A Cutting Pattern Recognition Method for Shearers Based on Improved Ensemble Empirical Mode Decomposition and a Probabilistic Neural Network

Abstract

:1. Introduction

2. Literature Review

2.1. Coal-Rock Cutting Pattern Recognition Methods

2.2. Ensemble Empirical Mode Decomposition

2.3. Discussion

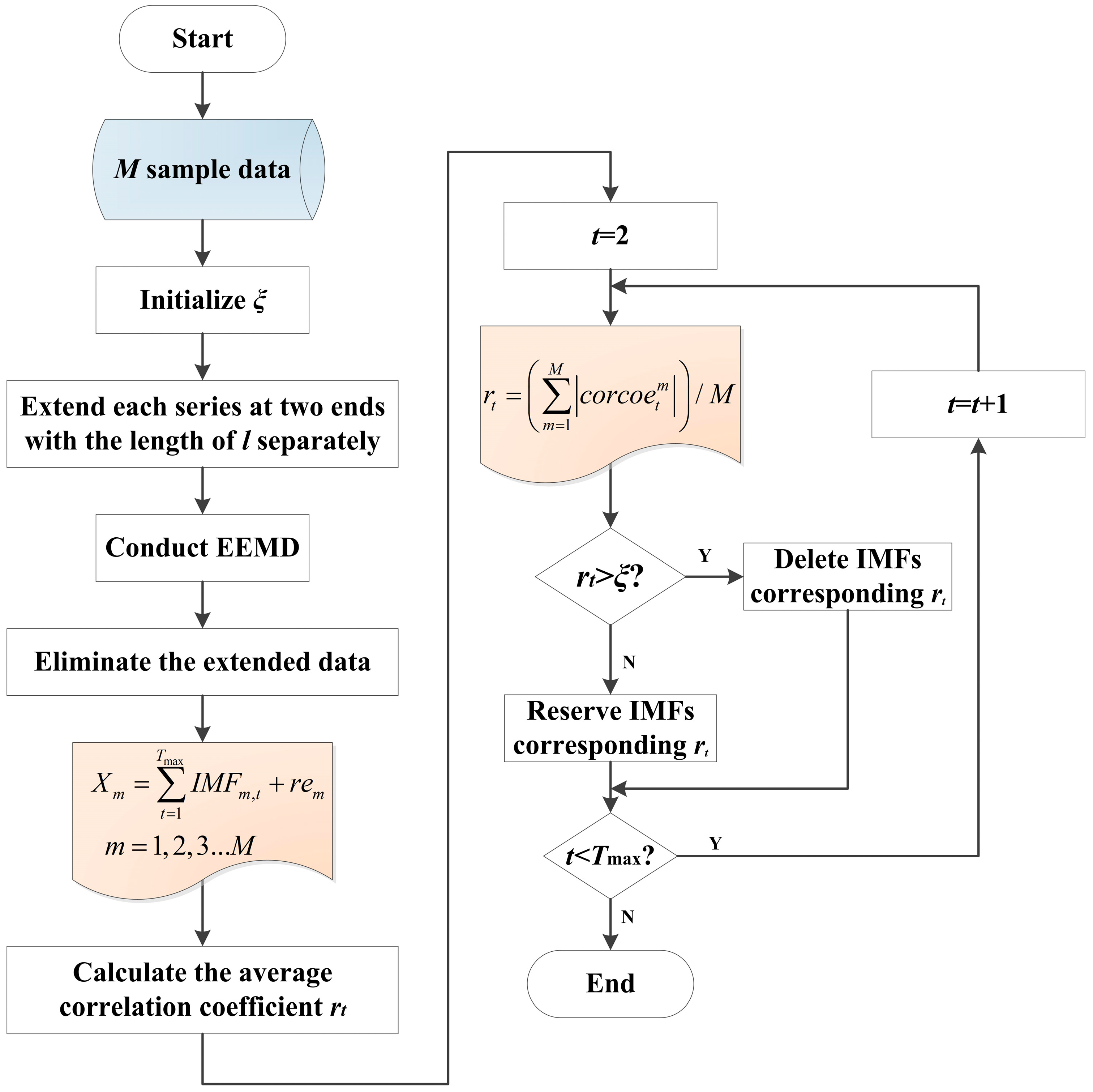

3. The Proposed Method

3.1. Improved Ensemble Empirical Mode Decomposition

- Step 1.1:

- Add a random white noise yi(t) to the original signal series X(t):where Xi(t) is the noisy-added signal, i = 1, 2… k, and k is the number of attempts.

- Step 1.2:

- For the noisy-added signal Xi(t), all extrema are searched at first. The upper and the lower envelopes are respectively constructed by connecting all the maxima and the minima through cubic splines. The mean of the two envelopes is defined as , then subtract the from Xi(t) to get a component , which can be described as follows:If satisfies the two conditions of IMF, then is the first IMF of Xi(t), called . Else is treated as the original signal Xi(t) and repeat the above step. Generally, contains the highest frequency component of the signal.

- Step 1.3:

- Separate from Xi(t), the remainder can be defined as follows:Then Xi(t) is replaced by , repeat the above operation until Ni-th remainder, namely , becomes a monotonic function. can be expressed as follows:

- Step 1.4:

- Xi(t) can be decomposed by the sum of Ni IMFs and a residual, which can be shown as follows:where is the residual, represents average trend of Xi(t).

- Step 1.5:

- Calculate N = min{N1, N2… Nk} and the ensemble means of corresponding IMFs of the decomposition as the final result:where Cn(n = 1,2…N) is the ensemble means of corresponding IMFs of the decomposition. In addition, the number of attempts is 100 and the standard deviation of the added noisy is 0.2 times that of the original signal, as suggested by Wu and Huang. In practical use, EEMD has a better effect than EMD. In this paper, an improved EEMD is presented to settle the problems of end-point effect and undesirable IMF components, which can be elaborated as follows:

- Step 2.1:

- The redundancy threshold ξ is introduced at first. M data series are selected and the length of each sequence is set as L. Based on the original storage data, extension is operated on the left and right of the data series with the length of l respectively. So the length of each analytic data is computed as L + 2l.

- Step 2.2:

- The data series are decomposed by EEMD to obtain a suite of IMFs. Considering the number of IMF may differ from each other, the biggest number is selected as Tmax. If the IMF number is smaller than Tmax, some zero vectors are supplemented in low frequency.

- Step 2.3:

- The extended data on both sides of every IMF are eliminated, so the result of EEMD can be expressed as follows:where Xm is m-th series, IMFm,t is t-th IMF of m-th series, rem represents the residual, and the length of Xm is L.

- Step 2.4:

- IMF1 is set as the first IMF, then correlation coefficients of IMF1 and IMF2, IMF1 and IMF3, ..., IMF1 and IMFT are calculated. The average correlation coefficient named rt is introduced and can be defined as follows:where represents the correlation coefficient between IMFt and IMF1 of m-th series.

- Step 2.5:

- The average correlation coefficients with the redundancy threshold ξ are compared and the coefficients greater than ξ are deleted. Also, IMFs correspond to the deleted coefficients are removed and the number of reminder IMFs can be marked as T.

3.2. Feature Extraction

3.3. Probabilistic Neural Network

3.4. Processing Method Based on IEEMD and PNN

- (1)

- Acquire N sample sound series in different cutting patterns and divide them into N1 training data and N2 testing data.

- (2)

- Extend the N series and decompose them into several IMF components. Then eliminate the continuation data and select essential IMF components. The selection process is confirmed by the relationship between the average correlation coefficients and the redundancy threshold ξ.

- (3)

- Extract the energy and standard deviation of the reminder IMFs as features, and normalize the feature vector of the sound series. Input the extracted vectors of N1 training series into the initial PNN, and the cutting pattern is the output of PNN.

- (4)

- Input the feature vectors of the testing series into the trained PNN, and acquire the cutting pattern of each testing sample finally. The flowchart of cutting pattern recognition method can be shown in Figure 2.

4. Simulation and Analysis

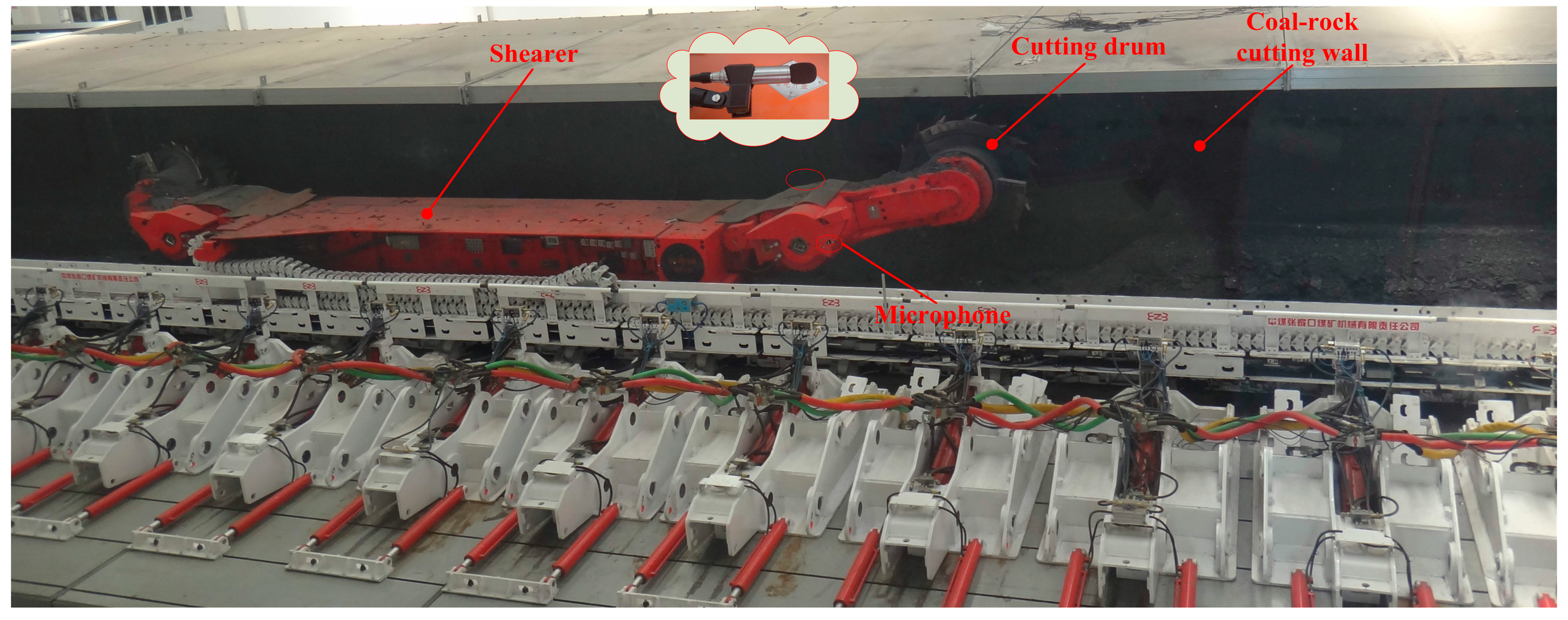

4.1. Sample Data Acquisition

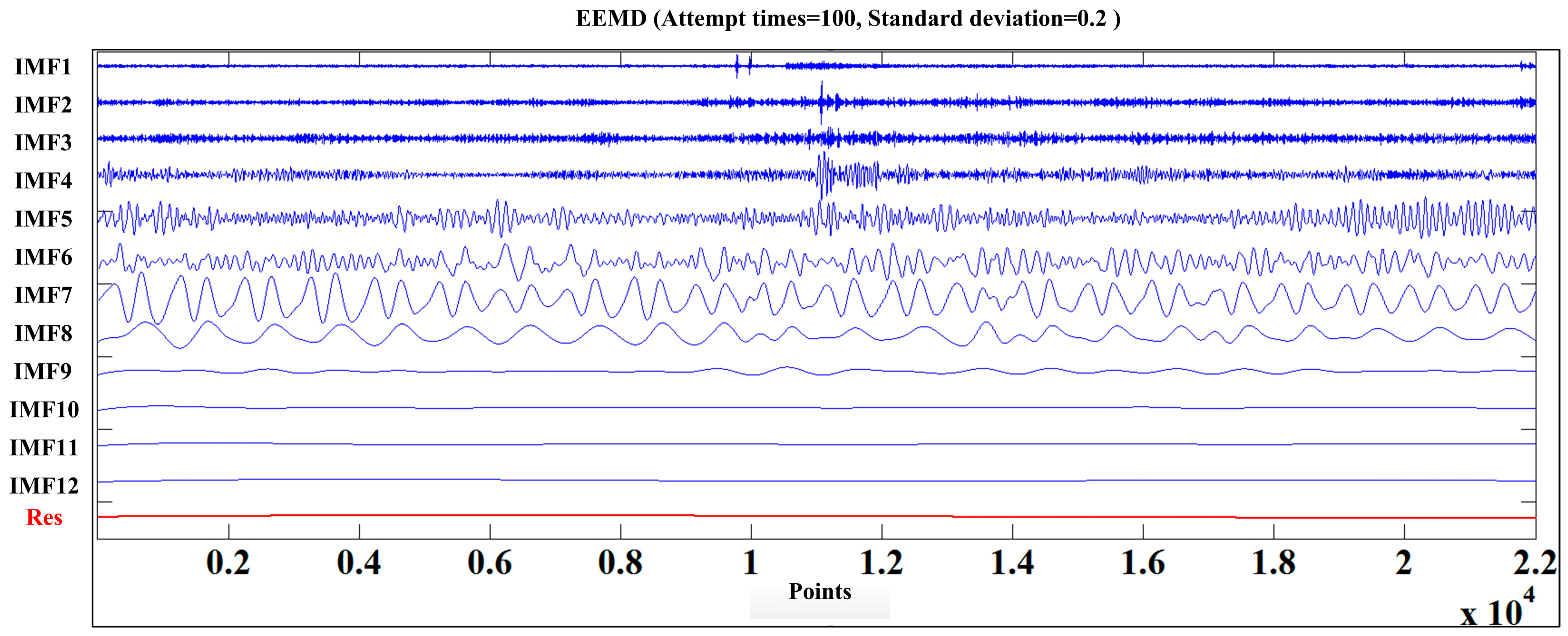

4.2. Sound Decomposition and Feature Extraction

| r1 | r2 | r3 | r4 | r5 | r6 | r7 | r8 | r9 | r10 | r11 | r12 | r13 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.0020 | 0.0029 | 0.0016 | 0.0035 | 0.0007 | 0.0012 | 0.0047 | 0.0021 | 0.0020 | 0.0031 | 0.0240 | 0.0019 | 0.0075 |

| Training Sample Number | Feature Vector |

|---|---|

| 1 | [0.0672, 0.1010, 0.3673, 0.0809, 0.6901, 0.1071, 0.7625, 0.946, 0.9218, 0.3012, 0.0362, 0.0421, 0.0043, 0.056, 0.0026, 0.0192] |

| 2 | [0.7037, 0.1662, 0.8445, 0.1760, 0.2710, 0.3091, 0.7370, 0.2522, 0.3111, 0.1631, 0.0063, 0.0172, 0.0353, 0.0132, 0.0084, 0.0006] |

| 3 | [0.9808, 0.0153, 0.0395, 0.3762, 0.6742, 0.0559, 0.7328, 0.0186, 0.6364, 0.0138, 0.1120, 0.0022, 0.5197, 0.8962, 0.58806, 0.0015] |

| ...... | |

| 599 | [0.0650, 0.0163, 0.3948, 0.0138, 0.1327, 0.0096, 0.2402, 0.0033, 0.6132, 0.7146, 0.3410, 0.0004, 0.0578, 0.0053, 0.0297, 0.0307] |

| 600 | [0.0118, 0.0023, 0.03407, 0.0038, 0.1841, 0.0087, 0.7196, 0.0622, 0.0343, 0.0566, 0.5617, 0.0059, 0.2671, 0.0036, 0.0644, 0.0016] |

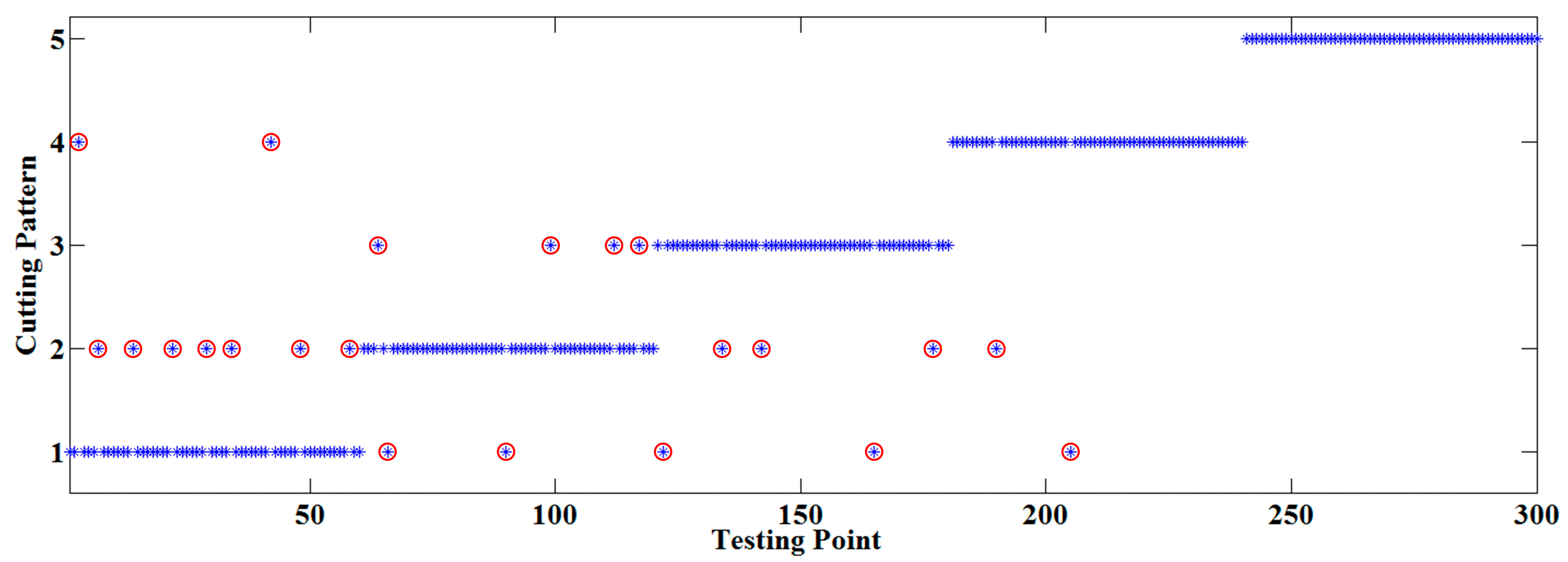

4.3. PNN Training and Testing

| ξ | Reminder IMF Number | Dimension of Feature Vector | Simulation Accuracy |

|---|---|---|---|

| 0.05 | 3 | 6 | 47.33% |

| 0.08 | 5 | 10 | 73.00% |

| 0.10 | 8 | 16 | 92.67% |

| 0.15 | 11 | 22 | 83.33% |

| 0.20 | 12 | 24 | 92.00% |

| 0.35 | 13 | 26 | 83.67% |

| 1.00 | 14 | 28 | 85.00% |

4.4. Discussion

| Compared Methods | Reminder IMF Number | Recognition Accuracy | Recognition Time (s) |

|---|---|---|---|

| Natural γ-ray detection | — | 66.67% | 92.7469 |

| WPT and PNN | — | 78.33% | 65.0264 |

| Traditional EEMD and PNN | 14 | 86.00% | 50.3133 |

| Yu’s method | 9 | 87.67% | 46.1962 |

| The proposed method | 8 | 92.67% | 45.0917 |

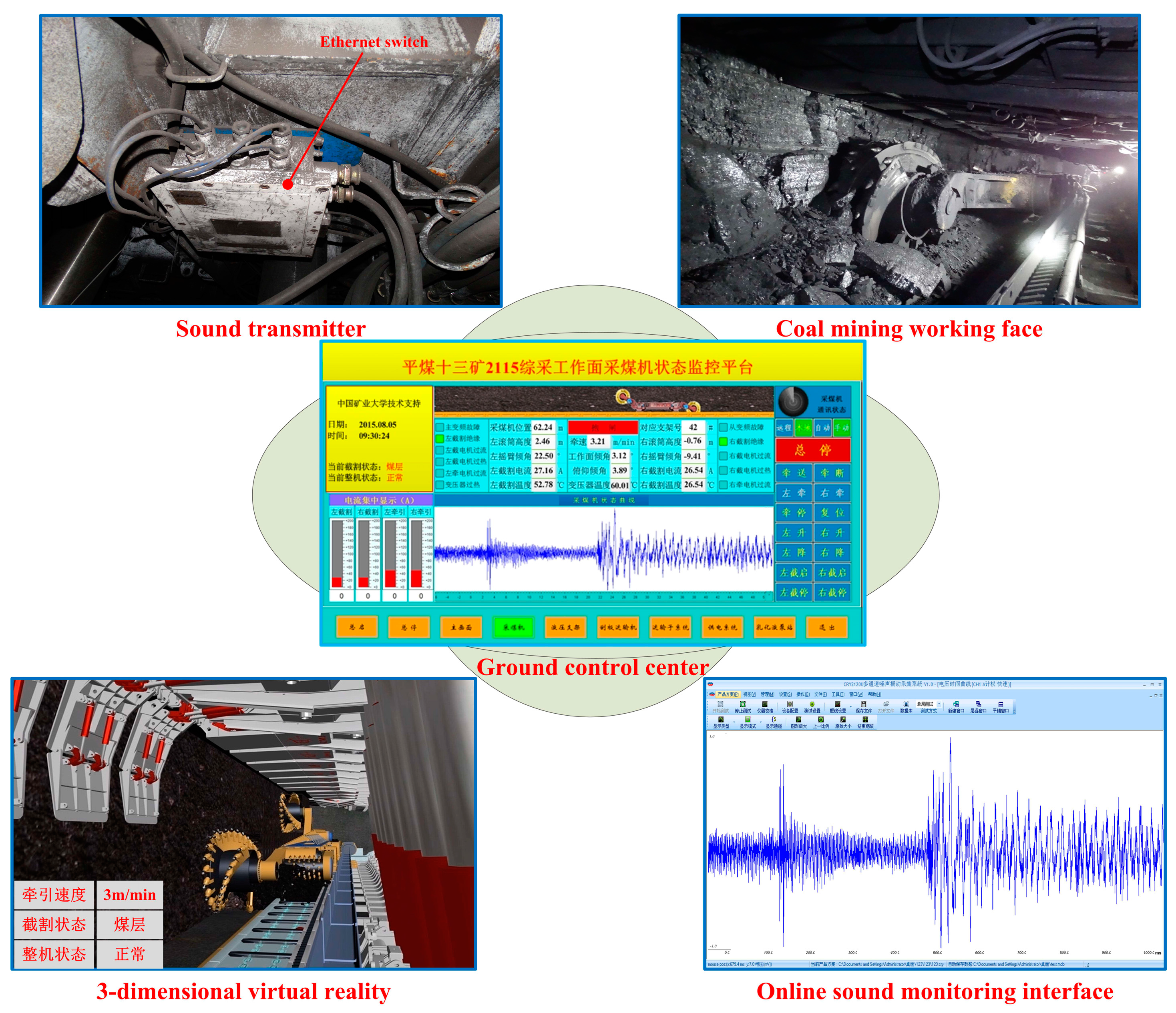

5. Industrial Application

6. Conclusions and Future Work

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Brady, B.H.G.; Brown, E.T. Rock Mechanics for Underground Mining; Springer Netherlands: Berlin, Germany, 1999; pp. 399–437. [Google Scholar]

- Zhang, Y. Recognition system of coal and rock on mechanized coal mining face. Adv. Inf. Sci. Serv. Sci. 2012, 8, 101–107. [Google Scholar]

- Si, L.; Wang, Z.B.; Tan, C.; Liu, X.H. A novel approach for coal seam terrain prediction through information fusion of improved D–S evidence theory and neural network. Measurement 2014, 54, 140–151. [Google Scholar] [CrossRef]

- Li, W.; Luo, C.M.; Yang, H.; Fan, Q.G. Memory cutting of adjacent coal seams based on a hidden Markov model. Arab. J. Geosci. 2014, 7, 5051–5060. [Google Scholar] [CrossRef]

- Komm, R.W.; Hill, F.; Howe, R. Empirical mode decomposition and Hilbert analysis applied to rotation residuals of the solar convection zone. Astrophys. J. 2001, 558, 428–441. [Google Scholar] [CrossRef]

- Huang, N.E.; Shen, Z.; Long, S.R.; Wu, M.C.; Shih, H.H.; Zheng, Q.; Yen, N.; Tung, C.C.; Liu, H.H. The empirical mode decomposition method and the Hilbert spectrum for non-stationary time series analysis. Proc. R. Soc. Lond. A 1998, 454, 903–995. [Google Scholar] [CrossRef]

- Wu, Z.H.; Huang, N.E.; Long, S.R.; Peng, C.K. On the trend, detrending, and variability of nonlinear and nonstationary time series. Proc. Natl. Acad. Sci. USA 2007, 104, 14889–14894. [Google Scholar] [CrossRef] [PubMed]

- Loh, C.R.; Wu, T.C.; Huang, N.E. Application of the empirical mode decomposition-Hilbert spectrum method to identify near-fault ground-motion characteristics and structural responses. Bull. Seismol. Soc. Am. 2001, 91, 1339–1357. [Google Scholar] [CrossRef]

- Boudraa, A.O.; Cexus, J.C. EMD-based signal filtering. IEEE Trans. Instrum. Meas. 2007, 56, 2196–2202. [Google Scholar] [CrossRef]

- Xuan, B.; Xie, Q.W.; Peng, S.L. EMD sifting based on bandwidth. IEEE Signal. Process. Lett. 2007, 14, 537–541. [Google Scholar] [CrossRef]

- Wu, Z.H.; Huang, N.E. A study of the characteristics of white noise using the empirical mode decomposition method. Proc. R. Soc. Lond. A 2004, 460, 1597–1611. [Google Scholar] [CrossRef]

- Lei, Y.G.; Zuo, M.J. Fault diagnosis of rotating machinery using an improved HHT based on EEMD and sensitive IMFs. Meas. Sci. Technol. 2009, 20. [Google Scholar] [CrossRef]

- Guo, W.; Tse, P.W. A novel signal compression method based on optimal ensemble empirical mode decomposition for bearing vibration signals. J. Sound. Vib. 2013, 332, 423–441. [Google Scholar] [CrossRef]

- Fang, Y.M.; Feng, H.L.; Li, J.; Li, G.H. Stress wave signal denoising using Ensemble Empirical Mode Decomposition and an instantaneous half period model. Sensors 2011, 11, 7554–7567. [Google Scholar] [CrossRef] [PubMed]

- Hong, H.; Zhu, X.H.; Su, W.M.; Geng, R.T.; Wang, X.L. Detection of time varying pitch in tonal languages: an approach based on Ensemble Empirical Mode Decomposition. J. Zhejiang Univ. Sci. C 2012, 13, 139–145. [Google Scholar] [CrossRef]

- Wang, W.C.; Chau, K.W.; Xu, D.M.; Chen, X.Y. Improving Forecasting Accuracy of Annual Runoff Time Series Using ARIMA Based on EEMD Decomposition. Water Resour. Manag. 2015, 29, 2655–2675. [Google Scholar] [CrossRef]

- Yu, Y.L.; Li, W.; Sheng, D.; Chen, J.H. A novel sensor fault diagnosis method based on modified Ensemble Empirical Mode Decomposition and Probabilistic Neural Network. Measurement 2015, 68, 328–336. [Google Scholar] [CrossRef]

- Wu, C.L.; Chau, K.W.; Li, Y.S. Methods to improve neural network performance in daily flows prediction. J. Hydrol. 2009, 372, 80–93. [Google Scholar] [CrossRef]

- Khan, J.; Wei, J.S.; Ringnér, M.; Saal, L.H.; Ladanyi, M.; Westermann, F.; Berthold, F.; Schwab, M.; Antonescu, C.R.; Peterson, C.; et al. Classification and diagnostic prediction of cancers using gene expression profiling and artificialneural networks. Nat. Med. 2001, 7, 673–679. [Google Scholar] [CrossRef] [PubMed]

- Taormina, R.; Chau, K.W. ANN-based interval forecasting of streamflow discharges using the LUBE method and MOFIPS. Eng. Appl. Artif. Intel. 2015, 45, 429–440. [Google Scholar] [CrossRef]

- Chau, K.W.; Wu, C.L. A hybrid model coupled with singular spectrum analysis for daily rainfall prediction. J. Hydroinform. 2010, 12, 458–473. [Google Scholar] [CrossRef]

- Specht, D.F. Probabilistic Neural Networks and the polynomial Adaline as complementary techniques for classification. IEEE Trans. Neural Netw. 1990, 1, 111–121. [Google Scholar] [CrossRef] [PubMed]

- Abdelaziz, A.Y.; Mekhamer, S.F.; Badr, M.A.L.; Khattab, H.M. Probabilistic Neural Network classifier for static voltage security assessment of power systems. Electr. Power Compom. Syst. 2012, 40, 147–160. [Google Scholar] [CrossRef]

- Venkatesh, S.; Gopal, S. Robust heteroscedastic Probabilistic Neural Network for multiple source partial discharge Pattern Recognition—Significance of outliers on classification capability. Expert Syst. Appl. 2011, 38, 11501–11514. [Google Scholar] [CrossRef]

- Shan, Y.C.; Zhao, R.H.; Xu, G.W.; Liebich, H.M.; Zhang, Y.K. Application of probabilistic neural network in the clinical diagnosis of cancers based on clinical chemistry data. Anal. Chim. Acta 2002, 471, 77–86. [Google Scholar] [CrossRef]

- Zhang, Y.D.; Wu, L.N. Classification of Fruits Using Computer Vision and a Multiclass Support Vector Machine. Sensors 2012, 12, 12489–12505. [Google Scholar] [CrossRef] [PubMed]

- Singh, S.; Haddon, J.; Markou, M. Nearest-neighbour classifiers in natural scene analysis. Pattern Recogn. 2001, 34, 1601–1612. [Google Scholar] [CrossRef]

- Bessinger, S.L.; Neison, M.G. Remnant roof coal thickness measurement with passive gamma ray instruments in coal mine. IEEE Trans. Ind. Appl. 1993, 29, 562–565. [Google Scholar] [CrossRef]

- Chufo, R.L.; Johnson, W.J. A radar coal thickness sensor. IEEE Trans. Ind. Appl. 1993, 29, 834–840. [Google Scholar] [CrossRef]

- Markham, J.R.; Solomon, P.R.; Best, P.E. An FT-IR based instrument for measuring spectral emittance of material at high temperature. Rev. Sci. Instrum. 1990, 61, 3700–3708. [Google Scholar] [CrossRef]

- Sun, J.P.; She, J. Wavelet-based coal-rock image feature extraction and recognition. J. Chin. Coal Soc. 2013, 38, 1900–1904. [Google Scholar]

- Wang, B.P.; Wang, Z.C.; Li, Y.X. Application of Wavelet Packet Energy Spectrum in Coal-rock Interface Recognition. Key Eng. Mater. 2011, 474, 1103–1106. [Google Scholar] [CrossRef]

- Wang, Z.B.; Xu, Z.P.; Dong, X.J. Self-adaptive adjustment height of the drum in the shearer based on artificial immune and memory cutting. J. Chin. Coal Soc. 2009, 34, 1405–1409. [Google Scholar]

- Xu, Z.P.; Wang, Z.B.; Mi, J.P. Shearer self-adaptive memory cutting. J. Chongqing Univ. 2011, 34, 134–140. [Google Scholar]

- Han, J.P.; Zheng, P.J.; Wang, H.T. Structural modal parameter identification and damage diagnosis based on Hilbert-Huang transform. Earthq. Eng. Eng. Vib. 2014, 13, 101–111. [Google Scholar] [CrossRef]

- Wang, T.; Zhang, M.C.; Yu, Q.H.; Zhang, H.Y. Comparing the applications of EMD and EEMD on time-frequency analysis of seismic signal. J. Appl. Geophys. 2012, 83, 29–34. [Google Scholar] [CrossRef]

- Jiang, F.; Zhu, Z.C.; Li, W.; Chen, G.A.; Zhou, G.B. Robust condition monitoring and fault diagnosis of rolling element bearings using improved EEMD and statistical features. Meas. Sci. Technol. 2014, 25. [Google Scholar] [CrossRef]

- Feng, Z.P.; Zuo, M.J.; Hao, R.J.; Chu, F.L.; Lee, J. Ensemble Empirical Mode Decomposition-based teager energy spectrum for bearing fault diagnosis. J. Vib. Acoust. 2013, 135. [Google Scholar] [CrossRef]

- Yi, C.; Lin, J.H.; Zhang, W.H.; Ding, J. Faults diagnostics of railway axle bearings based on IMF’s confidence index algorithm for ensemble EMD. Sensors 2015, 15, 10991–11011. [Google Scholar] [CrossRef] [PubMed]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, J.; Wang, Z.; Tan, C.; Si, L.; Liu, X. A Cutting Pattern Recognition Method for Shearers Based on Improved Ensemble Empirical Mode Decomposition and a Probabilistic Neural Network. Sensors 2015, 15, 27721-27737. https://doi.org/10.3390/s151127721

Xu J, Wang Z, Tan C, Si L, Liu X. A Cutting Pattern Recognition Method for Shearers Based on Improved Ensemble Empirical Mode Decomposition and a Probabilistic Neural Network. Sensors. 2015; 15(11):27721-27737. https://doi.org/10.3390/s151127721

Chicago/Turabian StyleXu, Jing, Zhongbin Wang, Chao Tan, Lei Si, and Xinhua Liu. 2015. "A Cutting Pattern Recognition Method for Shearers Based on Improved Ensemble Empirical Mode Decomposition and a Probabilistic Neural Network" Sensors 15, no. 11: 27721-27737. https://doi.org/10.3390/s151127721