An Open Source Low-Cost Wireless Control System for a Forced Circulation Solar Plant

Abstract

:1. Introduction

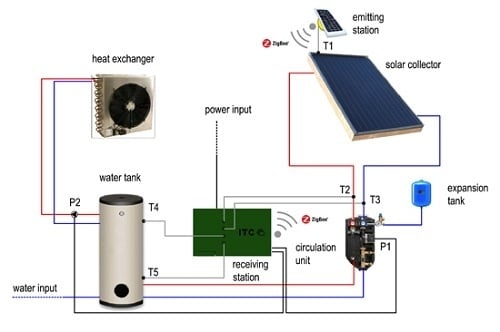

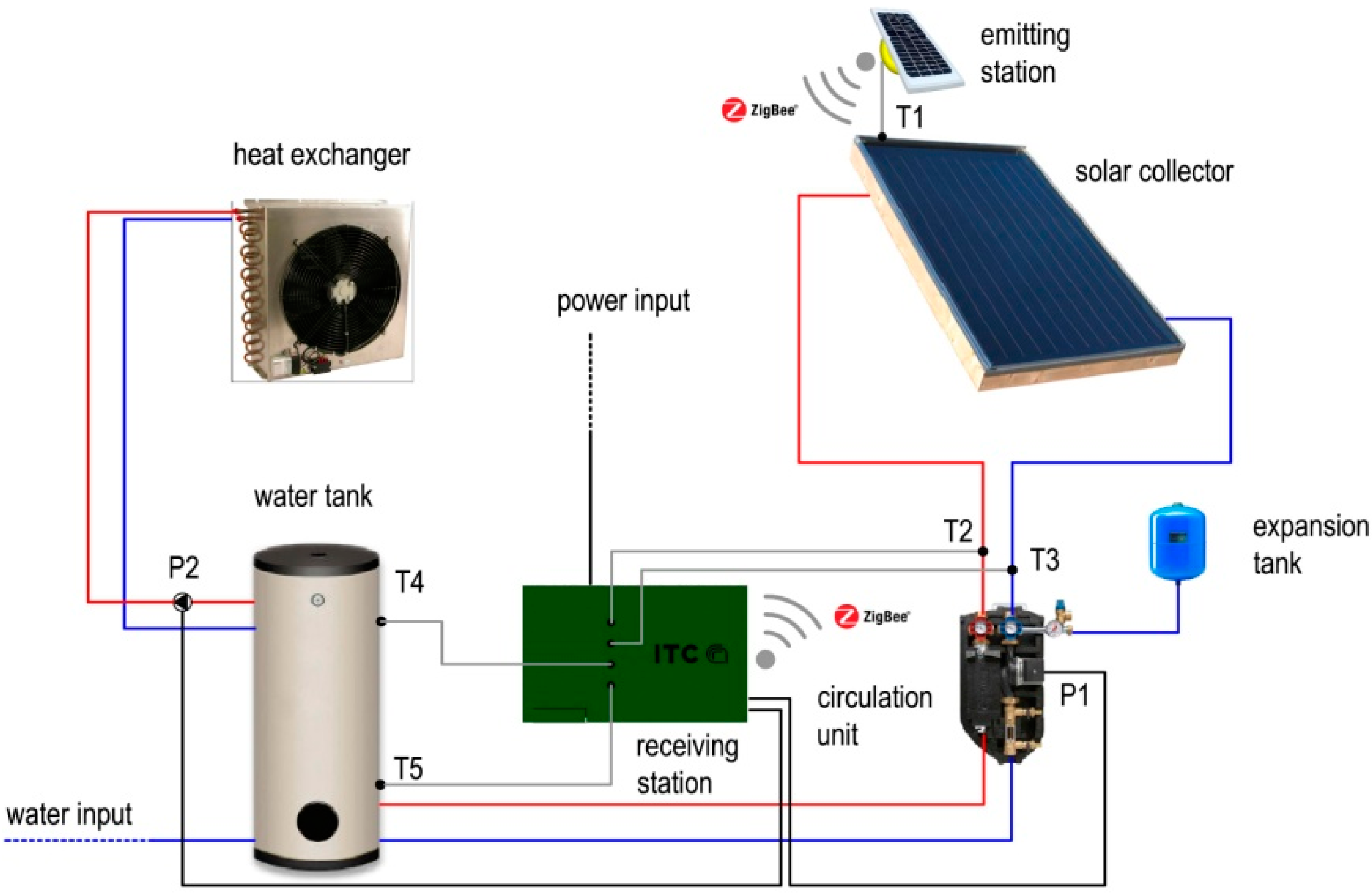

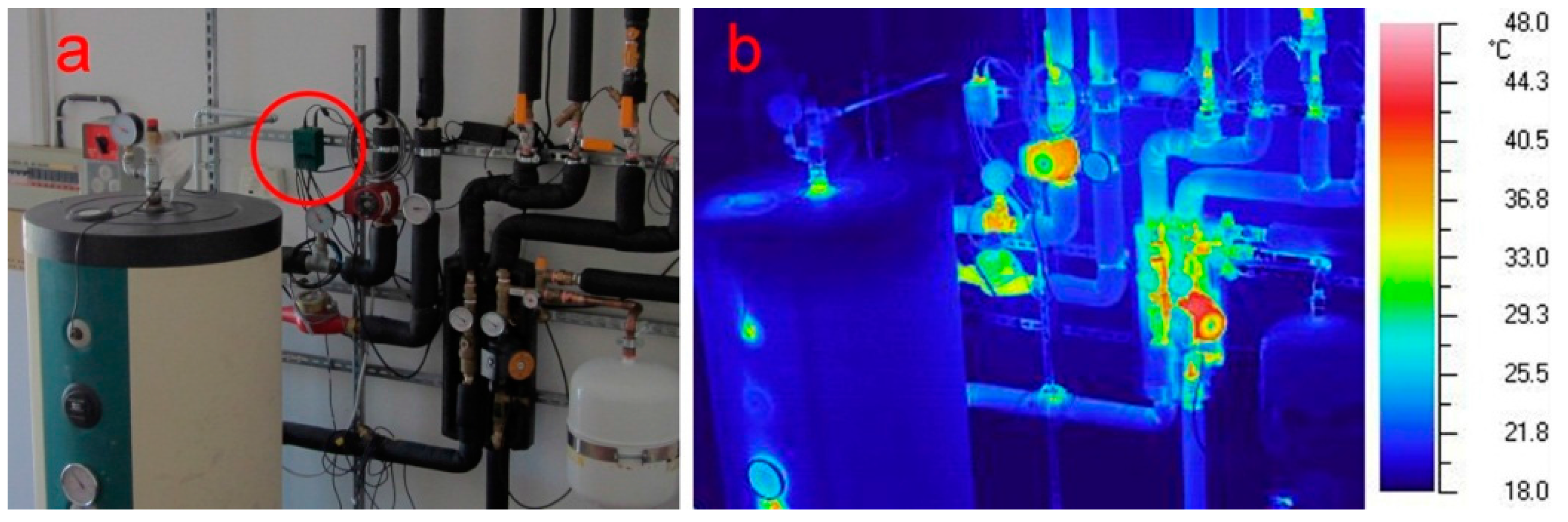

2. Experimental Section

- •

- T1 is the temperature of the water at the top of the solar panel.

- •

- T2 is the temperature of the outlet water from the panel.

- •

- T3 is the temperature of the inlet water to the panel.

- •

- T4 is the temperature at the top of the storage tank.

- •

- T5 is the temperature at the bottom of the storage tank.

- •

- P1 is the electric pump connecting the solar system to the storage tank.

- •

- P2 is the electric pump connecting the storage tank to the heat exchanger.

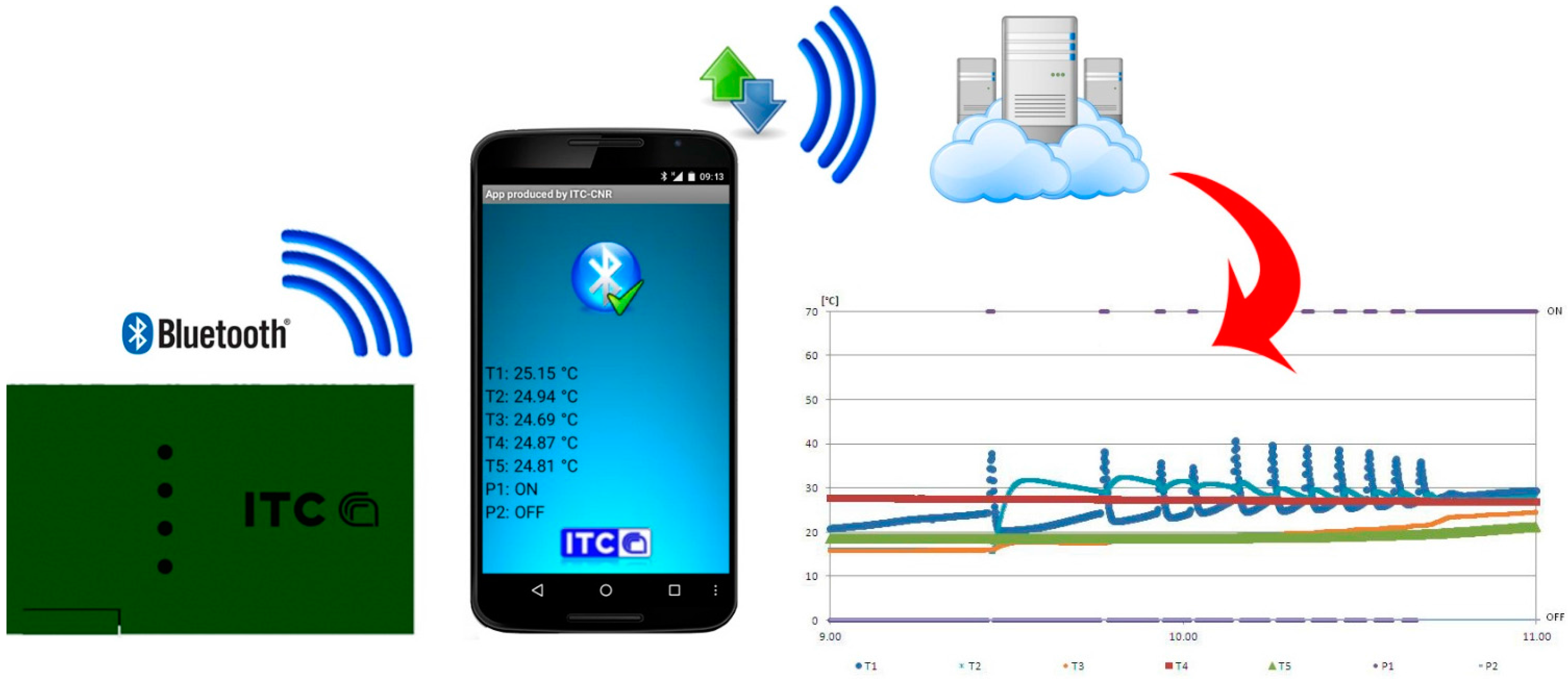

2.1. External Control Unit

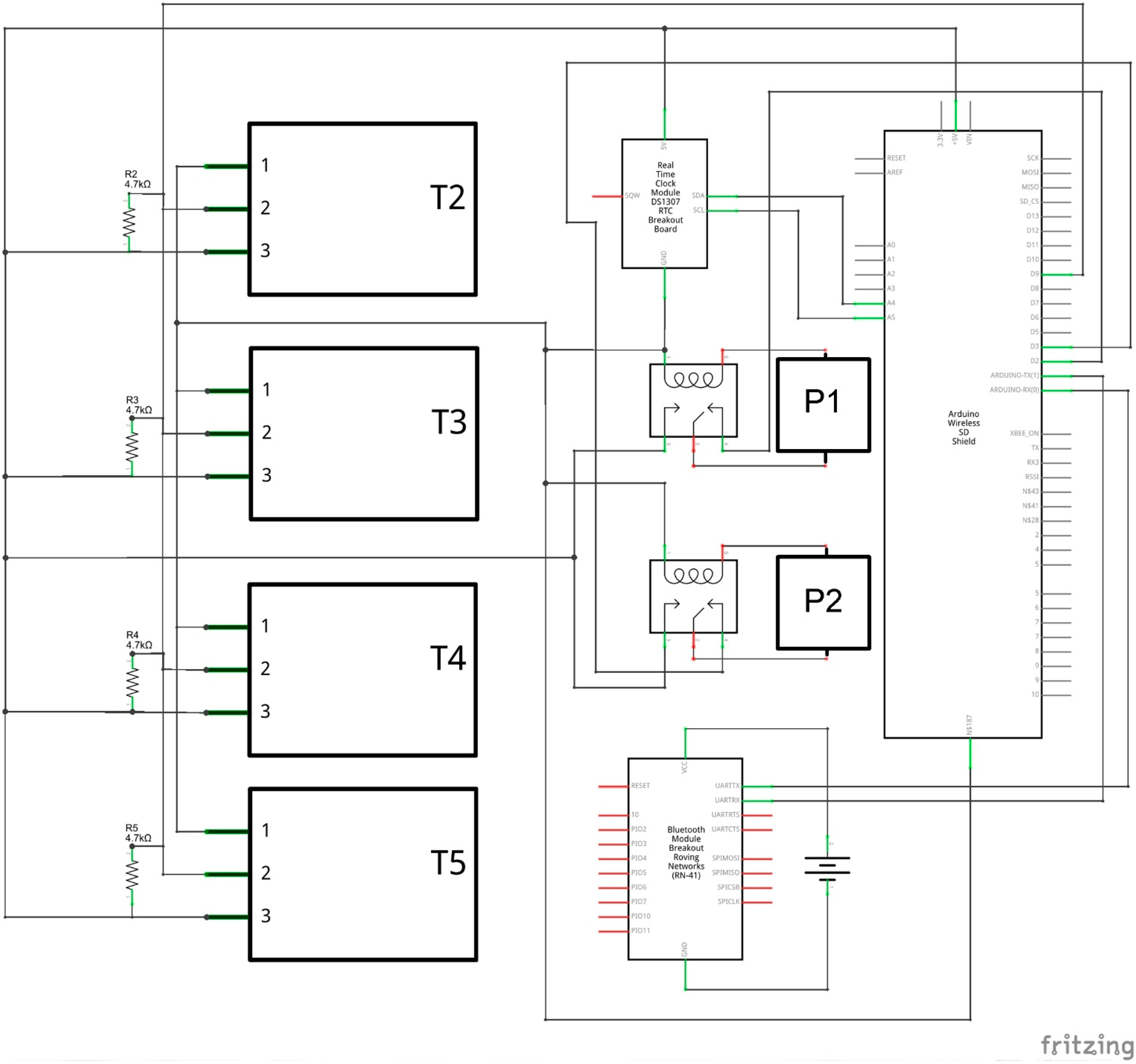

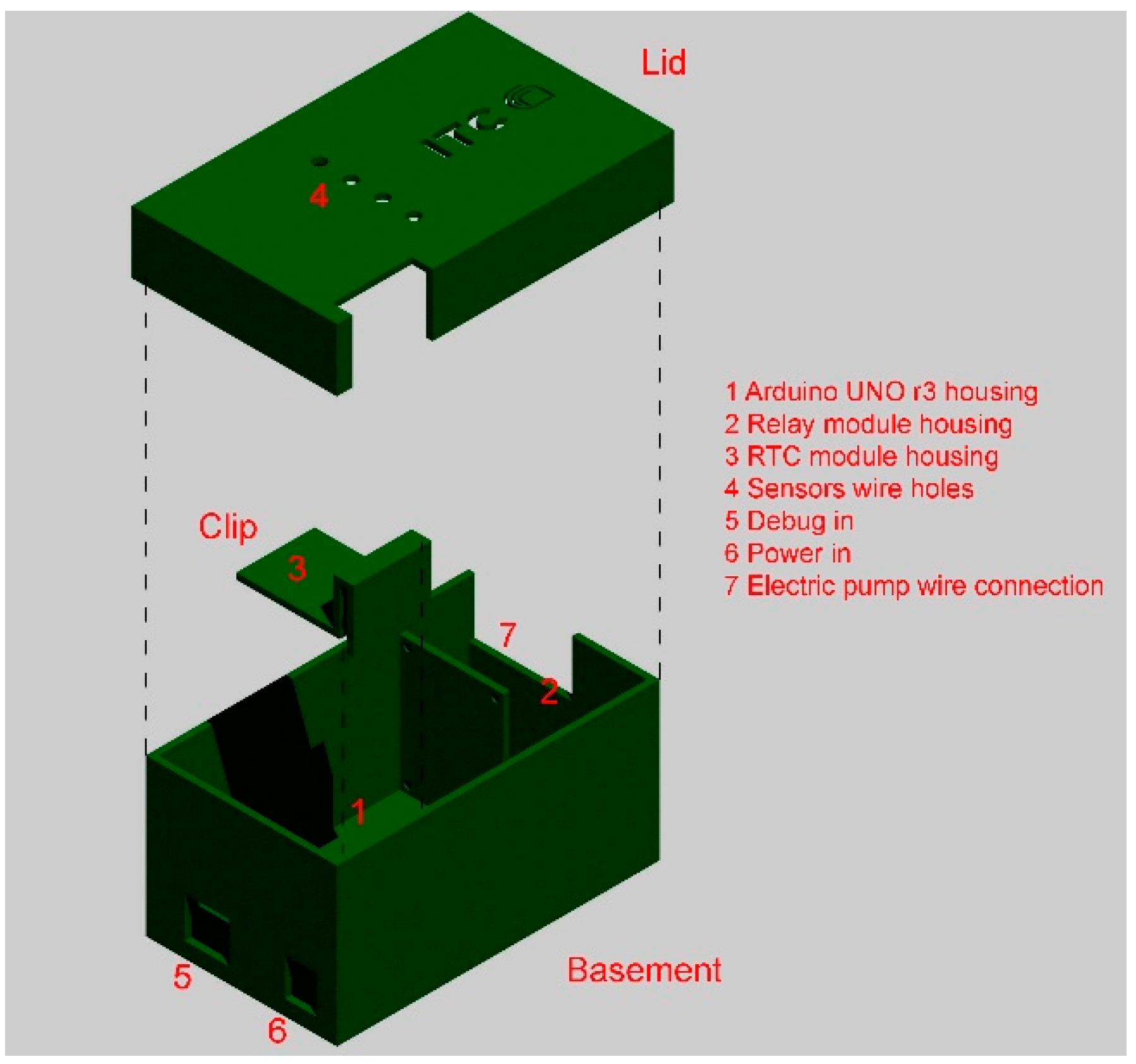

2.2. Internal Control Unit

2.3. Data Connection

| ZigBee End Device AT Configuration | ZigBee API Coordinator Configuration |

|---|---|

| Address: 0013A20040C281C1 | Address: 0013A20040BF97C0 |

| PAN ID 1984 | PAN ID 1984 |

| BAUD rate 115200 | BAUD rate 115200 |

| D0 ADC [2] | |

| IR 1388 |

| Sequential Number | Example Value | Purpose |

|---|---|---|

| 0 | 7E | Start delimiter |

| 1–2 | 00–12 | Frame length |

| 3 | 92 | Frame type |

| 4–7 | 00, 13, A2, 00 | First part of the sender address |

| 8–11 | 40, C2, 81, D4 | Second part of the sender address |

| 12–13 | 70, 13 | Network address assigned by the coordinator |

| 14 | 01 | Non-broadcast package |

| 15 | 01 | Number of samplings |

| 16–17 | 00, 00 | Bit mask indicating which pins of the XBee module are enabled for digital input |

| 18 | 01 | Bit mask indicating which pins are enabled for analogical input |

| 19–20 | 03, BC | Each pin enabled for analogical input returns a two-byte reading |

| 21 | 1C | Checksum |

2.4. Control Algorithm

3. Results and Discussion

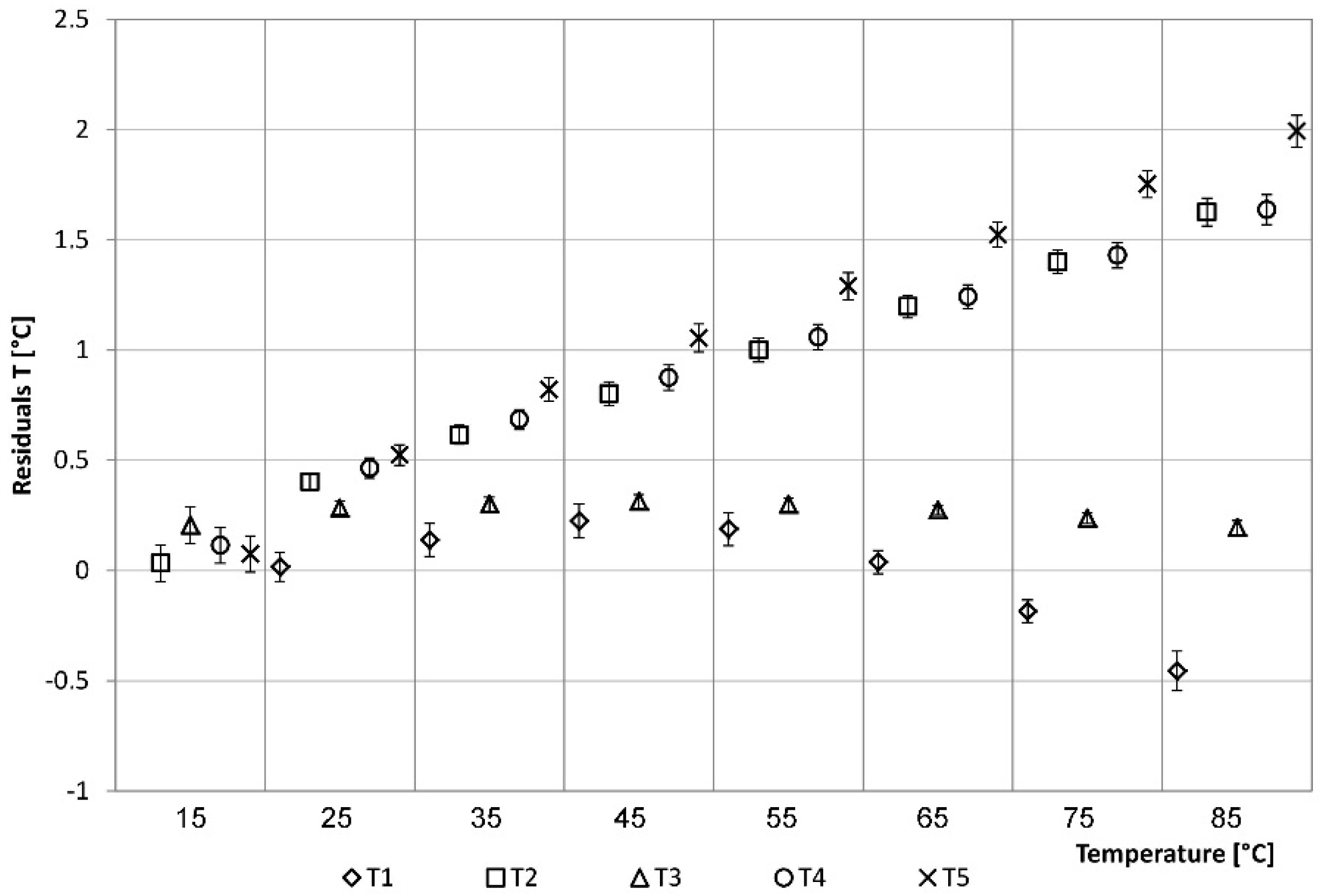

3.1. Sensor Calibration

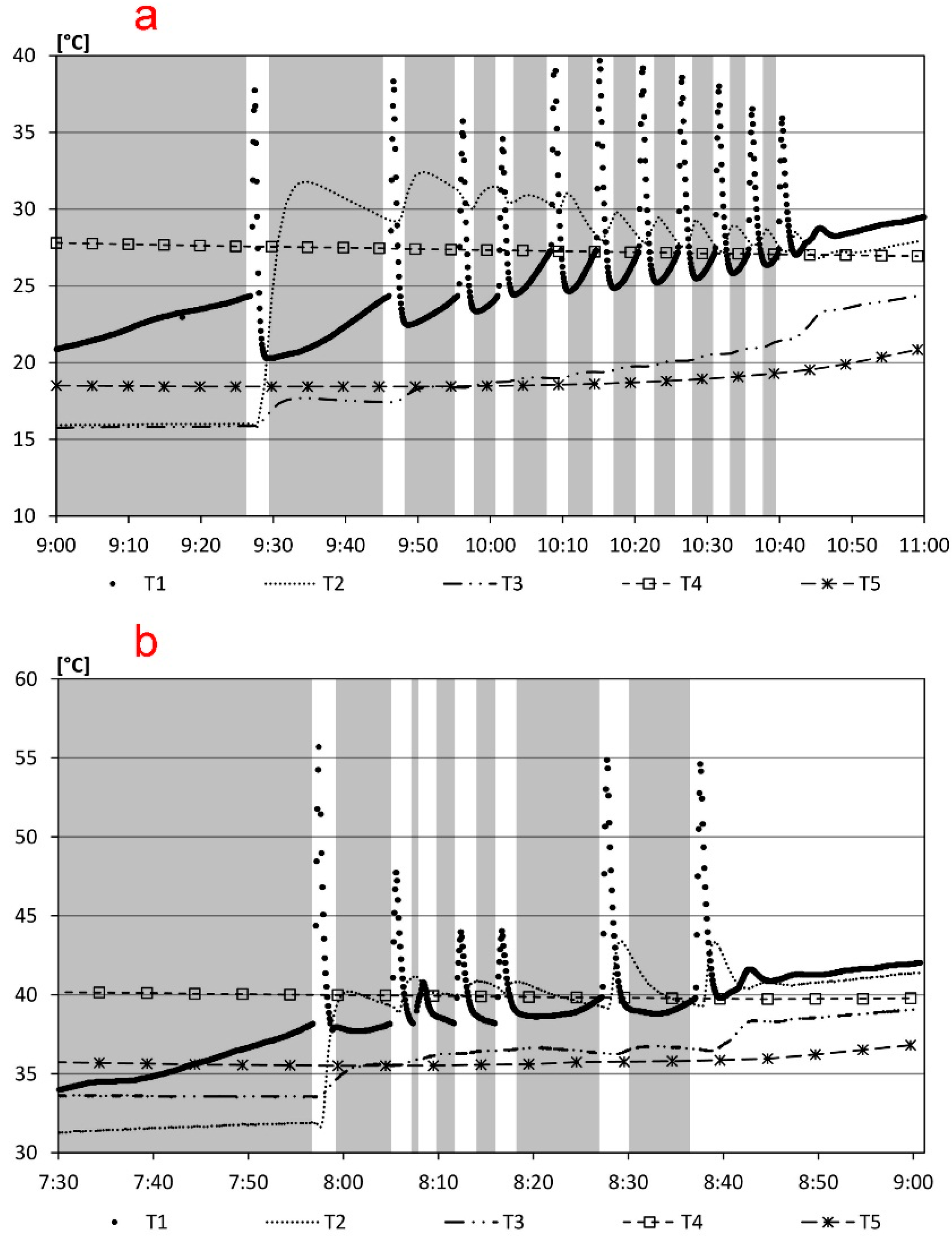

3.2. Application to the Real Plant

| 19 March 2015 | 9 July 2015 | |

|---|---|---|

| Tmin (°C) | 5.88 | 23.80 |

| Tmax (°C) | 17.52 | 32.80 |

| Pi (W/m2) | 600 | 950 |

- ŋ0

- is equal to 74.0 (%) (from datasheet);

- k1

- is equal to 3.89 (W/m2·K) (from datasheet);

- k2

- is equal to 0.018 (W/m2·K2) (from datasheet);

- Pi

- is the incident solar radiation (W/m2).

- T

- is the external temperature (°C).

- T2

- is the temperature of the outlet water from the panel (°C).

- T3

- is the temperature of the inlet water to the panel (°C).

| Time | Pi (W/m2) | ∆T (K) | ŋ (%) |

|---|---|---|---|

| 08:00 19 March 2015 | 114.31 | 8.53 | 73.70 |

| 12:00 19 March 2015 | 776.59 | 12.38 | 73.93 |

| 16:00 19 March 2015 | 452.62 | 17.12 | 73.84 |

| 20:00 19 March 2015 | 26.48 | 6.55 | 73.01 |

| 08:00 9 July 2015 | 207.41 | 6.70 | 73.87 |

| 12:00 9 July 2015 | 879.03 | 17.67 | 73.92 |

| 16:00 9 July 2015 | 631.65 | 21.84 | 73.85 |

| 20:00 9 July 2015 | 39.92 | 8.47 | 73.14 |

4. Conclusions and Future Work

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Anzalone, G.C.; Glover, A.G.; Pearce, J.M. Open-source colorimeter. Sensors 2013, 13, 5338–5346. [Google Scholar] [CrossRef] [PubMed]

- Martínez, M.A.; Andújar, J.M.; Enrique, J.M. A new and inexpensive pyranometer for the visible spectral range. Sensors 2009, 9, 4615–4634. [Google Scholar] [CrossRef] [PubMed]

- Salamone, F.; Belussi, L.; Danza, L.; Ghellere, M.; Meroni, I. Design and development of nEMoS, an all-in-one, low-cost, web-connected and 3D-printed device for environmental analysis. Sensors 2015, 15, 13012–13027. [Google Scholar] [CrossRef] [PubMed]

- Fox, S. Third wave Do-It-Yourself (DIY): Potential for prosumption, innovation, and entrepreneurship by local populations in regions without industrial manufacturing infrastructure. Technol. Soc. 2014, 39, 18–30. [Google Scholar] [CrossRef]

- Gubbi, J.; Buyya, R.; Marusic, S.; Palaniswami, M. Internet of things (IoT): A vision, architectural elements, and future directions. Future Gener. Comput. Syst. 2013, 29, 1645–1660. [Google Scholar] [CrossRef]

- Toffler, A. The Third Wave; Bantam Books: New York, NY, USA, 1981; pp. 32–33. [Google Scholar]

- Fox, S. Paradigm shift: Do-It-Yourself (DIY) invention and production of physical goods for use or sale. J. Manuf. Technol. Manag. 2013, 24, 218–234. [Google Scholar] [CrossRef]

- Anderson, C. The New Industrial Revolution; Crown Business: New York, NY, USA, 2010. [Google Scholar]

- Gershenfeld, N. How to make almost anything. Foreign Aff. 2012, 91, 43–57. [Google Scholar]

- Hatch, M. The Maker Movement Manifesto; McGraw-Hill Education: Columbus, OH, USA, 2014. [Google Scholar]

- Arduino. Available online: http://www.arduino.org/ (accessed on 24 August 2015).

- Genuino. Available online: https://www.arduino.cc/ (accessed on 24 August 2015).

- Baronti, P.; Pillai, P.; Chook, V.W.; Chessa, S.; Gotta, A.; Hu, Y.F. Wireless sensor networks: A survey on the state of the art and the 802.15. 4 and ZigBee standards. Comput. Commun. 2007, 30, 1655–1695. [Google Scholar] [CrossRef]

- Pan, M.S.; Fang, H.W.; Liu, Y.C.; Tseng, Y.C. Address Assignment and Routing Schemes for ZigBee-Based Long-Thin Wireless Sensor Networks. In Proceedings of the Vehicular Technology Conference, Singapore, 11–14 May 2008; pp. 173–177.

- 5V Regulator Module for Arduino. Available online: https://www.cooking-hacks.com/5v-regulator-module-for-arduino (accessed on 24 August 2015).

- Solar Panel 7.4V. Available online: https://www.cooking-hacks.com/solar-panel-7-4v (accessed on 24 August 2015).

- XBee to USB Adapter Datasheet. Available online: http://www.microbot.it/documents/mr002-004_datasheet.pdf (accessed on 24 August 2015).

- XBee S2 Module Datasheet. Available online: https://cdn.sparkfun.com/datasheets/Wireless/Zigbee/ds_xbeezbmodules.pdf (accessed on 24 August 2015).

- 10K Thermistor Datasheet. Available online: http://cdn.sparkfun.com/datasheets/Sensors/Temp/ntcle100.pdf (accessed on 24 August 2015).

- XCTU Software. Available online: http://www.digi.com/products/wireless-wired-embedded-solutions/zigbee-rf-modules/xctu (accessed on 24 August 2015).

- Oxer, J.; Blemings, H. Practical Arduino: Cool Projects for Open Source Hardware; Apress: New York, NY, USA, 2009. [Google Scholar]

- Arduino UNO r3 Datasheet. Available online: https://www.arduino.cc/en/Main/ArduinoBoardUno (accessed on 24 August 2015).

- Wireless SD Shield Datasheet. Available online: https://www.arduino.cc/en/Main/ArduinoWirelessShield (accessed on 24 August 2015).

- DS18B20 Datasheet. Available online: http://cdn.sparkfun.com/datasheets/Sensors/Temp/DS18B20.pdf (accessed on 24 August 2015).

- 2-Channel Relay Module Datasheet. Available online: http://www.microbot.it/documents/mr009-004_datasheet.pdf (accessed on 24 August 2015).

- Bluetooth Radio Datasheet. Available online: http://cdn.sparkfun.com/datasheets/Wireless/Bluetooth/Bluetooth-RN-41-DS.pdf (accessed on 24 August 2015).

- External Module Charger Datasheet. Available online: https://www.sparkfun.com/products/11231 (accessed on 24 August 2015).

- Lü, J.-B. Design of temperature measurement system based on single-wire DS18B20. Mod. Electron. Tech. 2012, 19, 037. [Google Scholar]

- Faludi, R. Building Wireless Sensor Networks: With ZigBee, XBee, arduino, and Processing; O’Reilly Media, Inc.: Sebastopol, CA, USA, 2010. [Google Scholar]

- Alliance, Z. IEEE 802.15. 4, ZigBee Standard. 2009. Available online: http://www. zigbee. Org (accessed on 24 August 2015).

- Liu, X.; Chen, H.; Wang, M.; Chen, S. An XBee-Pro Based Energy Monitoring System. In Proceedings of the 2012 Australasian Telecommunication Networks and Applications Conference (ATNAC), Brisbane, Australia, 7–9 November 2012; pp. 1–6.

- Wolber, D.; Abelson, H.; Spertus, E.; Looney, L. App Inventor; O’Reilly Media, Inc.: Sebastopol, CA, USA, 2011. [Google Scholar]

- MIT App Inventor. Available online: http://appinventor.mit.edu (accessed on 24 August 2015).

- Duffie, J.A.; Beckman, W.A. Solar Engineering of Thermal Processes (Vol. 3); Wiley: New York, NY, USA, 1980. [Google Scholar]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salamone, F.; Belussi, L.; Danza, L.; Ghellere, M.; Meroni, I. An Open Source Low-Cost Wireless Control System for a Forced Circulation Solar Plant. Sensors 2015, 15, 27990-28004. https://doi.org/10.3390/s151127990

Salamone F, Belussi L, Danza L, Ghellere M, Meroni I. An Open Source Low-Cost Wireless Control System for a Forced Circulation Solar Plant. Sensors. 2015; 15(11):27990-28004. https://doi.org/10.3390/s151127990

Chicago/Turabian StyleSalamone, Francesco, Lorenzo Belussi, Ludovico Danza, Matteo Ghellere, and Italo Meroni. 2015. "An Open Source Low-Cost Wireless Control System for a Forced Circulation Solar Plant" Sensors 15, no. 11: 27990-28004. https://doi.org/10.3390/s151127990