Platform for Real-Time Simulation of Dynamic Systems and Hardware-in-the-Loop for Control Algorithms

Abstract

: The development of new embedded algorithms for automation and control of industrial equipment usually requires the use of real-time testing. However, the equipment required is often expensive, which means that such tests are often not viable. The objective of this work was therefore to develop an embedded platform for the distributed real-time simulation of dynamic systems. This platform, called the Real-Time Simulator for Dynamic Systems (RTSDS), could be applied in both industrial and academic environments. In industrial applications, the RTSDS could be used to optimize embedded control algorithms. In the academic sphere, it could be used to support research into new embedded solutions for automation and control and could also be used as a tool to assist in undergraduate and postgraduate teaching related to the development of projects concerning on-board control systems.1. Introduction

The development of new embedded algorithms and control techniques for dynamic systems, such as motors, industrial processes, automobiles and aircraft, amongst others, normally requires real-time tests in the devices to be controlled. However, such tests using real systems can be very expensive and time consuming. For example, the refinement of a control algorithm for an automobile injection valve requires tests under real conditions that can last for hours or even days. In other cases, it is necessary to construct small prototypes in order to perform the tests, as in the case of aircraft and ships. Many of these tests under real conditions can be performed using off-line simulations (which are not performed in real time), although such simulations do not fully eliminate real-time testing.

Methods for the development of platforms for real-time simulation have been extensively studied for many years. However, research in this area has recently accelerated following advances in terms of speed and the ease of development associated with new hardware platforms. Methodologies for real-time simulation have included the use of hardware, such as digital signal processors, general-purpose processors and even reconfigurable computational solutions employing field-programmable gate arrays (FPGAs) [1–9]. The benefits of using real-time simulation platforms have been demonstrated in various areas of graduate teaching [10,11]. The combination of real-time simulation with hardware-in-the-loop (HIL) has also been widely investigated in recent years and has brought many benefits in terms of the optimization and prototyping of new control systems [12–17]

In [1], a low-cost real-time simulator (RTS) that can be constructed in the laboratory is proposed for electronic power systems. The system is implemented in a computer with a multi-core processor coupled with data acquisition and signal conditioning boards. The studies described in [2,3] present distributed solutions for RTS in software, where several computers are used in an Ethernet network in order to simulate real-time systems. Signal processing techniques able to reduce the sampling frequency and computational cost associated with RTS are presented in [4], where it is shown that the computational cost can be reduced up to 100-fold, without compromising the precision of the simulation. In [5], a methodology consisting of seven steps is proposed for the validation of real-time simulation models. In [6], a real-time simulation model is proposed for testing AC electrical drives, where the simulation is performed using a Hypersim real-time simulator platform provided by the company, OPAL-RT [18]. Hypersim uses a supercomputer with more than 2000 cores, together with data acquisition boards, and is widely used to simulate large-scale power systems [19]. The use of onboard systems with DSPs is a new approach described in [7], where the dynamic system is implemented using DSPs.

The studies described in [8,9] offer RTS proposals for energy systems employing FPGAs associated with a computer, the main advantage of which is the parallel implementation of the dynamic systems simulated. The benefits of using RTS in the teaching of engineering in graduate and postgraduate courses are described in detail in the works of [10,11], where various commercial RTS tools are presented. Reviews of the advances achieved using real-time simulation schemes with HIL are presented in [12–14], where [13] focuses on applications in energy systems, and [14] focuses on aspects associated with the automotive field. In [15], a real-time simulation system is implemented for testing complex onboard systems with HIL, with the proposed RTS utilizing high-performance hardware with various data acquisition platforms. Finally, modeling and simulation methodologies associated with commercial RTS platforms are presented in [16,17]. The work described in [16] used an RTS provided by the company, dSPACE [20], to simulate wind energy systems, and in [17], an eMEGAsim platform from OPAL-RT [18] was used in an all-electric ship project.

From the cited works, it can be seen that research involving RTS extends from new hardware and software proposals to new modeling techniques aimed at existing commercial systems. It can also be seen that the scope of this area is quite wide and that there is still considerable space for new solutions, especially in the context of simulations employing HIL. The proposal of the present work is therefore to present a new RTS and HIL platform applied to the optimization and testing of control algorithms. This new platform, here called the Real-Time Simulator for Dynamic Systems (RTSDS), possesses a distributed architecture composed of a range of different hardware platforms, enabling it to be constructed in the presence of various resource limitations. As an example, this paper presents a case study in which the RTSDS is composed of a personal computer (Intel DN2800MT Mini-ITX hardware) associated with low-cost and easily-accessible hardware platforms (with embedded software), such as the Arduino and CY8CKIT-001 kits [21–25]. It is important to emphasize that the RTSDS is a solution that does not provide a substitute for high-performance simulation platforms [18,20] that work with sampling times on the order of μs, although it can be used for a range of real systems that work with speeds on the order of ms [26].

The main objective of the Real-Time Simulator for Dynamic Systems (RTSDS) is to provide a support tool for the developers of embedded control systems, focusing on reducing the costs involved in real-time tests. In addition to having industrial applications, the RTSDS could also be used in the academic sphere as a programmable didactic model in various curriculum modules of courses in engineering. Using the RTSDS, the graduate or postgraduate student could test control algorithms in various types of dynamic system, simply and at a cost that is relatively low compared to those of real didactic models. Another point that should be emphasized about the proposal presented here is that the RTSDS can also simulate the functioning of the drivers and sensors associated with the control of dynamic systems, which is an important characteristic from the point of view of the development of control systems projects [27–29].

In order to verify all of the relevant aspects of the RTSDS, this paper presents two case studies in which real-time simulations are made of a level control design and a design for the speed control of a vehicle following a longitudinal route. All of the details concerning the architecture and functioning of the RTSDS are presented here, and all of the source codes can be found in [30], hence enabling the use of this platform by other researchers and students.

2. Physical Architecture of the RTSDS

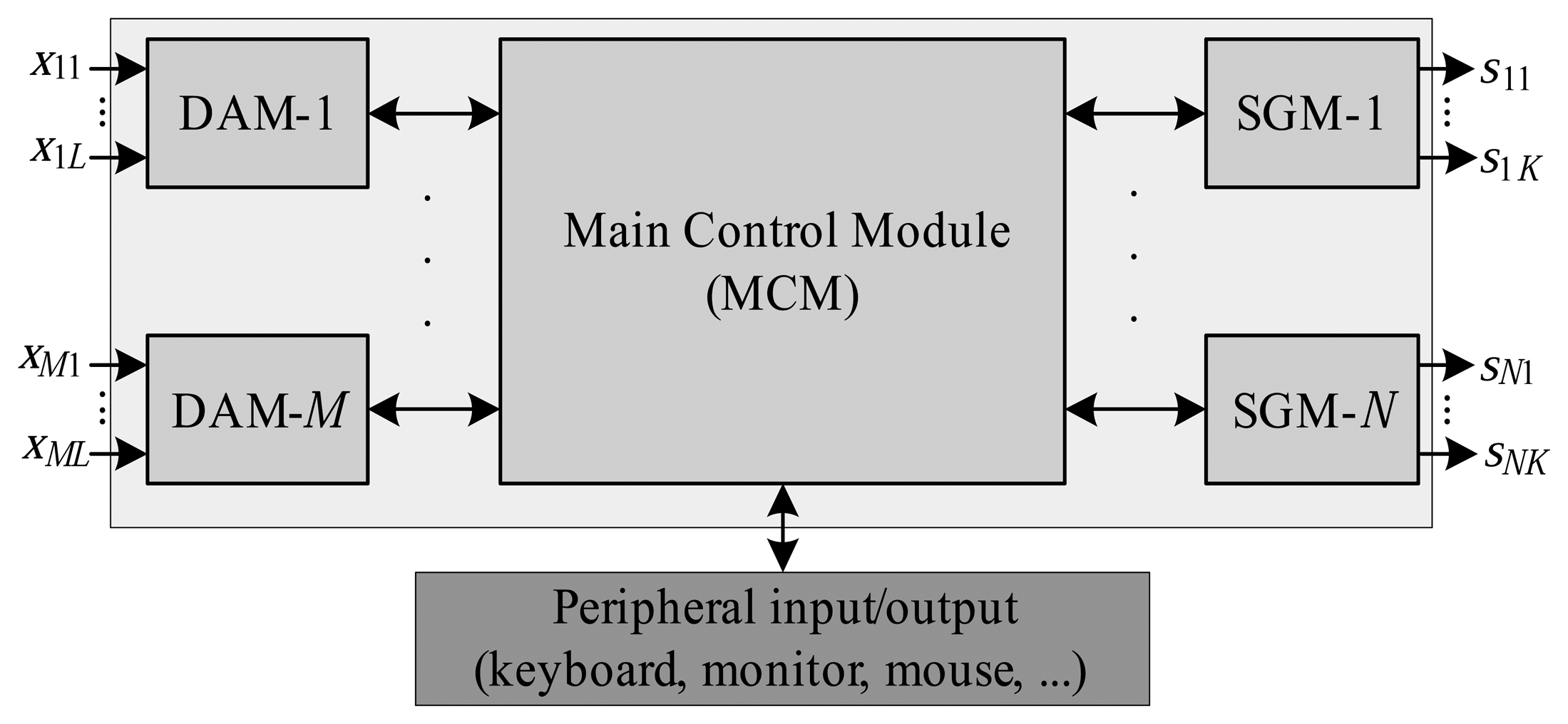

Figure 1 shows a block diagram of the architecture of the RTSDS. The main control module (MCM) is coupled to a set of M data acquisition modules (DAMs) and N signal generation modules (SGMs). The function of the MCM is to control, manage and configure the real-time simulation platform, and it is also responsible for the entry and retrieval of data by the user. In principle, the MCM should employ a high-performance processor, which in the present case was the Intel DN2800MT Mini-ITX [31], including an Atom N2800 processor.

The DAMs and SGMs are auxiliary hardware whose function is to receive and generate signals related to the dynamic system to be simulated by the MCM. In practice, the DAMs and SGMs can be implemented by a variety of hardware platforms, such as digital signal processors, microcontrollers and other devices possessing digital and/or analog inputs and outputs. As shown in Figure 1, each m-th DAM can include L digital and/or analog inputs, and each n-th SGM is characterized by K digital and/or analog outputs. Each RTSDS must possess at least one DAM and one SGM.

2.1. Main Control Module (MCM)

The main control module (implemented with the Intel DN2800MT Mini-ITX hardware) is responsible for configuring and implementing the simulation of the chosen dynamic system. The MCM performs its task by means of an embedded application called the main application (MA), which will be described in the following sections. In addition to the MA, the MCM must possess a set of integrated interfaces and communication protocols in order to achieve communication with the DAMs and SGMs. The RTSDS platform does not demand any specific communication protocol, although the transmission rate R (in bps) is an important factor in the functioning of a real-time simulator, especially in the case of fast-response dynamic systems [27].

2.2. Data Acquisition Modules (DAMs)

The DAMs are hardware connected to the MCM by means of a data communication protocol transferring bits at a rate of R1 bps. Each m-th DAM can comprise L inputs (analog and/or digital) and is responsible for capturing signals from the external environment that will be used by the real-time simulator executed in the MCM. The DAMs utilize an embedded software system, called the application DAM (ADAM). There is a different ADAM for each type of driver and actuator associated with the dynamic system to be simulated. The ADAM is responsible for transforming the L external signals connected to the m-th DAM into real values and transmitting them to the MCM. The l-th input signal of the m-th DAM is expressed by xml(t) and, depending on the driver, may be a variable amplitude and/or frequency analog signal or a variable frequency and/or pulse width digital signal [28].

2.3. Signal Generation Modules (SGMs)

These modules are hardware platforms responsible for the generation of signals associated with the outputs of the dynamic system simulated in the MCM. Similar to the DAMs, the SGMs are comprised of K outputs (analog and/or digital), communicate with the MCM by means of a data communication protocol at a rate of R2 bps and employ an embedded software system called the application SGM (ASGM), which converts the simulation data received from the MCM into external analog and/or digital signals. For each type of sensor to be simulated in the dynamic system, there is a different ASGM that converts the output information according to the instrumental characteristics of the sensor in question. The k-th output signal of the n-th SGM is expressed as snk(t) and, depending on the type of sensor, may be an analog signal of variable amplitude and/or frequency or a digital signal with variable frequency and/or pulse width [29].

3. Logical Architecture of the RTSDS

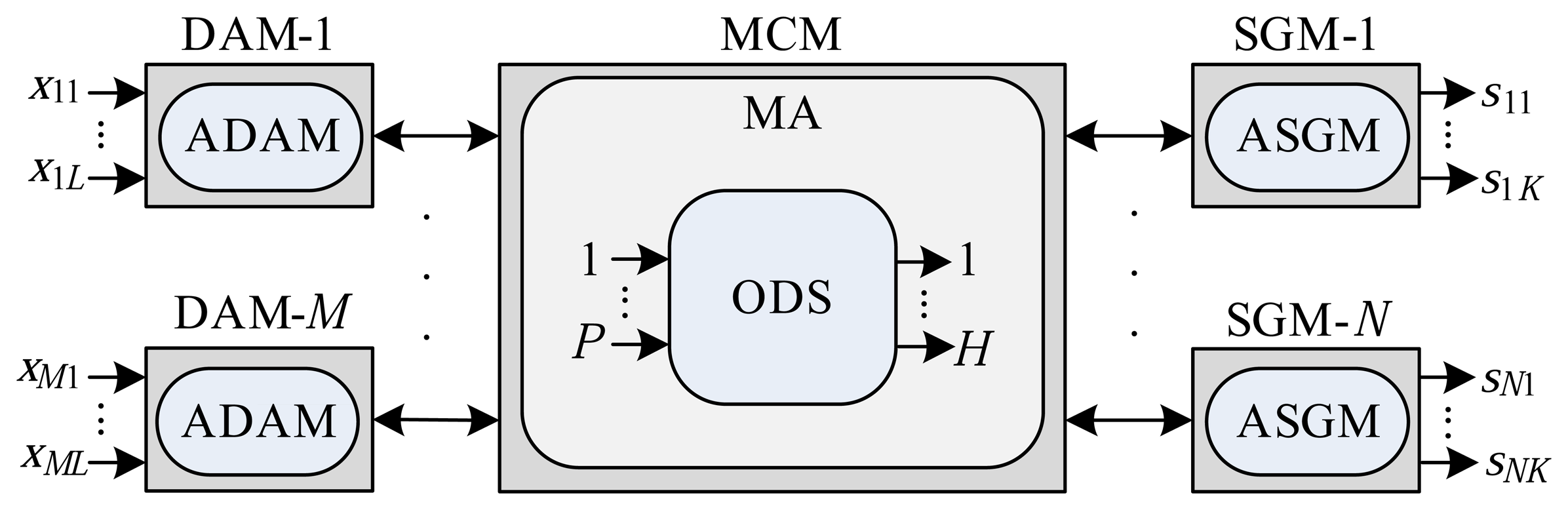

Figure 2 illustrates the logical architecture of the RTSDS, where an application located in the MCM, here known as the main application (MA), instantiates a class of software called the object dynamic system (ODS). An ODS represents the dynamic system to be simulated in real time and is composed, amongst others, of eight principal attributes expressed by {P, H, f(t),

P represents the number of inputs of the dynamic system.

H represents the number of outputs of the dynamic system.

f(t) defines the system of ordinary differential equations (ODEs) of the dynamic system to be simulated in real time.

defines a set of adjustable parameters associated with the dynamic system.

characterizes the set of embedded codes (the ADAMs) in the DAMs associated with the inputs of the dynamic system.

characterizes the set of embedded codes (the ASGMs) in the SGMs associated with the outputs of the dynamic system.

MethodODE is an attribute that defines which ODE numerical resolution method should be used in the real-time simulation. The RTSDS can implement various resolution methods, including those of Euler, Runge–Kutta, and others [32,33].

ta represents the sampling time to be employed in the real-time simulation process.

The RTSDS possesses a database, located in the MCM, composed of various ODSs that can be easily inserted by means of the MA.

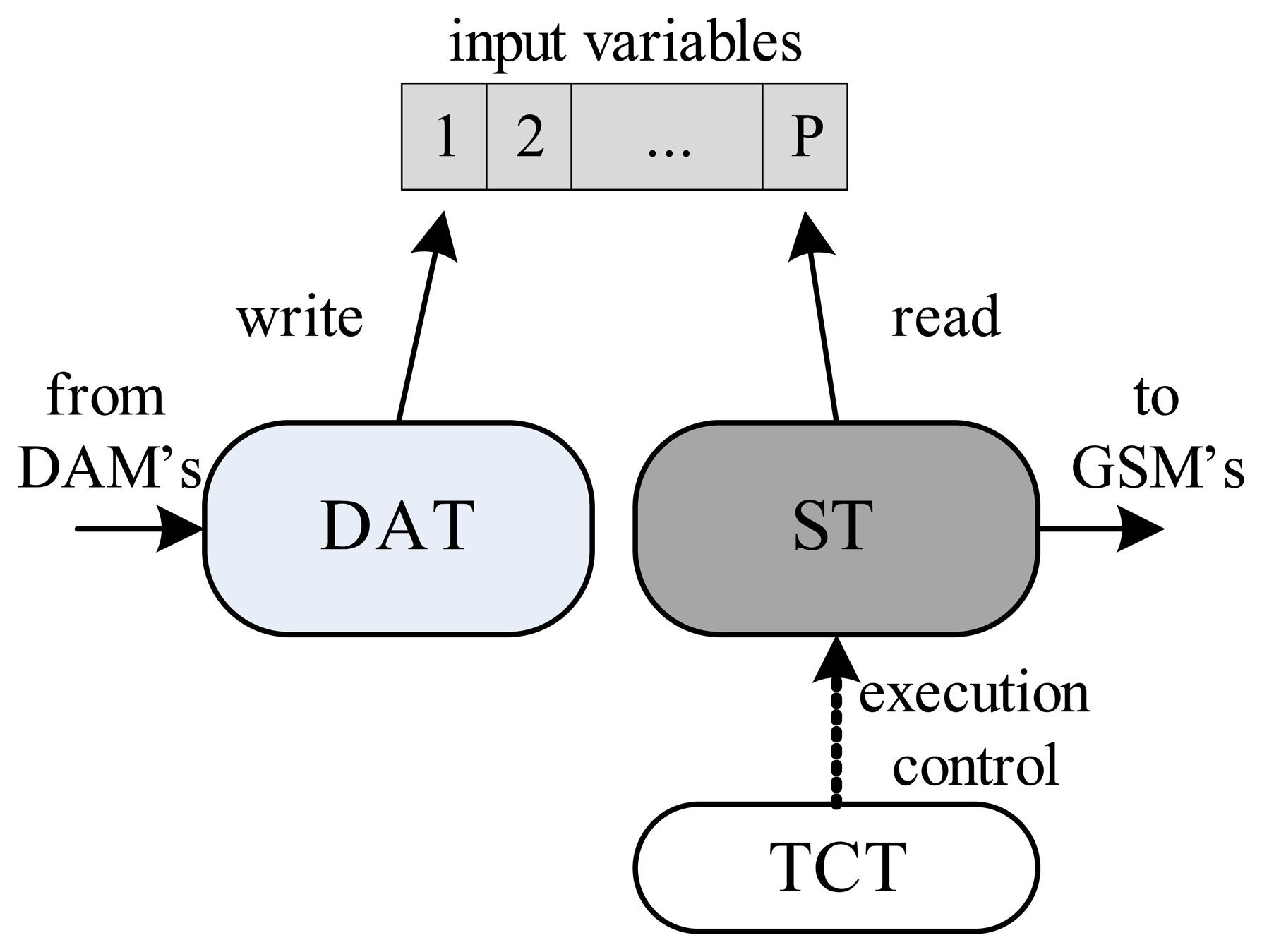

The execution of the real-time simulation of an ODS, in the MCM, is achieved using three threads working collaboratively. These are the data acquisition thread (DAT), the simulation thread (ST) and the time control thread (TCT). The function of the DAT is to update all of the P inputs of the dynamic system under simulation, reading all of the input buffers associated with the data connections between the MCM and the DAMs. The P input variables are shared between the data acquisition and simulation threads. The ST updates the H output variables and executes the ODE numerical resolution method (defined by the MethodODE variable) in the system of equations, f(t), in order to update the states of the dynamic system [27,32,33]. The execution of the simulation thread is controlled by the TCT, which uses semaphore logic [34] to regulate the execution time of the ST to a fixed value, ts, so that the resolution method always occurs at fixed intervals. The use of a fixed interval, ts, is not essential in numerical resolution methods, but is fundamental for parameterization of the simulation platform, which must have a sampling time, ta, that is much smaller than the response time, tr, of the dynamic system to be simulated. In other words, the simulation process must respect the restriction:

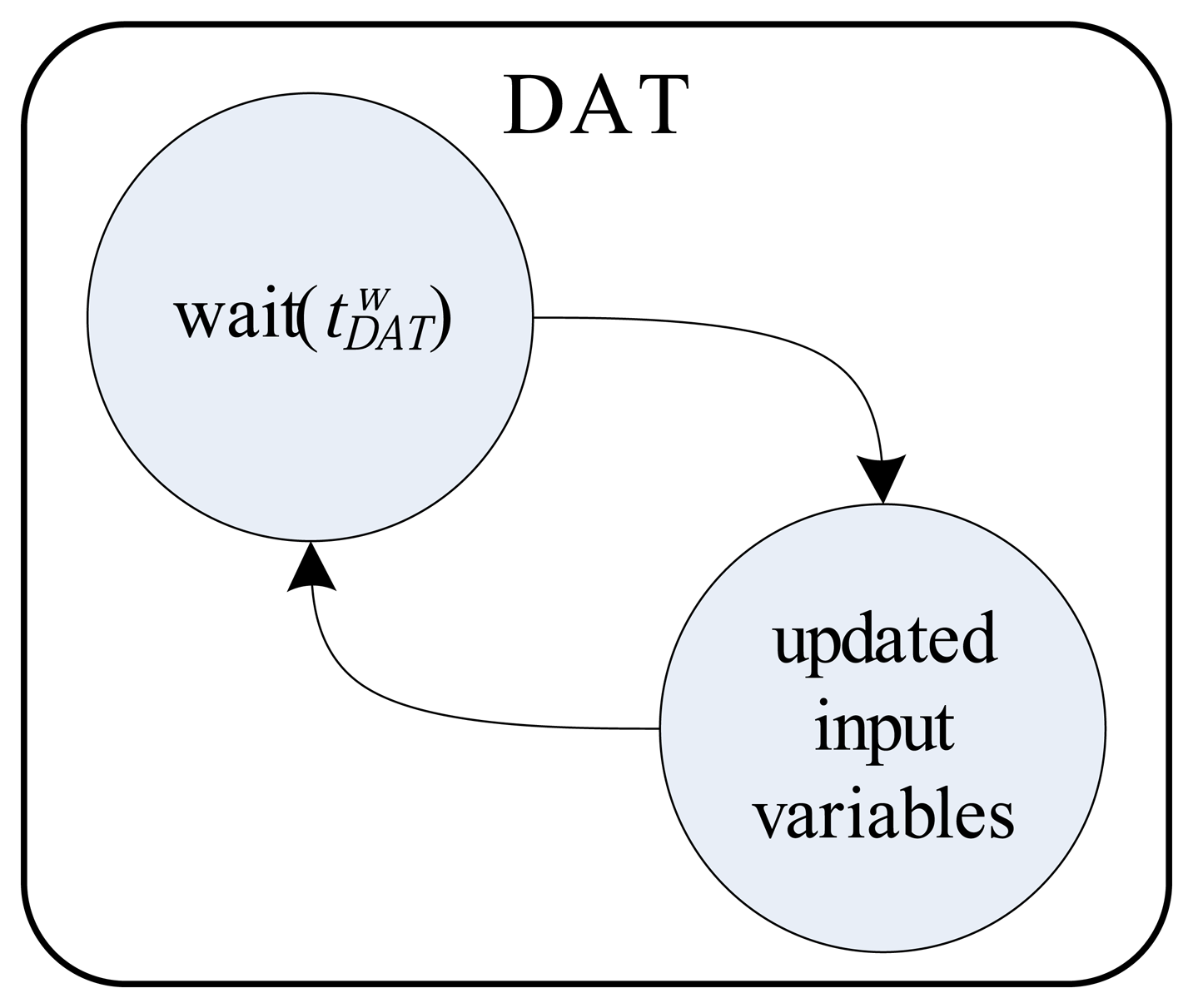

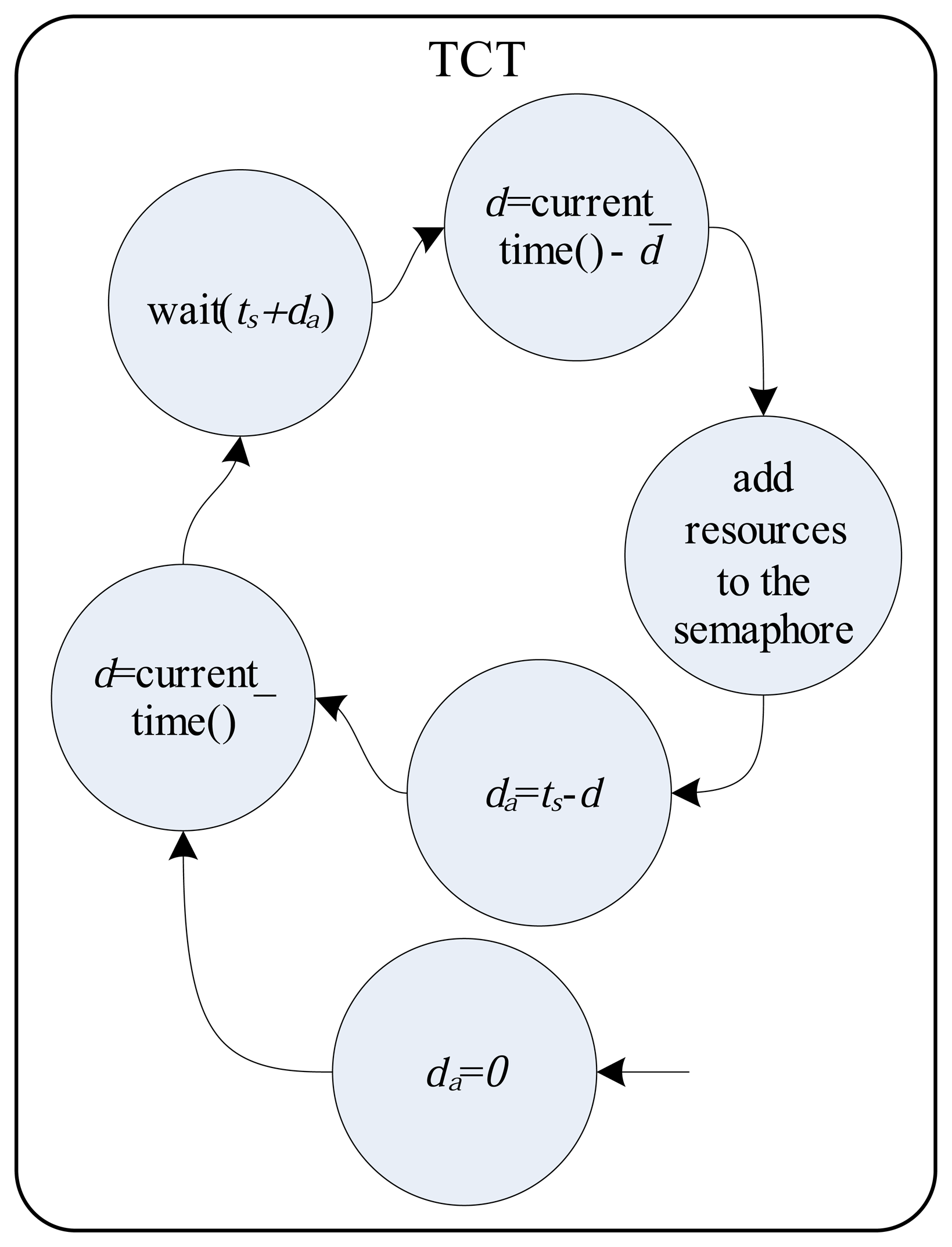

Figures 4, 5 and 6 detail the finite automata associated with the threads DAT, TS and TCT, respectively. The DAT (Figure 4) scans all communication interfaces buffers with DAMs and updates the P input variables of ODS (Figure 3). The DAT is asleep in a predetermined fixed time, , to minimize collision problems in the input variables update (write operation), since they are shared with the ST. The finite automata of ST (detailed in Figure 5) wait for the semaphore resource update (by TCT) to send the output variables to SGMs and then run the ODS. Finally, Figure 6 shows, by finite automata, the operation of TCT, which controls the insertion of the semaphore resource. The resource addition is done every, ts, seconds to ensure the run time of the ODS. The finite automata shown in Figure 6 also detail a system synchronization (using the variables da and d) that adjusts the run time in ts.

The codes of the set

Similar to the DAMs, the role of the set

The simulation of drivers and sensors (using the DAMs and SGMs, respectively) coupled to the dynamic system differentiates the proposed platform, with the simulation process becoming closer to the real case. This benefit is especially important in the development and validation of the embedded control of dynamic systems. Future work will consider the optimization of algorithms for the automatic allocation of DAMs and SGMs to the MCM.

After instantiation of an ODS, the sampling time, ta, can be expressed by:

4. Description of the Prototype

Validation of the proposed system involved the development of a prototype (illustrated in Figure 7) with M = 2 DAMs (DAM-1 and DAM-2) and N = 1 SGM (SGM-1). The MCM was implemented using the Intel DN2800MT Mini-ITX platform with the Linux operating system (distribution: Ubuntu 13.10 [35]), and the DAMs and SGMs were implemented in microcontrollers. DAM-1 utilized an Atmel ATmega 2560 processor [36] with the Arduino Mega 2560 development kit [21]; DAM-2 used an Atmel ATmega 328p processor [22] with the Arduino Uno development kit [23]; and the SGM utilized a Cypress PSOC 3 CY8C38 processor [24] with the PSOC CY8CKIT-001 kit [25]. Communication between the two DAMs and the MCM was accomplished using the USART protocol (Universal Synchronous and Asynchronous Serial Receiver and Transmitter) at a rate of R1 = 9.6 kbps, and communication between the SGM and the MCM was by means of the USB (Universal Serial Bus) protocol, at a rate of R2 = 1 Mbps. The main application of the MCM in the prototype was implemented with only one available ODS.

After the development of the prototype, the validation process was continued with the simulation of two dynamic systems whose characteristics are presented in the following subsections. The results associated with the simulations and HIL testing with a PID controller are presented in the next section.

4.1. Dynamic System 1: Water in a Tank

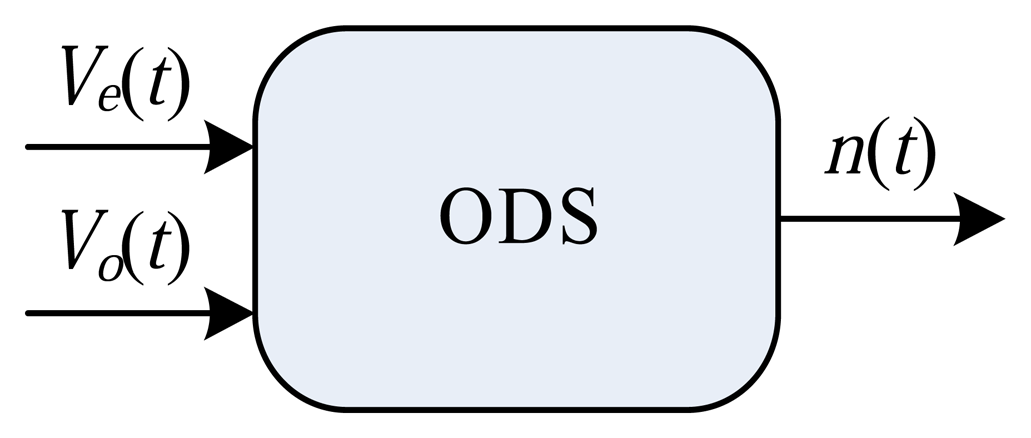

This dynamic system is illustrated in Figure 8, and the results are presented in the next section. The real-time simulation involved a tank of water coupled to a pump (see Figure 8). The pump with constant flow, qm, is coupled to an input valve with continuous control, Ve(t), generating a tank input flow of qe(t). The tank output valve also possesses a continuous control, Vo(t), and the flow after this valve is given by qs(t). The level of water in the tank is characterized by the n(t) variable. In this case, the ODS (Figure 9) possesses two inputs, P = 2, controlling the input valve, Ve(t), and the output valve, Vo(t), and one output, H = 1, which is the water level in the tank, n(t). The system of differential equations associated with the ODS can be expressed by:

, of the ODS, representing the pump flow (cm2/s), the transverse section of the tank (cm2), the gravitational acceleration (m/s2) and the transverse section of the tank output tube (cm2), respectively

, of the ODS, representing the pump flow (cm2/s), the transverse section of the tank (cm2), the gravitational acceleration (m/s2) and the transverse section of the tank output tube (cm2), respectivelyThe dynamic system was simulated in real time, employing the Euler method for ODE resolution (the MethodODE variable), which is a simple, but effective method for the dynamic system represented by Equation (5). In this method, Equation (5) can be rewritten as:

The Euler method approximates the integral, presented in Equation (7), by the area of a rectangle whose base has length Δt [32,33], in other words,

4.2. Dynamic System 2: Longitudinal Vehicle

The longitudinal vehicle model [37], illustrated in Figure 10, can be described by the expression:

According to [37], the friction force, fa(t), can be expressed as:

The aerodynamic friction can be described by:

The dynamic system was simulated in real time, employing the Euler method for ODE resolution (the MethodODE variable). In this method, Equation (12) can be rewritten as:

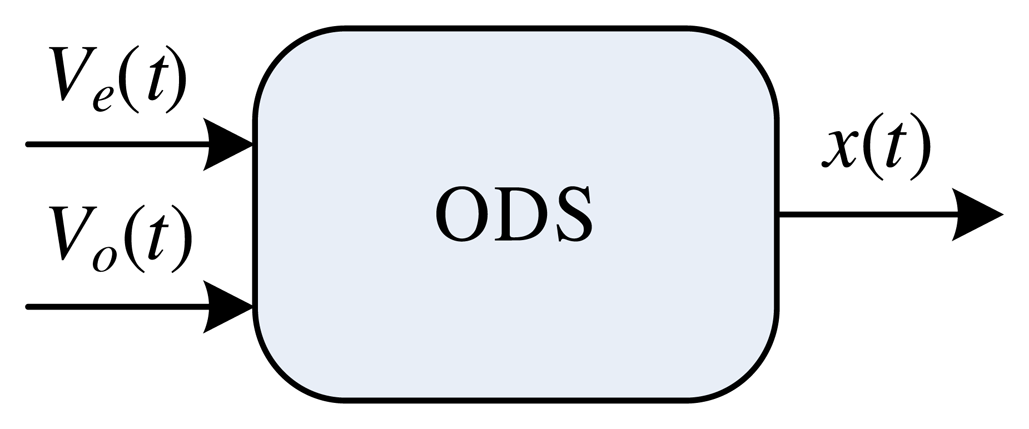

In this case, the ODS (Figure 11) possesses two inputs, P = 2, controlling the traction force, Ve(t), as well as the inclination angle, Vo(t), and one output, H = 1, which is the speed of the vehicle in the longitudinal direction, x(t).

4.3. General Parameters

The control signal, Ve(t), can have values of between zero and one in the ODS. In order to represent a more real situation, the external signal, x11(t), associated with Ve(t) consists of a digital signal with a fixed frequency and a pulse width that can be varied between 0% and 100% (pulse-width modulation, PWM) [28]. Hence, the DAM-1, using an embedded ADAM (set

In the case of the control signal, Vo(t), the ODS also operates with values of between zero and one. However, in order to differentiate this case from the preceding case, the external signal, x21(t), associated with Vo(t), has an amplitude that is variable between zero and 2.5 volts. In this way, the DAM-2, using an embedded ADAM (set

Finally, the output of the simulated dynamic system, n(t) (level in the tank) or x(t) (vehicle speed), was associated with an analog signal, s11(t), in SGM-1. In this case, the embedded ASGM (set

Table 1 summarizes the times estimated for the DAMs and SGMs, based on the variables presented in Equation (2). From these values and the response time of the dynamic system, tr, it is possible to estimate the value of ts and calculate the sampling time of the system, ta.

5. Experimental Results

The prototype developed was validated experimentally by varying the set of parameters,

5.1. Results of Dynamic System 1: Water in a Tank

In all of the experiments with Dynamic System 1, the pump flow was held constant at qm(t) = 69 cm3/s; the acceleration due to gravity was g = 9.8 m/s2; the maximum level of the tank was nmax = 30 cm; and the transverse section of the output tube was a = 0.1781 cm2, generating a maximum outlet flow, qs(t), of 17.81 cm3/s. The tests used values of A = 15.518 cm2 and A = 62.072 cm2 for the area of the transverse section of the tank, so that in the worst case, the response time of the dynamic system, tr, was in the region of tr ≈ 100 s. Based on the value of tr and the values presented above (summarized in Table 1), use of Equation (2) gives an estimated value of ts of 100 ms, while the calculated value of ta was 212 ms, taking into account the restriction presented in Equation (1).

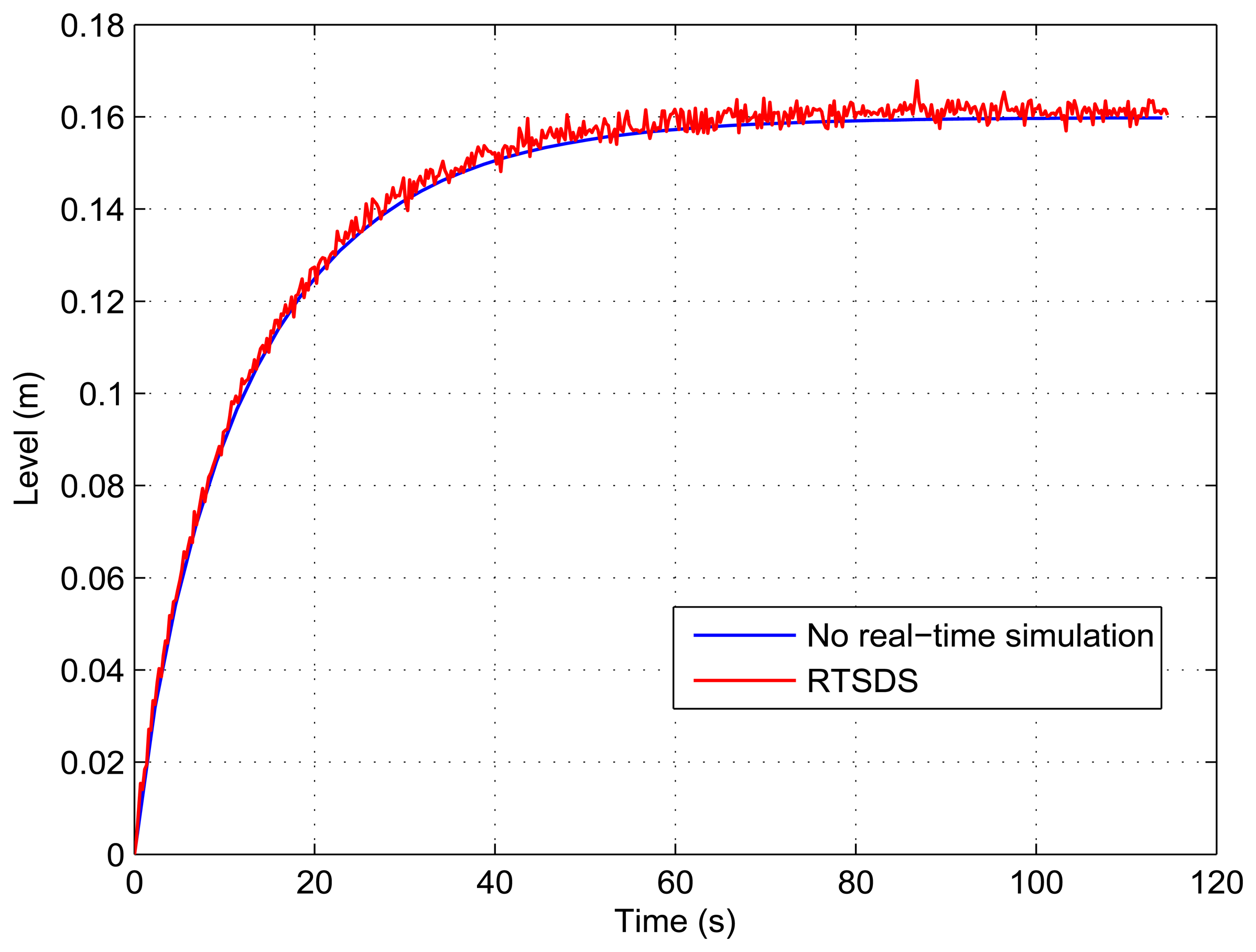

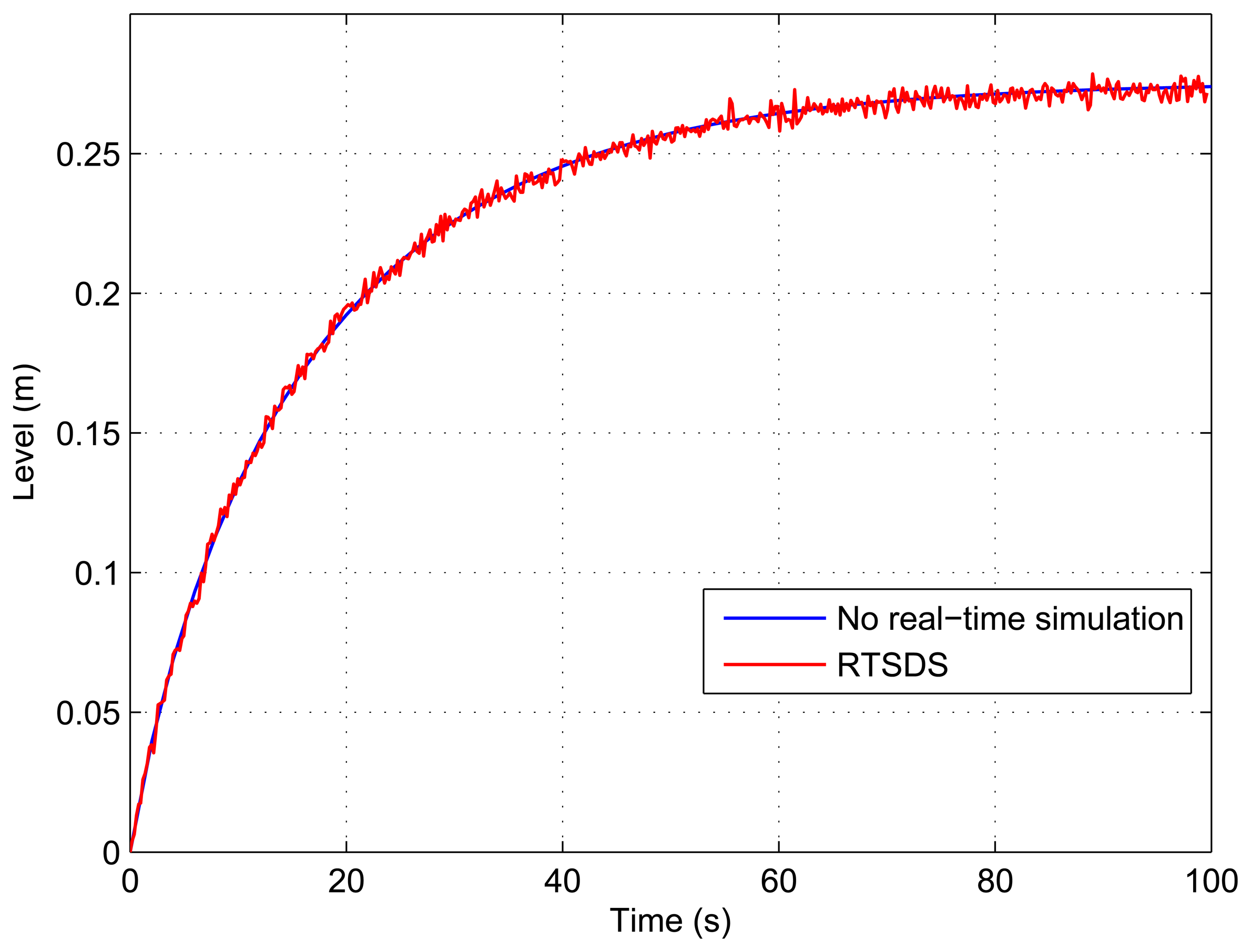

Figures 13, 14, 15, 16 and 17 show the results obtained for the RTSDS platform used to execute the prototype described above, together with the non-real-time results obtained using MATLAB/Simulink. In all cases (with Dynamic System 1), it can be seen that the RTSDS platform provided satisfactory results, with errors that were very small in relation to the reference method. In all of the tests with Dynamic System 1 (water in a tank) (Figures 13, 14, 15, 16 and 17), the outlet flow volume was fixed at the maximum value, Vo(t) = 1, and the inlet flow volume, Ve(t), was adjusted between zero and one, varying the inlet flow rate, qe(t), relative to the constant flow produced by the pump, qm(t) (see Equation (5)).

The results for a tank with A = 15.518 cm2 are shown in Figures 13 and 14 for qe(t) = 0.457 and qe(t) = 0.6, respectively. Figure 15 presents the results for a programmed sequence of perturbations, with DAM-1 being programmed to begin with qe(t) = 0.457 and then after 100 s to change to qe(t) = 0.6. Figures 16 and 17 present the results for a tank with A = 62.072 cm2 and qe(t) = 0.3 and qe(t) = 0.45, respectively.

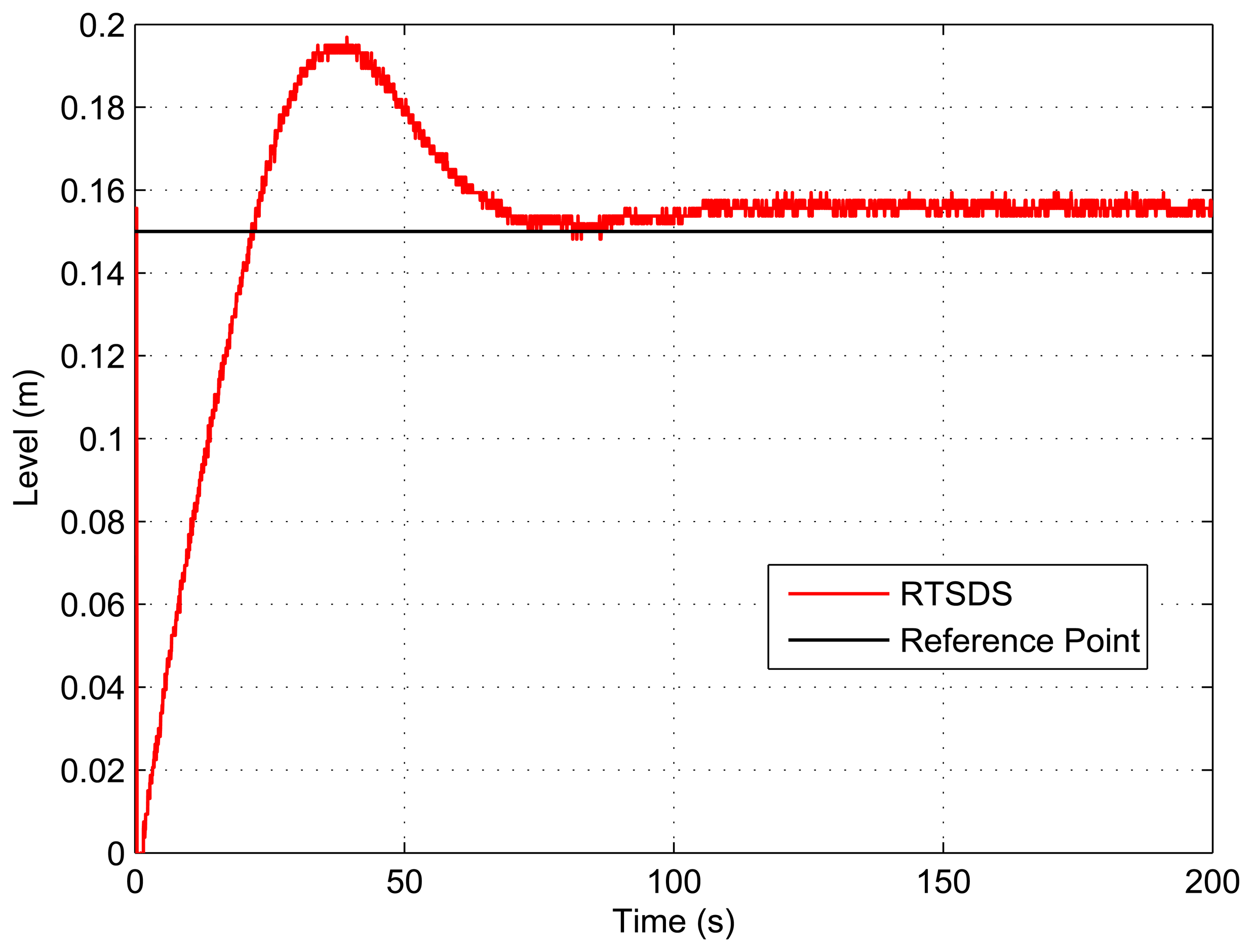

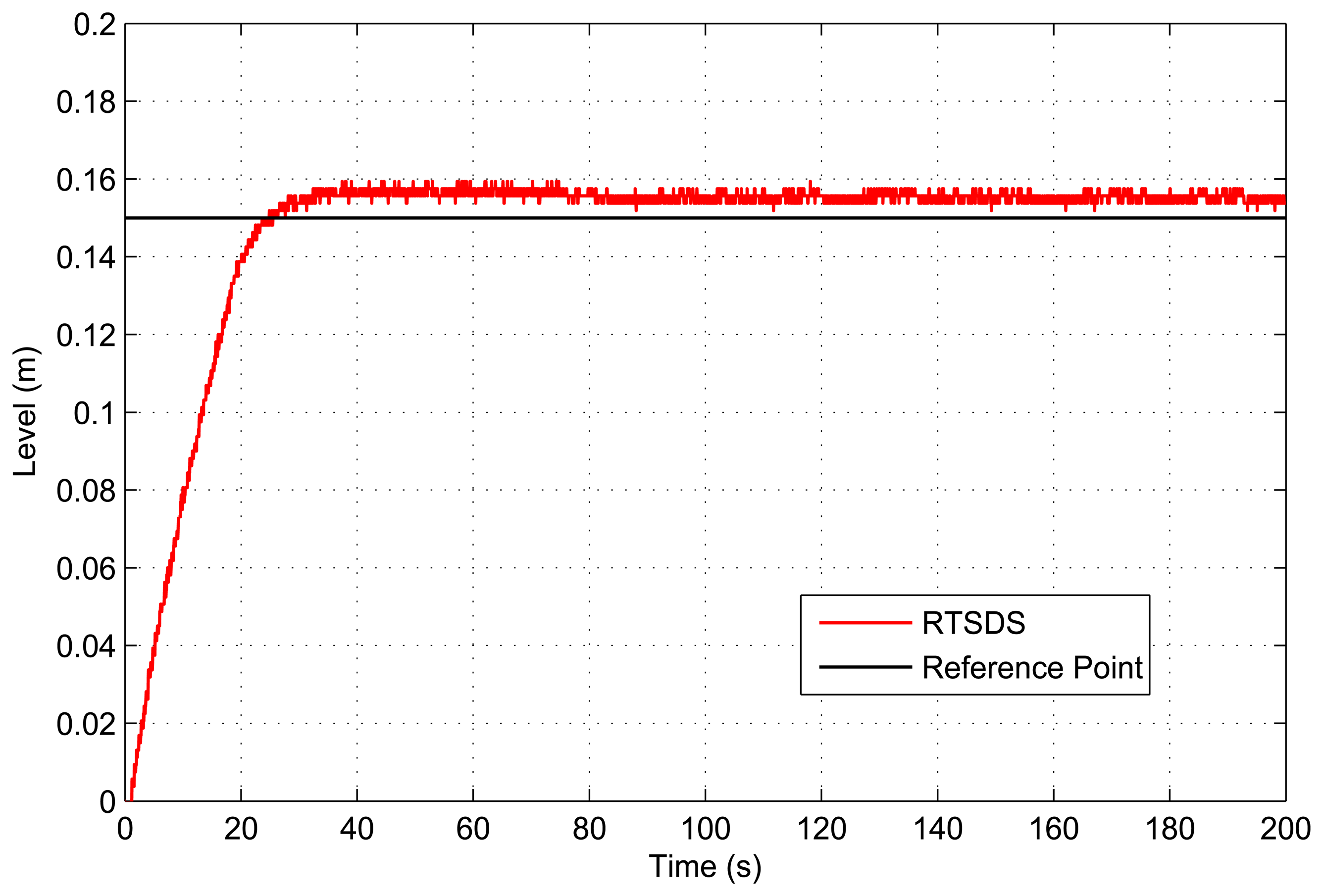

Figures 18 and 19 present the results obtained for an embedded PID controller [27] in an ATmega 2560 microcontroller (utilizing the Arduino Mega 2560 kit) external to the RTSDS platform. The system was controlled to a reference value (set point) of 15 cm, and the results show the response of the system in terms of the value associated with the level, n(t). This experiment clearly demonstrated the benefits derived from using the RTSDS in the development of embedded control algorithms, where the performance and viability of new algorithms could be tested in real time, without any need to acquire expensive physical equipment. Figure 20 shows the equipment used in testing with the PID.

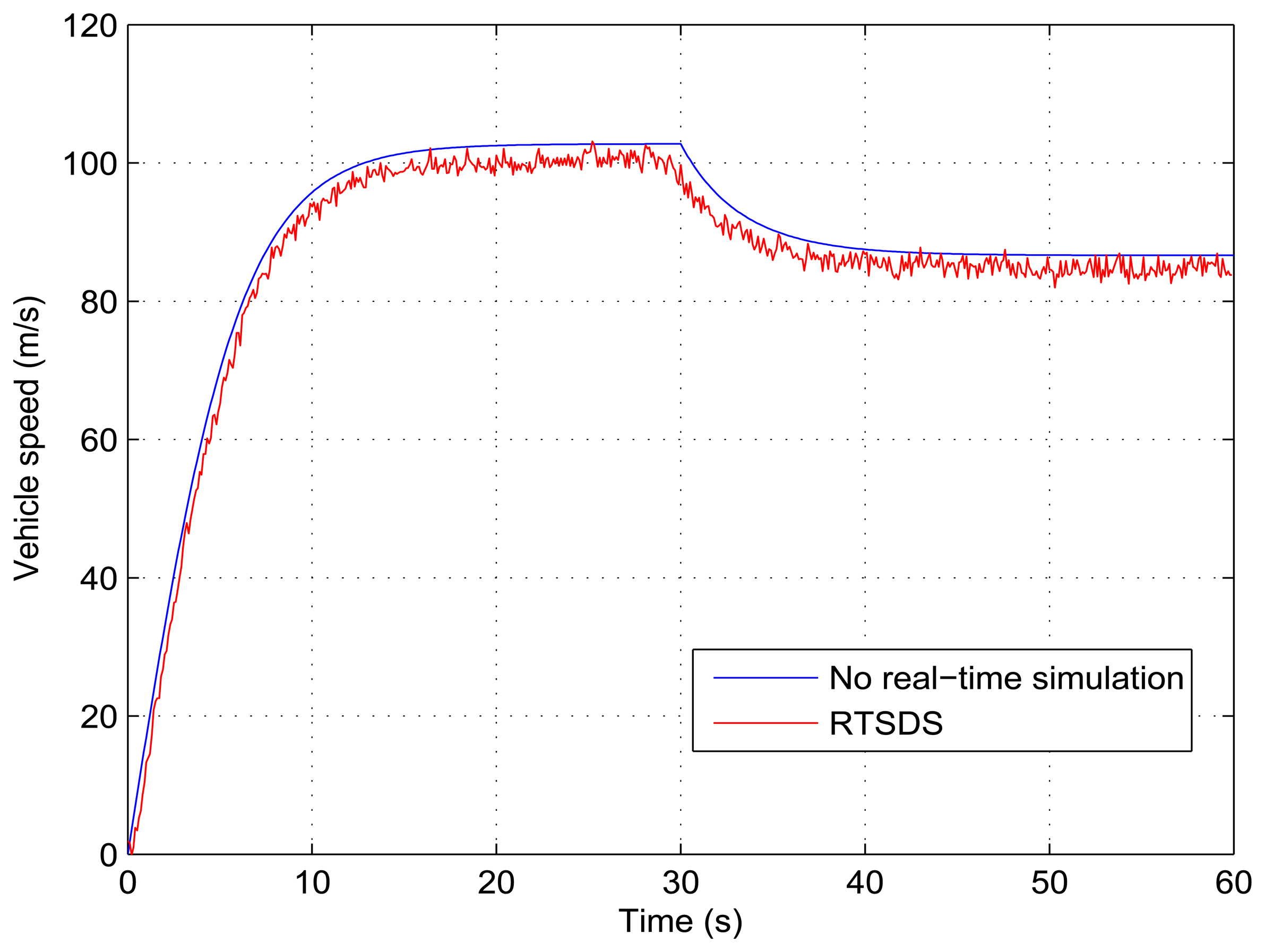

5.2. Results of Dynamic System 2: Longitudinal Vehicle

In all of the experiments with Dynamic System 2, the maximum torque was held constant at ; the acceleration due to gravity was g = 9.8 m/s2; the maximum speed of the vehicle was xmax = 200 m/s; the mass of the vehicle was M = 450 Kg; the density of air was Cd = 1.18; the aerodynamic drag coefficient was Cd = 0.51; the frontal area of the vehicle was Afr = 2.4 m2; the radius of the wheel was r = 0.26 m; the maximum inclination angle was θmax = 60 degrees ; and the rolling coefficients were C0 = 0.015 and C1 = 0.

The tr was in the region of tr ≈ 100 s. Based on the value of tr and the values presented above (summarized in Table 1), use of Equation (2) gives an estimated value of ts of 100 ms, while the calculated value of ta was 212 ms, taking into account the restriction presented in Equation (1).

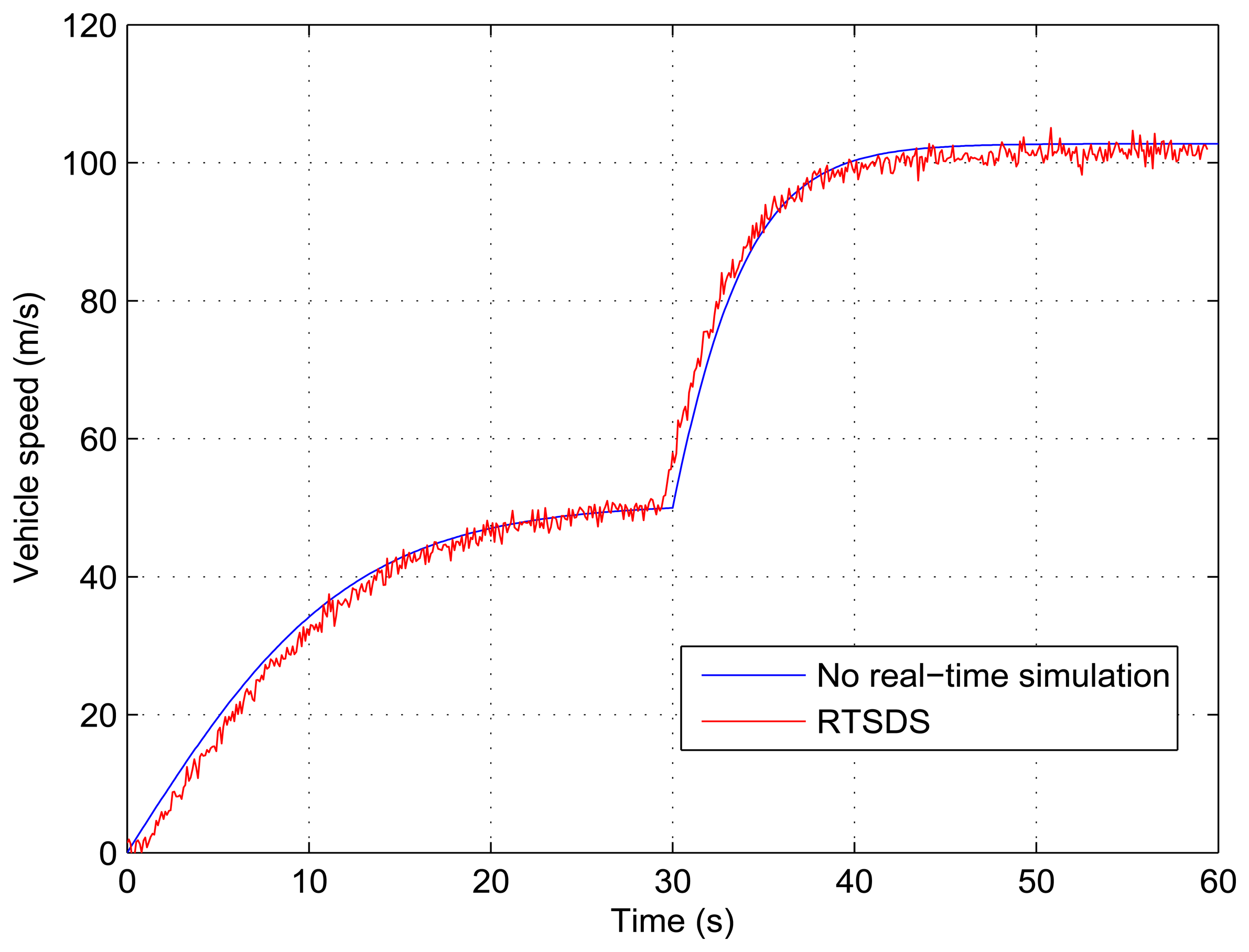

Figures 21 and 22 show the results obtained for the RTSDS platform used to execute the prototype described above, together with the non-real-time results obtained using MATLAB/Simulink. Figure 21 presents the results for a programmed sequence of perturbations, with DAM-1 being programmed to begin with τm(t) = 500 Nm (Ve(t) = 0.25) and, then, after 2000 Nm (Ve(t) = 1) with θ(t) = 0 degree (Vo(t) = 0). Figure 22 presents the results for a programmed sequence of perturbations, with DAM-2 being programmed to begin with θ(t) = 0 degree (Vo(t) = 0) and, then, after 30 degree (Vo(t) = 0.5) with τm(t) = 2000 Nm (Ve(t) = 1). In all cases with Dynamic System 2 (Longitudinal Vehicle), it can be seen that the RTSDS platform provided satisfactory results, with errors that were very small in relation to the reference method.

Figure 23 presents the results obtained for an embedded PID controller [27] in an ATmega 2560 microcontroller (utilizing the Arduino Mega 2560 kit) external to the RTSDS platform. The system was controlled to begin with a reference value (set point) of 55 m/s and, then, after 100 m/s.

6. Conclusions

This work presents a proposal for an embedded solution for the real-time simulation of dynamic systems, called the RTSDS. This platform is composed of a central hardware module (the MCM) and a set of ancillary hardware modules (the DAMs and SGMs), so that the platform is modular and distributed. Experimental trials were performed using a prototype developed using an Intel DN2800MT Mini-ITX kit as the MCM, Arduino Mega 2560 kits as the DAMs and a PSOC CY8CKIT-001 kit as the SGM. The results obtained showed that the RTSDS platform provided good performance, with errors that were very small, compared to simulations that were not performed in real time. The RTSDS could be used to optimize and synchronize embedded control algorithms used in industry and also as a learning tool to support graduate and postgraduate teaching.

Author Contributions

All the authors have contributed in various degrees to ensure the quality of this work. Marcelo A. C. Fernandes conceived the idea and experiments; Isaac D. T. de Souza, Sérgio N. Silva and Rafael M. Teles designed and performed the experiments; Marcelo A. C. Fernandes, Isaac D. T. de Souza, Sérgio N. Silva and Rafael M. Teles analyzed the data; Marcelo A. C. Fernandes wrote the paper.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Dixit, V.; Patil, M.; Chandorkar, M. Real time simulation of power electronic systems on multi-core processors. Proceedings of the International Conference on Power Electronics and Drive Systems, 2009 (PEDS 2009), 2–5 November 2009; Taipei, Taiwan; pp. 1524–1529.

- Boukerche, A.; Lu, K. A novel approach to real-time RTI based distributed simulation system. Proceedings of the 38th Annual Simulation Symposium, San Diego, CA, USA, 4–6 April 2005; pp. 267–274.

- You, T.; Zhu, Y.A.; Zhang, D.P. Applied Research of Delaminated Real-Time Network Framework Based on RTX in Simulation. Proceedings of the Second International Conference on Information and Computing Science, 2009 (ICIC ′09), Manchester, UK, 21–22 May 2009; Volume 1, pp. 389–392.

- Vityaz, O.; Zimmermann, G. Real-time simulation using graceful degradation of accuracy. Energy Build. 2005, 37, 795–806. [Google Scholar]

- Anagnostopoulos, D. A methodological approach for model validation in faster than real-time simulation. Simul. Model. Pract. Theory 2002, 10, 121–139. [Google Scholar]

- Champagne, R.; Dessaint, L.A.; Fortin-Blanchette, H. Real-time simulation of electric drives. Math. Comput. Simul. 2003, 63, 173–181. [Google Scholar]

- Ćosić, K.; Kopriva, I.; Šikić, T. A methodology for digital real time simulation of dynamic systems using modern DSPs. Simul. Pract. Theory 1997, 5, 137–151. [Google Scholar]

- Matar, M.; Iravani, R. FPGA implementation of the power electronic converter model for real-time simulation of electromagnetic transients. IEEE Trans. Power Deliv. 2010, 25, 852–860. [Google Scholar]

- Monga, M.; Karkee, M.; Tondehal, L.K.; Steward, B.; Kelkar, A.; Zambreno, J. Real-Time simulation of dynamic vehicle models using a high-performance reconfigurable platform. Proceedings of the 2012 International Conference on Computational Science (ICCS), Omaha, NE, USA, 4–6 June 2012.

- Menghal, P.M.; Laxmi, A. Real time simulation: A novel approach in engineering education. Proceedings of the 2011 3rd International Conference on Electronics Computer Technology (ICECT), Kanyakumari, India, 8–10 April 2011; Volume 1, pp. 215–219.

- Dufour, C.; Andrade, C.; Bélanger, J. Real-Time simulation technologies in education: A link to modern engineering methods and practices. Proceedings of the 2010 11th International Conference on Engineering and Technology Education (INTERTECH), Baía, Brazil, 7–10 March 2010; pp. 1–5.

- Bélanger, J.; Venne, P.; Paquin, J.N. The What, Where and Why of Real-Time Simulation; Planet-RT; Opal-RT Technologies Inc.: Montreal, QC, Canada, 2010. [Google Scholar]

- Venugopal, R.; Wang, W.; Belanger, J. Advances in real-time simulation for power distribution systems. Proceedings of the 2011 International Conference on Energy, Automation, and Signal (ICEAS), Bhubaneswar, India, 28–30 December 2011; pp. 1–6.

- Fathy, H.K.; Filipi, Z.S.; Hagena, J.; Stein, J.L. Review of hardware-in-the-loop simulation and its prospects in the automotive area. Proc. SPIE 2006, 6228, 62280E:1–62280E:20. [Google Scholar]

- Kim, W.; Lee, B.; Kim, K.; Yang, T.; Kim, S. A real-time HWIL simulation control system architecture for implementing evaluation environment of complex embedded systems. Proceedings of the 2011 13th International Conference on Advanced Communication Technology (ICACT), Phoenix Park, Korea, 13–16 February 2011; pp. 254–259.

- Li, H.; Steurer, M.; Shi, K.L.; Woodruff, S.; Zhang, D. Development of a unified design, test, and research platform for wind energy systems based on hardware-in-the-loop real-time simulation. IEEE Trans. Ind. Electron. 2006, 53, 1144–1151. [Google Scholar]

- Paquin, J.N.; Li, W.; Belanger, J.; Schoen, L.; Peres, I.; Olariu, C.; Kohmann, H. A modern and open real-time digital simulator of All-Electric Ships with a multi-platform co-simulation approach. Proceedings of the IEEE Electric Ship Technologies Symposium, 2009 (ESTS 2009), Baltimore, MD, USA,, 20–22 April 2009; pp. 28–35.

- HYPERSIM Power System Real-Time Digital Simulator, OPAL-RT. Available online: http://www.opal-rt.com (accessed on 13 October 2014).

- Paré, D.; Turmel, G.; Soumagne, J.C.; Do, V.Q.; Casoria, S.; Bissonnette, M.; Marcoux, B.; McNabb, D. Validation Tests of the Hypersim Digital Real Time Simulator with a Large AC-DC Network. Available online: http://ipstconf.org/papers/Proc_IPST2003/03IPST13-05.pdf (accessed on 14 October 2014).

- dSPACE Systems, dSPACE. Available online: http://www.dspace.com/en/inc/home.cfm (accessed on 13 October 2014).

- Arduino-ArduinoMega2560. Available online: http://arduino.cc/en/Main/ArduinoBoardMega2560 (accessed on 13 October 2014).

- Atmle-AVR-ATmega 328p. Available online: http://www.atmel.com/devices/ATMEGA328P.aspx (accessed on 13 October 2014).

- Arduino-Arduino Uno. Available online: http://arduino.cc/en/Main/ArduinoBoardUno (accessed on 13 October 2014).

- Cypress-PSoC 3: CY8C38 Family Data Sheet. Available online: http://www.cypress.com/?rID=35178 (accessed on 13 October 2014).

- Cypress-CY8CKIT-001 PSoC Development Kit. Available online: http://www.cypress.com/?rID=37464 (accessed on 13 October 2014).

- Popovici, K.; Mosterman, P. Real-Time Simulation Technologies: Principles, Methodologies, and Applications; Computational Analysis, Synthesis, and Design of Dynamic Systems; CRC Press: Boca Raton, FL, USA, 2012. [Google Scholar]

- Ogata, K. Modern Control Engineering, 4th ed.; Prentice Hall PTR: Upper Saddle River, NJ, USA, 2001. [Google Scholar]

- Trzynadlowski, A. Introduction to Modern Power Electronics; Wiley: Hoboken, NJ, USA, 2010. [Google Scholar]

- Garrett, P. High Performance Instrumentation and Automation; Taylor & Francis: London, UK, 2010. [Google Scholar]

- RTSDS Site, RTSDS. Available online: http://www.dca.ufrn.br/∼mfernandes/RTSDS/index.html (accessed on 13 October 2014).

- Intel-Intel Desktop Board DN2800MT. Available online: http://www.intel.com/content/www/us/en/motherboards/desktop-motherboards/desktop-board-dn2800mt.html (accessed on 13 October 2014).

- Butcher, J. Numerical Methods for Ordinary Differential Equations; Wiley: Hoboken, NJ, USA, 2008. [Google Scholar]

- Griffiths, D.; Higham, D. Numerical Methods for Ordinary Differential Equations: Initial Value Problems; Springer Undergraduate Mathematics Series; Springer: Berlin, Germany, 2010. [Google Scholar]

- Ben-Ari, M. Principles of Concurrent and Distributed Programming; Addison-Wesley: Upper Saddle River, NJ, USA, 2006. [Google Scholar]

- Ubuntu 13.10. Available online: http://www.ubuntu.com (accessed on13 October 2014).

- Atmel-AVR-ATmega 2560. Available online: http://www.atmel.com/devices/atmega2560.aspx (accessed on 13 October 2014).

- Pacejka, H.B. Tire and Vehicle Dynamics; Society of Automotive Engineers and Butterworth-Heinemann: Oxford, UK, 2002. [Google Scholar]

- Matlab/Simulink. Available online: http://www.mathworks.com (accessed on 13 October 2014).

- Quanser-Coupled Water Tanks. Available online: http://www.quanser.com/Products/coupled_tanks (accessed on 13 October 2014).

- Trovao, J.; Pereirinha, P.; Jorge, H. Simulation model and road tests comparative results of a small urban electric vehicle. Proceedings of the 35th Annual Conference of IEEE Industrial Electronics, 2009 (IECON ′09), Porto, Portugal, 3–5 November 2009; pp. 836–841.

- Elbakush, E.; Sharaf, A.; Altas, I. An efficient tri-loop controller for photovoltaic powered four-wheel electric vehicle. Proceedings of the 4th International Conference on Innovations in Information Technology, 2007 (IIT ′07), Dubai, UAE, 18–20 November 2007; pp. 421–425.

| Times | DAM-1 | DAM-2 | SGM-1 | MCM | Selected |

|---|---|---|---|---|---|

| tDAM | 110 ms | 20 ms | - | - | 110 ms |

| t1 | 0.83 ms | 0.83 ms | - | - | 0.83 ms |

| tSGM | - | - | 1 ms | - | 1 ms |

| t2 | - | - | 8 μs | - | 8 μs |

| - | - | - | 200 μs | 200 μs |

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

De Souza, I.D.T.; Silva, S.N.; Teles, R.M.; Fernandes, M.A.C. Platform for Real-Time Simulation of Dynamic Systems and Hardware-in-the-Loop for Control Algorithms. Sensors 2014, 14, 19176-19199. https://doi.org/10.3390/s141019176

De Souza IDT, Silva SN, Teles RM, Fernandes MAC. Platform for Real-Time Simulation of Dynamic Systems and Hardware-in-the-Loop for Control Algorithms. Sensors. 2014; 14(10):19176-19199. https://doi.org/10.3390/s141019176

Chicago/Turabian StyleDe Souza, Isaac D. T., Sergio N. Silva, Rafael M. Teles, and Marcelo A. C. Fernandes. 2014. "Platform for Real-Time Simulation of Dynamic Systems and Hardware-in-the-Loop for Control Algorithms" Sensors 14, no. 10: 19176-19199. https://doi.org/10.3390/s141019176