Improved l-Leucine Production in Corynebacterium glutamicum by Optimizing the Aminotransferases

Abstract

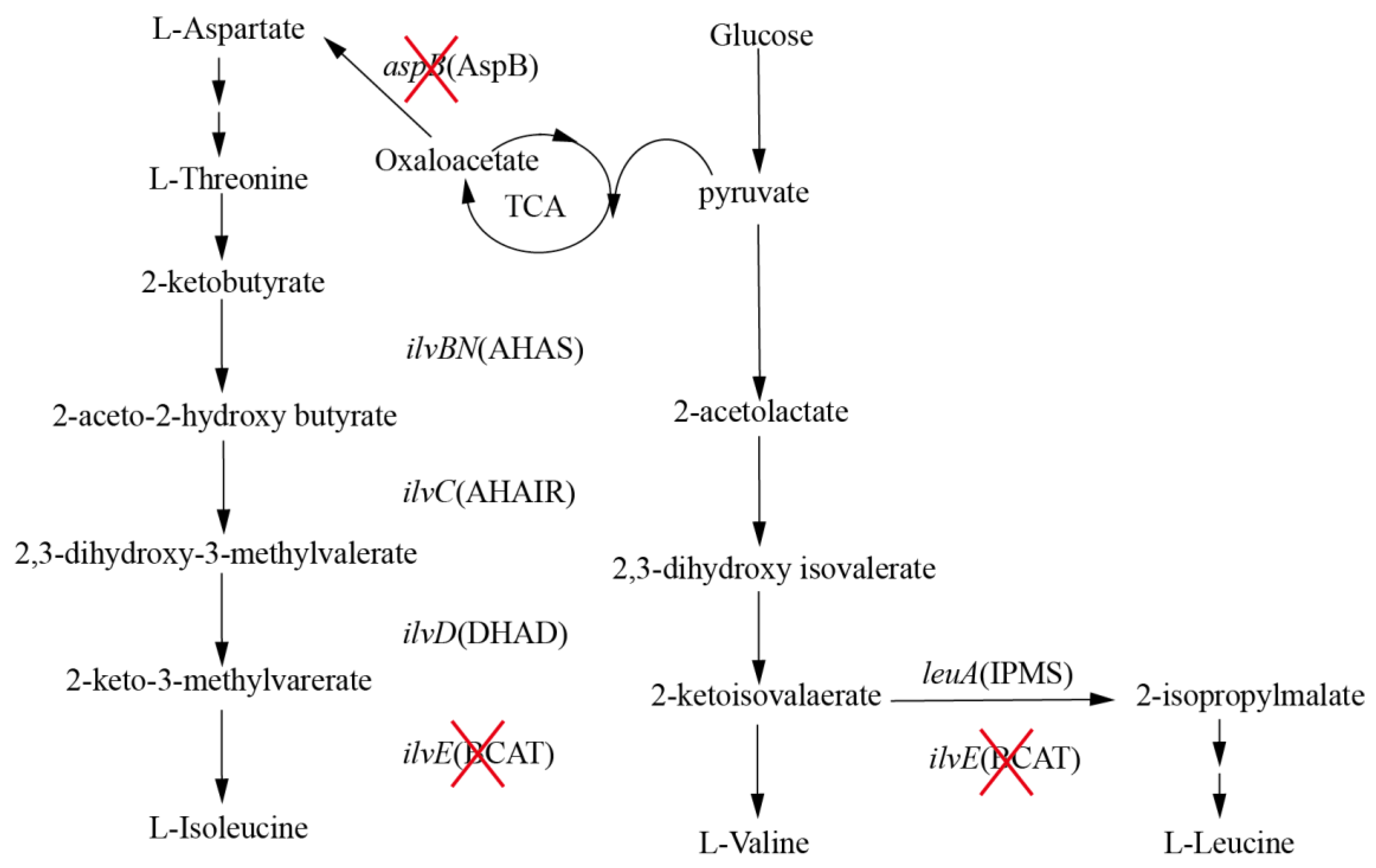

:1. Introduction

2. Results

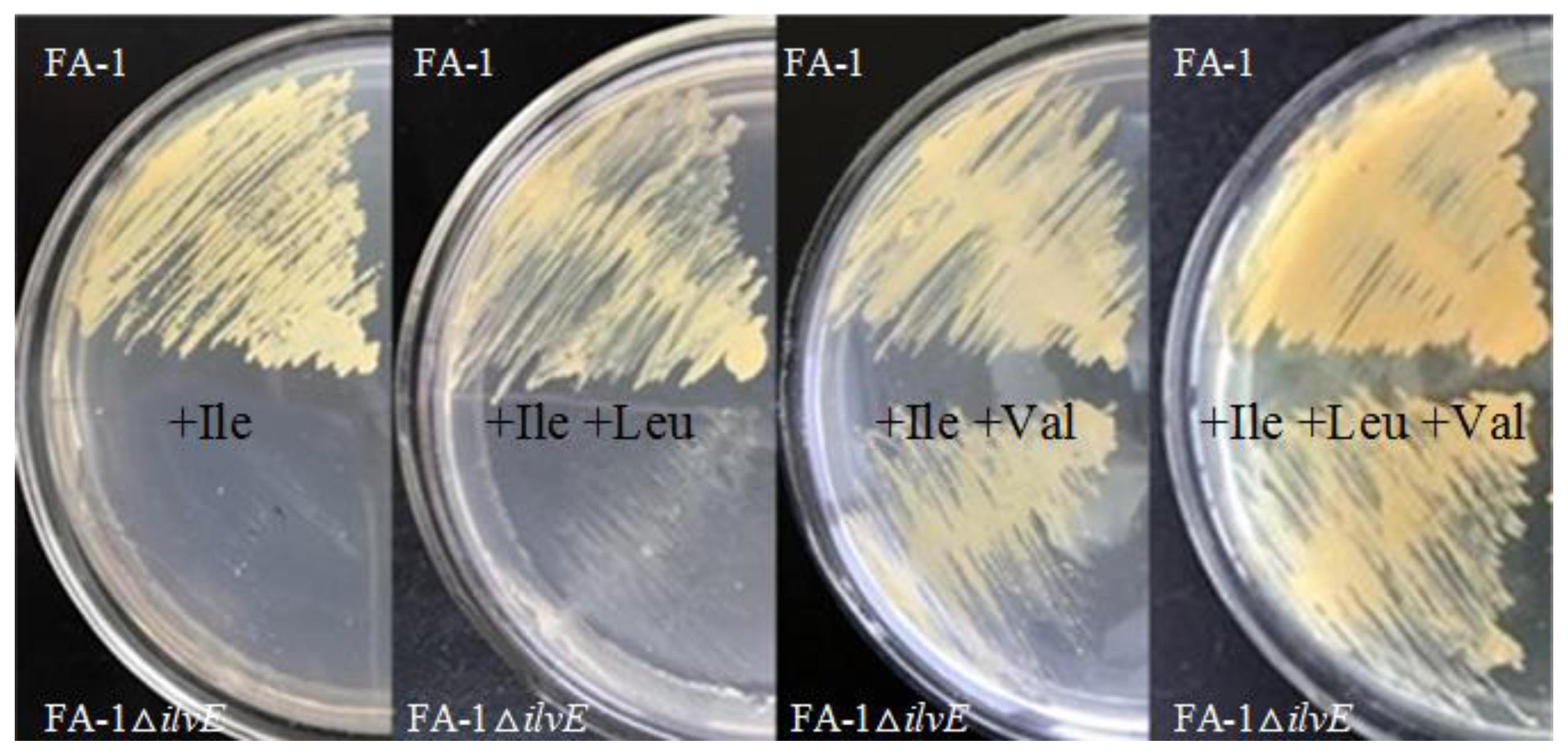

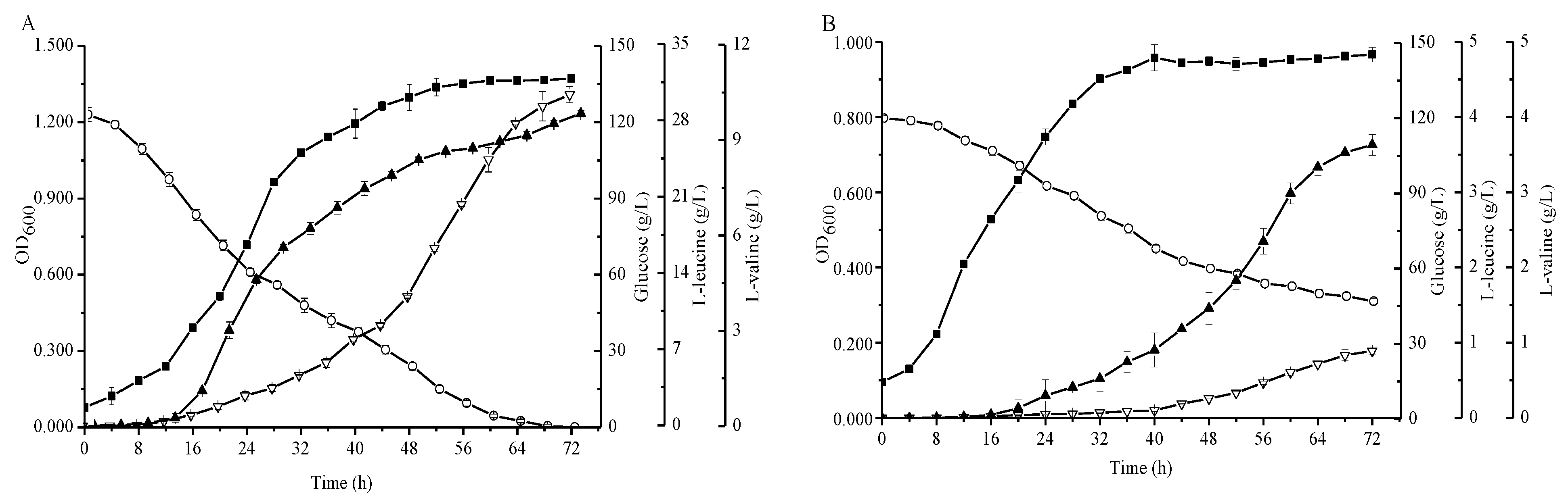

2.1. Effect of Inactivation of ilvE Gene on BCAAs

2.2. Effect of aspB on l-Leucine Production

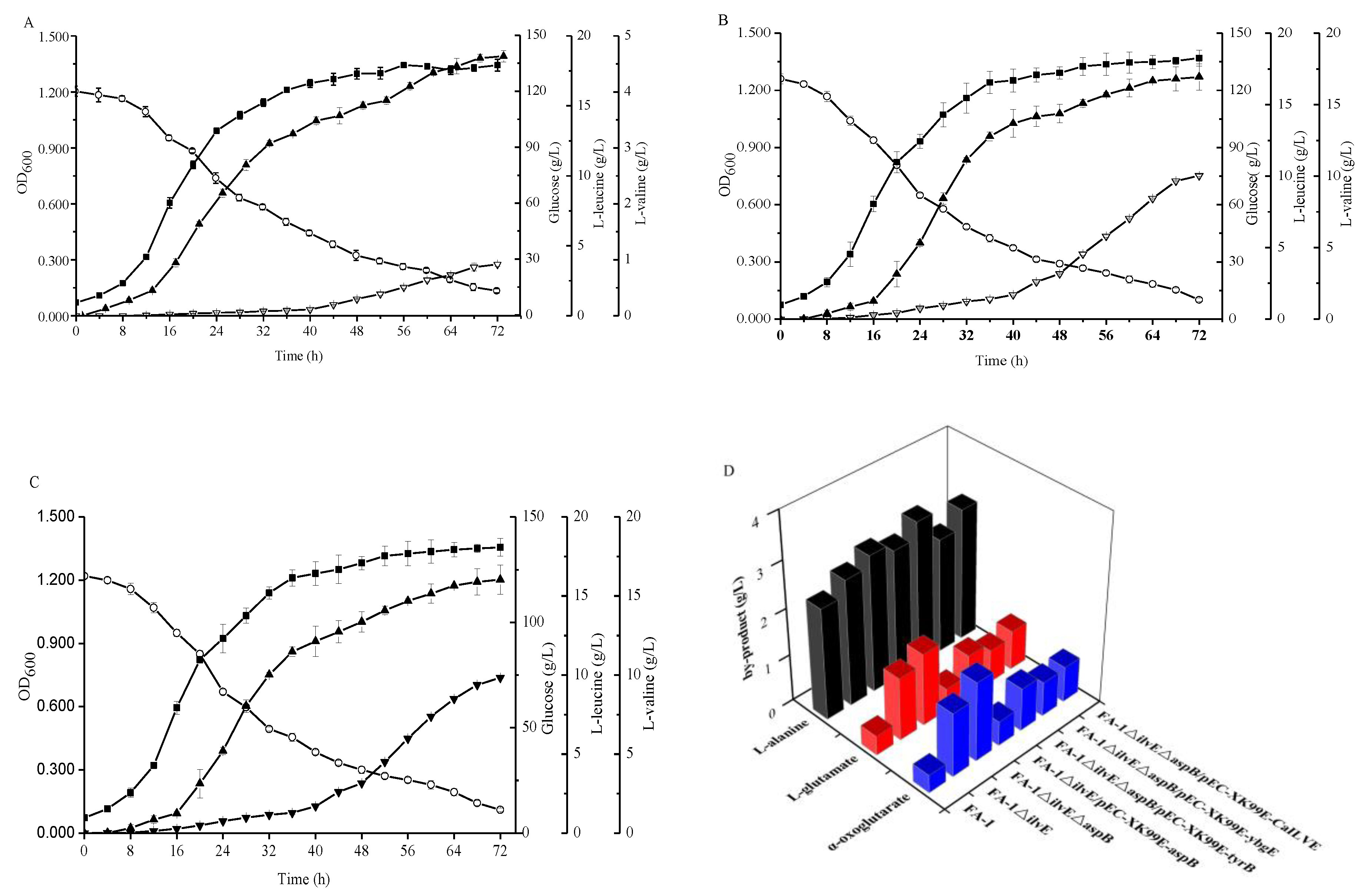

2.3. Effect of Different Aminotransferases on the Biosynthesis of l-Leucine or l-Valine

3. Discussion

4. Material and Methods

4.1. Bacterial Strains, Plasmids, and Growth Conditions

4.2. Construction of Plasmids

4.3. Construction of Strains

4.4. Preparation of Cell Extracts and Enzyme Assays

4.5. Analytical Methods

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Harper, A.; Miller, R.; Block, K. Branched-chain amino acid metabolism. Annu. Rev. Nutr. 1984, 4, 409–454. [Google Scholar] [CrossRef] [PubMed]

- Yamamoto, K.; Tsuchisaka, A.; Yukawa, H. Branched-Chain Amino Acids. Adv. Biochem. Eng. Biotechnol. 2017, 159, 103–128. [Google Scholar] [CrossRef] [PubMed]

- Monirujjaman, M.; Ferdouse, A. Metabolic and Physiological Roles of Branched-Chain Amino Acids. Adv. Mol. Biol. 2014, 2014, 364976. [Google Scholar] [CrossRef]

- Park, J.H.; Lee, S.Y. Fermentative production of branched chain amino acids: A focus on metabolic engineering. Appl. Microbiol. Biotechnol. 2010, 85, 491–506. [Google Scholar] [CrossRef] [PubMed]

- Leyval, D.; Uy, D.; Delaunay, S.; Goergen, J.L.; Engasser, J.M. Characterisation of the enzyme activities involved in the valine biosynthetic pathway in a valine-producing strain of Corynebacterium glutamicum. J. Biotechnol. 2003, 104, 241–252. [Google Scholar] [CrossRef]

- Jojima, T.; Inui, M.; Yukawa, H. Amino Acids, Branched Chain, l-Isoleucine. Encycl. Ind. Biotechnol. Bioprocess Biosep. Cell Technol. 2009, 1–6. [Google Scholar] [CrossRef]

- Radmacher, E.; Vaitsikova, A.; Burger, U.; Krumbach, K.; Sahm, H.; Eggeling, L. Linking Central Metabolism with Increased Pathway Flux: l-Valine Accumulation by Corynebacterium glutamicum. Appl. Environ. Microbiol. 2002, 68, 2246–2250. [Google Scholar] [CrossRef] [PubMed]

- Keilhauer, C.; Eggeling, L.; Sahm, H. Isoleucine synthesis in Corynebacterium glutamicum: Molecular analysis of the ilvB-ilvN-ilvC operon. J. Bacteriol. 1993, 175, 5595–5603. [Google Scholar] [CrossRef] [PubMed]

- Vogt, M.; Haas, S.; Klaffl, S.; Polen, T.; Eggeling, L.; van Ooyen, J.; Bott, M. Pushing product formation to its limit: Metabolic engineering of Corynebacterium glutamicum for l-leucine overproduction. Metab. Eng. 2014, 22, 40–52. [Google Scholar] [CrossRef] [PubMed]

- Powell, J.T.; Morrison, J.F. Role of the Escherichia coli aromatic amino acid aminotransferase in leucine biosynthesis. J. Bacteriol. 1978, 136, 1–4. [Google Scholar] [PubMed]

- Boyko, K.M.; Stekhanova, T.N.; Nikolaeva, A.Y.; Mardanov, A.V.; Rakitin, A.L.; Ravin, N.V.; Bezsudnova, E.Y.; Popov, V.O. First structure of archaeal branched-chain amino acid aminotransferase from Thermoproteus uzoniensis specific for l-amino acids and R-amines. Extremophiles 2016, 20, 215–225. [Google Scholar] [CrossRef] [PubMed]

- Uchida, Y.; Hayashi, H.; Washio, T.; Yamasaki, R.; Kato, S.; Oikawa, T. Cloning and characterization of a novel fold-type I branched-chain amino acid aminotransferase from the hyperthermophilic archaeon Thermococcus sp. CKU-1. Extremophiles 2014, 18, 589–602. [Google Scholar] [CrossRef] [PubMed]

- Cammarata, P.S.; Cohen, P.P. The scope of the transamination reaction in animal tissues. J. Biol. Chem. 1950, 187, 439–452. [Google Scholar] [PubMed]

- Feldman, L.I.; Gunsalus, I.C. The occurrence of a wide variety of transaminases in bacteria. J. Biol. Chem. 1950, 187, 821–830. [Google Scholar] [PubMed]

- Ichihara, A.; Koyama, E. Transaminase of Branched Chain Amino Acids. J. Biochem. 1966, 59, 160–169. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Taylor, R.T.; Jenkins, W.T. Leucine aminotransferase. II. Purification and characterization. J. Biol. Chem. 1966, 241, 4396–4405. [Google Scholar] [PubMed]

- Booth, I. Escherichia coli and Salmonella typhimurium; Cellular and Molecular Biology Vol. 1 (OF2). In Trends in Biochemical Sciences; Neidhardt, F.C., Ed.; Cell Press: Cambridge, MA, USA, 1987; Volume 13, pp. 493–494. [Google Scholar] [CrossRef]

- Romanos, M.; Scorer, C.; Sreekrishna, K.; Clare, J. The Generation of Multicopy Recombinant Strains. Methods Mol. Biol. 1998, 103, 55–72. [Google Scholar] [CrossRef] [PubMed]

- Ward, J.B.; Zahler, S.A. Genetic Studies of Leucine Biosynthesis in Bacillus subtilis. J. Bacteriol. 1973, 116, 719–726. [Google Scholar] [PubMed]

- Marienhagen, J.; Kennerknecht, N.; Sahm, H.; Eggeling, L. Functional analysis of all aminotransferase proteins inferred from the genome sequence of Corynebacterium glutamicum. J. Bacteriol. 2005, 187, 7639. [Google Scholar] [CrossRef] [PubMed]

- Jansonius, J.N. Structure, evolution and action of vitamin B6-dependent enzymes. Curr. Opin. Struct. Biol. 1998, 8, 759–769. [Google Scholar] [CrossRef]

- Mehta, P.K.; Hale, T.I.; Christen, P. Aminotransferases: Demonstration of homology and division into evolutionary subgroups. FEBS J. 1993, 214, 549–561. [Google Scholar] [CrossRef]

- Bezsudnova, E.Y.; Stekhanova, T.N.; Suplatov, D.A.; Mardanov, A.V.; Ravin, N.V.; Popov, V.O. Experimental and computational studies on the unusual substrate specificity of branched-chain amino acid aminotransferase from Thermoproteus uzoniensis. Arch. Biochem. Biophys. 2016, 607, 27–36. [Google Scholar] [CrossRef] [PubMed]

- McHardy, A.C.; Tauch, A.; Rückert, C.; Pühler, A.; Kalinowski, J. Genome-based analysis of biosynthetic aminotransferase genes of Corynebacterium glutamicum. J. Biotechnol. 2003, 104, 229–240. [Google Scholar] [CrossRef]

- Eggeling, L.; Bott, M. Handbook of Corynebacterium Glutamicum; CRC Press: Boca Raton, FL, USA, 2005; pp. 16–27. ISBN 9780849318214. [Google Scholar]

- Powell, J.T.; Morrison, J.F. The Purification and Properties of the Aspartate Aminotransferase and Aromatic-Amino-Acid Aminotransferase from Escherichia coli. FEBS J. 1978, 87, 391–400. [Google Scholar] [CrossRef]

- Mavrides, C.; Orr, W. Multispecific aspartate and aromatic amino acid aminotransferases in Escherichia coli. J. Biol. Chem. 1975, 250, 4128–4133. [Google Scholar] [PubMed]

- Berger, B.J.; English, S.; Chan, G.; Knodel, M.H. Methionine Regeneration and Aminotransferases in Bacillus subtilis, Bacillus cereus, and Bacillus anthracis. J. Bacteriol. 2003, 185, 2418–2431. [Google Scholar] [CrossRef] [PubMed]

- Collier, R.H.; Kohlhaw, G. Nonidentity of the Aspartate and the Aromatic Aminotransferase Components of Transaminase A in Escherichia coli. J. Bacteriol. 1972, 112, 365–371. [Google Scholar]

- Yu, X.; Wang, X.; Engel, P.C. The specificity and kinetic mechanism of branched-chain amino acid aminotransferase from Escherichia coli studied with a new improved coupled assay procedure and the enzyme’s potential for biocatalysis. FEBS J. 2014, 281, 391–400. [Google Scholar] [CrossRef] [PubMed]

- Francis, S.H.; Kim, K.J. Structural Insights into a Novel Class of Aspartate Aminotransferase from Corynebacterium glutamicum. PLoS ONE 2016, 11, e0158402. [Google Scholar] [CrossRef]

- Rudman, D.; Meister, A. Transamination in Escherichia coli. J. Biol. Chem. 1953, 200, 591. [Google Scholar] [PubMed]

- Leepeng, F.; Hermodson, M.A.; Kohlhaw, G.B. Transaminase B from Escherichia coli: Quaternary Structure, Amino-Terminal Sequence, Substrate Specificity, and Absence of a Separate Valine-α-Ketoglutarate Activity. J. Bacteriol. 1979, 139, 339–345. [Google Scholar]

- Yvon, M. Characterization and Role of the Branched-Chain Aminotransferase (BcaT) Isolated from Lactococcus lactis subsp. cremoris NCDO 763. Appl. Environ. Microbiol. 2000, 66, 571–577. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Montalvo-Arredondo, J.; Jiménez-Benítez, Á.; Colón-González, M.; González-Flores, J.; Flores-Villegas, M.; González, A.; Riego-Ruiz, L. Functional roles of a predicted branched chain aminotransferase encoded by the LkBAT1 gene of the yeast Lachancea kluyveri. Fungal Genet. Biol. 2015, 85, 71–82. [Google Scholar] [CrossRef] [PubMed]

- Sambrook, J.; David, W. Molecular Cloning: A Laboratory Manual, 3rd ed.; Cold Spring Harbor Laboratory Press: New York, NY, USA, 2001; ISBN-10 0879695773, ISBN-13 978-0879695774. [Google Scholar]

- Van der Rest, M.E.; Lange, C.; Molenaar, D. A heat shock following electroporation induces highly efficient transformation of Corynebacterium glutamicum with xenogeneic plasmid DNA. Appl. Microbiol. Biot. 1999, 52, 541–545. [Google Scholar] [CrossRef]

- Schäfer, A.; Tauch, A.; Jäger, W.; Kalinowski, J.; Thierbach, G.; Pühler, A. Small mobilizable multi-purpose cloning vectors derived from the Escherichia coli plasmids pK18 and pK19: Selection of defined deletions in the chromosome of Corynebacterium glutamicum. Gene 1994, 145, 69. [Google Scholar] [CrossRef]

- Xu, J.; Xia, X.; Zhang, J.; Guo, Y.; Qian, H.; Zhang, W. A method for gene amplification and simultaneous deletion in Corynebacterium glutamicum genome without any genetic markers. Plasmid 2014, 72, 9–17. [Google Scholar] [CrossRef] [PubMed]

- Lowry, O. Protein measurement with the Folin phenol regent. J. Biol. Chem. 1951, 193, 265. [Google Scholar] [PubMed]

- Hou, X.; Chen, X.; Zhang, Y.; Qian, H.; Zhang, W. (l)-Valine production with minimization of by-products’ synthesis in Corynebacterium glutamicum and Brevibacterium flavum. Amino Acids 2012, 43, 2301–2311. [Google Scholar] [CrossRef] [PubMed]

- Lindroth, P.; Mopper, K. High performance liquid chromatographic determination of subpicomole amounts of amino acids by precolumn fluorescence derivatization with o-phthaldialdehyde. Anal. Chem. 1979, 51, 1667–1674. [Google Scholar] [CrossRef]

Sample Availability: Samples of the compounds are available from the authors. |

| Strain | Growth Conditions a | Aminotransferase Specific Activity (mU/mg of Protein) | |

|---|---|---|---|

| Leucine | Valine | ||

| FA-1 | +Ile | 18.12 ± 2.12 | 10.07 ± 1.87 |

| FA-1△ilvE | +Ile + Val | 2.73 ± 0.92 | <1 |

| FA-1△ilvE△aspB | +Ile + Val + Leu + Asp | <1 | <1 |

| FA-1△ilvE/pEC-XK99E-aspB | +Ile + Val | 17.39 ± 2.67 | <1 |

| Strain | l-Leucine (g/L) | l-Valine (g/L) | l-Alanine (g/L) |

|---|---|---|---|

| FA-1△ilvE△aspB | <1 | <1 | 2.75 ± 0.23 |

| FA-1△ilvE△aspB/pEC-XK99E-aspC | <1 | <1 | 2.98 ± 0.72 |

| FA-1△ilvE△aspB/pEC-XK99E-yhdR | <1 | <1 | 2.69 ± 0.11 |

| FA-1△ilvE△aspB/pEC-XK99E-ywfG | <1 | <1 | 2.45 ± 0.35 |

| Strain | Growth Conditions a | Aminotransferase Specific Activity (mU/mg of Protein) | |

|---|---|---|---|

| Leucine | Valine | ||

| FA-1△ilvE△aspB/pEC-XK99E-tyrB | +Ile + Val + Leu + Asp | 16.85 ± 1.19 | <1 |

| FA-1△ilvE△aspB/pEC-XK99E-ybgE | +Ile + Val + Leu + Asp | 16.11 ± 2.01 | 8.79 ± 1.33 |

| FA-1△ilvE△aspB/pEC-XK99E-CaIlvE | +Ile + Val + Leu + Asp | 15.94 ± 1.88 | 8.33 ± 1.28 |

| FA-1△ilvE△aspB/pEC-XK99E-aspC | +Ile + Val + Leu + Asp | <1 | <1 |

| FA-1△ilvE△aspB/pEC-XK99E-yhdR | +Ile + Val + Leu + Asp | <1 | <1 |

| FA-1△ilvE△aspB/pEC-XK99E-ywfG | +Ile +Val + Leu + Asp | <1 | <1 |

| Strains and Plasmid | Description | Source or Reference |

|---|---|---|

| Strains | ||

| E. coli | ||

| BL21(DE3) | F- ompT gal dcm lon hsdSB (rB-mB-) λ(DE3) | Strata gene |

| W3110 | Wild type | Lab stock |

| C. glutamicum | ||

| ATCC 13032 | Type strain | ATCC |

| FA-1 | ilvE+aspB+ | Lab stock |

| FA-1△ilvE | As in FA-1, ilvE- | This work |

| FA-1△ilvE/pEC-XK99E-aspB | As in FA-1△ilvE, aspB+ | This work |

| FA-1△ilvE△aspB | As in FA-1△ilvE, aspB- | This work |

| FA-1△ilvE△aspB/pEC-XK99E-tyrB | As in FA-1△ilvE△aspB, tyrB+ | This work |

| FA-1△ilvE△aspB/pEC-XK99E-ybgE | As in FA-1△ilvE△aspB, ybgE+ | This work |

| FA-1△ilvE△aspB/pEC-XK99E-CaIlvE | As in FA-1△ilvE△aspB, CaIlv + | This work |

| FA-1△ilvE△aspB/pEC-XK99E-aspC | As in FA-1△ilvE△aspB, aspC+ | This work |

| FA-1△ilvE△aspB/pEC-XK99E-yhdR | As in FA-1△ilvE△aspB, yhdR+ | This work |

| FA-1△ilvE△aspB/pEC-XK99E-ywfG | As in FA-1△ilvE△aspB, ywfG + | This work |

| B. subtilis 168 | Wild type | ATCC |

| C. acetobutylicum ATCC 824 | Wild type | ATCC |

| Plasmids | ||

| pk18mobsacB | Integration vector | Lab stock |

| pk18mobsacB-△ilvE | pk18mobsacB carrying ilvE-L and ilvE-R gene | This work |

| pk18mobsacB-△aspB | pk18mobsacB carrying aspB -L and aspB -R gene | This work |

| pEC-XK99E | E. coli-C. glutamicum shuttle vector and Kanr | Lab stock |

| pEC-XK99E-aspB | pEC-XK99E with a 1.3 kb Kpn I/Xba I fragment containing aspB gene | This work |

| pEC-XK99E-tyrB | pEC-XK99E with a 1.2 kb EcoR I/BamH I fragment containing tyrB gene | This work |

| pEC-XK99E-ybgE | pEC-XK99E with a 1.0 kb EcoR I/BamH I fragment containing ybgE gene | This work |

| pEC-XK99E-CaIlvE | pEC-XK99E with a 1.0 kb EcoR I/BamH I fragment containing CaIlvE gene | This work |

| pEC-XK99E-aspC | pEC-XK99E with a 1.2 kb EcoR I/BamH I fragment containing aspC gene | This work |

| pEC-XK99E-yhdR | pEC-XK99E with a 1.1 kb EcoR I/BamH I fragment containing yhdR gene | This work |

| pEC-XK99E-ywfG | pEC-XK99E with a 1.2 kb Kpn I/Xba I fragment containing ywfG gene | This work |

| Primer | Sequence (5′ → 3′) | Description or Reference |

|---|---|---|

| P1 | TCCCCCGGGCAAGCCTAGCCATTCCTC (Smal I) | P1 to P4, primers for ilvE deletion |

| P2 | GCTCTAGACGTCTACCAGCAGTTCAAG (Xba I) | |

| P3 | GCTCTAGATGGGATACGAAGTAGAAGAGC (Xba I) | |

| P4 | ACGCGTCGACTTTCCAACCGTCAGCTG (Sal I) | |

| P5 | ATGACGTCATTAGAGTTCA | P5 and P6: primers for ilvE deletion identification |

| P6 | GGTCTTAAAACCGGTTGAT | |

| P7 | GGGGTACCATGAGTTCAGTTTCGCTGC (Kpn I) | P7 and P8: primers for aspB and aspB deletion identification |

| P8 | GCTCTAGATCTCCGCTGTATTCACTTTTAG (Xba I) | |

| P9 | GGAATTCTATCTTGTGAACTCCCCCAG (EcoR I) | P9 to P12, primers for aspB deletion |

| P10 | ACGCGTCGACTATCAACGATGCCATCCAG (Sal I) | |

| P11 | ACGCGTCGACCCGAAGTTCAACAAGGTTCTG (Sal I) | |

| P12 | CCCAAGCTTGGCCAGGCTCAAAATCTC (Hind III) | |

| P13 | GGAATTCTGGAGAACCATCGCATGTTTC (EcoR I) | P13 and P14: primers for tyrB |

| P14 | CGGGATCCTAATTTCACTGCAGGCTGGG (BamH I) | |

| P15 | GGAATTCATGAATAAGCTTATTGAACGAG (EcoR I) | P15 and P16: primers for ybgE |

| P16 | CGGGATCCTCACACTTCCACTGTCCAG (BamH I) | |

| P17 | GGAATTCCAGCGTTAATCTACTCATCATG (EcoR I) | P17 and P18: primers for CaIlvE |

| P18 | CGGGATCCTTTGCAACAGCCCATTC (BamH I) | |

| P19 | GGAATTCATGAATAAGCTTATTGAACGAG (EcoR I) | P19 and P20: primers for aspC |

| P20 | CGGGATCCTTACAGCACTGCCACAATCG (BamH I) | |

| P21 | GGAATTCATGAAATTGGCTGGGTTATC (EcoR I) | P21 and P22: primers for yhdR |

| P22 | CGGGATCCTGGATTGGAAGAGGAAGG (BamH I) | |

| P23 | GGGGTACCATGGAAATAACACCGTCC (Kpn I) | P23 and P24: primers for ywfG |

| P24 | GCTCTAGATTAGCGGGATGTTTCTTG (Xba I) |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, L.-Y.; Xu, J.-Z.; Zhang, W.-G. Improved l-Leucine Production in Corynebacterium glutamicum by Optimizing the Aminotransferases. Molecules 2018, 23, 2102. https://doi.org/10.3390/molecules23092102

Feng L-Y, Xu J-Z, Zhang W-G. Improved l-Leucine Production in Corynebacterium glutamicum by Optimizing the Aminotransferases. Molecules. 2018; 23(9):2102. https://doi.org/10.3390/molecules23092102

Chicago/Turabian StyleFeng, Li-Yan, Jian-Zhong Xu, and Wei-Guo Zhang. 2018. "Improved l-Leucine Production in Corynebacterium glutamicum by Optimizing the Aminotransferases" Molecules 23, no. 9: 2102. https://doi.org/10.3390/molecules23092102