Fully Automated On-Chip Imaging Flow Cytometry System with Disposable Contamination-Free Plastic Re-Cultivation Chip

Abstract

:1. Introduction

2. Results and Discussion

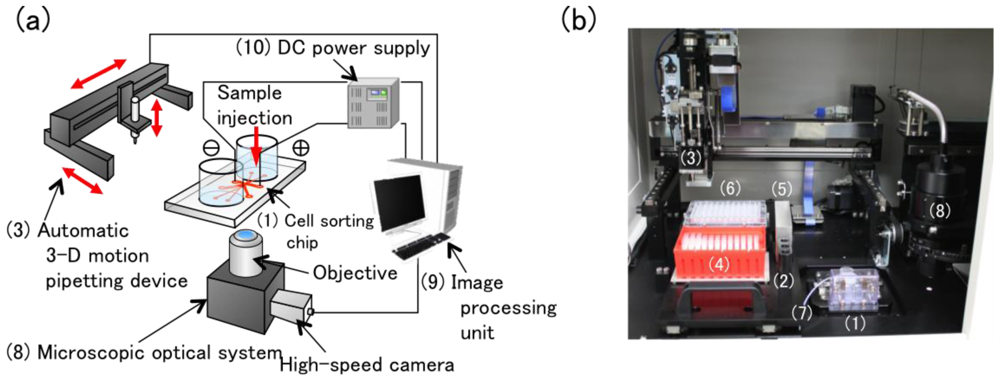

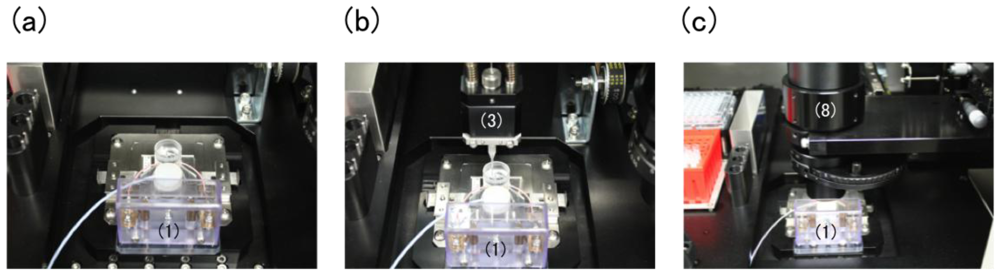

2.1. Fully Automated On-Chip Imaging Flow Cytometry System with Disposable Contamination-Free Plastic Re-Cultivation Chip

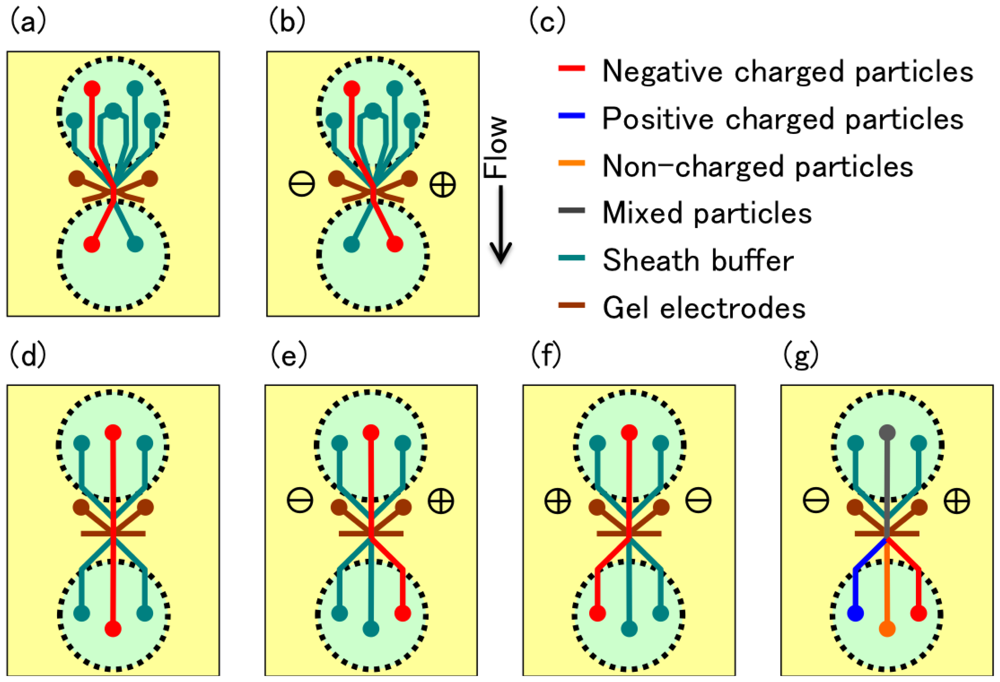

2.2. Design of Cell-Sorter Chips

2.3. Automated Sequential Process of Imaging Cytometry

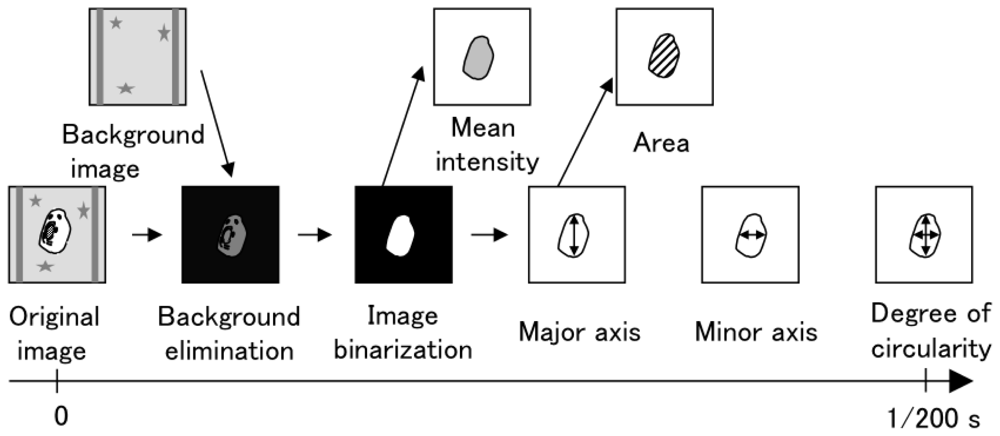

2.4. Real-Time Recognition of the Image of Flowing Particles

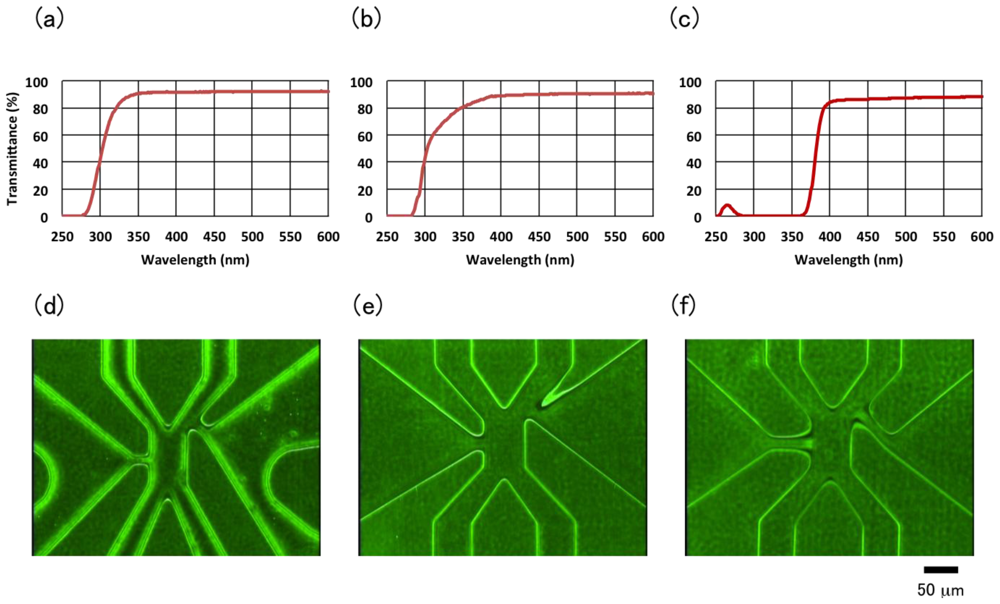

2.5. Development of Adisposable Poly(methyl methacrylate (PMMA)) Imaging Cell Sorter Chip

2.6. Spontaneous Filling of Agarose Sol into the Gel Electrode Channel of PMMA-Based Cell-Sorter Chip

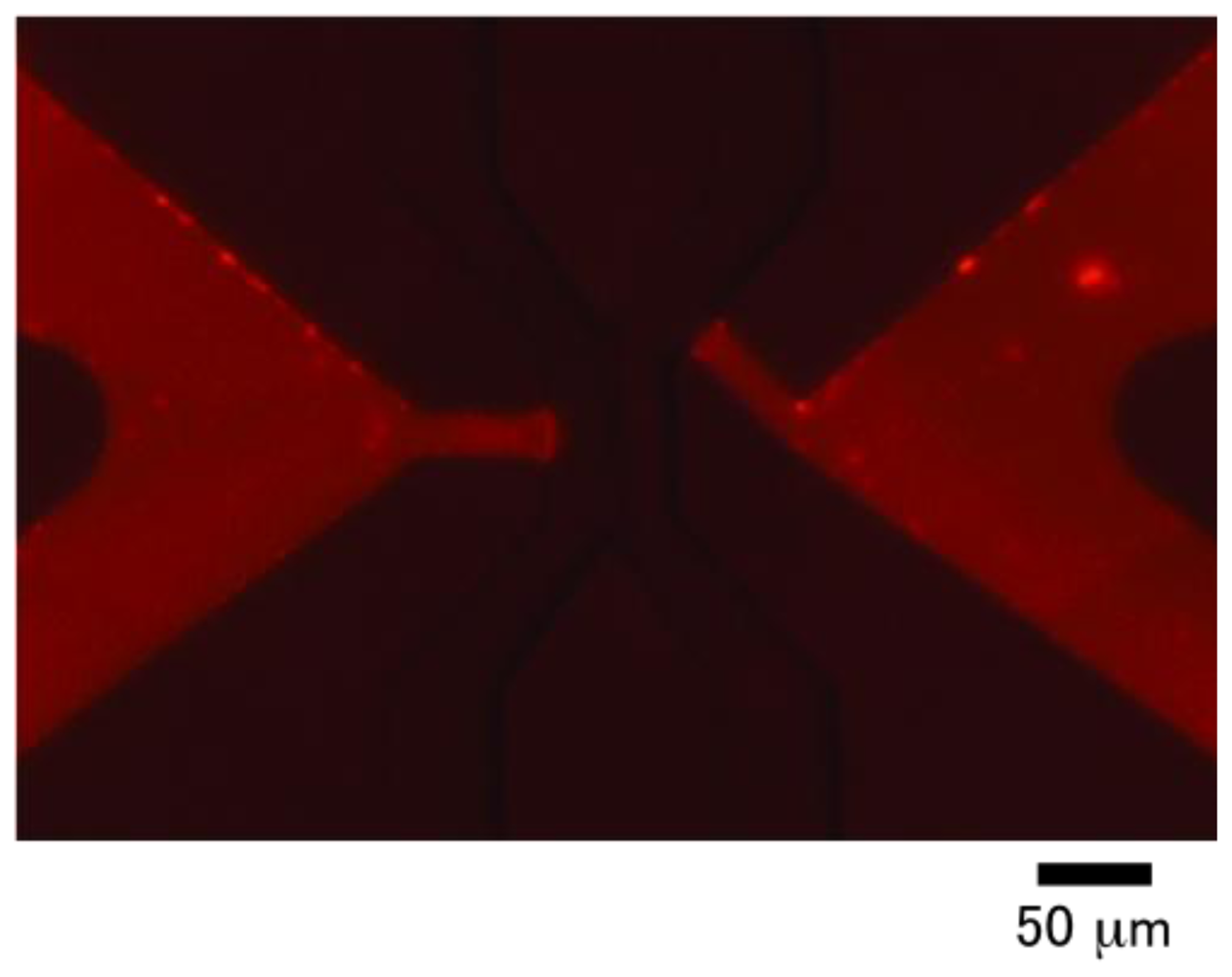

2.7. Laminar Flow of Sample Solution Sheathed by Hydrodynamic Focusing of Buffer Streams in the Microchannel of PMMA-Based Cell-Sorter Chip

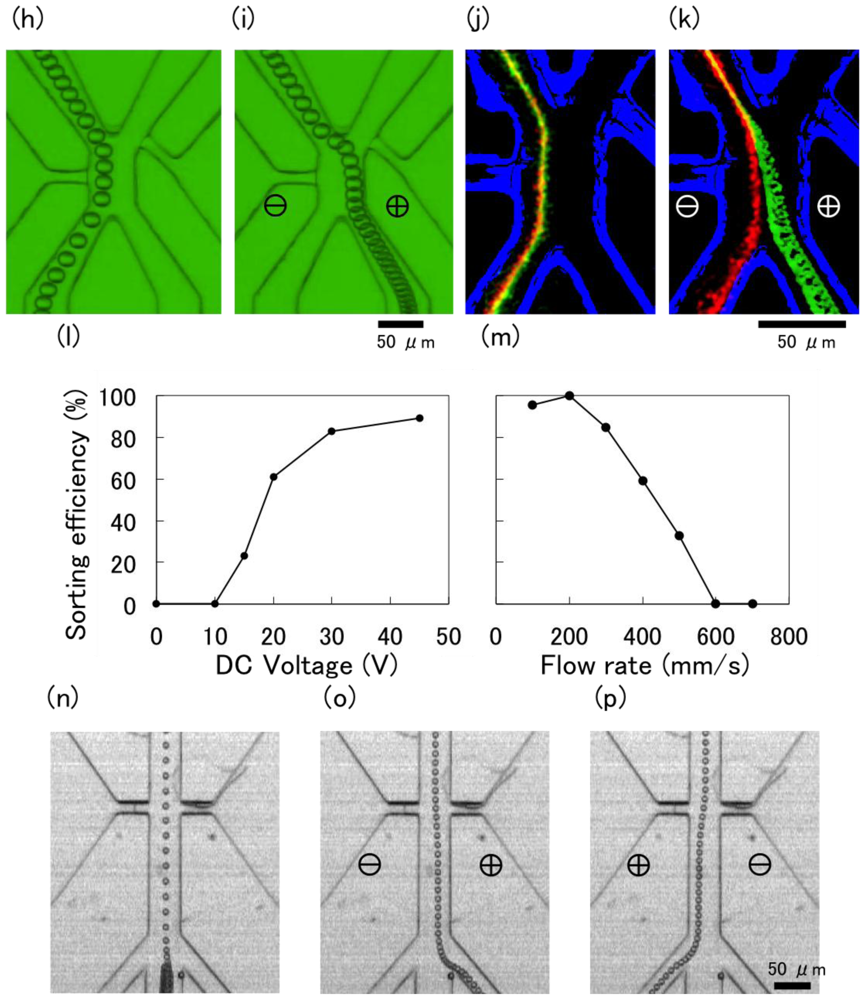

2.8. Particle Sorting and Separation Using Two- and Three-Way-Outlet Type Cell Sorter Chip

2.9. Real-Time Size-Discrimination of Two Similar Sized Particles by Microscopic Image

2.10. Estimation of the Maximum Processing Speed and the Necessary Time for Cell Sorting

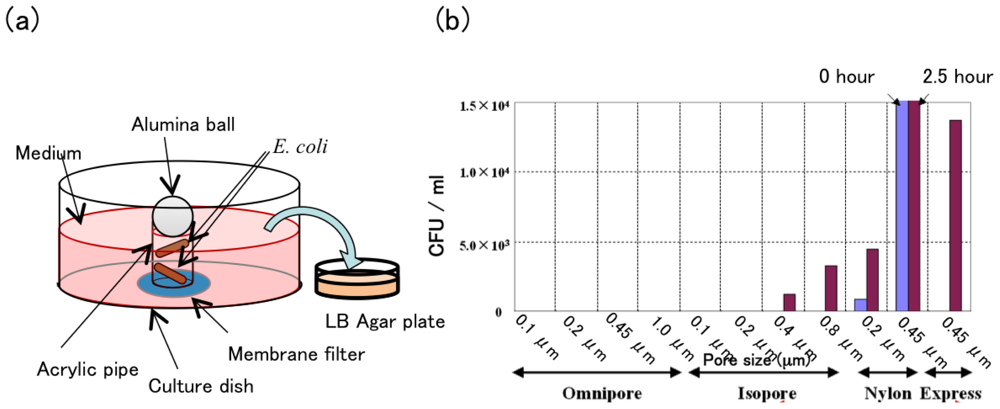

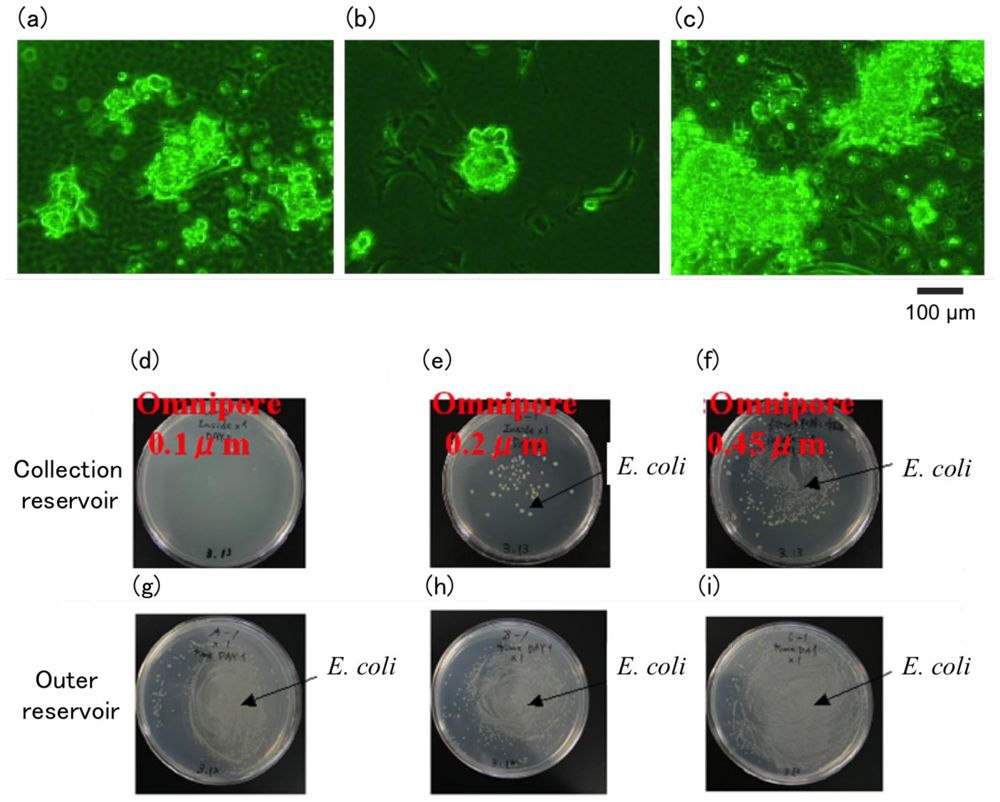

2.11. Sealing of Semipermeable Membrane on the Chip Reservoir for Contamination-Free Recultivation Chip

3. Experimental Section

3.1. System Configuration of an Automatic On-Chip Imaging Cytometer

3.2. Estimation of a Contamination-Free Re-Cultivation System on a Cell-Sorter Chip

3.3. Samples

4. Conclusions

Acknowledgements

References

- Bonner, WA; Hulett, HR; Sweet, RG; Herzenberg, LA. Development and application of a rapid cell sorter. Clin. Chem 1973, 19, 813–816. [Google Scholar]

- Schmitz, B; Radbruch, A; Kümmel, T; Wickenhauser, C; Korb, H; Hansmann, ML; Thiele, J; Fischer, R. Magnetic activated cell sorting (MACS)—a new immunomagnetic method for megakaryocytic cell isolation: Comparison of different separation techniques. Eur. J. Haematol 1994, 52, 267–275. [Google Scholar]

- Steinberg, M. Reconstruction of tissues by dissociated cells. Science 1963, 141, 401–408. [Google Scholar]

- Fu, AY; Spence, C; Scherer, A; Arnold, FH; Quake, SR. A microfabricated fluorescence-activated cell sorter. Nat. Biotechnol 1999, 17, 1109–1111. [Google Scholar]

- Fu, AY; Chou, HP; Spence, C; Arnold, FH; Quake, SR. An integrated microfabricated cell sorter. Anal. Chem 2002, 74, 2451–2457. [Google Scholar]

- Cho, SH; Chen, CH; Tsai, FS; Godin, JM; Lo, YH. Human mammalian cell sorting using a highly integrated micro-fabricated fluorescence-activated cell sorter (microFACS). Lab. Chip 2010, 10, 1567–1573. [Google Scholar]

- Cho, SH; Godin, JM; Chen, CH; Qiao, W; Lee, H; Lo, YH. Review article: Recent advancements in optofluidic flow cytometer. Biomicrofluidics 2010, 4. [Google Scholar]

- Hawkins, A; Schmidt, H. Handbook of Optofluidics; CRC: Boca Raton, FL, USA, 2010. [Google Scholar]

- Givan, A. First Principles. In Flow Cytometry; Wiley: New York, NY, USA, 2001. [Google Scholar]

- Shapiro, H; Leif, R. Practical Flow Cytometry; Wiley: New York, NY, USA, 2003. [Google Scholar]

- Takahashi, K; Hattori, A; Suzuki, I; Ichiki, T; Yasuda, K. Non-destructive on-chip cell sorting system with real-time microscopic image processing. J Nanobiotechnol 2004, 2, 5. [Google Scholar] [CrossRef]

- Hattori, A; Yasuda, K. Comprehensive study of microgel electrode for on-chip electrophoretic cell sorting. Jpn J Appl Phys 2010, 49, 06GM04:1–06GM04:4. [Google Scholar]

- Hattori, A; Yasuda, K. Development of on-chip highspeed imaging cell sorter (II): Improvement of particle alignment control and precise image acquisition. Jpn J Appl Phys 2011, in press. [Google Scholar]

| Omnipore | Express | Nylon | Durapore | Isopore | Fluoro-pore | PVC | |

|---|---|---|---|---|---|---|---|

| Thermal resistance | × | ○ | ○ | ○ | ○ | × | × |

| Ruck | ○ | ○ | ○ | ○ | × | × | × |

| Hydrophilia | ○ | ○ | ○ | × | × | × | × |

| Clarity | ○ | × | × | × | × | × | × |

| Result | ○ | × | × | × | × | × | × |

© 2011 by the authors; licensee Molecular Diversity Preservation International, Basel, Switzerland. This article is an open-access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Hayashi, M.; Hattori, A.; Kim, H.; Terazono, H.; Kaneko, T.; Yasuda, K. Fully Automated On-Chip Imaging Flow Cytometry System with Disposable Contamination-Free Plastic Re-Cultivation Chip. Int. J. Mol. Sci. 2011, 12, 3618-3634. https://doi.org/10.3390/ijms12063618

Hayashi M, Hattori A, Kim H, Terazono H, Kaneko T, Yasuda K. Fully Automated On-Chip Imaging Flow Cytometry System with Disposable Contamination-Free Plastic Re-Cultivation Chip. International Journal of Molecular Sciences. 2011; 12(6):3618-3634. https://doi.org/10.3390/ijms12063618

Chicago/Turabian StyleHayashi, Masahito, Akihiro Hattori, Hyonchol Kim, Hideyuki Terazono, Tomoyuki Kaneko, and Kenji Yasuda. 2011. "Fully Automated On-Chip Imaging Flow Cytometry System with Disposable Contamination-Free Plastic Re-Cultivation Chip" International Journal of Molecular Sciences 12, no. 6: 3618-3634. https://doi.org/10.3390/ijms12063618