Supramolecular Layer-by-Layer Assembly of 3D Multicomponent Nanostructures via Multivalent Molecular Recognition

Abstract

:1. Introduction

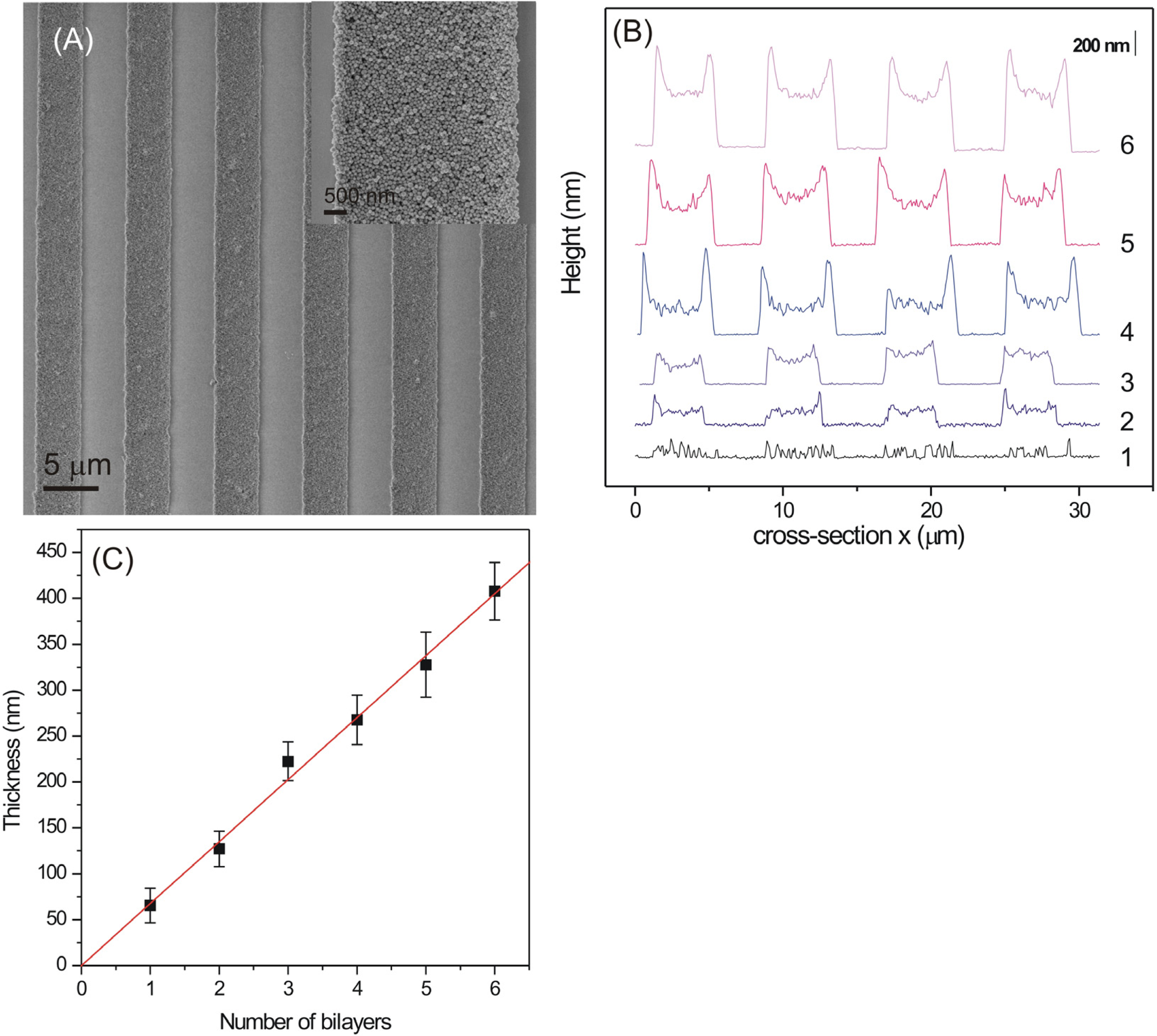

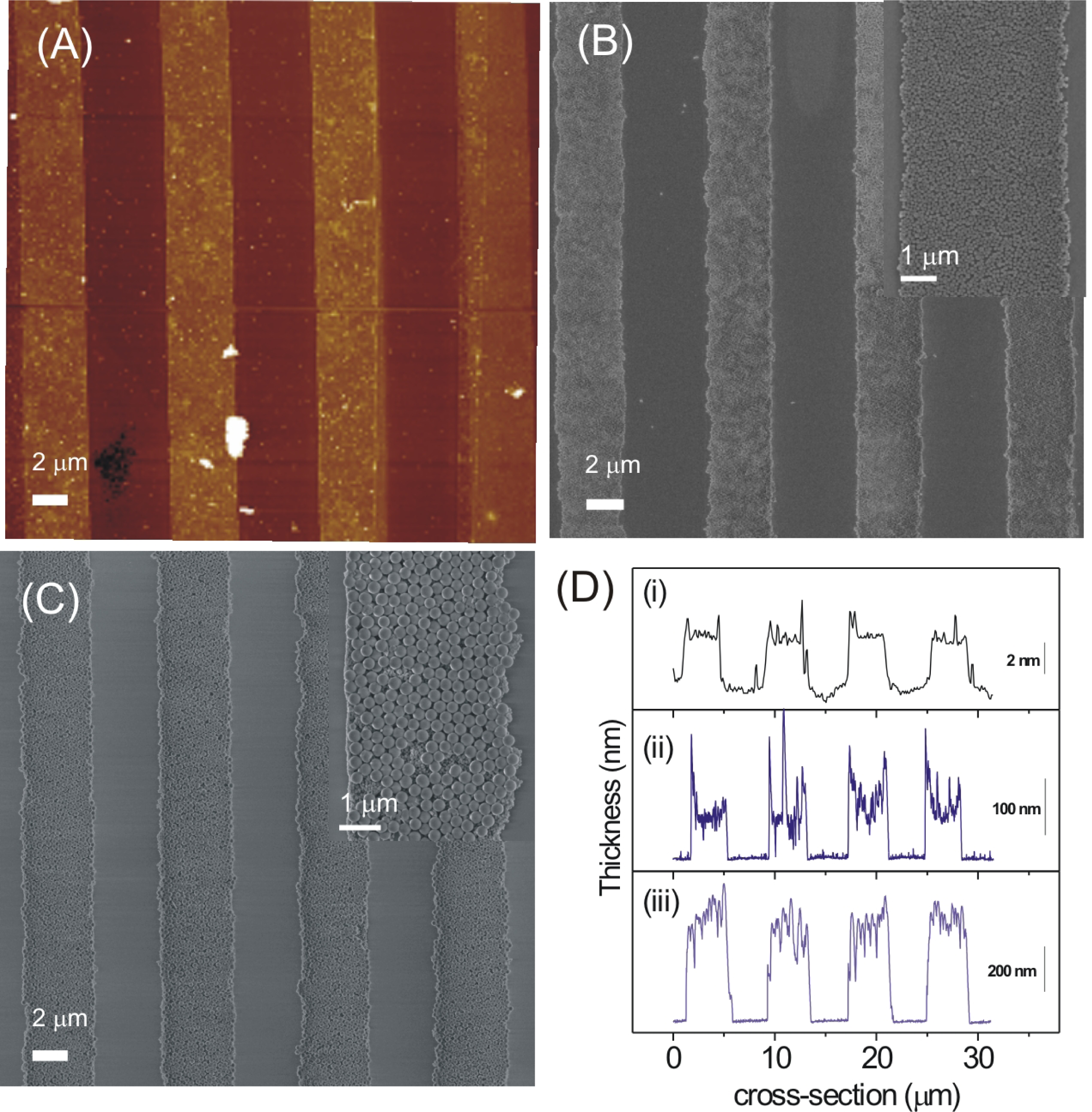

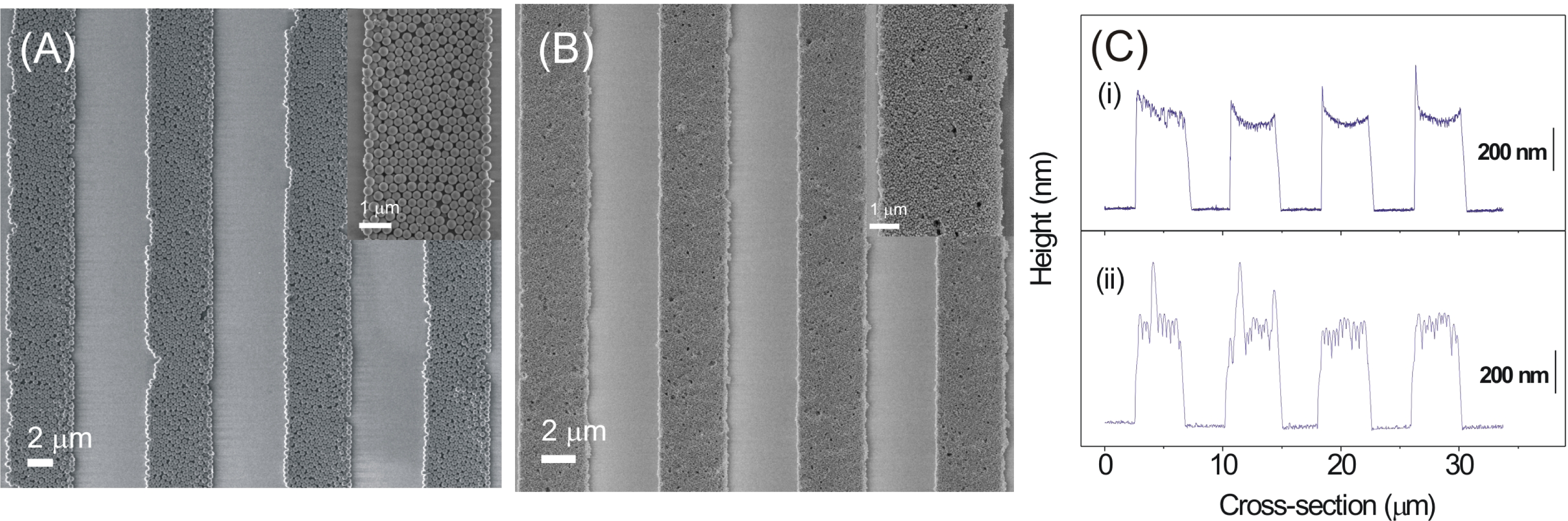

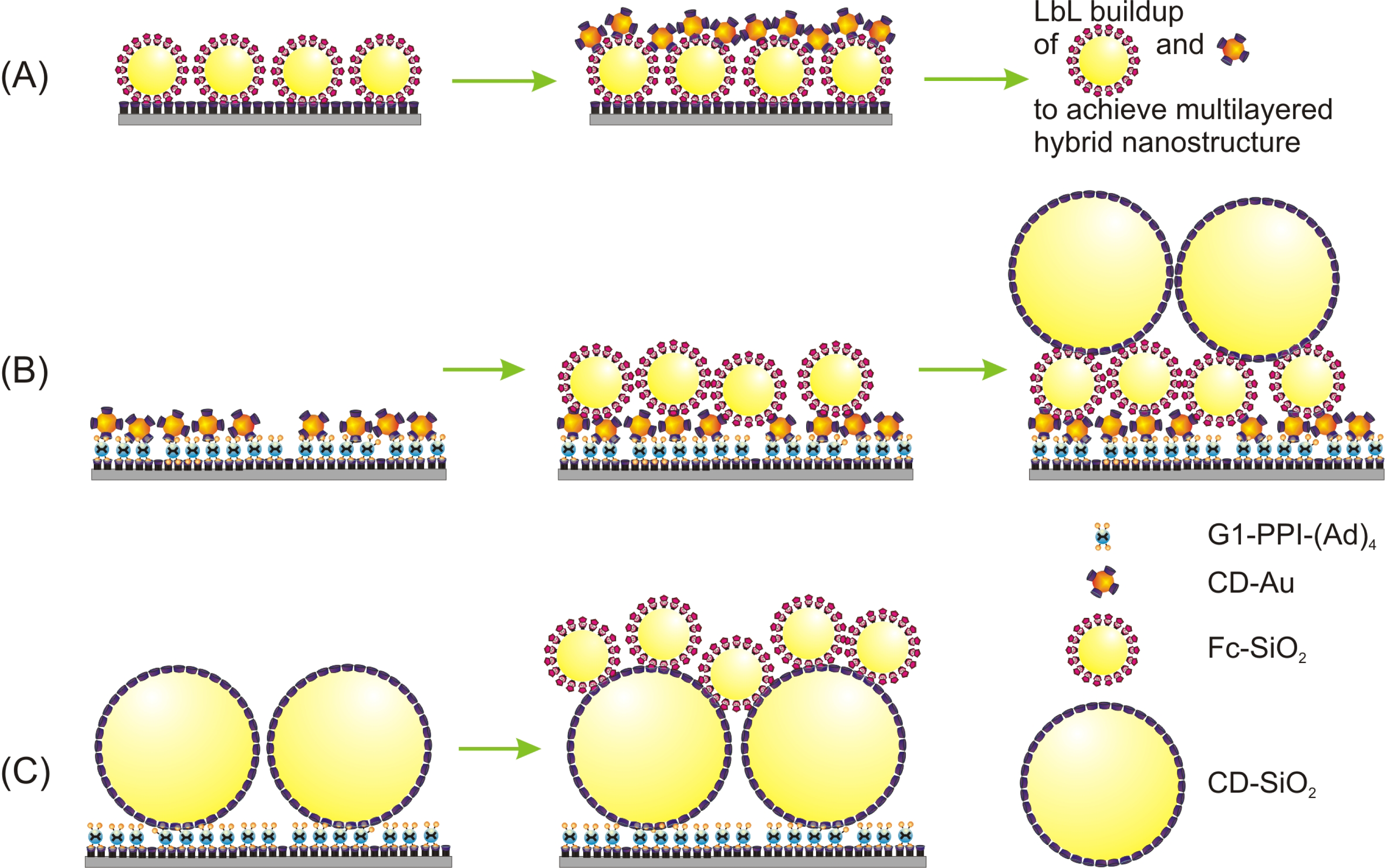

2. Results and Discussion

3. Conclusions

4. Experimental Section

Materials

Substrate and monolayer preparation

Nanoparticle Assembly

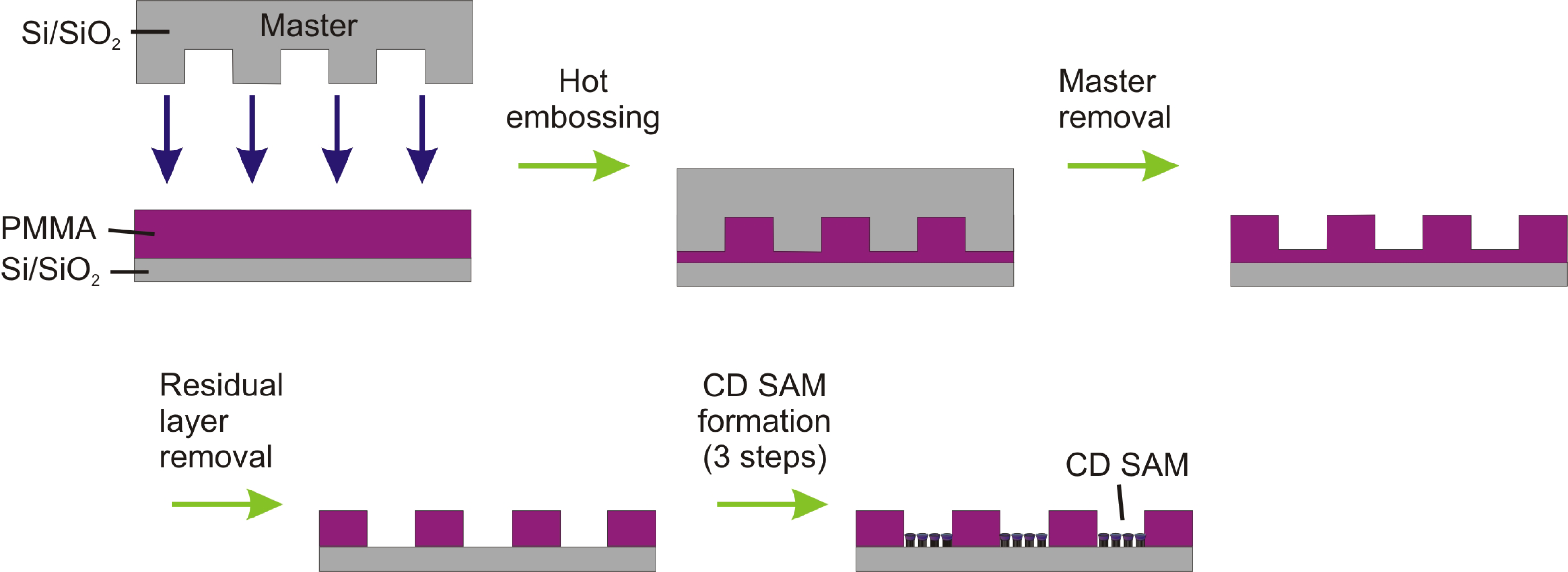

Nanoimprint Lithography (NIL)

Scanning electron microscopy (SEM)

Atomic force microscopy (AFM)

Acknowledgments

References

- Blodgett, KB; Langmuir, I. Built-Up Films of Barium Stearate and Their Optical Properties. Phys Rev 1937, 51, 964–982. [Google Scholar]

- Shipway, AN; Katz, E; Willner, I. Nanoparticle Arrays on Surfaces for Electronic, Optical, and Sensor Applications. ChemPhysChem 2000, 1, 18–52. [Google Scholar]

- Blanco, A; Chomski, E; Grabtchak, S; Ibisate, M; John, S; Leonard, SW; Lopez, C; Meseguer, F; Miguez, H; Mondia, JP; Ozin, GA; Toader, O; van Driel, HM. Large-scale Synthesis of a Silicon Photonic Crystal with a Complete Three-dimensional Bandgap near 1.5 Micrometres. Nature 2000, 405, 437–440. [Google Scholar]

- Lopez, C. Materials Aspects of Photonic Crystals. Adv Mater 2003, 15, 1679–1704. [Google Scholar]

- Malaquin, L; Kraus, T; Schmid, H; Delamarche, E; Wolf, H. Controlled Particle Placement through Convective and Capillary Assembly. Langmuir 2007, 23, 11513–11521. [Google Scholar]

- Fustin, CA; Glasser, G; Spiess, HW; Jonas, U. Parameters Influencing the Templated Growth of Colloidal Crystals on Chemically Patterned Surfaces. Langmuir 2004, 20, 9114–9123. [Google Scholar]

- Jiang, CY; Markutsya, S; Tsukruk, VV. Compliant, Robust, and Truly Nanoscale Free-Standing Multilayer Films Fabricated Using Spin-Assisted Layer-by-Layer Assembly. Adv Mater 2004, 16, 157–161. [Google Scholar]

- Salata, OV; Dobson, PJ; Hull, PJ; Hutchison, JL. Fabrication of PbS Nanoparticles Embedded in a Polymer Film by a Gas-aerosol Reactive Electrostatic Deposition Technique. Adv Mater 1994, 6, 772–775. [Google Scholar]

- Caruso, F; Spasova, M; Susha, A; Giersig, M; Caruso, RA. Magnetic Nanocomposite Particles and Hollow Spheres Constructed by a Sequential Layering Approach. Chem Mater 2001, 13, 109–116. [Google Scholar]

- Vossmeyer, T; Guse, B; Besnard, I; Bauer, RE; Mullen, K; Yasuda, A. Gold Nanoparticle/Polyphenylene Dendrimer Composite Films: Preparation and Vapor-Sensing Properties. Adv Mater 2002, 14, 238–242. [Google Scholar]

- Hammond, PT. Form and Function in Multilayer Assembly: New Applications at the Nanoscale. Adv Mater 2004, 16, 1271–1293. [Google Scholar]

- Hicks, JF; Seok-Shon, Y; Murray, RW. Layer-by-Layer Growth of Polymer/Nanoparticle Films Containing Monolayer-Protected Gold Clusters. Langmuir 2002, 18, 2288–2294. [Google Scholar]

- Lvov, Y; Ariga, K; Onda, M; Ichinose, I; Kunitake, T. Alternate Assembly of Ordered Multilayers of SiO2 and Other Nanoparticles and Polyions. Langmuir 1997, 13, 6195–6203. [Google Scholar]

- Andres, RP; Bielefeld, JD; Henderson, JI; Janes, DB; Kolagunta, VR; Kubiak, CP; Mahoney, WJ; Osifchin, RG. Self-Assembly of a Two-Dimensional Superlattice of Molecularly Linked Metal Clusters. Science 1996, 273, 1690–1693. [Google Scholar]

- Nakanishi, T; Ohtani, B; Uosaki, K. Fabrication and Characterization of CdS-Nanoparticle Mono- and Multilayers on a Self-Assembled Monolayer of Alkanedithiols on Gold. J Phys Chem B 1998, 102, 1571–1577. [Google Scholar]

- Crespo-Biel, O; Dordi, B; Reinhoudt, DN; Huskens, J. Supramolecular Layer-by-Layer Assembly: Alternating Adsorptions of Guest- and Host-Functionalized Molecules and Particles Using Multivalent Supramolecular Interactions. J Am Chem Soc 2005, 127, 7594–7600. [Google Scholar]

- Maury, P; Peter, M; Crespo-Biel, O; Ling, XY; Reinhoudt, DN; Huskens, J. Patterning the Molecular Printboard: Patterning Cyclodextrin Monolayers on Silicon Oxide Using Nanoimprint Lithography and its Application in 3D Multilayer Nanostructuring. Nanotechnology 2007, 18, 044007. [Google Scholar]

- Ling, XY; Reinhoudt, DN; Huskens, J. Ferrocenyl-Functionalized Silica Nanoparticles: Preparation, Characterization, and Molecular Recognition at Interfaces. Langmuir 2006, 22, 8777–8783. [Google Scholar]

- Wanunu, M; Popovitz-Biro, R; Cohen, H; Vaskevich, A; Rubinstein, I. Coordination-Based Gold Nanoparticle Layers. J Am Chem Soc 2005, 127, 9207–9215. [Google Scholar]

- Decher, G; Hong, JD; Schmitt, J. Buildup of Ultrathin Multilayer Films by a Self-assembly Process: III. Consecutively Alternating Adsorption of Anionic and Cationic Polyelectrolytes on Charged Surfaces. Thin Solid Films 1992, 210, 831–835. [Google Scholar]

- Dziomkina, NV; Vancso, GJ. Colloidal Crystal Assembly on Topologically Patterned Templates. Soft Matter 2005, 1, 265–279. [Google Scholar]

- Mrksich, M; Whitesides, GM. Patterning Self-assembled Monolayers Using Microcontact Printing: A New Technology for Biosensors? Trends Biotechnol 1995, 13, 228–235. [Google Scholar]

- Zheng, HP; Lee, I; Rubner, MF; Hammond, PT. Two Component Particle Arrays on Patterned Polyelectrolyte Multilayer Templates. Adv Mater 2002, 14, 569–572. [Google Scholar]

- Lee, I; Zheng, HP; Rubner, MF; Hammond, PT. Controlled Cluster Size in Patterned Particle Arrays via Directed Adsorption on Confined Surfaces. Adv Mater 2002, 14, 572–577. [Google Scholar]

- Jiang, CY; Markutsya, S; Pikus, Y; Tsukruk, VV. Freely Suspended Nanocomposite Membranes as Highly Sensitive Sensors. Nature Mater 2004, 3, 721–728. [Google Scholar]

- Maury, P; Escalante, M; Reinhoudt, DN; Huskens, J. Directed Assembly of Nanoparticles onto Polymer-Imprinted or Chemically Patterned Templates Fabricated by Nanoimprint Lithography. Adv Mater 2005, 17, 2718–2723. [Google Scholar]

- Ling, XY; Malaquin, L; Reinhoudt, DN; Wolf, H; Huskens, J. An in Situ Study of the Adsorption Behavior of Functionalized Particles on Self-Assembled Monolayers via Different Chemical Interactions. Langmuir 2007, 23, 9990–9999. [Google Scholar]

- Ling, XY; Reinhoudt, DN; Huskens, J. Reversible Attachment of Nanostructures at Molecular Printboards through Supramolecular Glue. Chem Mater 2008, 20. in press. [Google Scholar]

- Ludden, MJW; Reinhoudt, DN; Huskens, J. Molecular Printboards: Versatile Platforms for the Creation and Positioning of Supramolecular Assemblies and Materials. Chem Soc Rev 2006, 35, 1122–1134. [Google Scholar]

- Beulen, MWJ; Bügler, J; Lammerink, B; Geurts, FAJ; Biemond, E; van Leerdam, KGC; van Veggel, F; Engbersen, JFJ; Reinhoudt, DN. Self-Assembled Monolayers of Heptapodant -Cyclodextrins on Gold. Langmuir 1998, 14, 6424–6429. [Google Scholar]

- Onclin, S; Mulder, A; Huskens, J; Ravoo, BJ; Reinhoudt, DN. Molecular Printboards: Monolayers of -Cyclodextrins on Silicon Oxide Surfaces. Langmuir 2004, 20, 5460–5466. [Google Scholar]

- Michels, JJ; Baars, M; Meijer, EW; Huskens, J; Reinhoudt, DN. Well-defined Assemblies of Adamantyl-terminated Poly(propylene imine) Dendrimers and β-cyclodextrin in water. J Chem Soc Perkin Trans 2 2000, 1914–1918. [Google Scholar]

- Nijhuis, CA; Huskens, J; Reinhoudt, DN. Binding Control and Stoichiometry of Ferrocenyl Dendrimers at a Molecular Printboard. J Am Chem Soc 2004, 126, 12266–12267. [Google Scholar]

- Mahalingam, V; Onclin, S; Peter, M; Ravoo, BJ; Huskens, J; Reinhoudt, DN. Directed Self-Assembly of Functionalized Silica Nanoparticles on Molecular Printboards through Multivalent Supramolecular Interactions. Langmuir 2004, 20, 11756–11762. [Google Scholar]

- Crespo-Biel, O; Dordi, B; Maury, P; Peter, M; Reinhoudt, DN; Huskens, J. Patterned, Hybrid, Multilayer Nanostructures Based on Multivalent Supramolecular Interactions. Chem Mater 2006, 18, 2545–2551. [Google Scholar]

- Bruinink, CM; Nijhuis, CA; Peter, M; Dordi, B; Crespo-Biel, O; Auletta, T; Mulder, A; Schonherr, H; Vancso, GJ; Huskens, J; Reinhoudt, DN. Supramolecular Microcontact Printing and Dip-Pen Nanolithography on Molecular Printboards. Chem Eur J 2005, 11, 3988–3996. [Google Scholar]

- Zhang, JH; Zhan, P; Wang, ZL; Zhang, WY; Ming, NB. Preparation of Monodisperse Silica Particles with Controllable Size and Shape. J Mater Res 2003, 18, 649–653. [Google Scholar]

Share and Cite

Ling, X.Y.; Phang, I.Y.; Reinhoudt, D.N.; Vancso, G.J.; Huskens, J. Supramolecular Layer-by-Layer Assembly of 3D Multicomponent Nanostructures via Multivalent Molecular Recognition. Int. J. Mol. Sci. 2008, 9, 486-497. https://doi.org/10.3390/ijms9040486

Ling XY, Phang IY, Reinhoudt DN, Vancso GJ, Huskens J. Supramolecular Layer-by-Layer Assembly of 3D Multicomponent Nanostructures via Multivalent Molecular Recognition. International Journal of Molecular Sciences. 2008; 9(4):486-497. https://doi.org/10.3390/ijms9040486

Chicago/Turabian StyleLing, Xing Yi, In Yee Phang, David N. Reinhoudt, G. Julius Vancso, and Jurriaan Huskens. 2008. "Supramolecular Layer-by-Layer Assembly of 3D Multicomponent Nanostructures via Multivalent Molecular Recognition" International Journal of Molecular Sciences 9, no. 4: 486-497. https://doi.org/10.3390/ijms9040486