Physicochemical Changes and Resistant-Starch Content of Extruded Cornstarch with and without Storage at Refrigerator Temperatures

Abstract

:1. Introduction

2. Results and Discussion

2.1. Chemical Composition of Cornstarch

2.2. Model Fitting

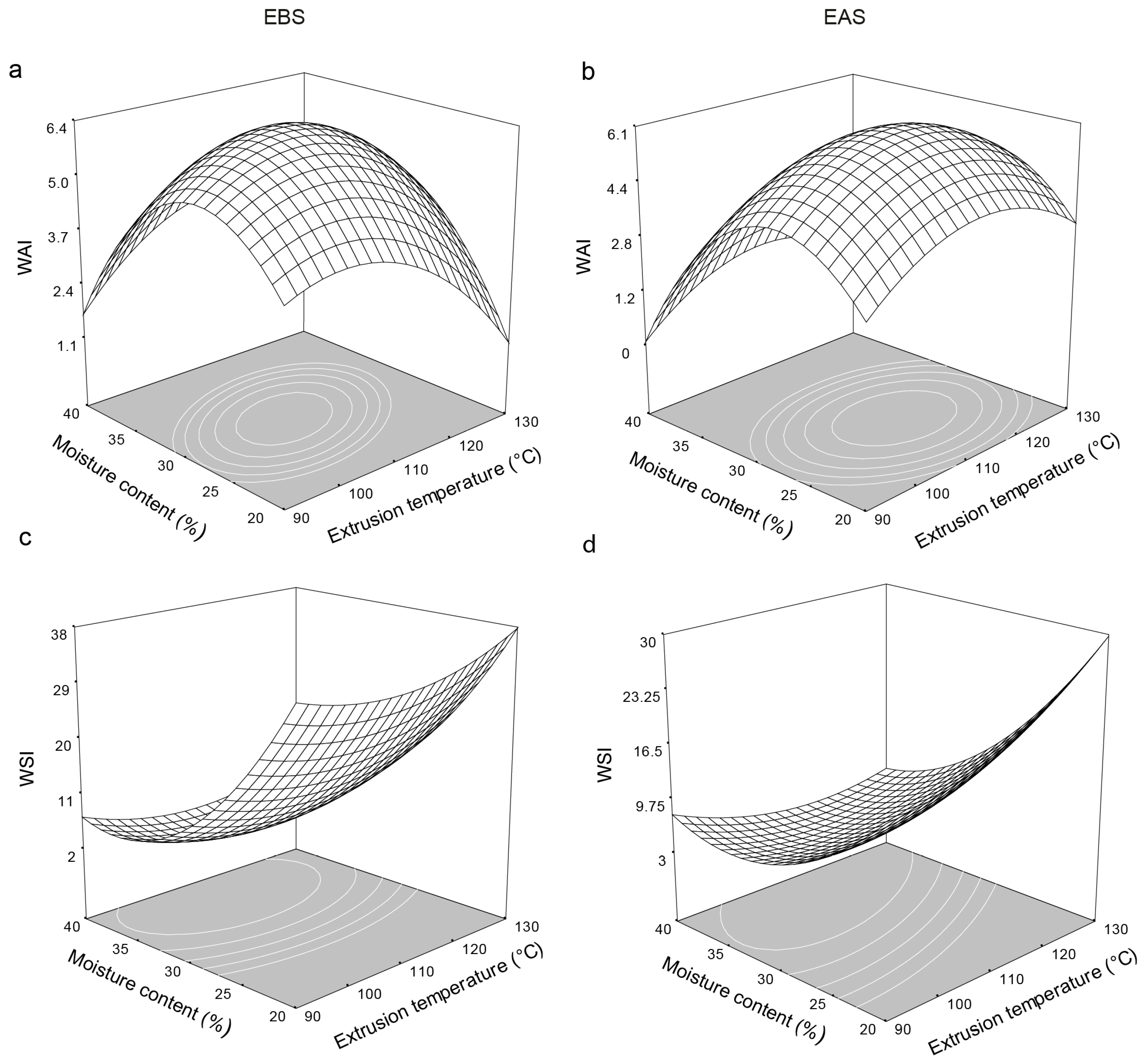

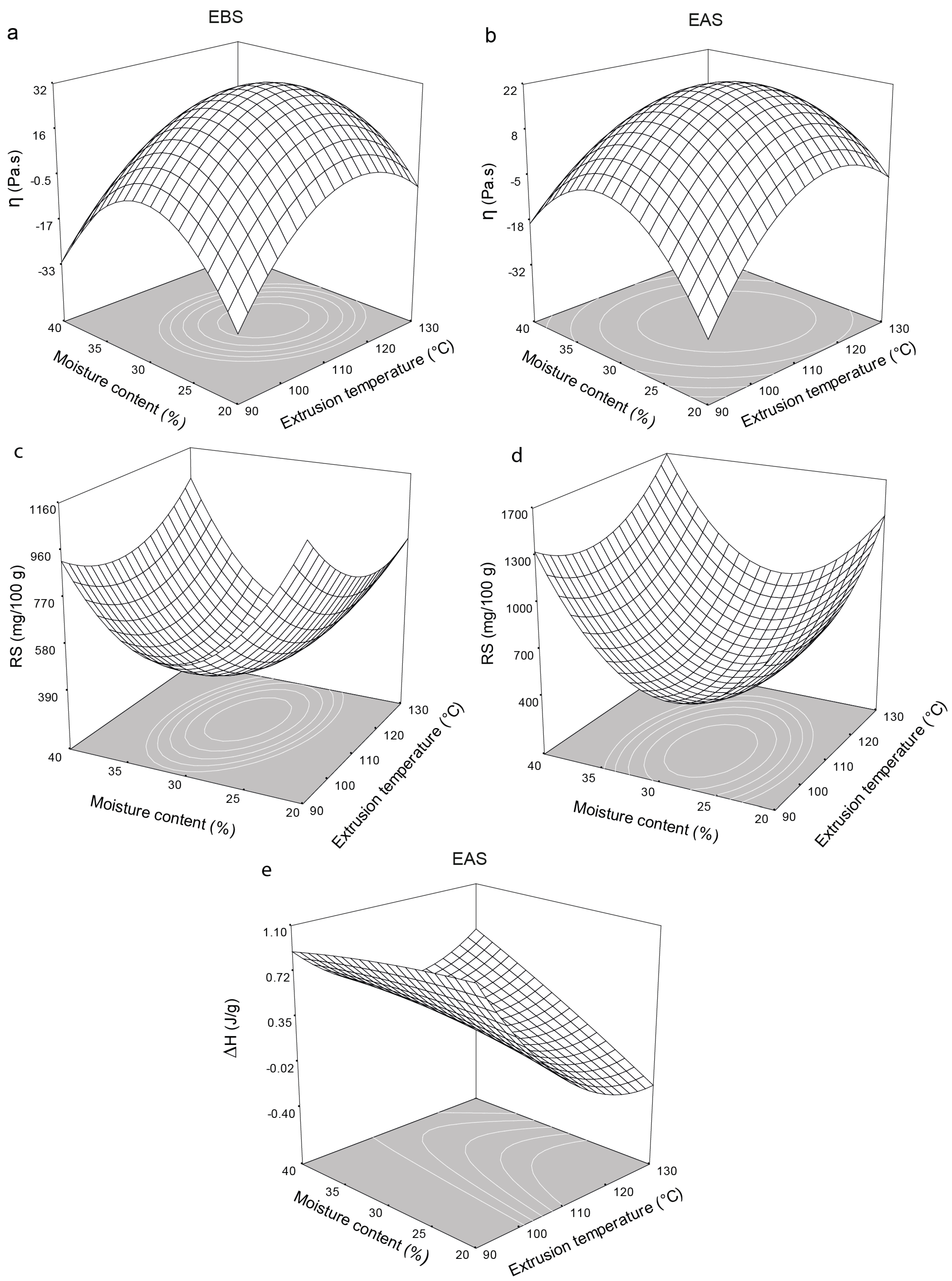

2.3. Water Absorption Index (WAI)

2.4. Water Solubility Index (WSI)

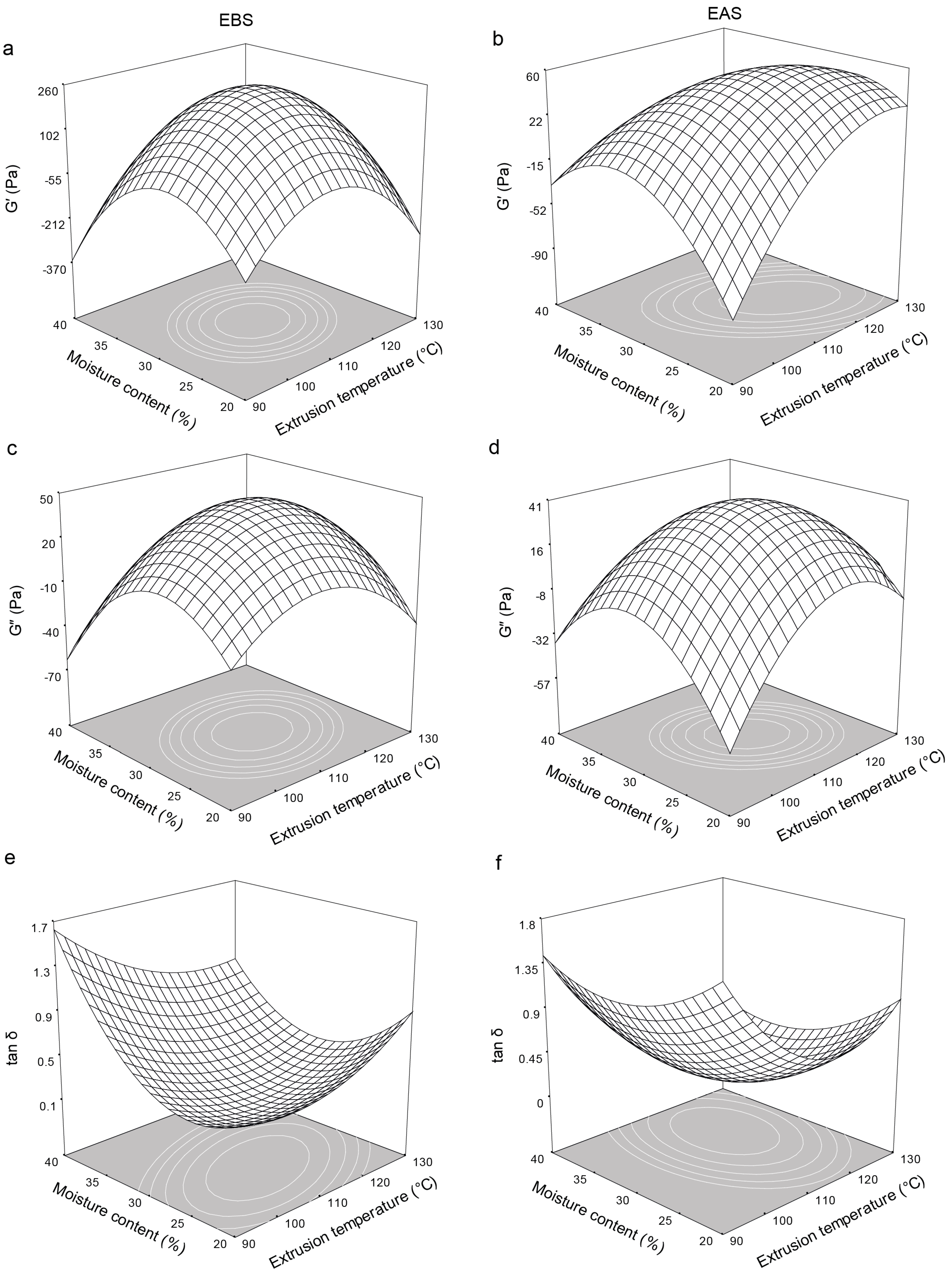

2.5. Viscoelastic Properties

2.6. Resistant Starch (RS) Content

2.7. Thermal Properties

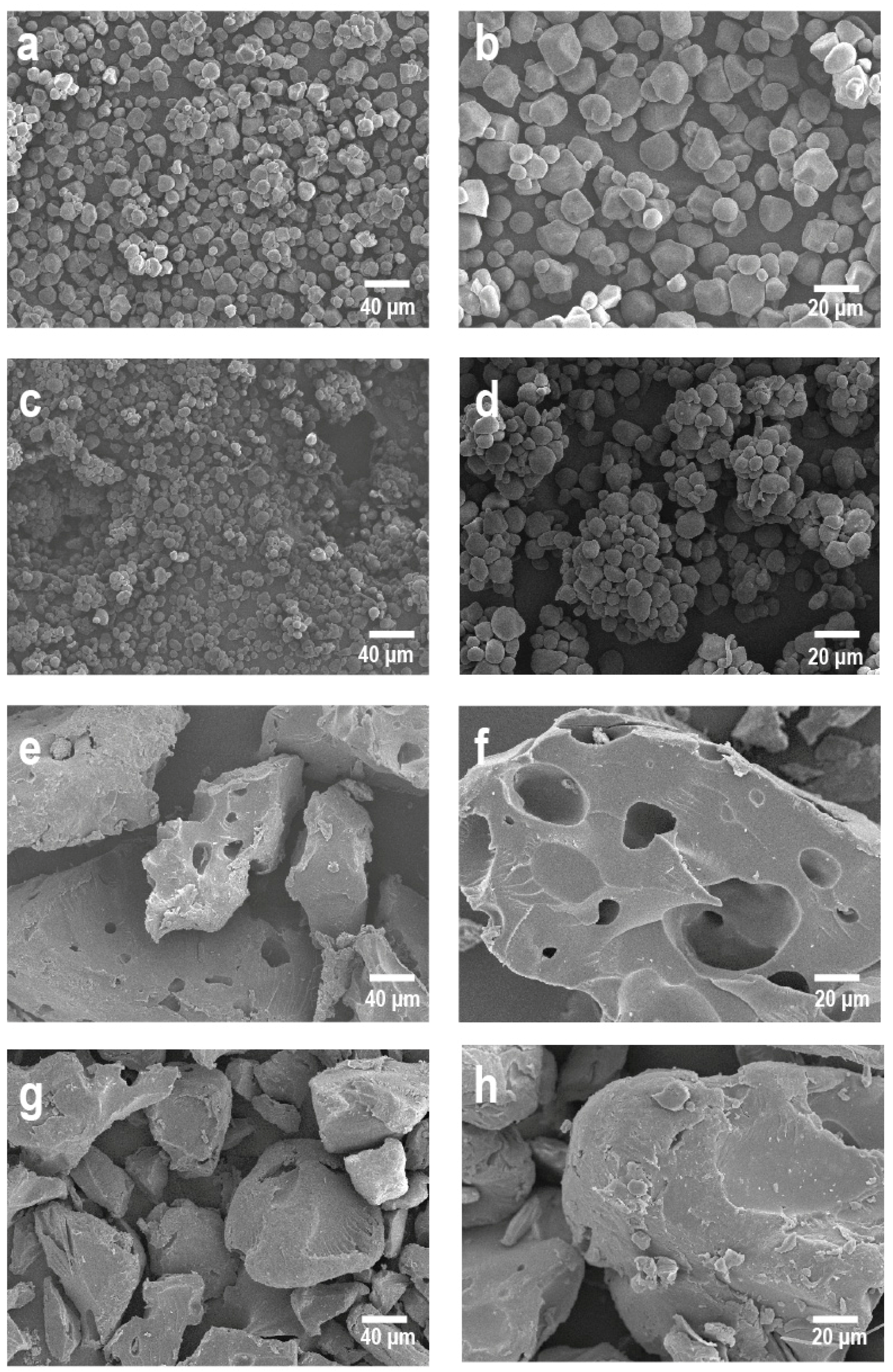

2.8. Scanning Electron Microscopy (SEM)

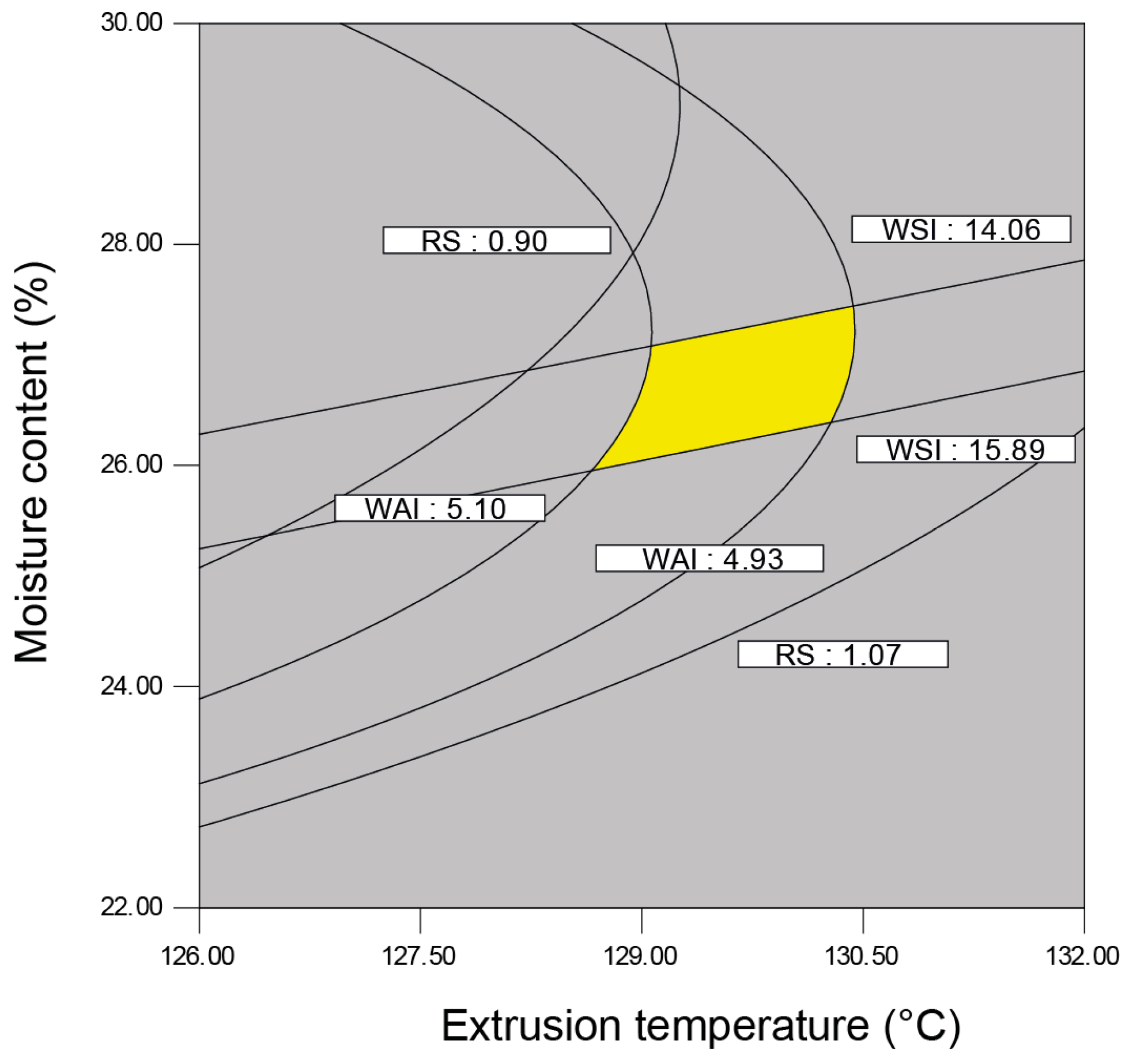

2.9. Identification of Optimum Conditions

3. Materials and Methods

3.1. Raw Material

3.2. Chemicals and Reagents

3.3. Extrusion Cooking

3.4. Extruded Cornstarch Flours

3.5. Physical and Chemical Analyses of Extruded Products

3.5.1. Water Absorption Index (WAI) and Water Solubility Index (WSI)

3.5.2. Thermal Analysis

3.5.3. Resistant Starch (RS) Content

3.5.4. Rheological Properties

3.5.5. Scanning Electron Microscopy

3.6. Experimental Design and Statistical Analysis

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

References

- Lopez-Rubio, A.; Htoon, A.; Gilbert, E.P. Influence of extrusion and digestion on the nanostructure of high-amylose maize starch. Bimonthly 2007, 8, 1564–1572. [Google Scholar] [CrossRef] [PubMed]

- Witczak, M.; Ziobro, R.; Juszczak, L.; Korus, J. Starch and starch derivatives in gluten-free systems. J. Cereal Sci. 2016, 67, 46–57. [Google Scholar] [CrossRef]

- Englyst, H.N.; Kingman, S.M.; Cummings, J.H. Classification and measurement of nutritionally important starch fractions. Eur. J. Clin. Nutr. 1996, 46, S33–S50. [Google Scholar]

- Haralampu, S.G. Resistant starch—A review of the physical properties and biological impact of RS 3. Carbohydr. Polym. 2000, 41, 285–292. [Google Scholar] [CrossRef]

- Kim, J.H.; Tanhehco, E.J.; Ng, P.K.W. Effect of extrusion conditions on resistant starch formation from pastry wheat flour. Food Chem. 2006, 99, 718–723. [Google Scholar] [CrossRef]

- Perera, A.; Meda, V.; Tyler, R.T. Resistant starch: A review of analytical protocols for determining resistant starch and of factors affecting the resistant starch content of foods. Food Res. Int. 2010, 43, 1959–1974. [Google Scholar] [CrossRef]

- Thompson, D.B. Strategies for the manufacture of resistant starch. Trends Food Sci. Technol. 2000, 11, 245–253. [Google Scholar] [CrossRef]

- Chung, H.J.; Hoover, R.; Liu, Q. The impact of single and dual hydrothermal modifications on the molecular structure and physicochemical properties of normal corn starch. Int. J. Biol. Macromol. 2009, 44, 203–210. [Google Scholar] [CrossRef] [PubMed]

- Koksel, H.; Masatcioglu, T.; Kahraman, K.; Ozturk, S.; Basman, A. Improving effect of lyophilization on functional properties of resistant starch preparations formed by acid hydrolysis and heat treatment. J. Cereal Sci. 2008, 47, 275–282. [Google Scholar] [CrossRef]

- Onyango, C.; Bley, T.; Jacob, A.; Henle, T.; Rohm, H. Influence of incubation temperature and time on resistant starch type III formation from autoclaved and acid-hydrolysed cassava starch. Carbohydr. Polym. 2006, 66, 494–499. [Google Scholar] [CrossRef]

- Xie, X.S.; Liu, Q.; Cui, S.W. Studies on the granular structure of resistant starches (type 4) from normal, high amylose and waxy corn starch citrates. Food Res. Int. 2006, 39, 332–341. [Google Scholar] [CrossRef]

- Song, D.; Thio, Y.S.; Deng, Y. Starch nanoparticle formation via reactive extrusion and related mechanism study. Carbohydr. Polym. 2011, 85, 208–214. [Google Scholar] [CrossRef]

- Hasjim, J.; Jane, J.L. Production of Resistant Starch by Extrusion Cooking of Acid-Modified Normal-Maize Starch. J. Food Sci. 2009, 74, C556–C562. [Google Scholar] [CrossRef] [PubMed]

- Dundar, A.N.; Gocmen, D. Effects of autoclaving temperature and storing time on resistant starch formation and its functional and physicochemical properties. Carbohydr. Polym. 2013, 97, 764–771. [Google Scholar] [CrossRef] [PubMed]

- Nasrin, T.A.A.; Anal, A.K. Resistant starch III from culled banana and its functional properties in fish oil emulsion. Food Hydrocoll. 2014, 35, 403–409. [Google Scholar] [CrossRef]

- Ozturk, S.; Koksel, H.; Ng, P.K. Production of resistant starch from acid-modified amylotype starches with enhanced functional properties. J. Food Eng. 2011, 103, 156–164. [Google Scholar] [CrossRef]

- Zhang, H.; Jin, Z. Preparation of products rich in resistant starch from maize starch by an enzymatic method. Carbohydr. Polym. 2011, 86, 1610–1614. [Google Scholar] [CrossRef]

- Moad, G. Chemical modification of starch by reactive extrusion. Prog. Polym. Sci. 2011, 36, 218–237. [Google Scholar] [CrossRef]

- Dust, J.M.; Gajda, M.A.; Flickinger, A.E.; Burkhalter, T.M.; Merchen, N.R.; Fahey, G.C., Jr. Extrusion conditions affect chemical composition and in vitro digestion of selected food ingredients. J. Agric. Food Chem. 2004, 52, 2989–2996. [Google Scholar] [CrossRef] [PubMed]

- Faraj, A.; Vasanthan, T.; Hoover, R. The effect of extrusion cooking on resistant starch formation in waxy and regular barley flours. Food Res. Int. 2004, 37, 517–525. [Google Scholar] [CrossRef]

- Stojceska, V.; Ainsworth, P.; Plunkett, A.; İbanoğlu, Ş. The advantage of using extrusion processing for increasing dietary fibre level in gluten-free products. Food Chem. 2010, 121, 156–164. [Google Scholar] [CrossRef]

- Agustiniano-Osornio, J.C.; González-Soto, R.A.; Flores-Huicochea, E.; Manrique-Quevedo, N.; Sánchez-Hernández, L.; Bello-Pérez, L.A. Resistant starch production from mango starch using a single-screw extruder. J. Sci. Food Agric. 2005, 85, 2105–2110. [Google Scholar] [CrossRef]

- Gonzalez-Soto, R.A.; Sanchez-Hernandez, L.; Solorza-Feria, J.; Nunez-Santiago, C.; Flores-Huicochea, E.; Bello-Perez, L.A. Resistant starch production from non-conventional starch sources by extrusion. Food Sci. Technol. Int. 2006, 12, 5–11. [Google Scholar] [CrossRef]

- Sarawong, C.; Schoenlechner, R.; Sekiguchi, K.; Berghofer, E.; Ng, P.K. Effect of extrusion cooking on the physicochemical properties, resistant starch, phenolic content and antioxidant capacities of green banana flour. Food Chem. 2014, 143, 33–39. [Google Scholar] [CrossRef] [PubMed]

- Hagenimana, A.; Ding, X.; Fang, T. Evaluation of rice flour modified by extrusion cooking. J. Cereal Sci. 2006, 43, 38–46. [Google Scholar] [CrossRef]

- Cieśla, K.; Eliasson, A.C. DSC studies of retrogradation and amylose–lipid complex transition taking place in gamma irradiated wheat starch. Nucl. Instrum. Methods Phys. Res. B 2007, 265, 399–405. [Google Scholar] [CrossRef]

- Van Hung, P.; Vien, N.L.; Phi, N.T.L. Resistant starch improvement of rice starches under a combination of acid and heat-moisture treatments. Food Chem. 2016, 191, 67–73. [Google Scholar] [CrossRef] [PubMed]

- Mun, S.H.; Shin, M. Mild hydrolysis of resistant starch from maize. Food Chem. 2006, 96, 115–121. [Google Scholar] [CrossRef]

- Waduge, R.N.; Hoover, R.; Vasanthan, T.; Gao, J.; Li, J. Effect of annealing on the structure and physicochemical properties of barley starches of varying amylose content. Food Res. Int. 2006, 39, 59–77. [Google Scholar] [CrossRef]

- Wandee, Y.; Puttanlek, C.; Rungsardthong, V.; Puncha-arnon, S.; Uttapap, D. Effects of gelatinization and gel storage conditions on the formation of canna resistant starch. Food Bioprocess. Technol. 2012, 5, 2665–2673. [Google Scholar] [CrossRef]

- Wang, Y.J.; Truong, V.D.; Wang, L. Structures and rheological properties of corn starch as affected by acid hydrolysis. Carbohydr. Polym. 2003, 52, 327–333. [Google Scholar] [CrossRef]

- Vasanthan, T.; Gaosong, J.; Yeung, J.; Li, J. Dietary fiber profile of barley flour as affected by extrusion cooking. Food Chem. 2002, 77, 35–40. [Google Scholar] [CrossRef]

- Hoover, R.; Manuel, H. The effect of heat–moisture treatment on the structure and physicochemical properties of normal maize, waxy maize, dull waxy maize and amylomaize V starches. J. Cereal Sci. 1996, 23, 153–162. [Google Scholar] [CrossRef]

- Shi, M.M.; Gao, Q.Y. Physicochemical properties, structure and in vitro digestion of resistant starch from waxy rice starch. Carbohydr. Polym. 2012, 84, 1151–1157. [Google Scholar] [CrossRef]

- González-Soto, R.A.; Mora-Escobedo, R.; Hernández-Sánchez, H.; Sánchez-Rivera, M.; Bello-Pérez, L.A. Extrusion of banana starch: Characterization of the extrudates. J. Sci. Food Agric. 2007, 87, 348–356. [Google Scholar] [CrossRef]

- Wang, N.; Maximiuk, L.; Toews, R. Pea starch noodles: Effect of processing variables on characteristics and optimisation of twin-screw extrusion process. Food Chem. 2012, 133, 742–753. [Google Scholar] [CrossRef]

- Zhu, L.J.; Shukri, R.; de Mesa-Stonestreet, N.J.; Alavi, S.; Dogan, H.; Shi, Y.C. Mechanical and microstructural properties of soy protein–high amylose corn starch extrudates in relation to physicochemical changes of starch during extrusion. J. Food Eng. 2010, 100, 232–238. [Google Scholar] [CrossRef]

- Hernandez-Diaz, J.R.; Quintero-Ramos, A.; Barnard, J.; Balandran-Quintana, R.R. Functional properties of extrudates prepared with blends of wheat flour/pinto bean meal with added wheat bran. Food Sci. Technol. Int. 2007, 13, 301–308. [Google Scholar] [CrossRef]

- Masatcioglu, M.T.; Yalcin, E.; Hwan, P.J.; Ryu, G.H.; Celik, S.; Koksel, H. Hull-less barley flour supplemented corn extrudates produced by conventional extrusion and CO2 injection process. Innov. Food Sci. Emerg. Technol. 2014, 26, 302–309. [Google Scholar] [CrossRef]

- Bhattacharya, S.; Sudha, M.L.; Rahim, A. Pasting characteristics of an extruded blend of potato and wheat flours. J. Food Eng. 1999, 40, 107–111. [Google Scholar] [CrossRef]

- Rodríguez-Miranda, J.; Delgado-Licon, E.; Ramírez-Wong, B.; Solís-Soto, A.; Vivar-Vera, M.A.; Gómez-Aldapa, C.A.; Medrano-Roldán, H. Effect of moisture, extrusion temperature and screw speed on residence time, specific mechanical energy and psychochemical properties of bean four and soy protein aquaculture feeds. J. Anim. Prod. Adv. 2012, 2, 65–73. [Google Scholar]

- Singh, N.; Singh, J.; Kaur, L.; Sodhi, N.S.; Gill, B.S. Morphological, thermal and rheological properties of starches from different botanical sources. Food Chem. 2003, 81, 219–231. [Google Scholar] [CrossRef]

- Karim, A.A.; Norziah, M.H.; Seow, C.C. Methods for the study of starch retrogradation. Food Chem. 2000, 71, 9–36. [Google Scholar] [CrossRef]

- Chanvrier, H.; Uthayakumaran, S.; Appelqvist, I.A.; Gidley, M.J.; Gilbert, E.P.; López-Rubio, A. Influence of storage conditions on the structure, thermal behavior, and formation of enzyme-resistant starch in extruded starches. J. Agric. Food Chem. 2007, 55, 9883–9890. [Google Scholar] [CrossRef] [PubMed]

- Yadav, B.S.; Sharma, A.; Yadav, R.B. Resistant starch content of conventionally boiled and pressure-cooked cereals, legumes and tubers. J. Food Sci. Technol. 2010, 47, 84–88. [Google Scholar] [CrossRef] [PubMed]

- Buckow, R.; Heinz, V.; Knorr, D. High pressure phase transition kinetics of maize starch. J. Food Eng. 2007, 81, 469–475. [Google Scholar] [CrossRef]

- Lazaridou, A.; Biliaderis, C.G.; Izydorczyk, M.S. Molecular size effects on rheological properties of oat β-glucans in solution and gels. Food Hydrocoll. 2003, 17, 693–712. [Google Scholar] [CrossRef]

- Alamri, M.S.; Mohamed, A.A.; Hussain, S. Effects of alkaline-soluble okra gum on rheological and thermal properties of systems with wheat or corn starch. Food Hydrocoll. 2013, 30, 541–551. [Google Scholar] [CrossRef]

- Jongsutjarittam, O.; Charoenrein, S. The effect of moisture content on physicochemical properties ofextruded waxy and non-waxy rice flour. Carbohydr. Polym. 2014, 114, 133–140. [Google Scholar] [CrossRef] [PubMed]

- Parada, J.; Aguilera, J.M.; Brennan, C. Effect of guar gum content on some physical and nutritional properties of extruded products. J. Food Eng. 2011, 103, 324–332. [Google Scholar] [CrossRef]

- Fannon, J.E.; Hauber, R.J.; BeMiller, J.N. Surface pores of starch granules. Cereal Chem. 1992, 69, 284–288. [Google Scholar]

- Reddy, C.K.; Haripriya, S.; Mohamed, A.N.; Suriya, M. Preparation and characterization of resistant starch III from elephant foot yam (Amorphophallus paeonifolius) starch. Food Chem. 2014, 155, 38–44. [Google Scholar] [CrossRef] [PubMed]

- Martínez-Bustos, F.; Chang, Y.K.; Bannwart, A.C.; Rodriguez, M.E.; Guedes, P.A.; Gaiotti, E.R. Effects of calcium hydroxide and processing conditions on corn meal extrudates. Cereal Chem. 1998, 75, 796–801. [Google Scholar] [CrossRef]

- Gill, S.; Vasanthan, T.; Ooraikul, B.; Rossnagel, B. Wheat bread quality as influenced by the substitution of waxy and regular barley flours in their native and extruded forms. J. Cereal Sci. 2002, 36, 219–237. [Google Scholar] [CrossRef]

- Quintero-Ramos, A.; Bourne, M.; Barnard, J.; Gonzalez-Laredo, R.; Anzaldua-Morales, A.; Pensaben-Esquivel, M.; Maquez-Melendez, R. Low temperature blanching of frozen carrots with calcium chloride solutions at different holding times on texture of frozen carrots. J. Food Process. Preserv. 2002, 26, 361–374. [Google Scholar] [CrossRef]

- Gómez-Moriel, C.B.; Quintero-Ramos, A.; Camacho-Dávila, A.; Ruiz-Gutiérrez, M.G.; Talamás-Abbud, R.; Olivas-Vargas, R.; Barnard, J. Optimization of chipotle pepper smoking process using response surface methodology. J. Food Qual. 2012, 35, 21–33. [Google Scholar] [CrossRef]

- AOAC. International Official Methods of Analysis; AOAC: Gaithersburg, MD, USA, 1998. [Google Scholar]

- Cortés-Ceballos, E.; Pérez-Carrillo, E.; Serna-Saldívar, S.O. Addition of Sodium Stearoyl Lactylate to Corn and Sorghum Starch Extrudates Enhances the Performance of Pregelatinized Beer Adjuncts. Cereal Chem. 2015, 92, 88–92. [Google Scholar] [CrossRef]

- Ruiz-Gutiérrez, M.G.; Amaya-Guerra, C.A.; Quintero-Ramos, A.; Pérez-Carrillo, E.; Ruiz-Anchondo, T.D.J.; Báez-González, J.G.; Meléndez-Pizarro, C.O. Effect of extrusion cooking on bioactive compounds in encapsulated red cactus pear powder. Molecules 2015, 20, 8875–8892. [Google Scholar] [CrossRef] [PubMed]

- Anderson, R.A.; Conway, H.F.; Pfeifer, V.F.; Griffin, E.L. Gelatinization of corn grits by roll-and extrusion-cooking. Cereal Sci. Today 1969, 14, 4–7. [Google Scholar]

- Goñi, I.; Garcia-Diaz, L.; Mañas, E.; Saura-Calixto, F. Analysis of resistant starch: A method for foods and food products. Food Chem. 1996, 56, 445–449. [Google Scholar] [CrossRef]

- Rao, M.A. Rheology of Fluid and Semisolid Foods: Principles and Applications; Springer Science & Business Media: New York, NY, USA, 2010; pp. 30–35. [Google Scholar]

- Mendez-Montealvo, G.; Sánchez-Rivera, M.M.; Paredes-López, O.; Bello-Perez, L.A. Thermal and rheological properties of nixtamalized maize starch. Int. J. Biol. Macromol. 2006, 40, 59–63. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; Wang, L.J.; Li, D.; Özkan, N.; Li, S.J.; Mao, Z.H. Rheological properties of waxy maize starch and xanthan gum mixtures in the presence of sucrose. Carbohydr. Polym. 2009, 77, 472–481. [Google Scholar] [CrossRef]

- Meyer, R.H. Response Surface Methodology; Allen and Bacon: Boston, MA, USA, 1971; pp. 126–175. [Google Scholar]

- Sample Availability: Samples of the treatments are available from the authors.

| Parameter | Content |

|---|---|

| Moisture content (%) | 10.9 ± 0.29 |

| Proteins (%) | 0.10 ± 0.06 |

| Fat (%) | 0.05 ± 0.03 |

| Ash (%) | 0.03 ± 0.01 |

| Resistant starch (g/100 g) | 0.67 ± 0.022 |

| Apparent viscosity (Pa∙s) | 0.89 ± 0.015 |

| Storage modulus (Pa) | 0.50 ± 0.02 |

| Loss modulus (Pa) | 0.47 ± 0.08 |

| The ratio of loss modulus/storage modulus | 0.87 ± 0.15 |

| Enthalpy (J/g) | 9.91 ± 0.80 |

| Gelatinization temperature (°C) | 72.40 ± 0.07 |

| Water absorption index | 1.80 ± 0.01 |

| Water solubility index | 0.13 ± 0.05 |

| T | A | B | C | Physicochemical Properties | Thermal Properties | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| EBS | EAS | EAS | |||||||||

| WAI | WSI | RS | WAI | WSI | RS | ∆H | Tg | ||||

| 1 | 100 | 25 | 240 | 5.54 ± 0.69 | 13.78 ± 1.68 | 0.604 ± 0.017 | 5.75 ± 0.31 | 10.96 ± 1.46 | 0.632 ± 0.064 | 0.59 ± 0.008 | 101.65 ± 0.89 |

| 2 | 120 | 25 | 240 | 4.90 ± 0.26 | 16.47 ± 2.10 | 0.540 ± 0.014 | 5.86 ± 0.08 | 14.23 ± 0.58 | 0.930 ± 0.040 | 0.06 ± 0.009 | 92.89 ± 1.31 |

| 3 | 100 | 35 | 240 | 4.41 ± 0.04 | 5.48 ± 0.23 | 0.638 ± 0.051 | 3.08 ± 0.33 | 4.78 ± 0.19 | 0.823 ± 0.013 | 0.43 ± 0.100 | 100.71 ± 1.55 |

| 4 | 120 | 35 | 240 | 4.90 ± 0.13 | 4.26 ± 0.67 | 0.559 ± 0.020 | 2.99 ± 0.12 | 4.11 ± 0.14 | 1.134 ± 0.028 | 0.46 ± 0.050 | 101.27 ± 0.23 |

| 5 | 100 | 25 | 320 | 4.74 ± 0.60 | 28.04 ± 4.52 | 0.681 ± 0.015 | 5.10 ± 0.16 | 13.71 ± 1.12 | 0.694 ± 0.010 | 0.69 ± 0.040 | 101.25 ± 0.28 |

| 6 | 120 | 25 | 320 | 4.42 ± 0.04 | 28.17 ± 1.88 | 0.572 ± 0.041 | 4.69 ± 0.16 | 20.11 ± 3.13 | 0.936 ± 0.024 | 0.01 ± 0.009 | 95.12 ± 0.74 |

| 7 | 100 | 35 | 320 | 4.77 ± 0.07 | 4.77 ± 0.20 | 0.625 ± 0.013 | 2.90 ± 0.20 | 2.90 ± 0.04 | 0.975 ± 0.017 | 0.79 ± 0.030 | 101.01 ± 0.95 |

| 8 | 120 | 35 | 320 | 5.40 ± 0.10 | 7.40 ± 0.65 | 0.576 ± 0.045 | 2.79 ± 0.33 | 5.14 ± 0.39 | 0.845 ± 0.036 | 0.08 ± 0.040 | 94.61 ± 0.36 |

| 9 | 90 | 30 | 280 | 6.02 ± 0.09 | 9.14 ± 0.40 | 0.488 ± 0.032 | 4.07 ± 0.01 | 6.20 ± 1.10 | 0.465 ± 0.024 | 0.92 ± 0.200 | 100.81 ± 0.79 |

| 10 | 130 | 30 | 280 | 4.56 ± 0.01 | 10.51 ± 0.21 | 0.502 ± 0.056 | 5.50 ± 0.02 | 10.47 ± 0.64 | 0.651 ± 0.019 | 0.38 ± 0.010 | 100.84 ± 0.91 |

| 11 | 110 | 20 | 280 | 4.37 ± 0.20 | 28.65 ± 1.58 | 0.791 ± 0.017 | 3.71 ± 0.20 | 17.54 ± 1.75 | 0.830 ± 0.015 | 0.01 ± 0.008 | 101.66 ± 0.33 |

| 12 | 110 | 40 | 280 | 4.12 ± 0.03 | 3.39 ± 0.70 | 0.679 ± 0.026 | 2.78 ± 0.21 | 4.67 ± 0.14 | 1.049 ± 0.020 | 0.53 ± 0.001 | 100.67 ± 1.91 |

| 13 | 110 | 30 | 200 | 6.45 ± 0.06 | 8.14 ± 0.78 | 0.503 ± 0.021 | 4.72 ± 0.06 | 3.96 ± 0.10 | 0.563 ± 0.025 | 0.39 ± 0.060 | 100.36 ± 1.23 |

| 14 | 110 | 30 | 360 | 5.77 ± 0.50 | 10.47 ± 0.21 | 0.492 ± 0.011 | 4.95 ± 0.06 | 6.19 ± 0.19 | 0.564 ± 0.033 | 0.38 ± 0.030 | 98.25 ± 1.05 |

| 15 | 110 | 30 | 280 | 6.76 ± 0.63 | 8.18 ± 0.14 | 0.323 ± 0.014 | 5.06 ± 0.23 | 4.46 ± 0.32 | 0.422 ± 0.022 | 0.21 ± 0.010 | 101.63 ± 0.14 |

| 16 | 110 | 30 | 280 | 6.21 ± 0.06 | 5.75 ± 1.76 | 0.405 ± 0.029 | 5.89 ± 0.27 | 4.85 ± 0.41 | 0.407 ± 0.035 | 0.26 ± 0.003 | 100.29 ± 0.60 |

| 17 | 110 | 30 | 280 | 6.52 ± 0.58 | 6.06 ± 0.90 | 0.388 ± 0.020 | 6.17 ± 0.28 | 6.14 ± 0.17 | 0.452 ± 0.025 | 0.24 ± 0.020 | 98.22 ± 0.28 |

| 18 | 110 | 30 | 280 | 6.29 ± 0.15 | 6.02 ± 1.12 | 0.419 ± 0.033 | 6.53 ± 0.16 | 8.73 ± 0.42 | 0.416 ± 0.010 | 0.39 ± 0.060 | 99.15 ± 0.49 |

| 19 | 110 | 30 | 280 | 6.12 ± 0.20 | 7.14 ± 0.13 | 0.394 ± 0.021 | 5.58 ± 0.31 | 5.24 ± 0.70 | 0.325 ± 0.025 | 0.35 ± 0.050 | 99.82 ± 0.53 |

| 20 | 110 | 30 | 280 | 6.93 ± 0.39 | 7.42 ± 0.26 | 0.323 ± 0.012 | 6.81 ± 0.05 | 8.11 ± 1.16 | 0.352 ± 0.019 | 0.32 ± 0.002 | 98.87 ± 0.27 |

| T | A | B | C | EBS | EAS | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| G′ | G″ | tan δ | η | G′ | G″ | tan δ | η | ||||

| 1 | 100 | 25 | 240 | 107.67 ± 1.07 | 24.93 ± 0.23 | 0.23 ± 0.001 | 16.24 ± 0.42 | 0.81 ± 0.19 | 0.66 ± 0.09 | 0.73 ± 0.064 | 0.11 ± 0.01 |

| 2 | 120 | 25 | 240 | 59.09 ± 1.48 | 18.97 ± 1.42 | 0.32 ± 0.030 | 27.05 ± 1.23 | 49.16 ± 9.27 | 17.85 ± 3.17 | 0.49 ± 0.019 | 11.51 ± 0.22 |

| 3 | 100 | 35 | 240 | 0.53 ± 0.34 | 0.37 ± 0.08 | 0.72 ± 0.179 | 0.08 ± 0.03 | 0.64 ± 0.23 | 0.53 ± 0.18 | 0.69 ± 0.152 | 0.073 ± 0.01 |

| 4 | 120 | 35 | 240 | 1.57 ± 0.58 | 1.69 ± 0.31 | 0.90 ± 0.610 | 0.80 ± 0.03 | 0.85 ± 0.26 | 0.43 ± 0.21 | 0.50 ± 0.104 | 0.17 ± 0.15 |

| 5 | 100 | 25 | 320 | 55.00 ± 21.0 | 17.34 ± 4.46 | 0.32 ± 0.042 | 6.36 ± 0.31 | 1.37 ± 0.21 | 1.29 ± 0.38 | 0.93 ± 0.148 | 0.20 ± 0.40 |

| 6 | 120 | 25 | 320 | 27.76 ± 3.01 | 13.76 ± 2.46 | 0.46 ± 0.020 | 10.64 ± 0.11 | 30.06 ± 3.93 | 14.97 ± 0.43 | 0.77 ± 0.087 | 6.26 ± 0.38 |

| 7 | 100 | 35 | 320 | 1.00 ± 0.42 | 1.21 ± 0.52 | 0.94 ± 0.138 | 1.03 ± 0.14 | 0.57 ± 0.08 | 0.35 ± 0.21 | 0.65 ± 0.157 | 0.09 ± 0.01 |

| 8 | 120 | 35 | 320 | 26.07 ± 6.50 | 11.20 ± 1.85 | 0.43 ± 0.066 | 2.46 ± 0.09 | 0.43 ± 0.11 | 0.22 ± 0.58 | 0.32 ± 0.013 | 0.22 ± 0.09 |

| 9 | 90 | 30 | 280 | 19.35 ± 2.70 | 8.89 ± 1.92 | 0.50 ± 0.006 | 1.75 ± 0.15 | 1.06 ± 0.02 | 1.57 ± 0.06 | 1.48 ± 0.079 | 0.30 ± 0.02 |

| 10 | 130 | 30 | 280 | 100.41 ± 3.80 | 26.96 ± 1.17 | 0.26 ± 0.010 | 19.79 ± 2.36 | 42.81 ± 1.66 | 13.95 ± 0.33 | 0.26 ± 0.001 | 9.46 ± 0.02 |

| 11 | 110 | 20 | 280 | 21.80 ± 1.76 | 11.01 ± 0.93 | 0.50 ± 0.014 | 1.71 ± 0.18 | 8.23 ± 0.84 | 6.36 ± 0.19 | 0.77 ± 0.066 | 1.77 ± 0.06 |

| 12 | 110 | 40 | 280 | 1.16 ± 0.36 | 0.89 ± 0.30 | 0.82 ± 0.013 | 0.44 ± 0.02 | 0.46 ± 0.15 | 0.52 ± 0.05 | 0.36 ± 0.005 | 0.31 ± 0.06 |

| 13 | 110 | 30 | 200 | 99.46 ± 5.60 | 29.10 ± 2.05 | 0.29 ± 0.009 | 9.57 ± 0.73 | 0.43 ± 0.06 | 0.64 ± 0.09 | 1.49 ± 0.082 | 0.31 ± 0.02 |

| 14 | 110 | 30 | 360 | 109.58 ± 8.62 | 26.96 ± 2.53 | 0.25 ± 0.013 | 15.75 ± 0.21 | 30.75 ± 2.15 | 13.09 ± 1.12 | 1.17 ± 0.251 | 1.96 ± 0.16 |

| 15 | 110 | 30 | 280 | 291.10 ± 7.63 | 56.41 ± 1.70 | 0.21 ± 0.004 | 32.84 ± 1.85 | 45.09 ± 3.28 | 55.85 ± 3.10 | 0.20 ± 0.001 | 22.11 ± 0.40 |

| 16 | 110 | 30 | 280 | 211.43 ± 24.1 | 40.72 ± 2.67 | 0.21 ± 0.005 | 29.52 ± 2.77 | 44.40 ± 4.15 | 37.40 ± 1.73 | 0.20 ± 0.010 | 20.43 ± 0.42 |

| 17 | 110 | 30 | 280 | 234.00 ± 23.5 | 48.83 ± 0.74 | 0.19 ± 0.009 | 25.11 ± 0.12 | 60.56 ± 5.32 | 35.63 ± 2.31 | 0.17 ± 0.003 | 23.43 ± 0.05 |

| 18 | 110 | 30 | 280 | 289.00 ± 2.82 | 39.34 ± 2.02 | 0.18 ± 0.011 | 33.87 ± 0.67 | 60.46 ± 3.23 | 52.50 ± 0.21 | 0.17 ± 0.003 | 21.06 ± 0.70 |

| 19 | 110 | 30 | 280 | 316.40 ± 22.5 | 53.31 ± 0.40 | 0.19 ± 0.009 | 37.47 ± 2.04 | 57.23 ± 2.70 | 31.77 ± 0.25 | 0.18 ± 0.007 | 23.32 ± 0.33 |

| 20 | 110 | 30 | 280 | 263.28 ± 27.9 | 51.30 ± 5.18 | 0.22 ± 0.003 | 28.35 ± 1.18 | 60.92 ± 2.26 | 36.11 ± 0.84 | 0.18 ± 0.006 | 22.10 ± 0.67 |

| Source | DF | Mean Squares | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Physicochemical Properties | Rheological Properties | Thermal Properties | |||||||||||||||

| EBS | EAS | EBS | EAS | EAS | |||||||||||||

| WAI | WSI | RS | WAI | WSI | RS | G′ | G″ | tan δ | η | G′ | G″ | tan δ | η | ∆H | Tg | ||

| Model | 9 | 1.41 * | 127.30 * | 0.030 * | 2.74 * | 44.84 * | 0.097 * | 22,390.78 * | 603.56 * | 0.10 * | 308.26 * | 1151.80 * | 620.72 * | 0.35 * | 188.81 * | 0.12 * | 6.43 |

| A | 1 | 0.48 | 3.04 | 0.004 | 0.35 | 24.46 | 0.075 | 789.77 | 82.14 | 0.021 | 177.78 | 1612.21 | 191.83 | 0.70 * | 81.07 | 0.55 * | 26.72 |

| B | 1 | 0.024 | 827.28 * | 0.003 | 8.27 | 287.51 * | 0.068 | 4278.16 | 407.39 | 0.33 * | 213.5 | 557.36 | 126.07 | 0.16 * | 26.15 | 0.13 * | 1.38 |

| C | 1 | 0.2 | 68.27 * | 5 × 10−4 | 0.19 | 9.36 | 0.004 | 94.09 | 2.85 | 0.0007 | 8.86 | 108.24 | 30.96 | 0.009 | 0.2 | 1 × 10−5 | 4.78 |

| AB | 1 | 0.54 | 0.25 | 2 × 10−4 | 0.001 | 8.2 | 0.017 | 1298.74 | 54.3 | 0.38 | 20.94 | 740.65 | 120.85 | 0.001 | 37.14 | 0.038 | 10.27 |

| AC | 1 | 0.028 | 0.21 | 4 × 10−5 | 0.036 | 4.57 | 0.03 | 257.15 | 15.25 | 0.51 | 4.23 | 50.03 | 1.58 | 0.0003 | 3.54 | 0.1 * | 2.34 |

| BC | 1 | 0.57 | 69.27 * | 0.001 | 0.26 | 11.21 | 0.004 | 1484.3 | 66.89 | 0.029 | 104.45 | 40.73 | 0.43 | 0.60 | 3.41 | 5 × 10−4 | 8.39 |

| A2 | 1 | 3.15 | 27.45 | 0.034 * | 3.21 * | 11.73 | 0.1 | 87,001.11 * | 2015.96 * | 0.093 | 797.83 * | 2254.50 * | 2215.74 * | 0.67 * | 567.04 * | 0.19 * | 0.48 |

| B2 | 1 | 9.52 * | 169.13 * | 0.24 * | 13.86 * | 47.63 * | 0.64 | 126,500 * | 3526.73 * | 0.042 * | 1361.98 * | 4834.64 * | 2754.69 * | 0.19 * | 819.45 * | 0.001 | 1.26 |

| C2 | 1 | 0.56 * | 21.01 | 0.036 * | 2.99 | 0.43 | 0.11 * | 57,122.64 * | 1005.44 * | 0.025 | 679.09 * | 3073.96 * | 2323 * | 1.93 * | 812.36 * | 0.012 | 1.47 |

| Residual | 10 | 0.3 | 9.86 | 0.004 | 0.84 | 4.77 | 0.032 | 38,113.3 | 123.83 | 0.26 | 52.94 | 182.98 | 105.05 | 0.025 | 13.56 | 0.014 | 6.28 |

| Lack of fit | 5 | 0.49 | 18.78 * | 0.007 | 1.28 | 6.38 | 0.062 * | 30,418.4 | 200.15 | 0.052 * | 86.47 | 302.91 | 109.78 | 0.050 * | 25.69 | 0.022 * | 11.1 * |

| Pure error | 5 | 0.1 | 0.93 | 0.002 | 0.41 | 3.15 | 0.003 | 7694.92 | 47.6 | 0.0019 | 19.41 | 63.05 | 100.33 | 0.0002 | 1.42 | 0.005 | 1.45 |

| R2 | 0.81 | 0.92 | 0.85 | 0.75 | 0.84 | 0.73 | 0.84 | 0.81 | 0.78 | 0.84 | 0.85 | 0.84 | 0.92 | 0.92 | 0.91 | 0.47 | |

| Coefficient | Physicochemical Properties | Rheological Properties | Thermal Properties | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| EBS | EAS | EBS | EAS | EAS | ||||||||||||

| WAI | WSI | RS | WAI | WSI | RS | G′ | G″ | tan δ | η | G′ | G″ | tan δ | η | ∆H | Tg | |

| b0 | 6.35 * | 7.32 * | 0.39 * | 6.35 * | 6.58 * | 0.44 * | 253.71 * | 45.80 * | 0.23 * | 30.14 * | 52.35 * | 39.66 * | 0.17 * | 21.18 * | 0.29 * | 99.35 |

| b1 | −0.17 | 0.44 | −0.01 | −0.17 | 1.24 | 0.06 | 7.03 | 2.27 | −0.036 | 3.33 | 10.04 | 3.46 | −0.21 * | 2.25 | −0.19 * | −1.29 |

| b2 | −0.04 | −7.19 * | −0.01 | −0.03 * | −4.74 * | 5 x 10−4 | −16.35 | −5.05 | 0.14 * | −3.65 * | −5.9 | −2.81 | −0.10 * | −1.28 | 0.09 * | 0.29 |

| b3 | −0.11 | 2.07 * | 0.01 | −0.11 | 0.76 | −0.04 | −2.43 | −0.36 | −0.006 | −0.74 | 2.6 | 1.39 | −0.024 | −0.11 | 0 | −0.55 |

| b12 | 0.26 | −0.18 | 5 × 10−4 | 0.26 | −1.01 | −0.06 | 12.74 | 2.61 | −0.069 | −1.62 | −9.62 | −3.89 | −0.015 | −2.15 | 0.07 | 1.13 |

| b13 | 0.06 | 0.16 | −5 × 10−4 | 0.06 | 0.76 | −0.02 | 5.67 | 1.38 | −0.080 | −0.73 | −2.5 | −0.44 | −0.006 | −0.66 | −0.11 * | −0.54 |

| b23 | 0.27 | −2.94 * | −2 × 10−4 | 0.27 | −1.18 | −0.02 | 13.62 | 2.89 | −0.060 | 3.61 | 2.26 | 0.23 | −0.087 | 0.65 | −0.01 | −1.02 |

| b11 | −0.35 | 1.04 | 0.04 * | −0.35 | 0.68 | 0.06 | −58.82 * | −8.96 * | 0.061 | −5.63 * | −9.47 * | −9.39 * | 0.16 * | −4.75 * | 0.09 * | 0.14 |

| b22 | −0.62 * | 2.59 * | 0.09 * | −0.62 * | 1.38 | 0.16 | −70.92 * | −11.84 * | 0.13 * | −8.06 * | −13.87 * | −10.47 * | 0.086 * | −5.71 * | −0.01 | 0.22 |

| b33 | −0.15 * | 0.91 | 0.03 * | −0.15 | −0.13 | 0.06 | −47.66 * | −6.32 * | 0.032 | −5.20 * | −11.06 * | −9.61 * | 0.28 * | −5.68 * | 0.02 | −0.24 |

| Experimental | Estimated | % Error | |

|---|---|---|---|

| WAI | 4.34 ± 0.15 | 4.84 | 10.33 |

| WSI | 21.06 ± 0.52 | 20.34 | 3.41 |

| RS | 0.88 ± 0.08 | 0.96 | 9.09 |

| Process Variables | Levels | ||||

|---|---|---|---|---|---|

| −2 | −1 | 0 | +1 | +2 | |

| Extrusion temperature (°C) | 90 | 100 | 110 | 120 | 130 |

| Moisture content (%) | 20 | 25 | 30 | 35 | 40 |

| Screw speed (rpm) | 200 | 240 | 280 | 320 | 360 |

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Neder-Suárez, D.; Amaya-Guerra, C.A.; Quintero-Ramos, A.; Pérez-Carrillo, E.; Alanís-Guzmán, M.G.d.J.; Báez-González, J.G.; García-Díaz, C.L.; Núñez-González, M.A.; Lardizábal-Gutiérrez, D.; Jiménez-Castro, J.A. Physicochemical Changes and Resistant-Starch Content of Extruded Cornstarch with and without Storage at Refrigerator Temperatures. Molecules 2016, 21, 1064. https://doi.org/10.3390/molecules21081064

Neder-Suárez D, Amaya-Guerra CA, Quintero-Ramos A, Pérez-Carrillo E, Alanís-Guzmán MGdJ, Báez-González JG, García-Díaz CL, Núñez-González MA, Lardizábal-Gutiérrez D, Jiménez-Castro JA. Physicochemical Changes and Resistant-Starch Content of Extruded Cornstarch with and without Storage at Refrigerator Temperatures. Molecules. 2016; 21(8):1064. https://doi.org/10.3390/molecules21081064

Chicago/Turabian StyleNeder-Suárez, David, Carlos A. Amaya-Guerra, Armando Quintero-Ramos, Esther Pérez-Carrillo, María G. de J. Alanís-Guzmán, Juan G. Báez-González, Carlos L. García-Díaz, María A. Núñez-González, Daniel Lardizábal-Gutiérrez, and Jorge A. Jiménez-Castro. 2016. "Physicochemical Changes and Resistant-Starch Content of Extruded Cornstarch with and without Storage at Refrigerator Temperatures" Molecules 21, no. 8: 1064. https://doi.org/10.3390/molecules21081064