Carbon Nanotube Integration with a CMOS Process

Abstract

:1. Introduction

2. Experimental Section

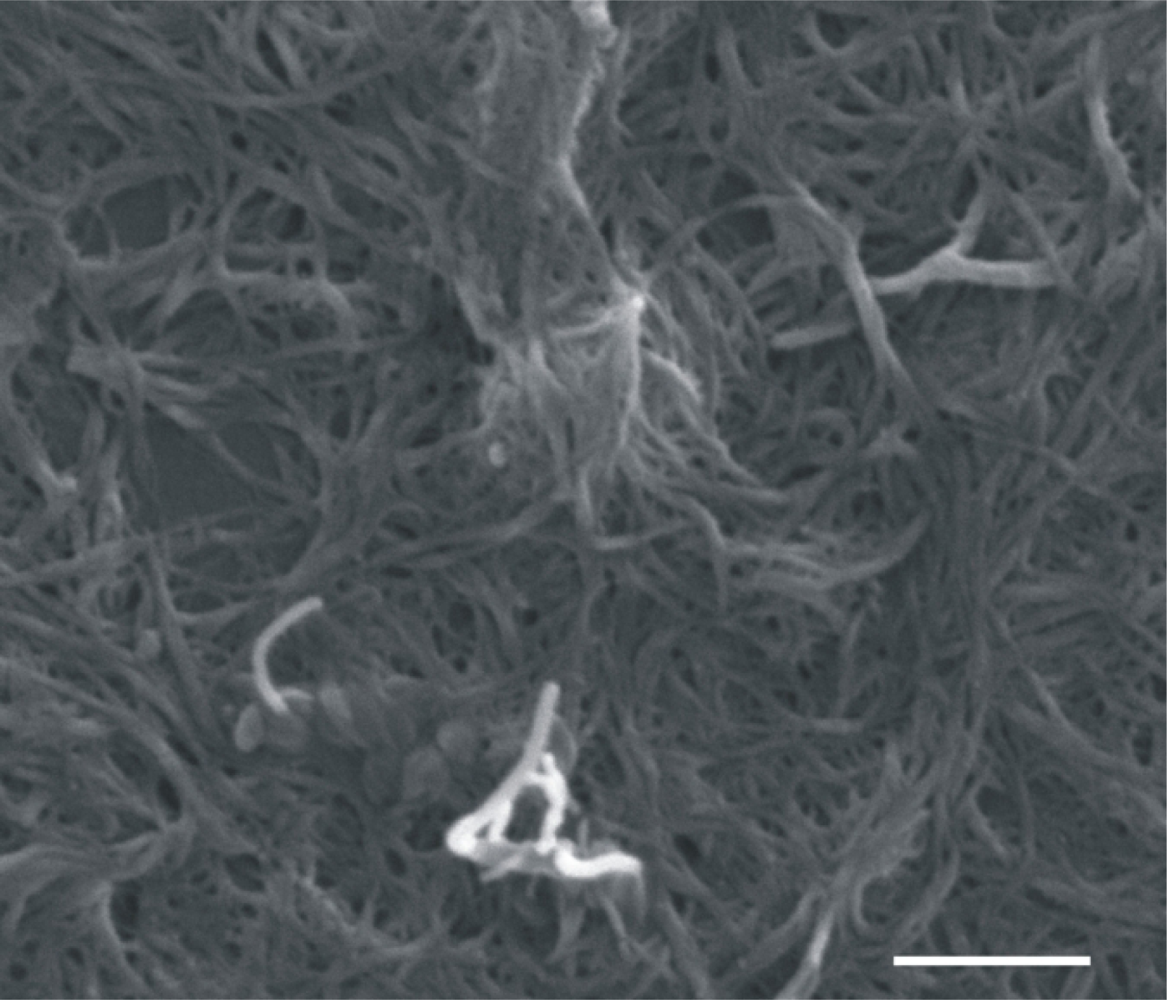

2.1. Carbon Nanotubes

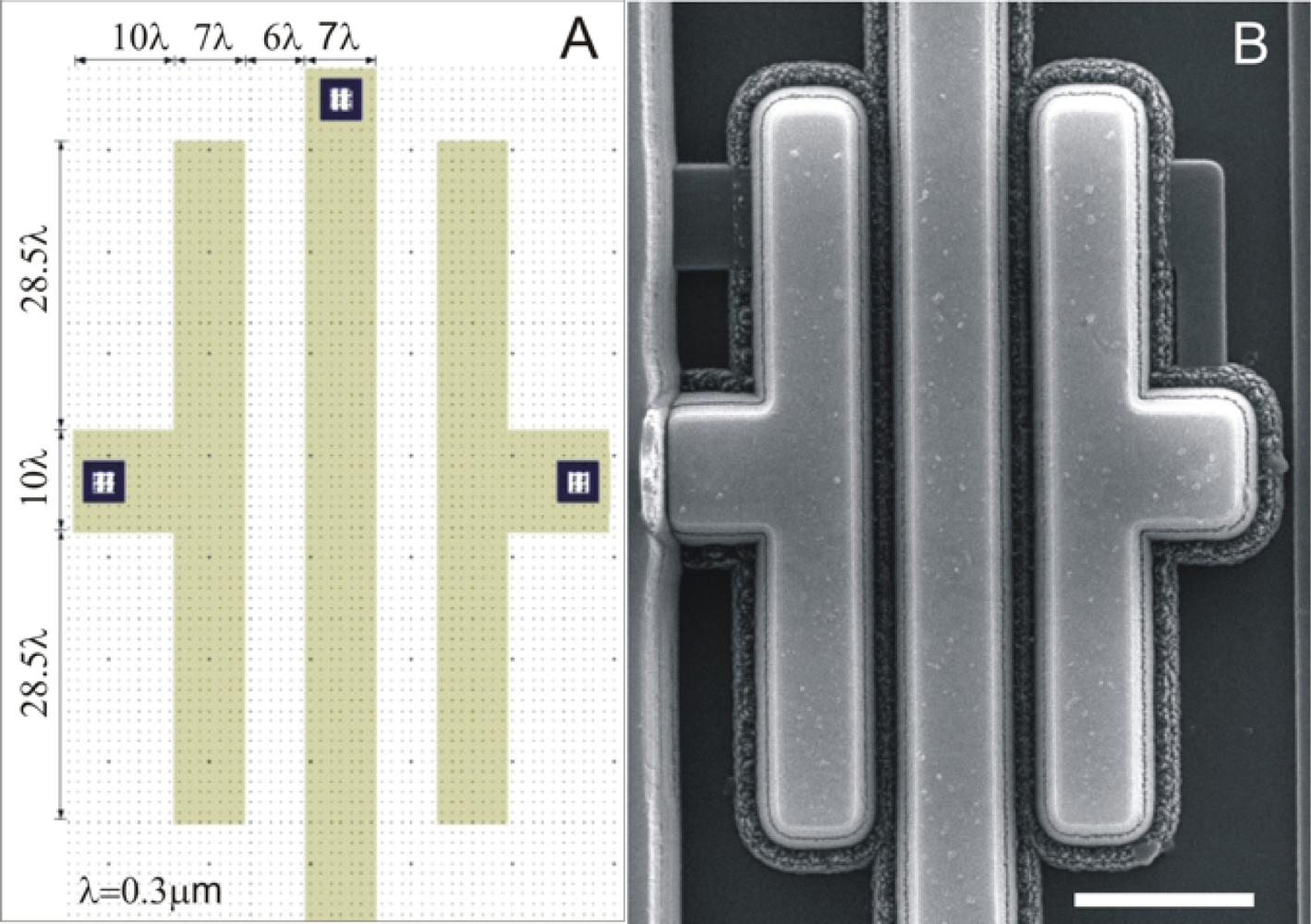

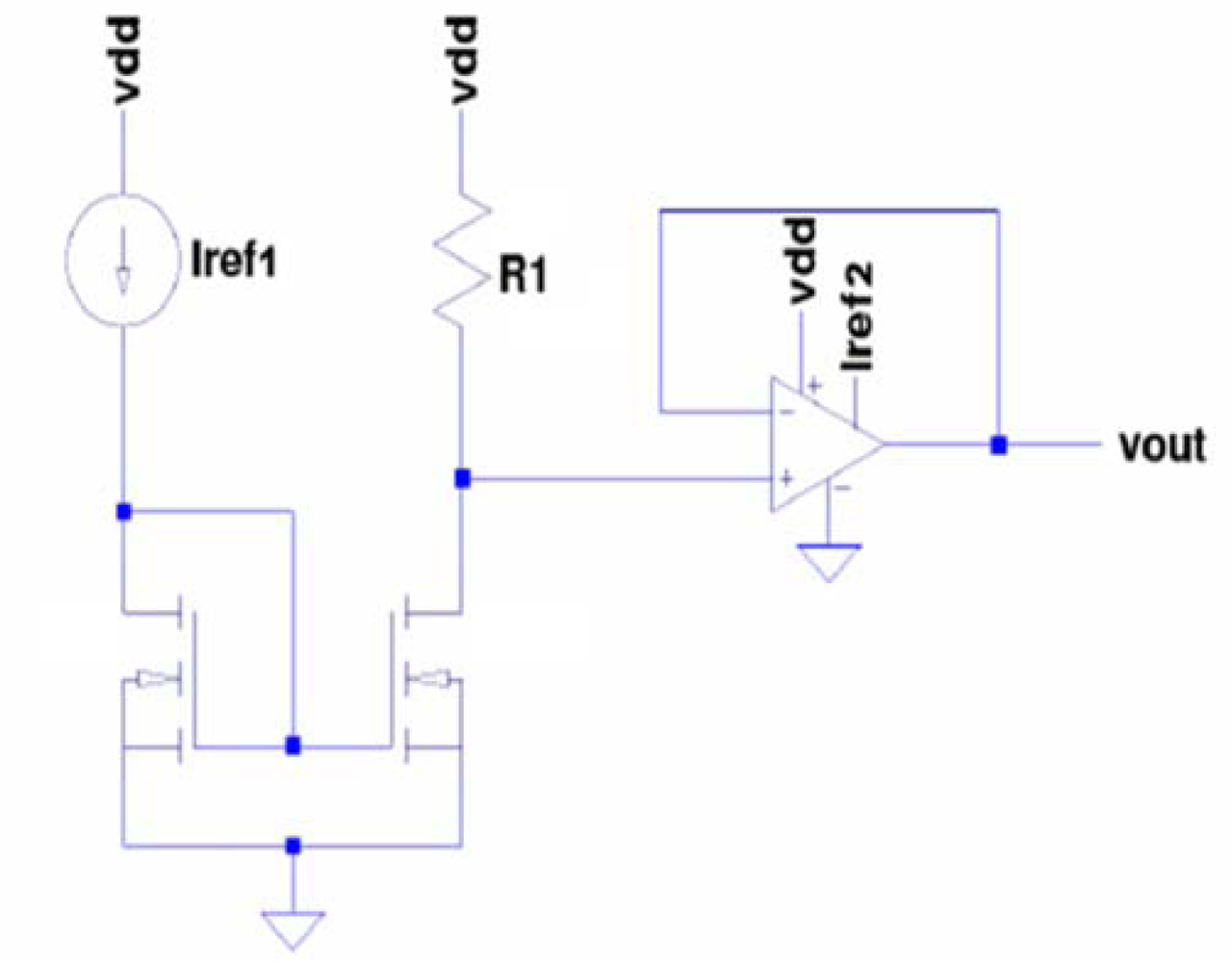

2.2. Chip Sensor

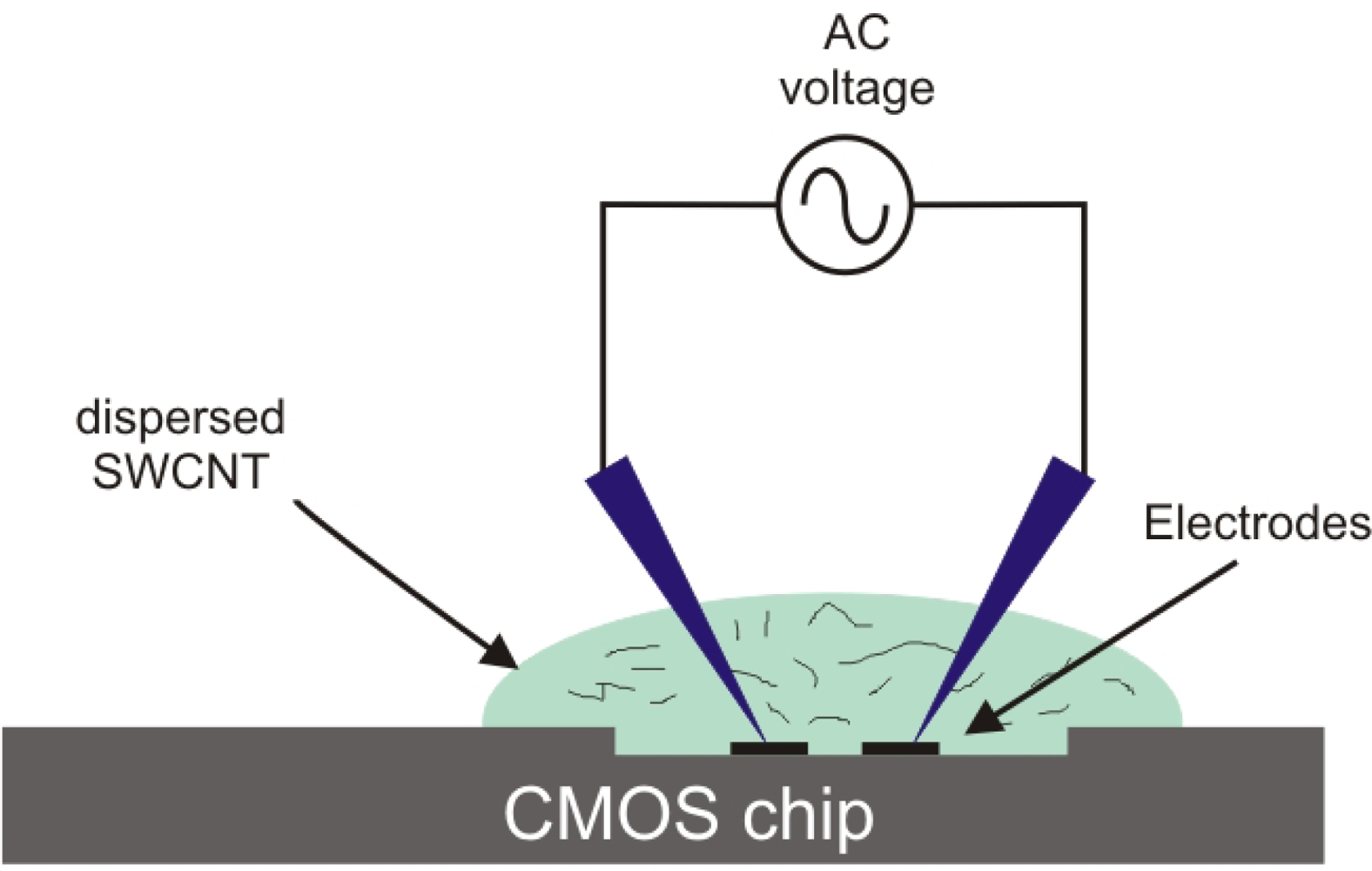

2.3. Carbon Nanotube Deposition

2.4. Humidity Control and Electrical Measurements

3. Results and Discussion

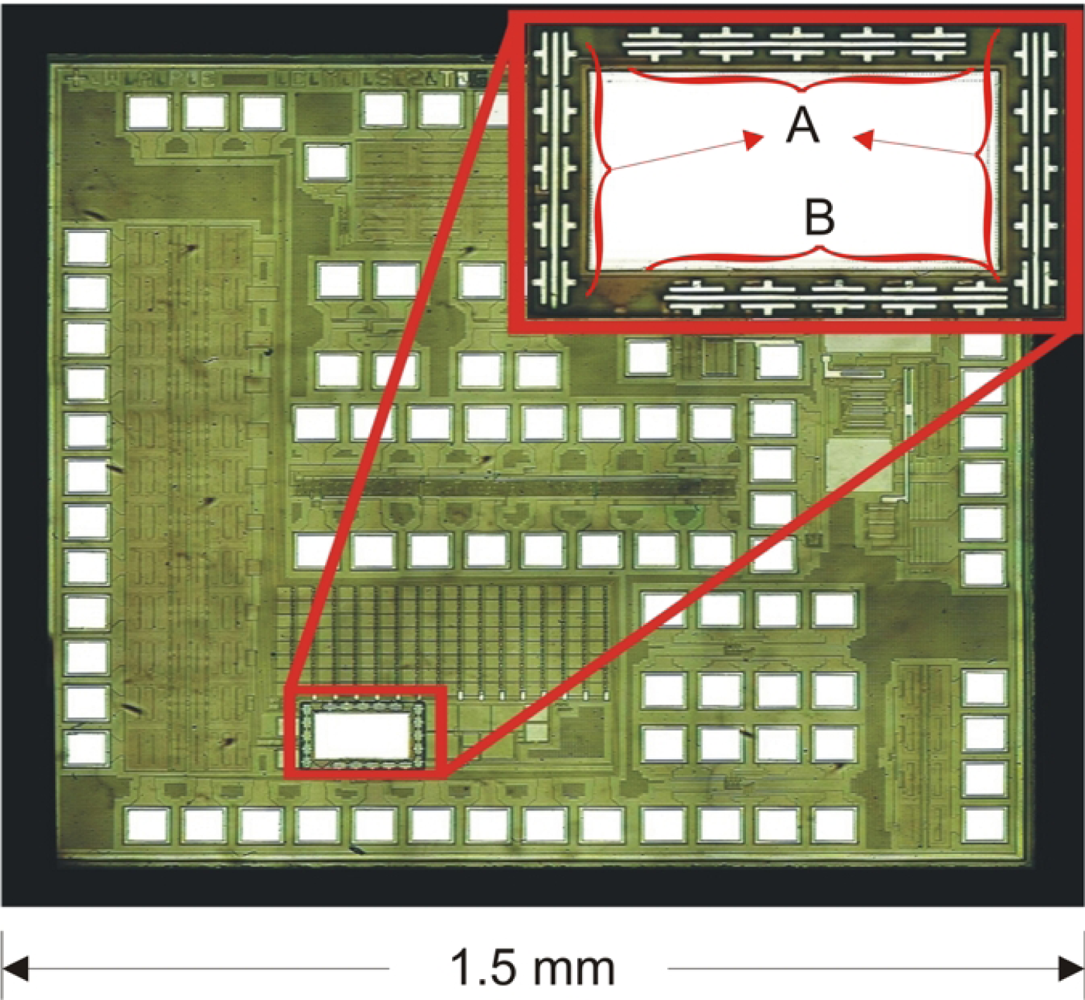

3.1. Chip Sensor Layout

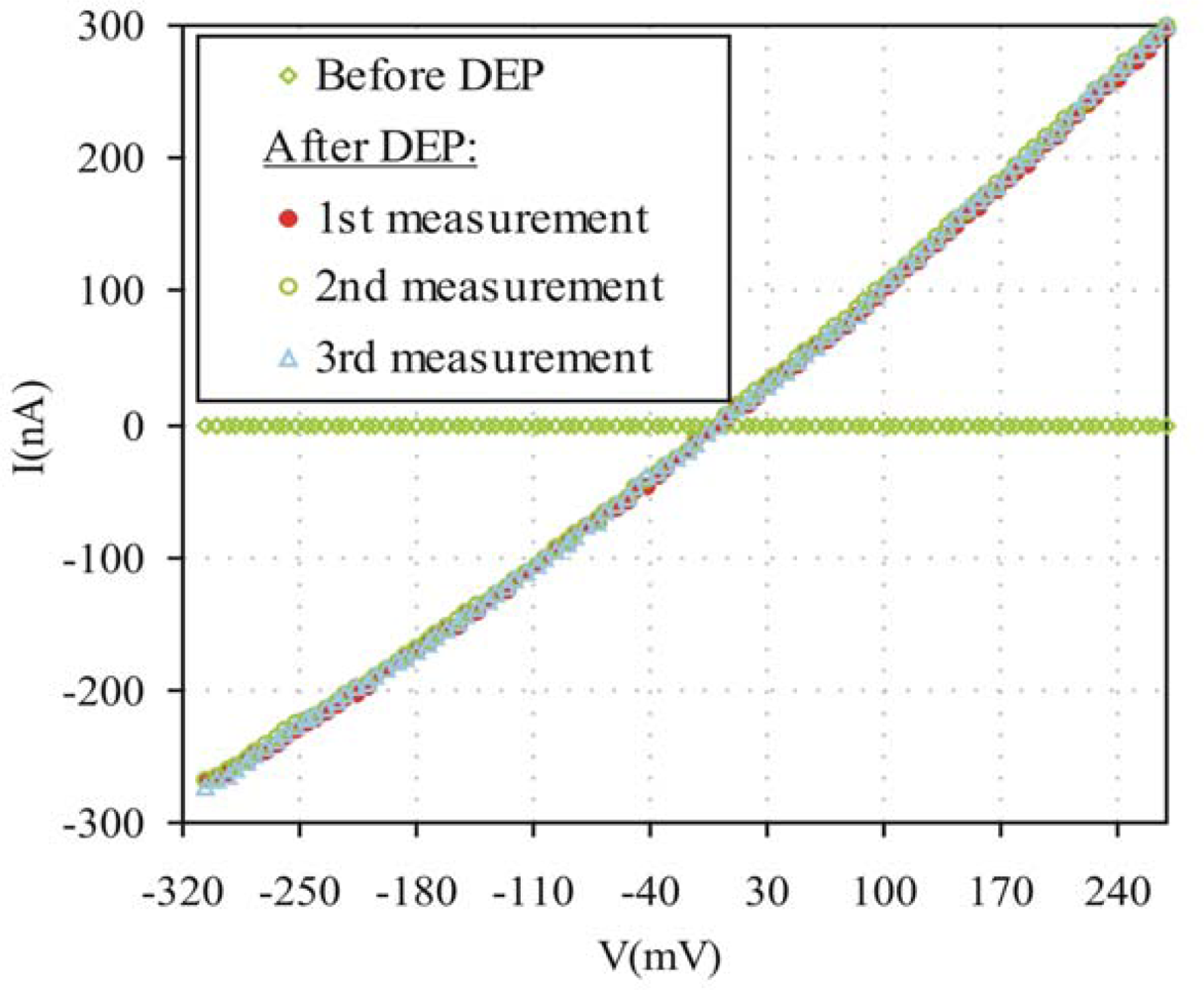

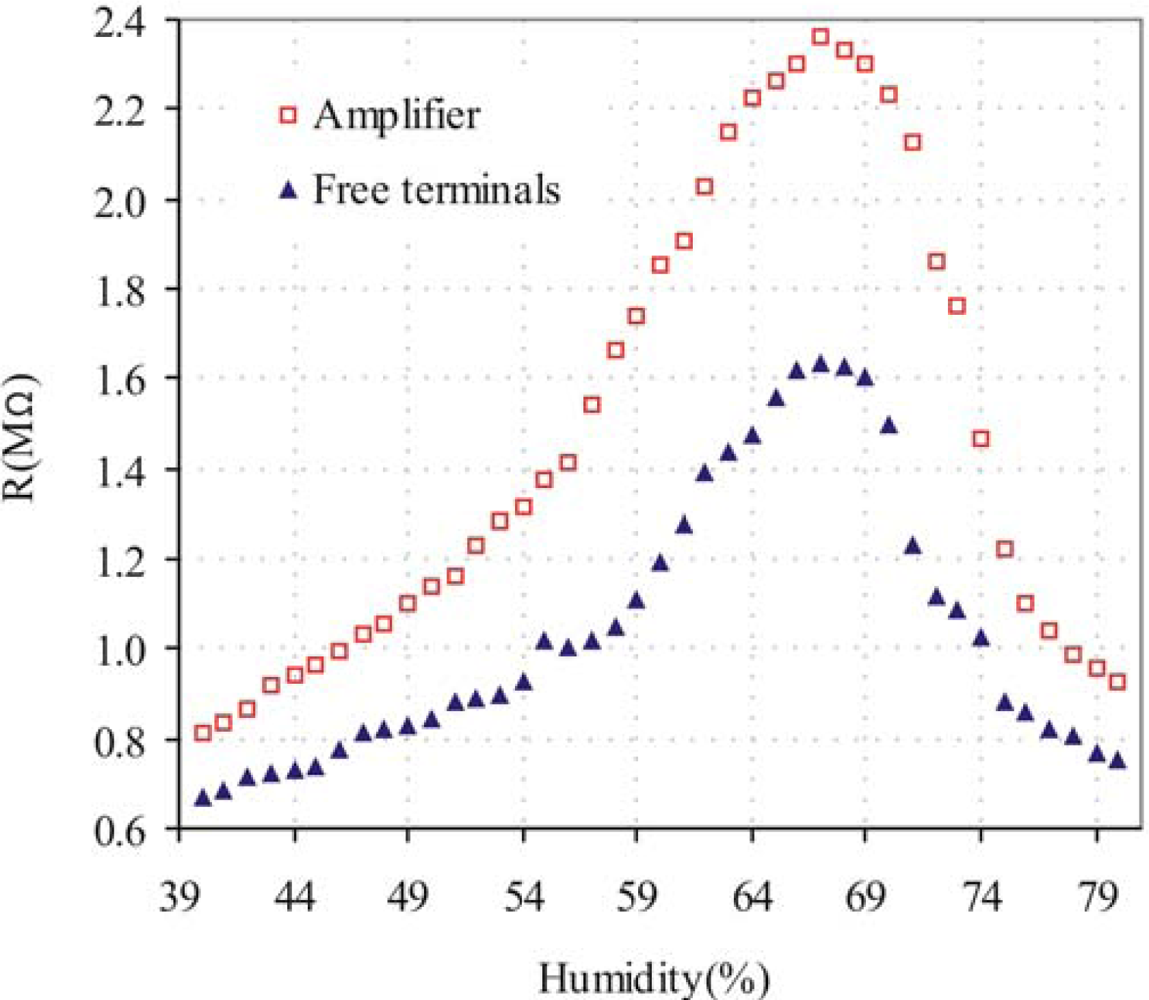

3.2. Effect of Humidity on the Electrical Transport Properties of SWCNTs

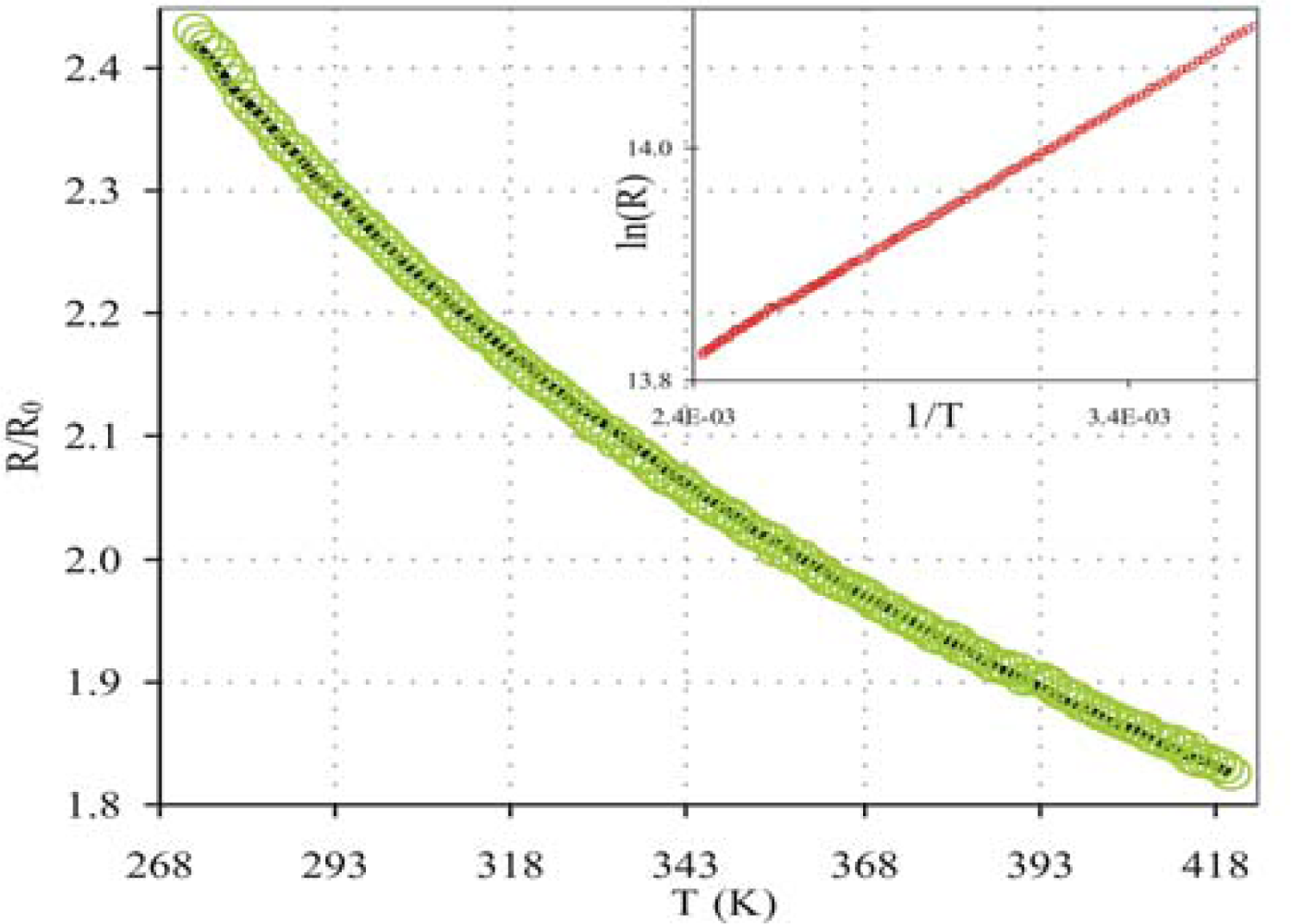

3.3. Effect of Temperature on the Electrical Transport Properties of SWCNTs

4. Conclusions

Acknowledgments

References and Notes

- Fung, C.; Zhang, M.; Dong, Z.; Li, W. Fabrication of CNT-based MEMS piezoresistive pressure sensors using DEP nanoassembly. Proceedings of IEEE NANO 2005, Nagoya, Japan, July 11–15, 2005; pp. 199–202.

- Sin, M.L.Y.; Chow, G.C.T.; Wong, G.M.K.; Li, W.J.; Leong, P.H.W.; Wong, K.W. Ultralow-power alcohol vapor sensors using chemically functionalized multiwalled carbon nanotubes. IEEE Trans. Nanotechnol 2007, 6, 571–577. [Google Scholar]

- Kauffman, D.; Star, A. Carbon nanotube gas and vapor sensors. Angew. Chem. Int. Ed 2008, 47, 6550–6571. [Google Scholar]

- Terranova, M.; Lucci, M.; Orlanducci, S.; Tamburri, E.; Sessa, V.; Reale, A.; Di Carlo, A. Carbon nanotubes for gas detection: materials preparation and device assembly. J. Phys-Condens. Mat 2007, 19, 225004. [Google Scholar]

- Maehashi, K.; Katsura, T.; Kerman, K.; Takamura, Y.; Matsumoto, K.; Tamiya, E. Label-free protein biosensor based on aptamer-modified carbon nanotube field-effect transistors. Anal. Chem 2007, 79, 782–787. [Google Scholar]

- Chen, R.; Choi, H.; Bangsaruntip, S.; Yenilmez, E.; Tang, X.; Wang, Q.; Chang, Y.; Dai, H. An investigation of the mechanisms of electronic sensing of protein adsorption on carbon nanotube devices. Nano Lett 2003, 3, 727. [Google Scholar]

- Rodríguez, D.; Lerner, B.; Perez, M.S.; Ibañez, F.; Leyva, A.; Bonaparte, J.; Rinaldi, C.; Boselli, A.; Lamagna, A. In comparison of the gas sensing properties of thin film sno produced by rgto and pore wetting technique. Proceedings of the 13th International Symposium on Olfaction and Electronic Nose, Brescia, Italy, April 2009; pp. 377–380.

- Star, A.; Tu, E.; Niemann, J.; Gabriel, J.; Joiner, C.; Valcke, C. Label-free detection of DNA hybridization using carbon nanotube network field-effect transistors. Proc. Natl. Acad. Sci. USA 2006, 103, 921. [Google Scholar]

- Pohl, H. Dielectrophoresis: The Behavior of Neutral Matter in Nonuniform Electric Fields; Cambridge University Press: Cambridge, UK, 1978. [Google Scholar]

- Li, J.; Zhang, Q.; Yang, D.; Tian, J. Fabrication of carbon nanotube field effect transistors by AC dielectrophoresis method. Carbon 2004, 42, 2263–2267. [Google Scholar]

- Chen, C.; Agarwal, V.; Sonkusale, S.; Dokmeci, M. The heterogeneous integration of single-walled carbon nanotubes onto complementary metal oxide semiconductor circuitry for sensing applications. Nanotechnology 2009, 20, 225302. [Google Scholar]

- Kim, G.; Jhang, S.; Park, J.; Park, Y.; Roth, S. Non-ohmic current-voltage characteristics in single-wall carbon nanotube network. Synth. Met 2001, 117, 123–126. [Google Scholar]

- Resasco, D.; Alvarez, W.; Pompeo, F.; Balzano, L.; Herrera, J.; Kitiyanan, B.; Borgna, A. A scalable process for production of single-walled carbon nanotubes (SWNTs) by catalytic disproportionation of CO on a solid catalyst. J. Nanopart. Res 2002, 4, 131–136. [Google Scholar]

- Bachilo, S.; Balzano, L.; Herrera, J.; Pompeo, F.; Resasco, D.; Weisman, R. Narrow (n, m)-distribution of single-walled carbon nanotubes grown using a solid supported catalyst. J. Am. Chem. Soc 2003, 125, 11186–11187. [Google Scholar]

- Herrera, J.; Balzano, L.; Pompeo, F.; Resasco, D. Raman Characterization of single-walled nanotubes of various diameters obtained by catalytic disproportionation of CO. J. Nanosci. Nanotechnol 2003, 3, 133–138. [Google Scholar]

- Alvarez, W.; Pompeo, F.; Herrera, J.; Balzano, L.; Resasco, D. Characterization of single-walled carbon nanotubes (swnts) produced by co disproportionation on co- mo catalysts. Chem. Mater 2002, 14, 1853–1858. [Google Scholar]

- Pop, E.; Mann, D.; Cao, J.; Wang, Q.; Goodson, K.; Dai, H. Negative differential conductance and hot phonons in suspended nanotube molecular wires. Phys. Rev. Lett 2005, 95, 155505. [Google Scholar]

- Pop, E.; Mann, D.; Wang, Q.; Goodson, K.; Dai, H. Thermal conductance of an individual single-wall carbon nanotube above room temperature. Nano Lett 2006, 6, 96–100. [Google Scholar]

- Salvato, M.; Cirillo, M.; Lucci, M.; Orlanducci, S.; Ottaviani, I.; Terranova, M.; Toschi, F. Charge transport and tunneling in single-walled carbon nanotube bundles. Phys. Rev. Lett 2008, 101, 246804. [Google Scholar]

- Na, P.; Kim, H.; So, H.; Kong, K.; Chang, H.; Ryu, B.; Choi, Y.; Lee, J.; Kim, B.; Kim, J. Investigation of the humidity effect on the electrical properties of single-walled carbon nanotube transistors. Appl. Phys. Lett 2005, 87, 093101. [Google Scholar]

- Zahab, A.; Spina, L.; Poncharal, P.; Marliere, C. Water-vapor effect on the electrical conductivity of a single-walled carbon nanotube mat. Phys. Rev. B 2000, 62, 10000–10003. [Google Scholar]

- Kaiser, A.; Düsberg, G.; Roth, S. Heterogeneous model for conduction in carbon nanotubes. Phys. Rev. B 1998, 57, 1418–1421. [Google Scholar]

- Zhang, R.; Baxendale, M.; Peijs, T. Universal resistivity-strain dependence of carbon nanotube/polymer composites. Phys. Rev. B 2007, 76, 195433. [Google Scholar]

- Sheng, P.; Sichel, E.; Gittleman, J. Fluctuation-induced tunneling conduction in carbon-polyvinylchloride composites. Phys. Rev. Lett 1978, 40, 1197–1200. [Google Scholar]

- Kaiser, A. Electronic transport properties of conducting polymers and carbon nanotubes. Rep. Progr. Phys 2001, 64, 1–49. [Google Scholar]

- Ksenevich, V.; Seliuta, D.; Martunas, Z.; Kasalynas, I.; Valusis, G.; Galibert, J.; Kozlov, M.; Samuilov, V. Charge carrier transport properties in single-walled carbon nanotube fibers. Acta Phys. Pol. A Gen. Phys 2008, 113, 1039–1042. [Google Scholar]

© 2010 by the authors; licensee Molecular Diversity Preservation International, Basel, Switzerland. This article is an open-access article distributed under the terms and conditions of the Creative Commons Attribution license ( http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Perez, M.S.; Lerner, B.; Resasco, D.E.; Obregon, P.D.P.; Julian, P.M.; Mandolesi, P.S.; Buffa, F.A.; Boselli, A.; Lamagna, A. Carbon Nanotube Integration with a CMOS Process. Sensors 2010, 10, 3857-3867. https://doi.org/10.3390/s100403857

Perez MS, Lerner B, Resasco DE, Obregon PDP, Julian PM, Mandolesi PS, Buffa FA, Boselli A, Lamagna A. Carbon Nanotube Integration with a CMOS Process. Sensors. 2010; 10(4):3857-3867. https://doi.org/10.3390/s100403857

Chicago/Turabian StylePerez, Maximiliano S., Betiana Lerner, Daniel E. Resasco, Pablo D. Pareja Obregon, Pedro M. Julian, Pablo S. Mandolesi, Fabian A. Buffa, Alfredo Boselli, and Alberto Lamagna. 2010. "Carbon Nanotube Integration with a CMOS Process" Sensors 10, no. 4: 3857-3867. https://doi.org/10.3390/s100403857