; Vazquez, M. Domain wall propagation in bistable amorphous wires. J. Magn. Magn. Mater. 2000, 212, 101–106. [Google Scholar] [CrossRef]

- Mapps, D.J. Magnetoresistive sensors. Sens. Actuators A Phys. 1997, 59, 9–19. [Google Scholar] [CrossRef]

- Tumenski, S.; Stabrowski, M. A new type of thin film magnetoresistive magnetometer—An analysis of circuit principles. IEEE Trans. Magn. 1984, 20, 963–965. [Google Scholar] [CrossRef]

- Hauser, H.; Hochreiter, J.; Stangl, G.; Chabicovsky, R.; Janiba, M.; Riedling, K. Anisotropic Magnetoresistance Effect Field Sensors. J. Magn. Magn. Mater. 2000, 216, 788–791. [Google Scholar] [CrossRef]

- Schotter, J.; Kamp, P.B.; Becker, A.; Puhler, A.; Brinkmann, D.; Schepper, W.; Bruckl, H.; Reiss, G. A biochip based on magnetoresistive sensors. IEEE Trans. Magn. 2002, 38, 3365–3367. [Google Scholar] [CrossRef]

- Garcia, A.; Morón, C.; Tremps, E. Magnetic Sensor for Building Structural Vibrations. Sensors 2014, 14, 2468–2475. [Google Scholar] [CrossRef] [PubMed]

- Morón, C.; Escribano, S. Linear displacement transducer. Word Sci. 1995, 1, 547–551. [Google Scholar]

- Morón, C.; Mora, M.; Garcia, A. Plastic deformation of the current annealed amorphous ribbons. J. Magn. Magn. Mater. 2000, 215–216, 469–471. [Google Scholar] [CrossRef]

- Aroca, C.; Rodriguez, M.; Sánchez, P. Magnetic device for density measurement. IEEE Trans. Magn. 1990, 26, 2032–2034. [Google Scholar] [CrossRef]

- Wu, S.T.; Mo, S.C.; Wu, B.S. An LVDT-based self-actuating displacement transducer. Sens. Actuators A Phys. 2008, 141, 558–564. [Google Scholar] [CrossRef]

- Chiriac, C.; Chiriac, H. Magnetic field and displacement sensor based on linear transformer with amorphous wire core. Sens. Actuators A Phys. 2003, 106, 172–173. [Google Scholar] [CrossRef]

- Morón, C.; Garcia, A. Giant magneto-impedance in nanocrystalline glass-covered microwires. J. Magn. Magn. Mater. 2005, 290–291, 1085–1088. [Google Scholar] [CrossRef]

- García-Chocano, V.M.; Garcia-Miquel, H. DC and AC linear magnetic field sensor based on glass coated amorphous microwires with Giant Magnetoimpedance. J. Magn. Magn. Mater. 2015, 378, 485–492. [Google Scholar] [CrossRef]

- Asfour, A.; Zidi, M.; Yonnet, J.P. High Frequency Amplitude Detector for GMI Magnetic Sensors. Sensors 2014, 14, 24502–24522. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.; Bao, C.C.; Yang, H.; Li, D.; Lei, C.; Wang, T.; Hu, H.Y.; He, M.; Zhou, Y.; Cui, D.X. A prototype of giant magnetoimpedance-based biosensing system for targeted detection of gastric cancer cells. Biosens. Bioelectron. 2011, 26, 3246–3253. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.; Yang, Z.; Lei, J.; Zhou, Y. An integrated giant magnetoimpedance biosensor for detection of biomarker. Biosens. Bioelectron. 2014, 58, 338–344. [Google Scholar] [CrossRef] [PubMed]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Morón, C.; Cabrera, C.; Morón, A.; García, A.; González, M. Magnetic Sensors Based on Amorphous Ferromagnetic Materials: A Review. Sensors 2015, 15, 28340-28366. https://doi.org/10.3390/s151128340

Morón C, Cabrera C, Morón A, García A, González M. Magnetic Sensors Based on Amorphous Ferromagnetic Materials: A Review. Sensors. 2015; 15(11):28340-28366. https://doi.org/10.3390/s151128340

Chicago/Turabian StyleMorón, Carlos, Carolina Cabrera, Alberto Morón, Alfonso García, and Mercedes González. 2015. "Magnetic Sensors Based on Amorphous Ferromagnetic Materials: A Review" Sensors 15, no. 11: 28340-28366. https://doi.org/10.3390/s151128340