Effect of Filler Size and Temperature on Packing Stress and Viscosity of Resin-composites

Abstract

:1. Introduction

2. Results and Discussions

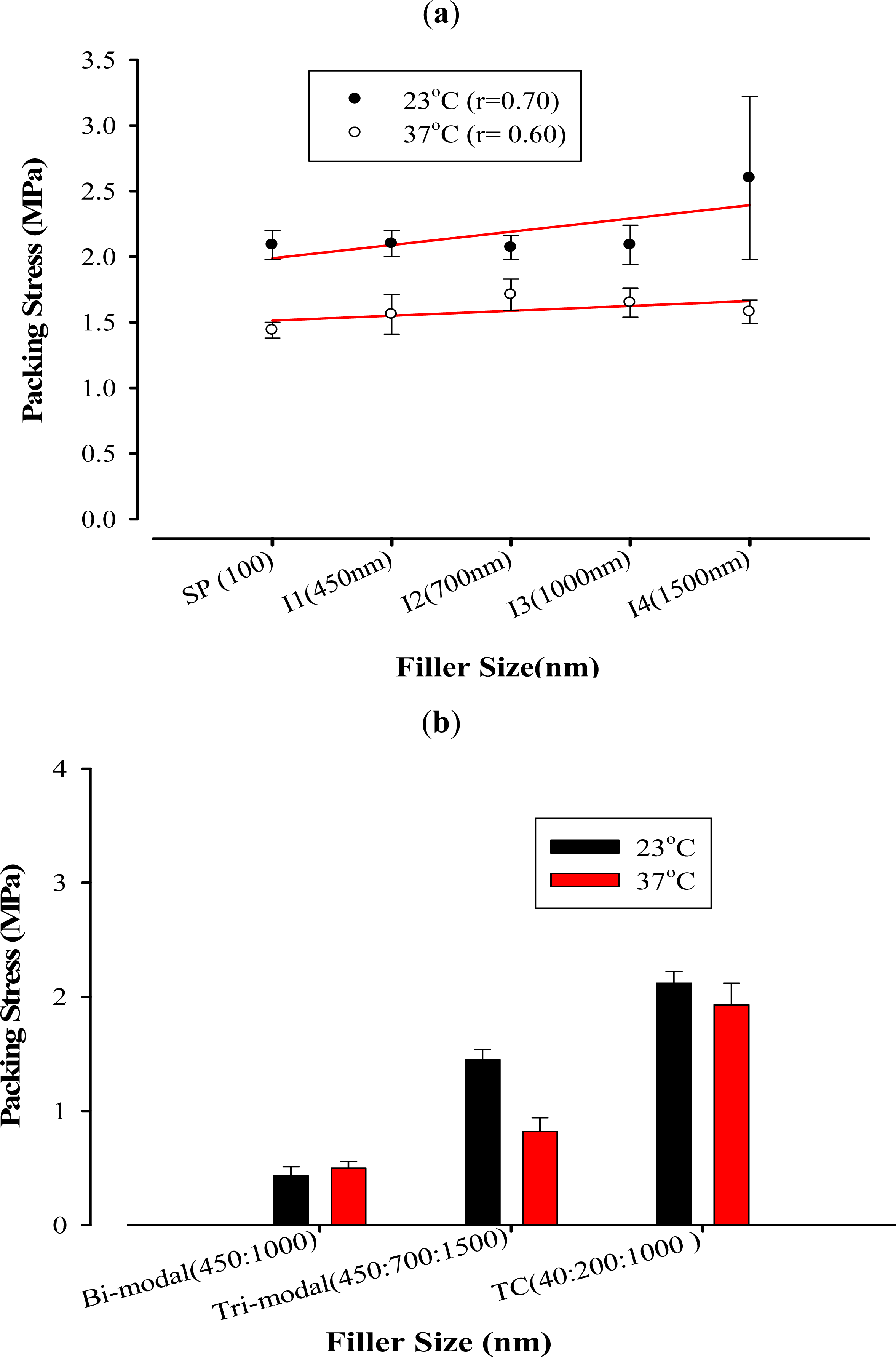

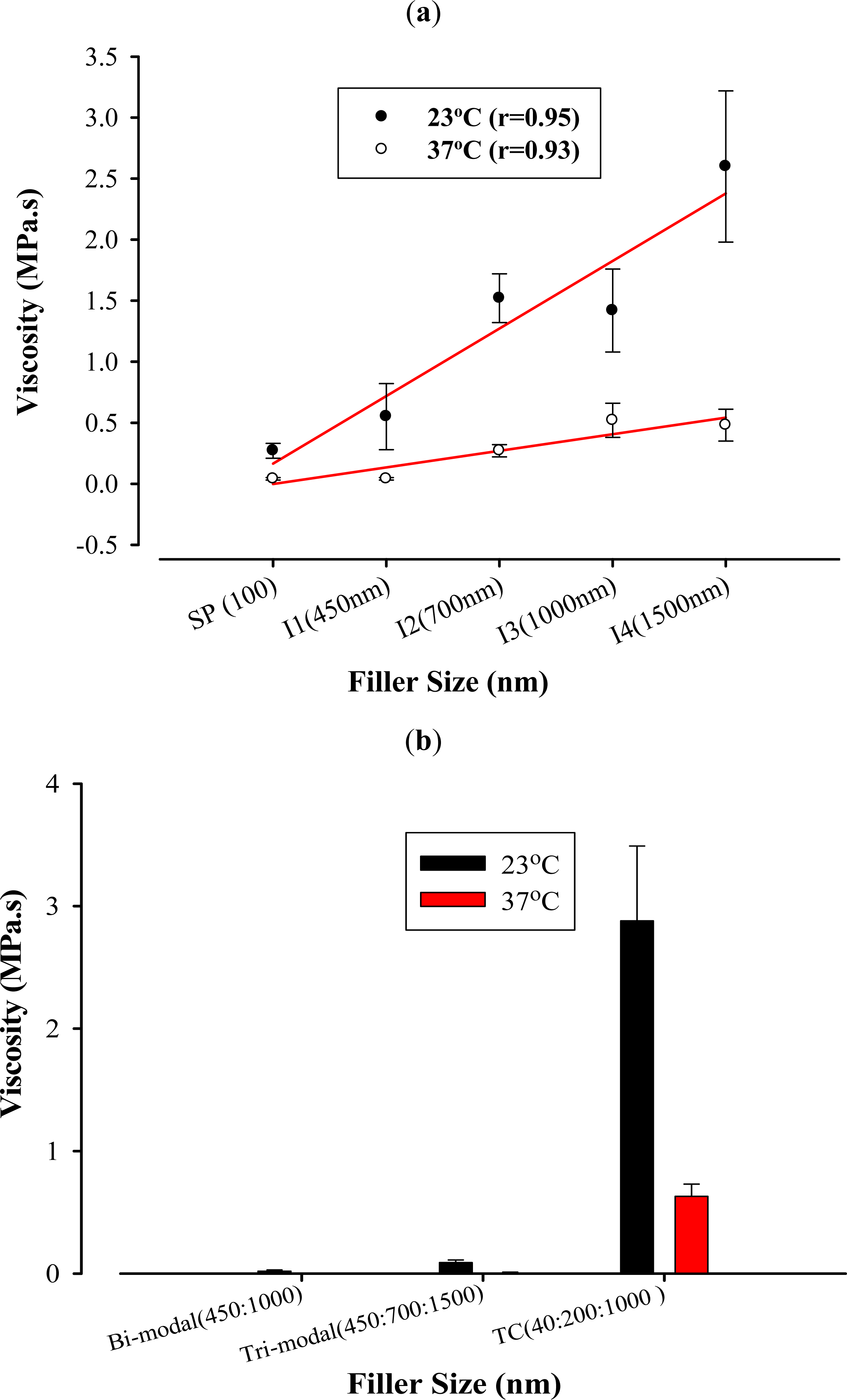

- Filler size and distribution have an effect on the packing stress and viscosity.

- Temperature has a prominent effect on the handling properties of resin-composite, i.e., as temperature increases the packing stress and viscosity decreases.

- Filler sizes and their combinations (bimodal and trimodal distributions) can have a fine-tuning effect on the handling properties and clinical performance.

3. Materials and Methods

Acknowledgments

- Conflict of InterestThe authors declare no conflict of interest.

References

- Stangel, I; Barolet, RY. Clinical evaluation of two posterior composite resins: Two-year results. J. Oral. Rehabil 1990, 17, 257–268. [Google Scholar]

- Knobloch, LA; Kerby, RE; Seghi, R; Berlin, JS; Clelland, N. Fracture toughness of packable and conventional composite materials. J. Prosthet. Dent 2002, 88, 307–313. [Google Scholar]

- Kohler, B; Rasmusson, CG; Odman, P. A five-year clinical evaluation of Class II composite resin restorations. J. Dent 2000, 28, 111–116. [Google Scholar]

- Collins, CJ; Bryant, RW; Hodge, KL. A clinical evaluation of posterior composite resin restorations: 8-year findings. J. Dent 1998, 26, 311–317. [Google Scholar]

- Opdam, NJ; Loomans, BA; Roeters, FJ; Bronkhorst, EM. Five-year clinical performance of posterior resin composite restorations placed by dental students. J. Dent 2004, 32, 379–383. [Google Scholar]

- Brunthaler, A; Konig, F; Lucas, T; Sperr, W; Schedle, A. Longevity of direct resin composite restorations in posterior teeth. Clin. Oral. Investig 2003, 7, 63–70. [Google Scholar]

- Gaengler, P; Hoyer, I; Montag, R. Clinical evaluation of posterior composite restorations: The 10-year report. J. Adhes. Dent 2001, 3, 185–194. [Google Scholar]

- Bae, JM; Kim, KN; Hattori, M; Hasegawa, K; Yoshinari, M; Kawada, E; Oda, Y. Fatigue strengths of particulate filler composites reinforced with fibers. Dent. Mater. J 2004, 23, 166–174. [Google Scholar]

- Moszner, N; Salz, U. New developments of polymeric dental composites. Prog. Polymer Sci 2001, 26, 535–576. [Google Scholar]

- Chen, MH. Update on dental nanocomposites. J. Dent. Res 2010, 89, 549–560. [Google Scholar]

- Ferracane, JL. Resin composite—State of the art. Dent. Mater 2011, 27, 29–38. [Google Scholar]

- Silikas, N; Watts, DC. Rheology of urethane dimethacrylate and diluent formulations. Dent Mater 1999, 15, 257–261. [Google Scholar]

- Taylor, DF; Kalachandra, S; Sankarapandian, M; McGrath, JE. Relationship between filler and matrix resin characteristics and the properties of uncured composite pastes. Biomaterials 1998, 19, 197–204. [Google Scholar]

- Bayne, SC; Thompson, JY; Swift, EJ, Jr; Stamatiades, P; Wilkerson, M. A characterization of first-generation flowable composites. J. Am. Dent. Assoc 1998, 129, 567–577. [Google Scholar]

- Leinfelder, K; Prasad, A. A new condensable composite for the restoration of posterior teeth. Dent. Today 1998, 17, 112–116. [Google Scholar]

- Opdam, NJ; Roeters, JJ; Peters, TC; Burgersdijk, RC; Kuijs, RH. Consistency of resin composites for posterior use. Dent. Mater 1996, 12, 350–354. [Google Scholar]

- Ferracane, JL; Moser, JB; Greener, EH. Rheology of composite restoratives. J. Dent. Res 1981, 60, 1678–1685. [Google Scholar]

- Al-Sharaa, KA; Watts, DC. Stickiness prior to setting of some light cured resin-composites. Dent. Mater 2003, 19, 182–187. [Google Scholar]

- Kim, K-H; Ong, JL; Okuno, O. The effect of filler loading and morphology on the mechanical properties of contemporary composites. J. Prosthet. Dent 2002, 87, 642–649. [Google Scholar]

- Masouras, K; Akhtar, R; Watts, DC; Silikas, N. Effect of filler size and shape on local nanoindentation modulus of resin-composites. J. Mater. Sci. Mater. Med 2008, 19, 3561–3566. [Google Scholar]

- Satterthwaite, JD; Vogel, K; Watts, DC. Effect of resin-composite filler particle size and shape on shrinkage-strain. Dent. Mater 2009, 25, 1612–1615. [Google Scholar]

- Beun, S; Bailly, C; Dabin, A; Vreven, J; Devaux, J; Leloup, G. Rheological properties of experimental Bis-GMA/TEGDMA flowable resin composites with various macrofiller/microfiller ratio. Dent. Mater 2009, 25, 198–205. [Google Scholar]

- Lee, J-H; Um, C-M; Lee, I-B. Rheological properties of resin composites according to variations in monomer and filler composition. Dent. Mater 2006, 22, 515–526. [Google Scholar]

- Choi, KK; Ferracane, JL; Hilton, TJ; Charlton, D. Properties of packable dental composites. J. Esthet. Dent 2000, 12, 216–226. [Google Scholar]

- Knight, JS; Fraughn, R; Norrington, D. Effect of temperature on the flow properties of resin composite. Gen. Dent 2006, 54, 14–16. [Google Scholar]

- Silikas, N; Watts, DC. Rheology of urethane dimethacrylate and diluent formulations. Dent. Mater 1999, 15, 257–261. [Google Scholar]

| Group | Packing Stress at 23 °C Mean (SD) | Packing Stress at 37 °C Mean (SD) |

|---|---|---|

| I1 | 2.10 (0.10) a* | 1.56 (0.15) a,b |

| I2 | 2.07 (0.09) a* | 1.71 (0.12) a,c |

| I3 | 2.09 (0.15) a* | 1.65 (0.11) a,d |

| I4 | 2.60 (0.62) a* | 1.58 (0.09) a,d |

| I5 | 0.43 (0.08) b* | 0.50 (0.06) e |

| I6 | 1.45 (0.09) c* | 0.82 (0.12) f |

| TC | 2.12 (0.10) a | 1.93 (0.19) c |

| SP | 2.09 (0.11) a* | 1.44 (0.06) b, d |

| Group | Viscosity at 23 °C Mean (SD) | Viscosity at 37 °C Mean (SD) |

|---|---|---|

| I1 | 0.55 (0.27) a, d, e* | 0.04 (0.01) a |

| I2 | 1.52 (0.20) b* | 0.27 (0.05) b |

| I3 | 1.42 (0.34) b* | 0.52 (0.14) b, c |

| I4 | 2.60 (0.62) b,c* | 0.48 (0.13) b, c |

| I5 | 0.02 (0.01) d* | 0.003 (0.001) d |

| I6 | 0.09 (0.02) e* | 0.01 (0.002) d |

| TC | 2.88 (0.61) c* | 0.63 (0.10) c |

| SP | 0.27 (0.06) a* | 0.04 (0.01) a |

| Resin-Composite | Filler Particles (Ground Glass [Ba-Al-B-silicate glass]) | Matrix | |||

|---|---|---|---|---|---|

| Shape | Size (nm) | Wt% | Vol% | ||

| I1 | Irregular | 450 | 76.4 | 56.7 | BisGMA, UDMA, TEGDMA |

| I2 | Irregular | 700 | 76.4 | 56.7 | |

| I3 | Irregular | 1000 | 76.4 | 56.7 | |

| I4 | Irregular | 1500 | 76.4 | 56.7 | |

| I5 | Irregular | 450, 1000 (1:3) | 76.4 | 56.7 | |

| I6 | Irregular | 450, 700 &1500 (1:1:3) | 76.4 | 56.7 | |

| SP | Spherical | 100 | 72.4 | 56.7 | |

| TC | Irregular& Spherical | 40, 200 &1000 | 79 | 60 | |

| Lot: C49490 | |||||

© 2011 by the authors; licensee MDPI, Basel, Switzerland. This article is an open-access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Elbishari, H.; Satterthwaite, J.; Silikas, N. Effect of Filler Size and Temperature on Packing Stress and Viscosity of Resin-composites. Int. J. Mol. Sci. 2011, 12, 5330-5338. https://doi.org/10.3390/ijms12085330

Elbishari H, Satterthwaite J, Silikas N. Effect of Filler Size and Temperature on Packing Stress and Viscosity of Resin-composites. International Journal of Molecular Sciences. 2011; 12(8):5330-5338. https://doi.org/10.3390/ijms12085330

Chicago/Turabian StyleElbishari, Haitham, Julian Satterthwaite, and Nick Silikas. 2011. "Effect of Filler Size and Temperature on Packing Stress and Viscosity of Resin-composites" International Journal of Molecular Sciences 12, no. 8: 5330-5338. https://doi.org/10.3390/ijms12085330