Quality Traits of “Cannabidiol Oils”: Cannabinoids Content, Terpene Fingerprint and Oxidation Stability of European Commercially Available Preparations

Abstract

:1. Introduction

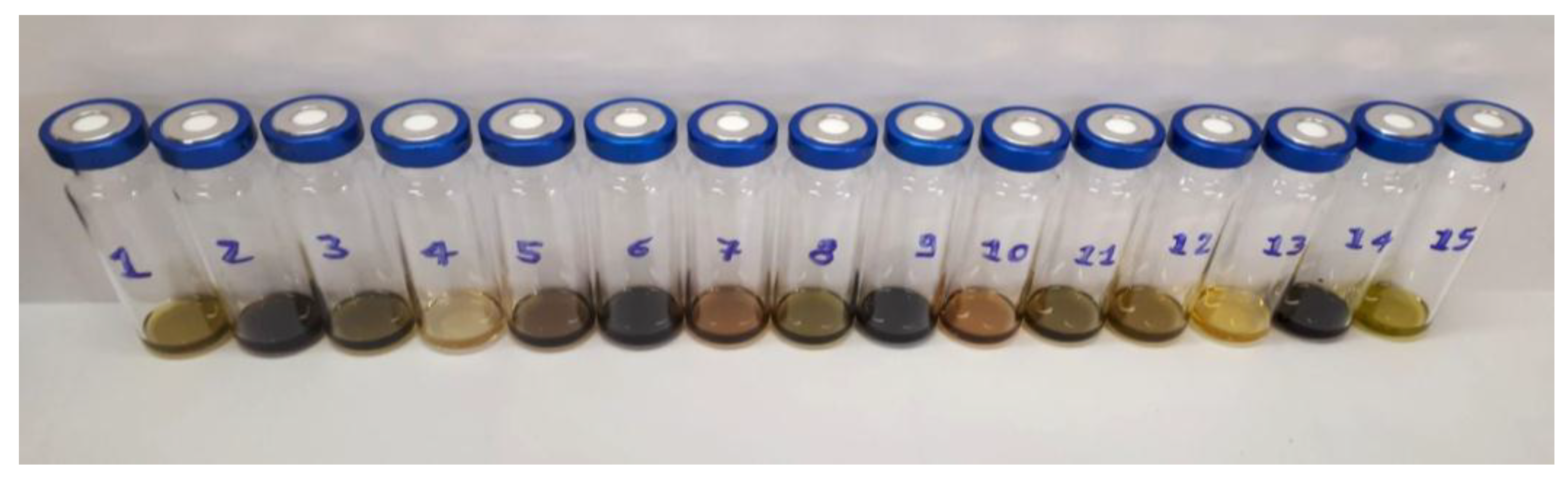

2. Results and Discussion

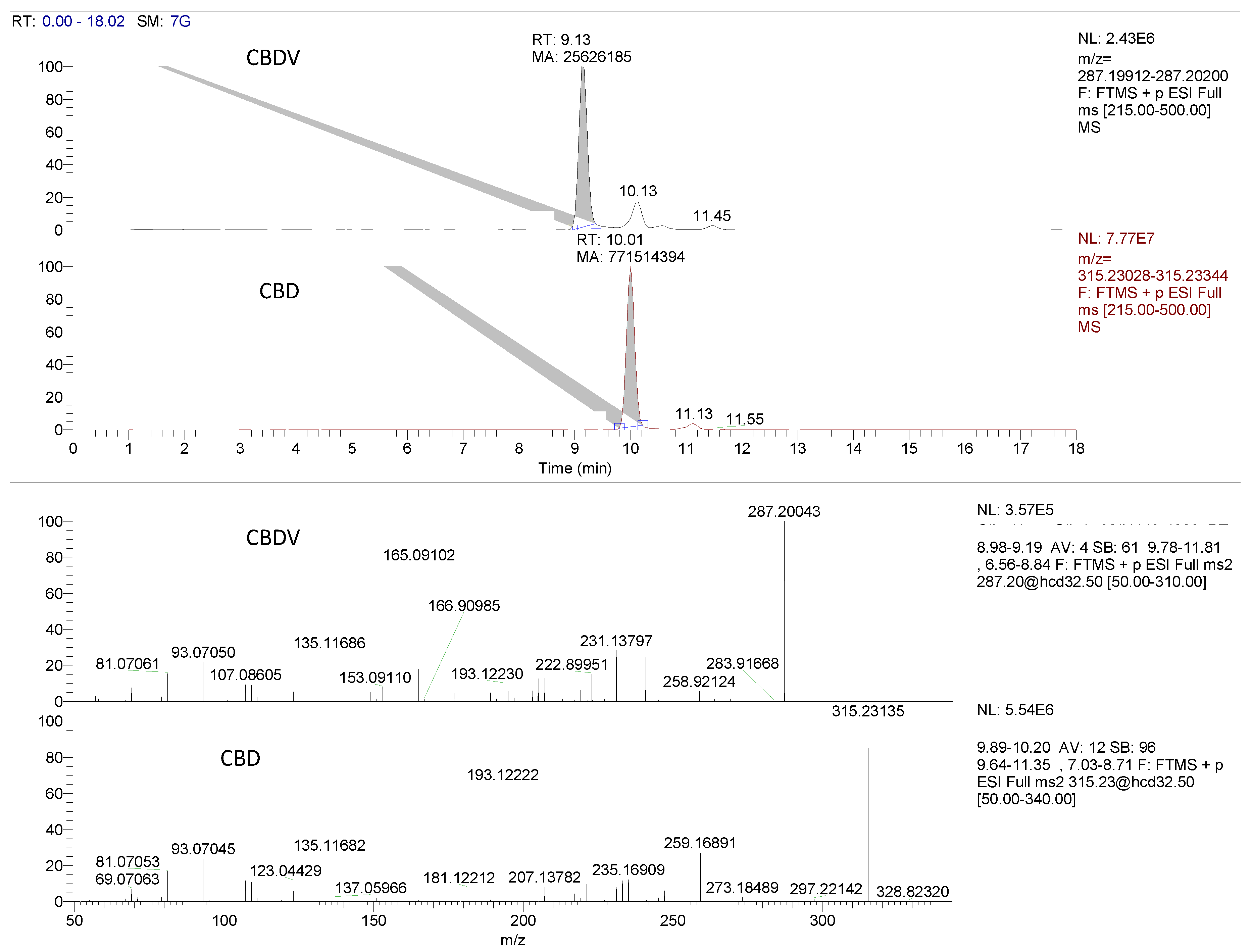

2.1. Cannabinoids Content

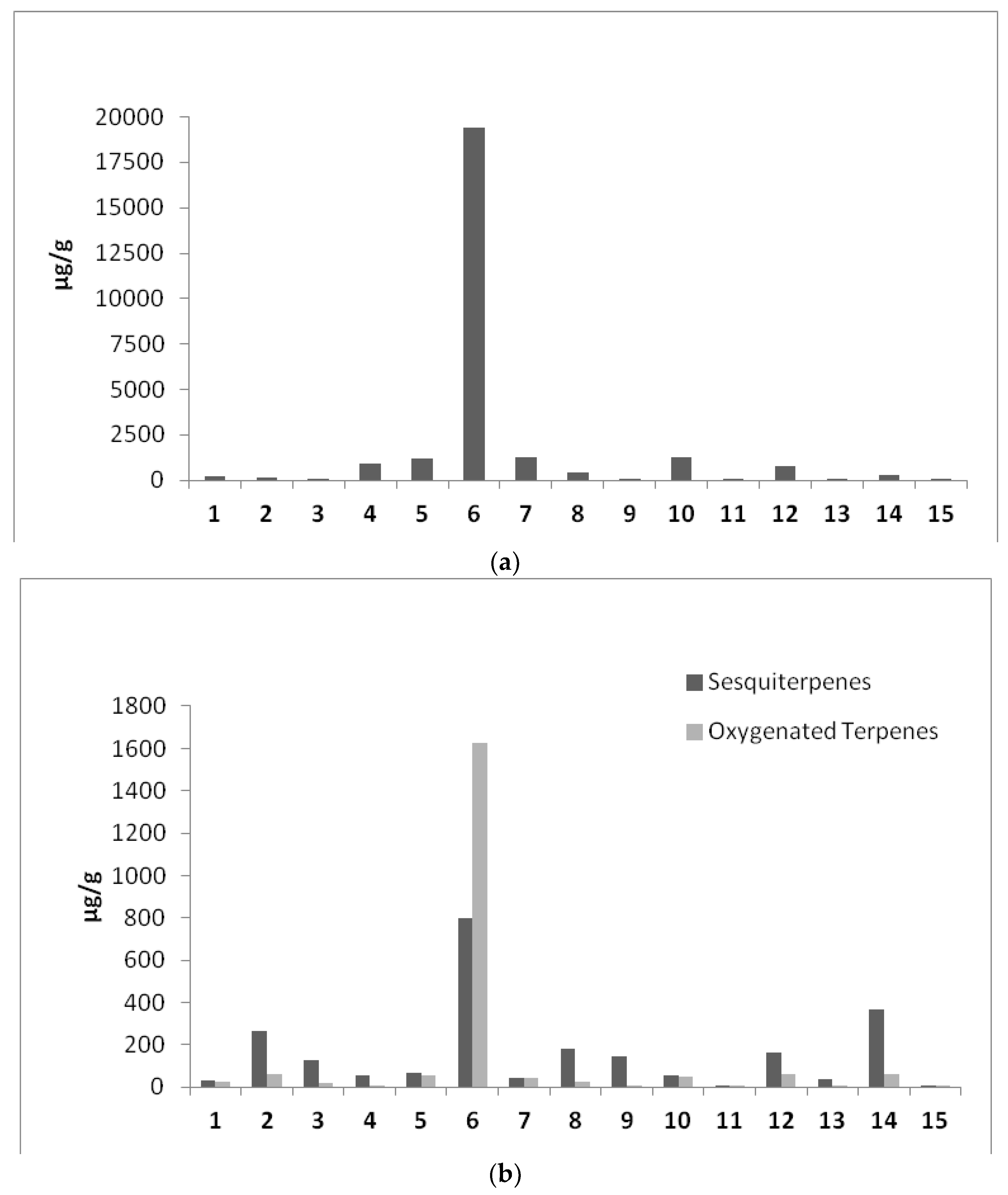

2.2. Volatile Fingerprint: Terpene Profile and Secondary Lipid’s Oxidation Products

3. Materials and Methods

3.1. Materials

3.2. Chemical and Reagents

3.3. Terpenes GC-MS Analysis

3.4. Cannabinoids LC-Q-Exactive-Orbitrap-MS Analysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References and Note

- Leung, L. Cannabis and its derivatives: Review of medical use. J. Am. Board Fam. Med. 2011, 24, 452–462. [Google Scholar] [CrossRef] [PubMed]

- Flores-Sanchez, I.J.; Verpoorte, R. Secondary metabolism in Cannabis. Phytochem. Rev. 2008, 7, 615–639. [Google Scholar] [CrossRef]

- Rong, C.; Lee, Y.; Carmona, N.E.; Cha, D.S.; Ragguett, R.M.; Rosenblat, J.D.; Mansur, R.B.; Ho, R.C.; McIntyre, R.S. Cannabidiol in medical marijuana: Research vistas and potential opportunities. Pharmacol. Res. 2017, 121, 213–218. [Google Scholar] [CrossRef] [PubMed]

- Russo, E.B. Cannabinoids in the management of difficult to treat pain. Ther. Clin. Risk Manag. 2008, 4, 245–259. [Google Scholar] [CrossRef] [PubMed]

- Whiting, P.F.; Wolff, R.F.; Deshpande, S.; Di Nisio, M.; Duffy, S.; Hernandez, A.V.; Keurentjes, J.C.; Lang, S.; Misso, K.; Ryder, S.; et al. Cannabinoids for medical use: A systematic review and meta-analysis. JAMA 2015, 313, 2456–2473. [Google Scholar] [CrossRef] [PubMed]

- Borgelt, L.M.; Franson, K.L.; Nussbaum, A.M.; Wang, G.S. The pharmacologic and clinical effects of medical cannabis. Pharmacotherapy 2013, 33, 195–209. [Google Scholar] [CrossRef] [PubMed]

- Pisanti, S.; Malfitano, A.M.; Ciaglia, E.; Lamberti, A.; Ranieri, R.; Cuomo, G.; Abate, M.; Faggiana, G.; Proto, M.C.; Fiore, D.; et al. Cannabidiol: State of the art and new challenges for therapeutic applications. Pharmacol. Ther. 2017, 175, 133–150. [Google Scholar] [CrossRef] [PubMed]

- Mead, A. The legal status of cannabis (marijuana) and cannabidiol (CBD) under U.S. law. Epilepsy Behav. 2017, 70, 288–291. [Google Scholar] [CrossRef] [PubMed]

- Carcieri, C.; Tomasello, C.; Simiele, M.; De Nicolò, A.; Avataneo, V.; Canzoneri, L.; Cusato, J.; Di Perri, G.; D’Avolio, A. Cannabinoids concentration variability in cannabis olive oil galenic preparations. J. Pharm. Pharmacol. 2018, 70, 143–149. [Google Scholar] [CrossRef] [PubMed]

- Pacifici, R.; Marchei, E.; Salvatore, F.; Guandalini, L.; Busardò, F.P.; Pichini, S. Evaluation of cannabinoids concentration and stability in standardized preparations of cannabis tea and cannabis oil by ultra-high performance liquid chromatography tandem mass spectrometry. Clin. Chem. Lab. Med. 2017, 55, 1555–1563. [Google Scholar] [CrossRef] [PubMed]

- Citti, C.; Ciccarella, G.; Braghiroli, D.; Parenti, C.; Vandelli, M.A.; Cannazza, G. Medicinal cannabis: Principal cannabinoids concentration and their stability evaluated by a high performance liquid chromatography coupled to diode array and quadrupole time of flight mass pectrometry method. J. Pharm. Biomed. Anal. 2016, 128, 201–209. [Google Scholar] [CrossRef] [PubMed]

- Calvi, L.; Pentimalli, D.; Panseri, S.; Giupponi, L.; Gelmini, F.; Beretta, G.; Vitali, D.; Bruno, M.; Zilio, E.; Pavlovic, R.; et al. Comprehensive quality evaluation of medical Cannabis sativa L. inflorescence and macerated oils based on HS-SPME coupled to GC–MS and LC-HRMS (q-exactive orbitrap®) approach. J. Pharm. Biomed. Anal. 2018, 150, 208–219. [Google Scholar] [CrossRef] [PubMed]

- Grotenhermen, M.K.F.; Lohmeyer, D. THC Limits for Food: A Scientific Study; Nova-Institute: Hürth, Germany, 2015. [Google Scholar]

- DAC/NRF. 2015/2. Cannabidiol. Available online: http://dacnrf.pharmazeutische-zeitung.de/index.php?id=557 (accessed on 1 May 2018).

- Hazekamp, A. The medicinal power of cannabis [Cannabinoïden werken - Bewezen - pijnstillend: De medicinale kracht van cannabis]. Pharm. Weekbl. 2007, 142, 38–41. [Google Scholar]

- Website: Decreto 9 novembre 2015: Funzioni di Organismo statale per la cannabis previsto dagli articoli 23 e 28 della convenzione unica sugli stupefacenti del 1961, come modificata nel 1972. Available online: http://www.gazzettaufficiale.it/eli/id/2015/11/30/15A08888/sg;jsessionid=p1rnwNujUKlqQ5azhA%20Q95A__.ntc-as3-guri2a (accessed on 1 May 2018).

- Regulation (EU) No 1307/2013 of the European Parliament and of the Council of 17 December 2013 establishing rules for direct payments to farmers under support schemes within the framework of the common agricultural policy and repealing Council Regulation (EC) No 637/2008 and Council Regulation (EC) No 73/2009; 2013.

- Attard, T.M.; Bainier, C.; Reinaud, M.; Lanot, A.; McQueen-Mason, S.J.; Hunt, A.J. Utilisation of supercritical fluids for the effective extraction of waxes and Cannabidiol (CBD) from hemp wastes. Ind. Crops Prod. 2018, 112, 38–46. [Google Scholar] [CrossRef]

- Sexton, M.; Shelton, K.; Haley, P.; West, M. Evaluation of cannabinoid and terpenoid content: Cannabis flower compared to supercritical CO2 Concentrate. Planta Med. 2018, 84, 234–241. [Google Scholar] [CrossRef] [PubMed]

- Brenneisen, R. Chemistry and Analysis of Phytocannabinoids and Other Cannabis Constituents. In Marijuana and the Cannabinoids; ElSohly, M.A., Ed.; Humana Press: New York, NY, USA, 2007; pp. 17–49. [Google Scholar]

- Rothschild, M.; Bergström, G.; Wängberg, S.A. Cannabis sativa: Volatile compounds from pollen and entire male and female plants of two variants, Northern Lights and Hawaian Indica. Bot. J. Linn. Soc. 2005, 147, 387–397. [Google Scholar] [CrossRef]

- Elzinga, S.; Fischedick, R.; Podkolinski, J.; Raber, C. Cannabinoids and terpenes as chemotaxonomic markers in cannabis. Nat. Prod. Chem. Res. 2015, 3, 181. [Google Scholar] [CrossRef]

- Lewis, M.A.; Russo, E.B.; Smith, K.M. Pharmacological Foundations of Cannabis Chemovars. Planta Med. 2018, 84, 225–233. [Google Scholar] [CrossRef] [PubMed]

- Aizpurua-Olaizola, O.; Soydaner, U.; Öztürk, E.; Schibano, D.; Simsir, Y.; Navarro, P.; Etxebarria, N.; Usobiaga, A. Evolution of the Cannabinoid and Terpene Content during the Growth of Cannabis sativa Plants from Different Chemotypes. J. Nat. Prod. 2016, 79, 324–331. [Google Scholar] [CrossRef] [PubMed]

- Russo, E.B. Taming THC: Potential cannabis synergy and phytocannabinoid-terpenoid entourage effects. Br. J. Pharmacol. 2011, 163, 1344–1364. [Google Scholar] [CrossRef] [PubMed]

- Pagano, E.; Capasso, R.; Piscitelli, F.; Romano, B.; Parisi, O.A.; Finizio, S.; Lauritano, A.; Di Marzo, V.; Izzo, A.A.; Borrelli, F. An Orally Active Cannabis Extract with High Content in Cannabidiol attenuates Chemically-induced Intestinal Inflammation and Hypermotility in the Mouse. Front. Pharmacol. 2016, 7, 341. [Google Scholar] [CrossRef] [PubMed]

- Panseri, S.; Soncin, S.; Chiesa, L.M.; Biondi, P.A. A Headspace Solid-Phase Microextraction Gas-Chromatographic Mass-Spectrometric Method (Hs-Spme-Gc/Ms) to Quantify Hexanal In Butter during Storage as Marker of Lipid Oxidation. Food Chem. 2011, 127, 886–889. [Google Scholar] [CrossRef] [PubMed]

- Raikos, V.; Konstantinidi, V.; Duthie, G. Processing and storage effects on the oxidative stability of hemp (Cannabis sativa L.) oil-in-water emulsions. Int. J. Food Sci. Technol. 2015, 50, 2316–2322. [Google Scholar] [CrossRef]

- Casiraghi, A.; Roda, G.; Casagni, E.; Cristina, C.; Musazzi, U.M.; Franzè, S.; Rocco, P.; Giuliani, C.; Fico, G.; Minghetti, P.; et al. Extraction Method and Analysis of Cannabinoids in Cannabis Olive Oil Preparations. Planta Med. 2018, 84, 242–249. [Google Scholar] [CrossRef] [PubMed]

- Bonn-Miller, M.O.; Loflin, M.J.E.; Thomas, B.F.; Marcu, J.P.; Hyke, T.; Vandrey, R. Labeling Accuracy of Cannabidiol Extracts Sold Online. JAMA 2017, 318, 1708–1709. [Google Scholar] [CrossRef] [PubMed]

- Citti, C.; Braghiroli, D.M.; Vandelli, A.; Cannazza, G. Pharmaceutical and biomedical analysis of cannabinoids: A critical review. J. Pharm. Biomed. Anal. 2018, 147, 566–579. [Google Scholar] [CrossRef] [PubMed]

- Romano, L.; Hazekamp, A. Cannabis Oil: Chemical evaluation of an upcoming cannabis based medicine. Cannabinoids 2013, 1, 1–11. [Google Scholar]

- Iannotti, F.A.; Hill, C.L.; Leo, A.; Alhusaini, A.; Soubrane, C.; Mazzarella, E.; Russo, E.; Whalley, B.J.; Di Marzo, V.; Stephens, G.J. Nonpsychotropic plant cannabinoids, cannabidivarin (CBDV) and cannabidiol (CBD), activate and desensitize transient receptor potential vanilloid 1 (TRPV1) channels in vitro: Potential for the treatment of neuronal hyperexcitability. ACS Chem. Neurosci. 2014, 5, 1131–1141. [Google Scholar] [CrossRef] [PubMed]

- Citti, C.; Pacchetti, B.; Vandelli, M.A.; Forni, F.; Cannazza, G. Analysis of cannabinoids in commercial hemp seed oil and decarboxylation kinetics studies of cannabidiolic acid (CBDA). J. Pharm. Biomed. Anal. 2018, 149, 532–540. [Google Scholar] [CrossRef] [PubMed]

- Marchini, L.M.; Charvoz, C.; Dujourdy, L.; Baldovini, N.; Filippi, J.J. Multidimensional analysis of cannabis volatile constituents: Identification of 5,5-dimethyl-1-vinylbicyclo[2.1.1] hexane as a volatile marker of hashish, the resin of Cannabis sativa. J. Chromatogr. A 2014, 1370, 200–215. [Google Scholar] [CrossRef] [PubMed]

- Novak, J.; Zitterl-Eglseer, K.; Deans, S.G.; Franz, C.M. Essential oils of different cultivars of Cannabis sativa L. and their antimicrobial activity. Flavour Fragr. J. 2001, 16, 259–262. [Google Scholar] [CrossRef]

- Guillén, M.D.; Goicoechea, E. Toxic oxygenated alpha, beta-unsaturated aldehydes and their study in foods: A review. Crit. Rev. Food Sci. Nutr. 2008, 48, 119–136. [Google Scholar] [CrossRef] [PubMed]

- Petrović, M.; Debeljak, Ž.; Kezić, N.; Džidara, P. Relationship between cannabinoids content and composition of fatty acids in hempseed oils. Food Chem. 2015, 170, 218–225. [Google Scholar] [CrossRef] [PubMed]

- Sarmento, L.; Grotenhermen, F.; Kruse, D. Scientifically Sound Guidelines for THC in Food; Nova-Institute: Hürth, Germany, 2015. [Google Scholar]

- Callaway, J.C. Hempseed as a nutritional resource: An overview. Euphytica 2004, 140, 65–72. [Google Scholar] [CrossRef]

- Callaway, J.C.; Pate, D.W. Hempseed oil. In Gourmet and Health-Promoting Specialty Oils; Moreau, R.A., Kamal-Eldin, A., Eds.; Academic Press and AOCS Press: Cambridge, MA, USA, 2009; pp. 185–213. [Google Scholar]

- Da Porto, C.; Decorti, D.; Tubaro, F. Fatty acid composition and oxidation stability of hemp (Cannabis sativa L.) seed oil extracted by supercritical carbon dioxide. Ind. Crops Prod. 2012, 36, 401–404. [Google Scholar] [CrossRef]

- Smeriglio, A.; Galati, E.M.; Monforte, M.T.; Lanuzza, F.; D’Angelo, V.; Circosta, C. Polyphenolic Compounds and Antioxidant Activity of Cold-Pressed Seed Oil from Finola Cultivar of Cannabis sativa L. Phytother. Res. 2016, 30, 1298–1307. [Google Scholar] [CrossRef] [PubMed]

- Sapino, S.; Carlotti, M.E.; Peira, E.; Gallarate, M. Hemp-seed and olive oils: Their stability against oxidation and use in O/W emulsions. J. Cosmet. Sci. 2005, 56, 227–251. [Google Scholar] [CrossRef] [PubMed]

Sample Availability: Samples of the compounds are not available from the authors. |

| (% w/w) | Cannabinoids Content (μg/g) | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Samples Code | Deviation from Declared CBD Percentage | Declared CBD 1 | Revealed CBD 2 | CBD | THC | CBN | CBG | CBDA | THCA | CBGA | ||||||||

| Average | ±SD | Average | ±SD | Average | ±SD | Average | ±SD | Average | ±SD | Average | ±SD | Average | ±SD | |||||

| Oil_1 3 | 9.00 | 0.9 | 0.89 | 8143 | 170.2 | 232 | 4.9 | 14 | 0.3 | <0.01 | / | 884 | 18.8 | 123 | 2.6 | 7 | 0.1 | |

| Oil_2 | 8.49 | 4 | 3.66 | 36,567 | 257.3 | 1908 | 13.5 | 208 | 1.5 | 716 | 5.1 | 42 | 0.3 | 1 | 0.0 | 12 | 0.1 | |

| Oil_3 | 21.21 | 1 | 0.79 | 3247 | 241.7 | 148 | 10.5 | 40 | 2.8 | 16 | 1.1 | 5282 | 373.5 | 191 | 13.5 | 693 | 49.0 | |

| Oil_4 | 15.29 | 5 | 4.24 | 42,352 | 2395.8 | 0.01 | 0.0 | 3 | 0.2 | <0.01 | / | 6 | 0.3 | 196 | 11.1 | 19 | 1.1 | |

| Oil_5 | 10.53 | 4 | 4.42 | 43,509 | 3076.6 | 533 | 37.7 | 69 | 4.9 | <0.01 | / | 802 | 56.7 | 17 | 1.2 | 27 | 1.9 | |

| Oil_6 | 4.44 | 3 | 2.87 | 28,536 | 1008.9 | 3546 | 125.4 | 481 | 17.0 | <0.01 | / | 152 | 5.4 | 29 | 1.0 | 8 | 0.3 | |

| Oil_7 | 8.27 | 4 | 4.33 | 42,601 | 1807.4 | 526 | 22.3 | 65 | 2.8 | <0.01 | / | 804 | 34.1 | 12 | 0.5 | 26 | 1.1 | |

| Oil_8 | 35.41 | 3 | 4.06 | 39,962 | 3108.3 | 695 | 54.1 | 62 | 4.8 | <0.01 | / | 753 | 58.6 | 47 | 3.7 | 22 | 1.7 | |

| Oil_9 | 7.63 | 3 | 3.23 | 32,212 | 683.3 | 1607 | 34.1 | 345 | 7.3 | 23 | 0.5 | 88 | 1.9 | 25 | 0.5 | 6 | 0.1 | |

| Oil_10 | 23.89 | 4 | 4.96 | 48,879 | 1036.9 | 557 | 11.8 | 79 | 1.7 | <0.01 | / | 774 | 16.4 | 58 | 1.2 | 23 | 0.5 | |

| Oil_11 | / | / | 0.24 | 1875 | 68.9 | 36 | 1.3 | 7 | 0.3 | <0.01 | / | 634 | 23.3 | 32 | 1.2 | 18 | 0.7 | |

| Oil_12 | 19.28 | 2 | 1.61 | 12,758 | 180.4 | 494 | 7.0 | 188 | 2.7 | 6 | 0.1 | 3862 | 54.6 | 107 | 1.5 | 97 | 1.4 | |

| Oil_13 | 36.20 | 4 | 2.55 | 24,444 | 2419.8 | 568 | 56.2 | 1105 | 109.4 | 624 | 61.8 | 1229 | 121.7 | 27 | 2.7 | 22 | 2.2 | |

| Oil_14 | 38.14 | 5 | 3.09 | 23,186 | 655.8 | 524 | 14.8 | 67 | 1.9 | 460 | 13.0 | 8828 | 249.7 | 358 | 10.1 | 216 | 6.1 | |

| Oil_15 | 24.33 | 3 | 2.27 | 22,692 | 320.9 | <0.01 | / | <0.01 | / | 5687 | 80.4 | 9 | 0.1 | <0.01 | / | 4 | 0.1 | |

| Oil Samples | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | ||||||||||

| Matrix | FU Oil | Hemp Seed Oil | Olive Oil | MCT Oil | Olive Oil | Hemp Seed Oil | Olive Oil | Hemp Seed Oil | ||||||||||

| RI a | R.T b | Compound | Averagec μg/g | SD (±) | Average c μg/g | SD (±) | Average c μg/g | SD (±) | Average c μg/g | SD (±) | Average c μg/g | SD (±) | Average c μg/g | SD (±) | Average c μg/g | SD (±) | Average c μg/g | SD (±) |

| Alcohols | ||||||||||||||||||

| 831 | 20.63 | 1-Hexanol | 2.08 | 0.14 | 5.15 | 0.71 | n.d. | - | n.d. | - | 2.55 | 0.16 | 8.10 | 0.12 | 2.58 | 0.03 | 11.52 | 0.37 |

| 868 | 21.43 | 3-Hexen-1-ol | 0.66 | 0.07 | 0.67 | 0.11 | n.d. | - | 0.55 | 0.02 | 1.47 | 0.08 | 1.46 | 0.04 | 1.76 | 0.05 | n.d. | - |

| 849 | 22.02 | 2-Hexen-1-ol | n.d. | - | n.d. | - | n.d. | - | n.d. | - | 0.77 | 0.11 | n.d. | - | 1.10 | - | n.d. | - |

| 969 | 23.07 | 1-Octen-3-ol | n.d. | - | 3.90 | 0.47 | n.d. | - | n.d. | - | 0.73 | 0.15 | 1.73 | 0.03 | 1.09 | 0.51 | n.d. | - |

| 960 | 23.17 | 1-Heptanol | n.d. | - | 0.83 | 0.13 | n.d. | - | n.d. | - | 0.50 | 0.01 | 2.49 | 0.10 | n.d. | - | n.d. | - |

| 1059 | 25.48 | 1-Octanol | n.d. | - | n.d. | - | 1.29 | 0.11 | n.d. | - | 0.59 | 0.03 | 5.23 | 0.63 | n.d. | - | n.d. | - |

| 1068 | 27.98 | 3,3,6-Trimethyl-1,5-heptadien-4-ol | 2.39 | 0.46 | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - |

| 1036 | 31.59 | α-Toluenol | 0.42 | 0.03 | 2.74 | 0.59 | n.d. | - | n.d. | - | 2.36 | 0.16 | 3.96 | 0.47 | 3.22 | 0.23 | n.d. | - |

| 1136 | 32.06 | Benzeneethanol | 0.51 | 0.04 | 1.39 | 0.32 | n.d. | - | n.d. | - | 2.73 | 0.16 | 5.05 | 0.58 | 3.43 | 0.22 | 0.76 | 0.01 |

| Total | 6.06 | 14.68 | 1.29 | 0.55 | 11.70 | 28.01 | 13.18 | 12.28 | ||||||||||

| Aldehydes | ||||||||||||||||||

| 508 | 2.31 | Propanal | n.d. | - | n.d. | - | 0.77 | 0.03 | n.d. | - | 0.96 | 0.04 | 1.10 | 0.08 | 0.97 | 0.05 | n.d. | - |

| 574 | 3.23 | 2-Methyl-2-propenal | n.d. | - | n.d. | - | 0.61 | 0.03 | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - |

| 643 | 3.74 | 2-Methyl-butanal | 1.73 | 0.02 | 0.56 | 0.02 | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - |

| 643 | 3.83 | 3-Methyl-butanal | 0.90 | 0.16 | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - |

| 785 | 10.12 | Hexanal | 0.70 | 0.02 | 5.57 | 0.14 | 10.15 | 0.29 | n.d. | - | 2.97 | 0.17 | 6.89 | 0.01 | 2.60 | 0.15 | 3.42 | 0.03 |

| 905 | 15.05 | Heptanal | 0.76 | 0.03 | n.d. | - | 1.03 | 0.03 | n.d. | - | n.d. | - | n.d. | - | 0.67 | 0.10 | 0.62 | 0.03 |

| 814 | 16.24 | 2-Hexenal | n.d. | - | n.d. | - | n.d. | - | n.d. | - | 1.19 | 0.12 | n.d. | - | 1.41 | 0.03 | n.d. | - |

| 1005 | 18.74 | Octanal | n.d. | - | n.d. | - | 2.47 | 0.02 | n.d. | - | 2.03 | 0.23 | 17.40 | 0.16 | 1.87 | 0.03 | n.d. | - |

| 913 | 19.72 | 2-Heptenal | n.d. | - | 3.10 | 0.05 | 2.61 | 0.22 | n.d. | - | 1.86 | 0.09 | 6.44 | 0.41 | 1.59 | 0.03 | 1.22 | 0.05 |

| 1104 | 21.67 | Nonanal | 0.73 | 0.16 | n.d. | - | 2.63 | 0.30 | n.d. | - | n.d. | - | 4.92 | 0.03 | 1.07 | - | n.d. | - |

| 1013 | 22.53 | 2-Octenal | n.d. | - | n.d. | - | 0.68 | 0.05 | n.d. | - | n.d. | - | 2.07 | 0.08 | n.d. | - | 0.61 | 0.02 |

| 921 | 24.01 | 2,4-Heptadienal | n.d. | - | 1.27 | 0.05 | 0.74 | 0.14 | n.d. | - | n.d. | - | 7.97 | 0.34 | n.d. | - | n.d. | - |

| 982 | 24.77 | Benzaldehyde | n.d. | - | n.d. | - | n.d. | - | n.d. | - | 1.86 | 0.01 | 25.84 | 0.45 | n.d. | - | n.d. | - |

| 1174 | 28.04 | 3,7-Dimethyl-2,6-octadienal | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | 44.49 | 4.40 | n.d. | - | n.d. | - |

| Total | 4.82 | 10.50 | 21.68 | n.d. | 10.87 | 117.14 | 10.19 | 5.88 | ||||||||||

| Esters | ||||||||||||||||||

| 487 | 2.63 | Acetic acid-methyl ester | 0.78 | 0.02 | 0.72 | 0.04 | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - |

| 586 | 3.33 | Acetic acid-ethyl ester | n.d. | - | 8.70 | 0.12 | 302.74 | 12.32 | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - |

| 686 | 5.35 | Acetic acid-propyl ester | n.d. | - | n.d. | - | 1.45 | 0.07 | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - |

| 721 | 6.77 | Acetic acid-2-methyl-propyl ester | n.d. | - | n.d. | - | 5.39 | 0.06 | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - |

| 785 | 9.76 | Acetic acid-buthyl ester | n.d. | - | n.d. | - | 1.17 | 0.11 | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - |

| 820 | 12.27 | 1-Butanol-3-methyl acetate | n.d. | - | n.d. | - | 7.46 | 0.17 | n.d. | - | n.d. | - | 16.98 | 0.21 | n.d. | - | n.d. | - |

| 992 | 19.62 | 3-Hexen-1-ol-acetate | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | 0.64 | 0.02 | n.d. | - |

| 1183 | 22.24 | Butanoic acid-hexyl ester | n.d. | - | n.d. | - | n.d. | - | 0.60 | 0.02 | n.d. | - | n.d. | - | n.d. | - | n.d. | - |

| Total | 0.78 | 9.42 | 318.21 | 0.60 | n.d. | 16.98 | 0.64 | n.d. | ||||||||||

| Ketones | ||||||||||||||||||

| 455 | 2.50 | 2-Propanone | 1.76 | 0.13 | 3.50 | 0.47 | 8.56 | 0.57 | n.d. | - | 2.46 | 0.51 | 5.03 | 0.65 | 1.78 | 0.14 | 0.96 | 0.01 |

| 1161 | 13.19 | 1-(1,3-dimethyl-3-cyclohexen-1-yl)-Ethanone | n.d. | - | 1.89 | 0.18 | n.d. | - | n.d. | - | n.d. | - | 2.07 | 0.15 | n.d. | - | 0.90 | 0.06 |

| 853 | 14.89 | 2-Heptanone | n.d. | - | 3.32 | 0.09 | 0.71 | 0.02 | n.d. | - | 2.69 | 0.16 | n.d. | - | 2.74 | 0.06 | 1.00 | 0.06 |

| 952 | 18.57 | 2-Octanone | n.d. | - | 4.63 | 0.64 | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - |

| 960 | 19.99 | 6-Octen-2-one | n.d. | - | 0.86 | 0.11 | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - |

| 987 | 20.17 | 6-Methyl-5 hepten-2 one | 1.25 | 0.04 | 8.97 | 1.20 | 10.55 | 0.42 | n.d. | - | 2.28 | 0.11 | 17.04 | 0.14 | 1.63 | 0.00 | 2.26 | 0.13 |

| 960 | 21.96 | 3-Octen-2-one | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - |

| 962 | 22.51 | Ketone | 0.69 | 0.02 | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - |

| 968 | 24.67 | 3,5-Octadien-2-one | n.d. | - | n.d. | - | 4.94 | 0.41 | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - |

| Total | 3.70 | 23.17 | 24.77 | n.d. | 7.44 | 24.14 | 6.15 | 5.12 | ||||||||||

| Terpenes | ||||||||||||||||||

| 939 | 6.67 | α-Pinene | 14.25 | 0.55 | 21.47 | 0.38 | n.d. | - | 73.23 | 9.63 | 112.95 | 1.47 | 5883.13 | 22.05 | 119.09 | 0.23 | 52.84 | 1.11 |

| 932 | 7.03 | α-Thujene | 0.98 | 0.17 | 1.18 | 0.08 | n.d. | - | 0.79 | 0.08 | 2.86 | 0.19 | 44.54 | 1.08 | 3.24 | 0.10 | n.d. | - |

| 961 | 8.67 | Camphene | n.d. | - | n.d. | - | n.d. | - | 0.94 | 0.27 | 1.57 | 0.09 | 65.97 | 3.91 | 1.60 | 0.01 | 0.95 | 0.03 |

| 989 | 10.75 | β-Pinene | 4.15 | 0.05 | 4.45 | 0.08 | n.d. | - | 23.36 | 4.71 | 35.65 | 2.06 | 625.28 | 4.35 | 37.08 | 0.48 | 17.91 | 0.28 |

| 985 | 11.66 | Sabinene | n.d. | - | 1.26 | 0.07 | n.d. | - | n.d. | - | 1.66 | 0.01 | 98.17 | 0.06 | 1.53 | 0.08 | n.d. | - |

| 879 | 11.74 | 2,4(10)-Thujadien | n.d. | - | 0.85 | 0.00 | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - |

| 1017 | 12.99 | δ-3-Carene | 1.73 | 0.03 | 0.61 | 0.09 | n.d. | - | 7.42 | 1.33 | 50.22 | 1.18 | 4.69 | 0.31 | 51.31 | 2.68 | 6.17 | 0.50 |

| 1015 | 13.81 | α-Phellandrene | 3.70 | 0.14 | 3.90 | 0.09 | n.d. | - | 2.91 | 0.65 | 6.78 | 0.01 | 4.97 | 0.04 | 8.06 | 0.18 | 1.85 | 0.09 |

| 991 | 14.24 | β-Myrcene | 108.13 | 0.09 | 34.63 | 1.00 | 9.14 | 0.48 | 419.53 | 33.32 | 389.37 | 20.60 | 2908.00 | 60.01 | 419.01 | 6.04 | 189.05 | 1.74 |

| 1026 | 14.44 | α-Terpinene | 3.60 | 0.38 | 10.01 | 0.56 | n.d. | - | 2.44 | 0.07 | 5.51 | 0.17 | 34.87 | 3.09 | 6.82 | 0.12 | 1.74 | 0.01 |

| 1038 | 15.31 | Limonene | 6.05 | 0.01 | 8.03 | 0.44 | 1.60 | 0.07 | 65.17 | 7.36 | 23.67 | 1.33 | 8841.42 | 171.34 | 20.17 | 0.26 | 23.97 | 0.34 |

| 1045 | 15.49 | Eucalyptol | 3.67 | 0.01 | 5.60 | 0.35 | 7.15 | 0.26 | 2.65 | 0.13 | 4.18 | 0.27 | 13.66 | 1.60 | 3.09 | 0.07 | 8.62 | 0.12 |

| 946 | 15.61 | β-Phellandrene | 7.16 | 0.14 | 4.80 | 0.52 | n.d. | - | 8.40 | 0.80 | 19.02 | 1.05 | 61.90 | 4.71 | 20.05 | 0.16 | 7.38 | 0.22 |

| 976 | 17.05 | Cis-ocimene | 0.48 | 0.02 | 2.17 | 0.17 | 0.48 | 0.00 | 16.55 | 1.07 | 21.17 | 0.88 | 7.13 | 0.24 | 19.24 | 0.23 | 5.50 | 0.11 |

| 1066 | 17.15 | γ-Terpinene | 5.38 | 0.01 | 5.84 | 0.58 | 0.59 | 0.06 | 2.11 | 0.09 | 4.80 | 0.23 | 499.58 | 9.26 | 4.61 | 0.08 | 2.48 | 0.04 |

| 1000 | 17.24 | Terpene | n.d. | - | n.d. | - | 2.48 | 0.24 | n.d. | - | 2.59 | 0.02 | 17.49 | 0.05 | 1.82 | 0.04 | n.d. | - |

| 1029 | 17.60 | β-Ocimene | 21.75 | 1.08 | 7.55 | 0.53 | 9.96 | 0.48 | 194.00 | 21.13 | 192.39 | 5.19 | 22.82 | 0.17 | 213.15 | 1.26 | 42.00 | 1.72 |

| 1034 | 18.01 | p-Cymene | 3.13 | 0.11 | 8.53 | 0.97 | 0.81 | 0.01 | 2.98 | 0.33 | 12.37 | 0.05 | 144.55 | 1.92 | 10.02 | 0.15 | 5.62 | 0.09 |

| 1094 | 18.43 | α-Terpinolene | 62.12 | 0.67 | 7.48 | 0.80 | n.d. | - | 111.31 | 14.58 | 265.95 | 16.97 | 33.73 | 0.11 | 297.20 | 3.11 | 73.16 | 3.13 |

| 1177 | 22.74 | Para-cymenyl | 13.97 | 0.88 | 11.28 | 0.16 | n.d. | - | 3.30 | 0.82 | 64.48 | 5.97 | 134.94 | 1.32 | 49.21 | 0.39 | 4.70 | 0.24 |

| 1136 | 23.01 | Terpene | n.d. | - | n.d. | - | n.d. | - | 1.55 | 0.36 | 1.39 | 0.11 | n.d. | - | 1.43 | 0.05 | n.d. | - |

| 1083 | 23.35 | 4,8-Epoxy-p-menth-1-ene | 1.30 | 0.08 | 2.08 | 0.23 | n.d. | - | 2.22 | 0.03 | 6.44 | 0.16 | 3.08 | 0.03 | 5.20 | 0.60 | 1.32 | 0.01 |

| 1164 | 23.48 | Linalool oxide | n.d. | - | n.d. | - | n.d. | - | n.d. | - | 1.11 | 0.03 | 17.95 | 0.94 | 1.51 | 0.01 | n.d. | - |

| 1221 | 23.68 | α-Ylangene | n.d. | - | 1.09 | 0.23 | n.d. | - | n.d. | - | 0.52 | 0.00 | 2.19 | 0.09 | n.d. | - | 1.18 | 0.07 |

| 1082 | 25.29 | β-Linalool | 5.52 | 0.81 | 2.22 | 0.32 | 10.55 | 1.27 | 0.82 | 0.01 | 5.19 | 0.01 | 1471.75 | 15.90 | 5.36 | 0.37 | n.d. | - |

| 1494 | 25.75 | γ-Caryophyllene | n.d. | - | 5.87 | 1.68 | 2.02 | 0.24 | 1.03 | 0.06 | 1.81 | 0.05 | 30.72 | 1.10 | 1.32 | 0.04 | 4.40 | 0.17 |

| 1430 | 26.03 | α-Bergamotene | 2.42 | 0.21 | 11.89 | 3.95 | 1.75 | 0.08 | 2.21 | 0.19 | 2.31 | 0.02 | 40.96 | 0.21 | 1.01 | 0.08 | 9.44 | 0.07 |

| 1456 | 26.12 | α-Guaiene | 2.46 | 0.05 | n.d. | - | 7.19 | 0.57 | n.d. | - | n.d. | - | 5.20 | 0.18 | n.d. | - | n.d. | - |

| 1494 | 26.23 | Trans-caryophyllene | 17.34 | 1.81 | 159.92 | 49.08 | 90.68 | 7.15 | 40.67 | 3.44 | 48.77 | 1.93 | 425.63 | 7.84 | 32.06 | 4.48 | 110.41 | 1.33 |

| Terpenes | ||||||||||||||||||

| 1209 | 26.40 | 4-Terpineol | 2.32 | 0.23 | 3.34 | 0.62 | 0.55 | 0.06 | n.d. | - | 2.80 | 0.24 | 15.34 | 1.66 | 1.71 | 0.18 | n.d. | - |

| 1440 | 26.59 | Sesquiterpene | n.d. | - | 3.03 | 0.70 | 1.37 | 0.18 | n.d. | - | 1.64 | 0.07 | 17.73 | 0.11 | n.d. | - | 1.13 | 0.10 |

| 1386 | 27.21 | Sesquiterpene | n.d. | - | 6.09 | 2.17 | n.d. | - | n.d. | - | 0.58 | 0.05 | 12.62 | 0.59 | n.d. | - | 7.01 | 0.26 |

| 1131 | 27.47 | Trans-pinocarveol | n.d. | - | 9.69 | 1.69 | n.d. | - | n.d. | - | 3.04 | 0.07 | 10.99 | 0.49 | 2.30 | 0.08 | 5.12 | 0.08 |

| 1482 | 27.73 | α-Humulene | 6.28 | 0.44 | 45.95 | 15.88 | 21.61 | 1.49 | 10.13 | 1.54 | 9.62 | 0.69 | 117.14 | 3.27 | 5.94 | 0.88 | 32.25 | 1.15 |

| 1189 | 28.13 | 1,8-Menthadien-4-ol | 6.23 | 1.02 | 21.18 | 4.16 | n.d. | - | 2.19 | 0.43 | 19.68 | 0.44 | 44.91 | 2.39 | 12.61 | 0.58 | 6.86 | 0.41 |

| 1209 | 28.32 | α-Terpineol | 2.79 | 0.43 | 3.31 | 0.85 | 1.13 | 0.02 | n.d. | - | 2.90 | 0.24 | 14.35 | 1.10 | 1.83 | 0.04 | 0.63 | 0.07 |

| 1189 | 28.40 | Borneol | 0.52 | 0.04 | 2.78 | 0.74 | n.d. | - | n.d. | - | 0.64 | 0.04 | 1.59 | 2.25 | n.d. | - | n.d. | - |

| 1490 | 28.65 | δ-Guaiene | 1.56 | 0.01 | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - |

| 1519 | 28.72 | β-Selinene | 0.85 | 0.01 | 11.64 | 4.28 | 1.65 | 0.02 | 0.96 | 0.19 | 1.46 | 0.13 | 41.02 | 1.77 | 0.85 | 0.17 | 8.15 | 0.36 |

| 1522 | 28.82 | α-Selinene | 1.04 | 0.01 | 7.51 | 2.69 | 1.06 | 0.14 | n.d. | - | 1.04 | 0.06 | 26.41 | 1.64 | n.d. | - | 4.51 | 0.20 |

| 1474 | 28.98 | Sesquiterpene | n.d. | - | 1.88 | 0.58 | n.d. | - | n.d. | - | n.d. | - | 53.97 | 6.99 | n.d. | - | 0.92 | 0.02 |

| 1190 | 29.03 | Carvone | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - |

| 1507 | 29.86 | Selina-3,7(11)-diene | n.d. | - | 6.79 | 2.41 | n.d. | - | 0.96 | 0.31 | 1.85 | 0.06 | 25.33 | 2.61 | n.d. | - | 3.78 | 0.21 |

| 1191 | 30.13 | Myrtenol | n.d. | - | 1.49 | 0.26 | n.d. | - | n.d. | - | 0.94 | 0.04 | 3.18 | 0.40 | n.d. | - | 0.80 | 0.03 |

| 1284 | 31.17 | Cuminol | 4.00 | 0.64 | 7.44 | 1.98 | n.d. | - | 0.54 | 0.07 | 7.87 | 0.61 | 30.26 | 3.84 | 7.02 | 0.08 | 1.46 | 0.10 |

| 1322 | 33.41 | Humulene oxide | n.d. | - | 2.22 | 0.92 | 0.72 | 0.13 | n.d. | - | n.d. | - | n.d. | - | n.d. | - | 1.36 | 0.14 |

| 1419 | 34.11 | Sesquiterpene | n.d. | - | n.d. | - | 1.54 | 0.03 | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - |

| 1392 | 34.86 | Eugenol | n.d. | - | n.d. | - | n.d. | - | n.d. | - | 0.82 | 0.00 | 1.12 | 0.05 | 1.17 | 0.02 | n.d. | - |

| Total | 314.90 | 457.03 | 174.05 | 1000.37 | 1339.56 | 21860.3 | 1367.63 | 644.70 | ||||||||||

| Miscellaneous | ||||||||||||||||||

| 906 | 11.03 | 3,3,6-Trimethyl-1,5-heptadiene | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | 11.87 | 0.33 | n.d. | - | n.d. | - |

| 907 | 12.72 | 1,3-Dimethyl-benzene | n.d. | - | 0.96 | 0.08 | n.d. | - | 2.17 | 0.38 | n.d. | - | 1.41 | 0.02 | n.d. | - | n.d. | - |

| 1040 | 16.87 | 2-Pentyl-furan | n.d. | - | 1.82 | 0.20 | n.d. | - | n.d. | - | 0.24 | 0.01 | 3.94 | 0.10 | n.d. | - | 1.99 | 0.07 |

| 1020 | 18.31 | 1,2,4,-Trimethyl-benzene | n.d. | - | n.d. | - | 1.35 | 0.38 | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - |

| 894 | 19.54 | 2,5-Dimethyl-pyrazine | 1.03 | 0.05 | n.d. | - | n.d. | - | n.d. | - | n.d. | - | 1.23 | 0.04 | n.d. | - | n.d. | - |

| 891 | 19.74 | 2,6-Dimethyl-pyrazine | 0.82 | 0.03 | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - |

| 1176 | 20.72 | 1,4-Bis (1-methylethyl)-benzene | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | 1.81 | 0.01 | n.d. | - | n.d. | - |

| 985 | 21.89 | 2,6-Dimethyl-2,6-octadiene | n.d. | - | n.d. | - | 3.25 | 0.14 | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - |

| 1081 | 22.10 | Diethyl carbitol | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - |

| 1039 | 22.36 | 1,3,5-Trimethylenecycloheptane | n.d. | - | 1.07 | 0.26 | n.d. | - | 0.80 | 0.12 | 1.52 | 0.00 | 2.62 | 0.06 | 1.70 | 0.02 | n.d. | - |

| 986 | 28.45 | 5-Ethyldihydro-2(3H)-furanone | n.d. | - | 1.92 | 0.14 | n.d. | - | n.d. | - | 3.89 | 0.41 | 27.39 | 2.75 | 6.63 | 0.41 | 0.96 | 0.15 |

| 1190 | 30.85 | 1-Methoxy-4(1-propenyl)-benzene | n.d. | - | n.d. | - | n.d. | - | 3.22 | 0.07 | n.d. | - | n.d. | - | n.d. | - | n.d. | - |

| Total | 1.85 | 7.19 | 4.60 | 6.19 | 8.38 | 54.23 | 10.93 | 2.95 | ||||||||||

| Oil Samples | 9 | 10 | 11 | 12 | 13 | 14 | 15 | |||||||||||

| Matrix | Hemp Seed Oil | Olive Oil | Hemp Seed Oil | Hemp Seed Oil | Olive Oil | Hemp Seed Oil | Hemp Seed Oil | |||||||||||

| RI a | R.T b | Compound | Average c μg/g | SD (±) | Average c μg/g | SD (±) | Average c μg/g | SD (±) | Average c μg/g | SD (±) | Average c μg/g | SD (±) | Average c μg/g | SD (±) | Averagec μg/g | SD (±) | ||

| Alcohols | ||||||||||||||||||

| 831 | 20.63 | 1-Hexanol | 6.19 | 0.32 | 2.66 | 0.08 | 2.00 | 0.14 | 4.37 | 0.20 | 0.67 | 0.02 | 3.52 | 0.23 | 9.67 | 0.16 | ||

| 868 | 21.43 | 3-Hexen-1-ol | n.d. | - | 1.81 | 0.03 | n.d. | - | n.d. | - | 0.65 | 0.01 | 0.86 | 0.06 | n.d. | - | ||

| 849 | 22.02 | 2-Hexen-1-ol | n.d. | - | 1.15 | 0.05 | n.d. | - | 0.62 | 0.07 | 0.63 | 0.00 | n.d. | - | n.d. | - | ||

| 969 | 23.07 | 1-Octen-3-ol | 1.08 | 0.03 | 0.79 | 0.01 | 1.26 | 0.13 | 1.23 | 0.07 | n.d. | - | 1.35 | 0.00 | n.d. | - | ||

| 960 | 23.17 | 1-Heptanol | n.d. | - | n.d. | - | n.d. | - | 0.72 | 0.04 | n.d. | - | n.d. | - | n.d. | - | ||

| 1059 | 25.48 | 1-Octanol | n.d. | - | 0.58 | 0.11 | n.d. | - | n.d. | - | n.d. | - | 2.30 | 0.25 | n.d. | - | ||

| 1068 | 27.98 | 3,3,6-Trimethyl-1,5-heptadien-4-ol | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | 1.56 | 0.10 | n.d. | - | ||

| 1036 | 31.59 | α-Toluenol | n.d. | - | 3.03 | 0.35 | n.d. | - | 1.39 | 0.15 | n.d. | - | 2.08 | 0.61 | n.d. | - | ||

| 1136 | 32.06 | Benzeneethanol | 0.62 | 0.03 | 3.07 | 0.62 | n.d. | - | 1.25 | 0.01 | 0.87 | 0.13 | 2.72 | 0.98 | n.d. | - | ||

| Total | 7.89 | 13.09 | 3.26 | 9.57 | 2.82 | 14.38 | 9.67 | |||||||||||

| Aldehydes | ||||||||||||||||||

| 508 | 2.31 | Propanal | n.d. | - | 1.04 | 0.00 | n.d. | - | n.d. | - | 0.97 | 0.02 | 0.62 | 0.10 | n.d. | - | ||

| 574 | 3.23 | 2-Methyl-2-propenal | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | ||

| 643 | 3.74 | 2-Methyl-butanal | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | ||

| 643 | 3.83 | 3-Methyl-butanal | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | ||

| 785 | 10.12 | Hexanal | 6.35 | 0.40 | 2.53 | 0.01 | 10.51 | 0.36 | 7.04 | 0.29 | 3.18 | 0.36 | 2.60 | 0.18 | 1.80 | 0.12 | ||

| 905 | 15.05 | Heptanal | n.d. | - | 0.63 | 0.03 | 0.46 | 0.02 | n.d. | - | n.d. | - | n.d. | - | n.d. | - | ||

| 814 | 16.24 | 2-Hexenal | 1.23 | 0.06 | 1.41 | 0.03 | 1.02 | 0.02 | 0.53 | 0.75 | 11.50 | 0.40 | 0.82 | 0.04 | n.d. | - | ||

| 1005 | 18.74 | Octanal | n.d. | - | 1.92 | 0.07 | n.d. | - | 1.93 | 0.32 | n.d. | - | n.d. | - | n.d. | - | ||

| 913 | 19.72 | 2-Heptenal | 1.17 | 0.05 | 1.72 | 0.09 | 5.21 | 0.57 | 8.29 | 0.77 | 1.54 | 0.00 | 5.44 | 0.12 | 1.11 | 0.02 | ||

| 1104 | 21.67 | Nonanal | n.d. | - | 1.20 | 0.14 | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | ||

| 1013 | 22.53 | 2-Octenal | 1.49 | 0.02 | n.d. | - | n.d. | - | 0.95 | 0.00 | n.d. | - | n.d. | - | n.d. | - | ||

| 921 | 24.01 | 2,4-Heptadienal | 8.05 | 0.11 | n.d. | - | 2.31 | 0.19 | 1.37 | 0.20 | n.d. | - | 1.24 | 0.02 | n.d. | - | ||

| 982 | 24.77 | Benzaldehyde | 1.45 | 0.18 | n.d. | - | 1.90 | 1.67 | 1.55 | 0.31 | 0.43 | 0.10 | 8.46 | 3.09 | n.d. | - | ||

| 1174 | 28.04 | 3,7-Dimethyl-2,6-octadienal | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | 1.30 | 0.07 | n.d. | - | ||

| Total | 19.73 | 10.43 | 21.41 | 21.66 | 17.61 | 20.48 | 2.92 | |||||||||||

| 487 | 2.63 | Acetic acid-methyl ester | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | ||

| 586 | 3.33 | Acetic acid-ethyl ester | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | ||

| 686 | 5.35 | Acetic acid-propyl ester | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | ||

| 721 | 6.77 | Acetic acid-2-methyl-propyl ester | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | ||

| 785 | 9.76 | Acetic acid-buthyl ester | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | ||

| 820 | 12.27 | 1-Butanol-3-methyl acetate | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | ||

| 992 | 19.62 | 3-Hexen-1-ol-acetate | n.d. | - | 0.66 | 0.01 | n.d. | - | n.d. | - | 0.82 | 0.08 | n.d. | - | n.d. | - | ||

| 1183 | 22.24 | Butanoic acid-hexyl ester | n.d. | - | 0.53 | 0.04 | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | ||

| Total | n.d. | 1.19 | n.d. | n.d. | 0.82 | n.d. | n.d. | |||||||||||

| Ketones | ||||||||||||||||||

| 455 | 2.50 | 2-Propanone | 0.63 | 0.04 | 2.20 | 0.24 | 0.54 | 0.05 | 2.11 | 0.02 | 0.78 | 0.15 | 2.41 | 0.45 | n.d. | - | ||

| 1161 | 13.19 | 1-(1,3-dimethyl-3-cyclohexen-1-yl)-Ethanone | n.d. | - | n.d. | - | n.d. | - | 2.75 | 0.05 | n.d. | - | 0.89 | 0.05 | n.d. | - | ||

| 853 | 14.89 | 2-Heptanone | n.d. | - | 2.70 | 0.03 | 1.05 | 0.04 | 1.32 | 0.02 | n.d. | - | 1.45 | 0.36 | n.d. | - | ||

| 952 | 18.57 | 2-Octanone | n.d. | - | n.d. | - | 5.08 | 0.42 | 0.55 | 0.03 | n.d. | - | n.d. | - | n.d. | - | ||

| 960 | 19.99 | 6-Octen-2-one | n.d. | - | n.d. | - | 0.80 | 0.04 | n.d. | - | n.d. | - | n.d. | - | n.d. | - | ||

| 987 | 20.17 | 6-Methyl-5 hepten-2 one | 0.73 | 0.10 | 1.65 | 0.06 | 0.53 | 0.03 | 6.00 | 0.58 | 0.76 | 0.04 | 6.50 | 0.28 | n.d. | - | ||

| 960 | 21.96 | 3-Octen-2-one | n.d. | - | n.d. | - | 0.57 | 0.05 | n.d. | - | n.d. | - | n.d. | - | n.d. | - | ||

| 962 | 22.51 | Ketone | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | 0.71 | 0.01 | n.d. | - | ||

| 968 | 24.67 | 3,5-Octadien-2-one | 0.59 | 0.07 | n.d. | - | 1.44 | 0.17 | 1.44 | 0.13 | n.d. | - | 1.39 | 0.20 | n.d. | - | ||

| Total | 1.94 | 6.55 | 10.01 | 14.16 | 1.54 | 13.35 | n.d. | |||||||||||

| Terpenes | ||||||||||||||||||

| 939 | 6.67 | α-Pinene | 1.35 | 0.06 | 120.21 | 0.54 | 4.27 | 0.25 | 147.07 | 1.23 | n.d. | - | 94.47 | 3.96 | 2.27 | 0.07 | ||

| 932 | 7.03 | α-Thujene | n.d. | - | 2.86 | 0.13 | n.d. | - | 9.40 | 0.18 | n.d. | - | 2.16 | 0.11 | n.d. | - | ||

| 961 | 8.67 | Camphene | n.d. | - | 1.69 | 0.15 | n.d. | - | 3.04 | 0.02 | n.d. | - | 7.45 | 0.26 | n.d. | - | ||

| 989 | 10.75 | β-Pinene | 0.70 | 0.00 | 37.67 | 1.33 | 1.30 | 0.14 | 33.28 | 0.36 | n.d. | - | 21.91 | 0.34 | 0.87 | 0.01 | ||

| 985 | 11.66 | Sabinene | n.d. | - | 1.64 | 0.13 | n.d. | - | 0.71 | 0.05 | n.d. | - | n.d. | - | n.d. | - | ||

| 879 | 11.74 | 2,4(10)-Thujadien | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | ||

| 1017 | 12.99 | δ-3-Carene | n.d. | - | 48.70 | 4.87 | n.d. | - | 3.82 | 0.10 | n.d. | - | 6.63 | 0.99 | n.d. | - | ||

| 1015 | 13.81 | α-Phellandrene | n.d. | - | 7.37 | 0.11 | n.d. | - | 2.59 | 0.40 | n.d. | - | 3.70 | 0.60 | n.d. | - | ||

| 991 | 14.24 | β-Myrcene | 13.88 | 2.66 | 429.64 | 5.70 | 10.12 | 0.33 | 344.78 | 5.22 | n.d. | - | 74.69 | 5.07 | 10.65 | 0.30 | ||

| 1026 | 14.44 | α-Terpinene | n.d. | - | 4.29 | 0.26 | n.d. | - | 2.35 | 0.19 | n.d. | - | 2.95 | 0.49 | n.d. | - | ||

| 1038 | 15.31 | Limonene | 2.38 | 0.50 | 20.56 | 0.29 | 2.40 | 0.15 | 50.09 | 1.95 | n.d. | - | 23.56 | 1.63 | 5.53 | 0.46 | ||

| 1045 | 15.49 | Eucalyptol | n.d. | - | 3.13 | 0.02 | 0.41 | 0.06 | 15.41 | 0.72 | 0.56 | 0.09 | 17.91 | 0.72 | n.d. | - | ||

| 946 | 15.61 | β-Phellandrene | n.d. | - | 20.96 | 0.14 | n.d. | - | 7.16 | 0.27 | n.d. | - | 13.75 | 0.51 | n.d. | - | ||

| 976 | 17.05 | Cis-ocimene | n.d. | - | 19.76 | 0.13 | n.d. | - | 5.45 | 0.45 | n.d. | - | 7.22 | 0.43 | n.d. | - | ||

| 1066 | 17.15 | γ-Terpinene | n.d. | - | 4.77 | 0.03 | n.d. | - | 7.17 | 0.43 | n.d. | - | 4.59 | 0.24 | n.d. | - | ||

| Terpenes | ||||||||||||||||||

| 1000 | 17.24 | Terpene | 0.87 | 0.01 | 1.88 | 0.14 | n.d. | - | n.d. | - | n.d. | - | 1.30 | 0.17 | n.d. | - | ||

| 1029 | 17.60 | β-Ocimene | 4.44 | 0.07 | 217.33 | 2.36 | 2.42 | 0.28 | 40.93 | 2.46 | 0.88 | 0.01 | 24.18 | 1.39 | 2.91 | 0.27 | ||

| 1034 | 18.01 | p-Cymene | n.d. | - | 10.17 | 0.39 | 0.66 | 0.05 | 43.02 | 2.52 | 0.66 | 0.27 | 13.51 | 0.89 | n.d. | - | ||

| 1094 | 18.43 | α-Terpinolene | 3.55 | 0.19 | 249.23 | 0.57 | 0.76 | 0.07 | 52.02 | 3.15 | n.d. | - | 16.01 | 1.06 | 1.00 | 0.07 | ||

| 1177 | 22.74 | Para-cymenyl | 1.81 | 0.11 | 47.64 | 0.55 | 0.56 | 0.20 | 7.84 | 0.51 | 1.07 | 0.02 | 7.16 | 0.93 | n.d. | - | ||

| 1136 | 23.01 | Terpene | n.d. | - | 1.67 | 0.11 | n.d. | - | 0.53 | 0.06 | n.d. | - | n.d. | - | n.d. | - | ||

| 1083 | 23.35 | 4,8-Epoxy-p-menth-1-ene | n.d. | - | 5.65 | 0.01 | n.d. | - | 2.49 | 0.35 | n.d. | - | n.d. | - | n.d. | - | ||

| 1164 | 23.48 | Linalool oxide | 0.70 | 0.01 | 1.37 | 0.40 | n.d. | - | 2.96 | 0.25 | n.d. | - | n.d. | - | n.d. | - | ||

| 1221 | 23.68 | α-Ylangene | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | ||

| 1082 | 25.29 | β-Linalool | n.d. | - | 6.35 | 0.07 | n.d. | - | 3.98 | 0.45 | n.d. | - | 4.90 | 0.14 | n.d. | - | ||

| 1494 | 25.75 | γ-Caryophyllene | 8.60 | 1.21 | 1.63 | 0.09 | 0.57 | 0.00 | 5.30 | 0.59 | 1.23 | 0.05 | 8.86 | 1.07 | n.d. | - | ||

| 1430 | 26.03 | α-Bergamotene | 6.78 | 1.09 | 1.06 | 0.24 | 0.53 | 0.03 | 11.82 | 1.57 | 2.94 | 0.11 | 19.89 | 3.59 | n.d. | - | ||

| 1456 | 26.12 | α-Guaiene | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | 1.08 | 0.19 | n.d. | - | ||

| 1494 | 26.23 | Trans-caryophyllene | 78.99 | 10.43 | 39.18 | 2.69 | 4.72 | 0.14 | 92.75 | 9.99 | 15.78 | 0.51 | 228.18 | 33.12 | 1.62 | 0.28 | ||

| 1209 | 26.40 | 4-Terpineol | n.d. | - | 2.07 | 0.13 | n.d. | - | 3.74 | 0.68 | n.d. | - | 2.46 | 0.32 | n.d. | - | ||

| 1440 | 26.59 | Sesquiterpene | n.d. | - | n.d. | - | n.d. | - | 2.50 | 0.02 | n.d. | - | 2.80 | 1.76 | n.d. | - | ||

| 1386 | 27.21 | Sesquiterpene | 1.73 | 0.24 | n.d. | - | n.d. | - | 6.03 | 0.75 | 1.56 | 0.03 | 7.09 | 1.10 | n.d. | - | ||

| 1131 | 27.47 | Trans-pinocarveol | n.d. | - | 2.74 | 0.03 | n.d. | - | 8.40 | 0.80 | 0.85 | 0.10 | 2.41 | 0.17 | n.d. | - | ||

| 1482 | 27.73 | α-Humulene | 31.19 | 5.31 | 7.35 | 0.58 | 1.28 | 0.04 | 27.08 | 3.69 | 5.27 | 0.05 | 68.14 | 12.59 | n.d. | - | ||

| 1189 | 28.13 | 1,8-Menthadien-4-ol | 2.13 | 0.13 | 15.23 | 1.04 | 1.44 | 0.81 | 12.22 | 1.05 | 2.44 | 0.08 | 19.06 | 0.12 | n.d. | - | ||

| 1209 | 28.32 | α-Terpineol | n.d. | - | 2.13 | 0.19 | n.d. | - | 3.26 | 0.03 | 0.76 | 0.12 | 3.59 | 1.20 | n.d. | - | ||

| 1189 | 28.40 | Borneol | n.d. | - | n.d. | - | n.d. | - | 1.13 | 0.09 | n.d. | - | n.d. | - | n.d. | - | ||

| 1490 | 28.65 | δ-Guaiene | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | ||

| 1519 | 28.72 | β-Selinene | 6.81 | 1.46 | 0.90 | 0.15 | n.d. | - | 8.70 | 1.17 | 3.03 | 0.03 | 13.72 | 2.84 | n.d. | - | ||

| 1522 | 28.82 | α-Selinene | 3.53 | 0.59 | 1.05 | 0.12 | n.d. | - | 5.44 | 0.74 | 1.81 | 0.05 | 9.48 | 1.82 | n.d. | - | ||

| 1474 | 28.98 | Sesquiterpene | 1.60 | 0.24 | n.d. | - | n.d. | - | 1.01 | 0.15 | 0.58 | 0.04 | 2.13 | 0.41 | n.d. | - | ||

| 1190 | 29.03 | Carvone | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | 0.79 | 0.14 | ||

| 1507 | 29.86 | Selina-3,7(11)-diene | 5.95 | 1.25 | 1.88 | 0.33 | n.d. | - | n.d. | - | 1.86 | 0.03 | 6.99 | 1.18 | n.d. | - | ||

| 1191 | 30.13 | Myrtenol | n.d. | - | n.d. | - | n.d. | - | 1.23 | 0.16 | n.d. | - | n.d. | - | n.d. | - | ||

| 1284 | 31.17 | Cuminol | 1.51 | 0.26 | 8.56 | 1.41 | n.d. | - | 3.13 | 0.07 | 0.97 | 0.11 | 6.46 | 1.79 | n.d. | - | ||

| 1322 | 33.41 | Humulene oxide | 1.71 | 0.47 | n.d. | - | n.d. | - | 1.54 | 0.32 | 0.92 | 0.05 | 2.44 | 0.37 | n.d. | - | ||

| 1419 | 34.11 | Sesquiterpene | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | ||

| 1392 | 34.86 | Eugenol | 0.76 | 0.15 | 1.18 | 0.14 | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | ||

| Total | 180.97 | 1349.52 | 31.43 | 981.37 | 43.15 | 752.82 | 25.64 | |||||||||||

| Miscellaneous | ||||||||||||||||||

| 906 | 11.03 | 3,3,6-Trimethyl-1,5-heptadiene | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | ||

| 907 | 12.72 | 1,3-Dimethyl-benzene | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | ||

| 1040 | 16.87 | 2-Pentyl-furan | 3.01 | 0.27 | n.d. | - | 0.56 | 0.04 | n.d. | - | n.d. | - | 1.26 | 0.12 | n.d. | - | ||

| 1020 | 18.31 | 1,2,4,-Trimethyl-benzene | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | ||

| 894 | 19.54 | 2,5-Dimethyl-pyrazine | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | ||

| 891 | 19.74 | 2,6-Dimethyl-pyrazine | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | ||

| 1176 | 20.72 | 1,4-Bis (1-methylethyl)-benzene | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | ||

| 985 | 21.89 | 2,6-Dimethyl-2,6-octadiene | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | ||

| 1081 | 22.10 | Diethyl carbitol | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | 0.91 | 0.23 | ||

| 1039 | 22.36 | 1,3,5-Trimethylenecycloheptane | n.d. | - | 1.54 | 0.00 | n.d. | - | n.d. | - | n.d. | - | 1.15 | 0.06 | n.d. | - | ||

| 986 | 28.45 | 5-Ethyldihydro-2(3H)-furanone | 0.82 | 0.04 | 5.86 | 1.44 | 0.73 | 0.19 | 1.26 | 0.10 | n.d. | - | 5.40 | 1.36 | n.d. | - | ||

| 1190 | 30.85 | 1-Methoxy-4(1-propenyl)-benzene | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | n.d. | - | ||

| Samples | CBD Declared Content (%, w/w) | Matrix | Origin | Extraction Method (When Indicated) |

|---|---|---|---|---|

| Oil_1 | / | Olive oil | Italy | Calvi et al., 2018 |

| Oil_2 | 4 | Hemp seed oil | Switzerland | ND * |

| Oil_3 | 1 | Olive oil | Switzerland | ND |

| Oil_4 | 5 | Caprylic/Capric Triglyceride (MCT) | Italy | ND |

| Oil_5 | 4 | Olive oil | Switzerland | CO2 supercritical |

| Oil_6 | 3 | Hemp oil | The Netherlands | CO2 supercritical |

| Oil_7 | 4 | Olive oil | Spain | ND |

| Oil_8 | 3 | Hemp seed oil | The Netherlands | ND |

| Oil_9 | 3 | Hemp seed oil | The Netherlands | ND |

| Oil_10 | 4 | Olive oil | The Netherlands | ND |

| Oil_11 | / | Hemp seed oil | Switzerland | ND |

| Oil_12 | 2 | Hemp seed oil | Switzerland | CO2 supercritical |

| Oil_13 | 4 | Olive oil | France | ND |

| Oil_14 | 5 | Hemp seed oil | Slovenia | CO2 supercritical |

| Oil_15 | 3 | Hemp seed oil | UK | ND |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pavlovic, R.; Nenna, G.; Calvi, L.; Panseri, S.; Borgonovo, G.; Giupponi, L.; Cannazza, G.; Giorgi, A. Quality Traits of “Cannabidiol Oils”: Cannabinoids Content, Terpene Fingerprint and Oxidation Stability of European Commercially Available Preparations. Molecules 2018, 23, 1230. https://doi.org/10.3390/molecules23051230

Pavlovic R, Nenna G, Calvi L, Panseri S, Borgonovo G, Giupponi L, Cannazza G, Giorgi A. Quality Traits of “Cannabidiol Oils”: Cannabinoids Content, Terpene Fingerprint and Oxidation Stability of European Commercially Available Preparations. Molecules. 2018; 23(5):1230. https://doi.org/10.3390/molecules23051230

Chicago/Turabian StylePavlovic, Radmila, Giorgio Nenna, Lorenzo Calvi, Sara Panseri, Gigliola Borgonovo, Luca Giupponi, Giuseppe Cannazza, and Annamaria Giorgi. 2018. "Quality Traits of “Cannabidiol Oils”: Cannabinoids Content, Terpene Fingerprint and Oxidation Stability of European Commercially Available Preparations" Molecules 23, no. 5: 1230. https://doi.org/10.3390/molecules23051230