New Aspects in the Formulation of Drugs Based on Three Case Studies

Abstract

:1. Introduction

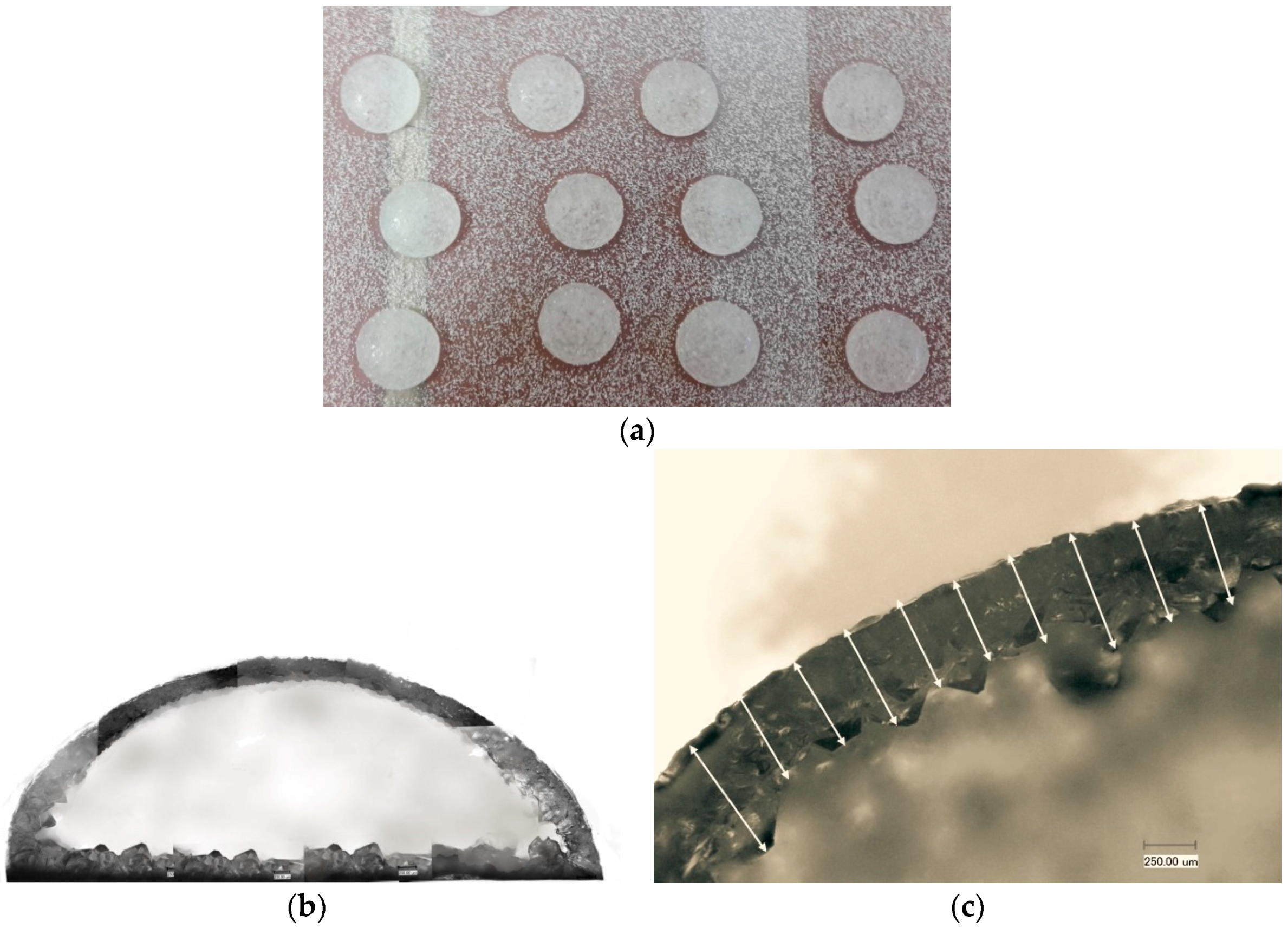

2. In Situ Coating

- Mixability with the drug material in the melt

- Crystallization prior to the drug material

- Stability at its melting point, and stability at the reduced melting temperature of the mixture with the API.

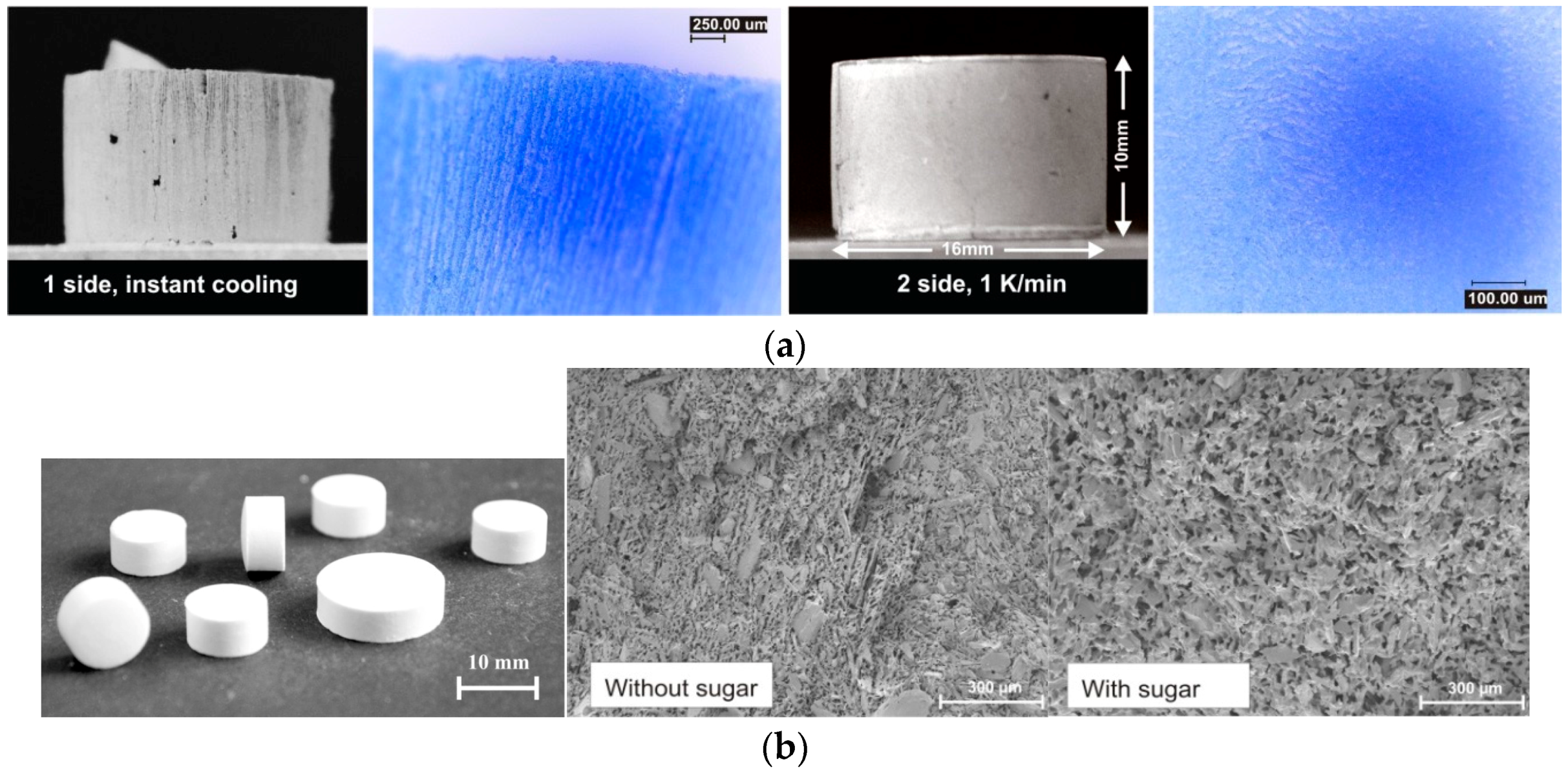

3. Freeze Casting—An Alternative Technique to Produce Controlled Release Tablets

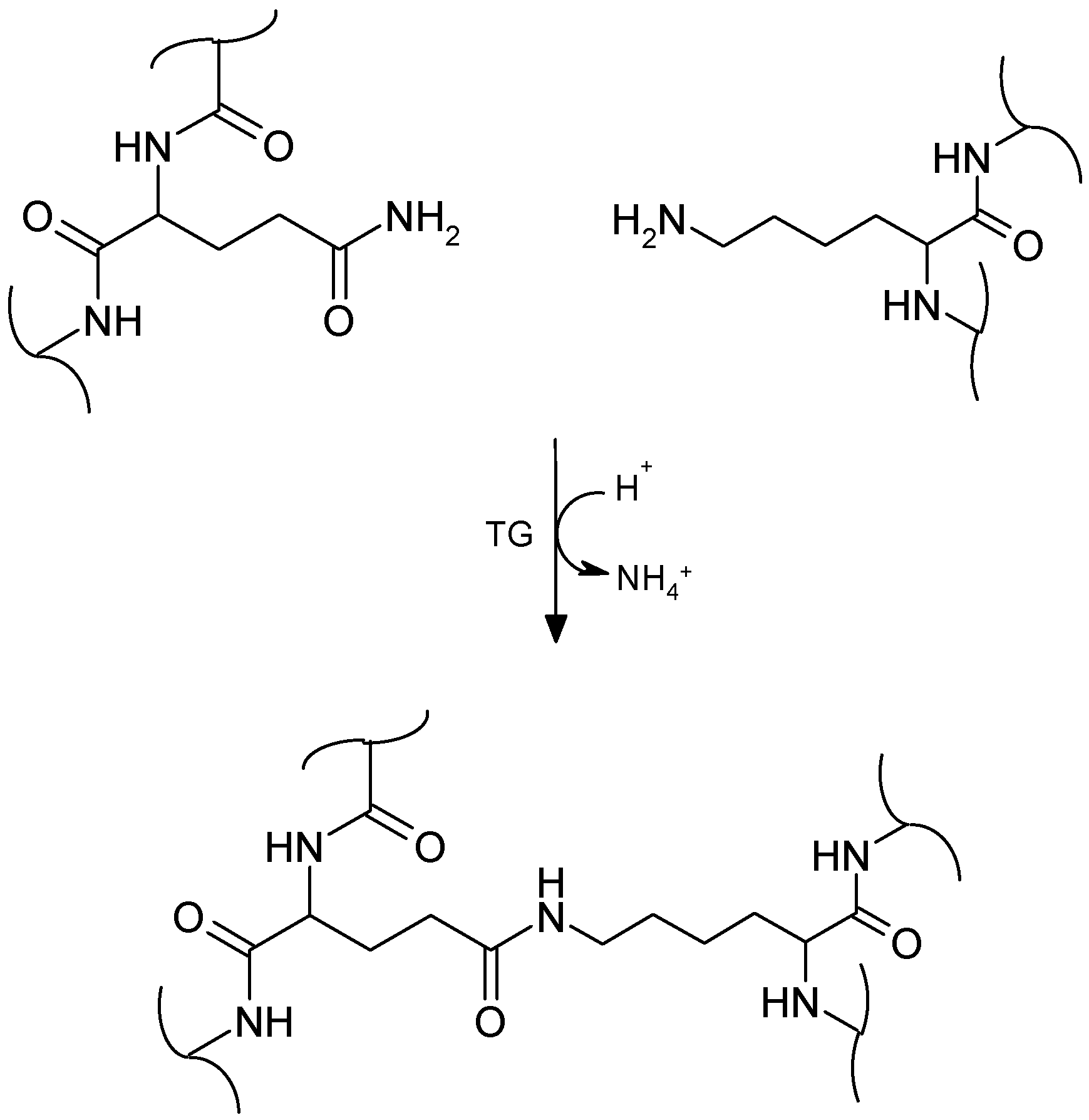

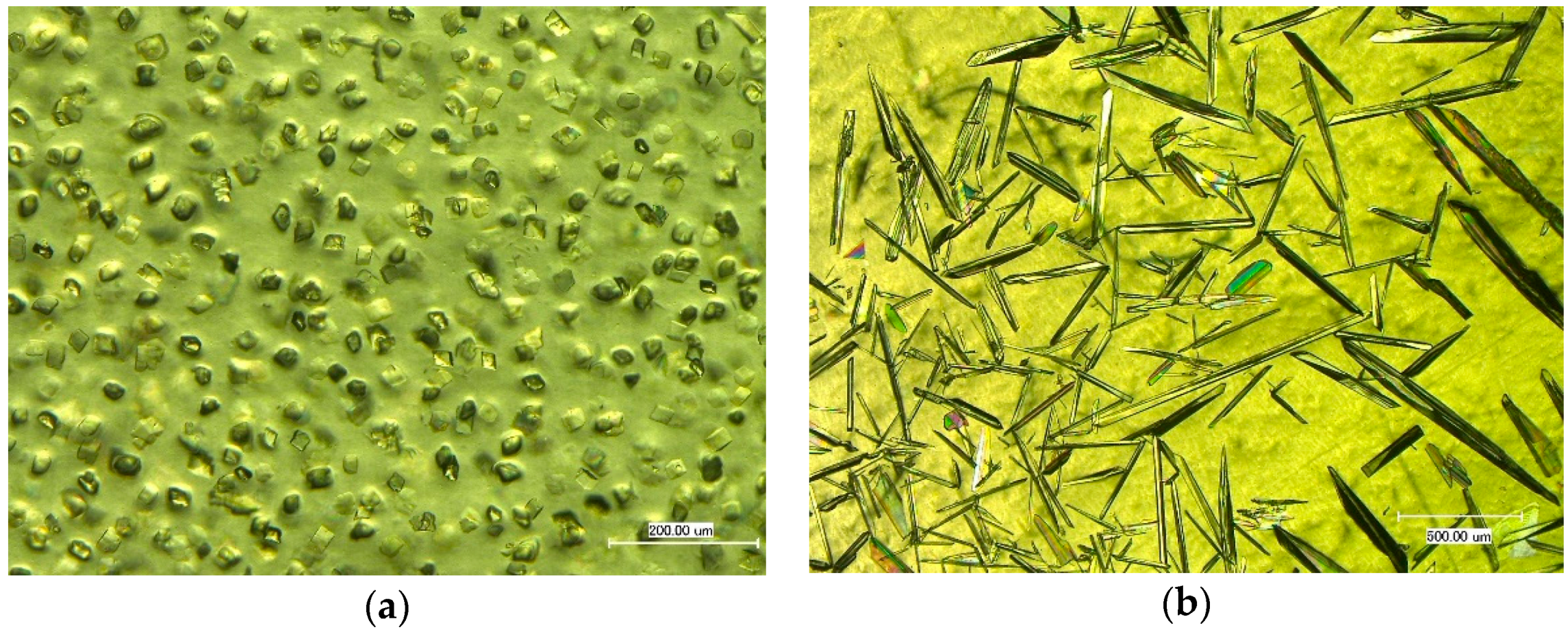

4. Protein-Based Biocomposites as Drug Delivery Systems

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Abouzeid, A.; Petersen, S.; Ulrich, J. Optimized Coating through Phase Separation in Tablets by Melt Crystallization. Chem. Eng. Technol. 2014, 37, 1369–1375. [Google Scholar] [CrossRef]

- Abouzeid, A.; Petersen, S.; Ulrich, J. Utilizing melt crystallization fundamentals in the development of a new tabletting technology. Front. Chem. Sci. Eng. 2014, 8, 346–352. [Google Scholar] [CrossRef]

- Ulrich, J.; Abouzeid, A.; Hartwig, A.; Petersen, S.; Wendt, K. Geht es nicht einfacher? In situ Coating—Beschichtung direkt aus der Schmelze. CIT Plus 2015, 18, 44–45. [Google Scholar]

- Wendt, K.; Petersen, S.; Ulrich, J. Application of in-situ coating on a Two-Compound test system. Chem. Eng. Technol. 2014, 37, 1408–1412. [Google Scholar] [CrossRef]

- Abouzeid, A.; Petersen, S.; Ulrich, J. The effect of seeding on the phase separation phenomenon in a solidifying molten drop. Adv. Powder Technol. 2015, 26, 309–314. [Google Scholar] [CrossRef]

- Wendt, K.; Petersen, S.; Ulrich, J. Influence of seeding on concentration distribution within pastilles drop formed out of binary melts. Chem. Eng. Sci. 2015, 133, 70–74. [Google Scholar] [CrossRef]

- Abouzeid, A. Application of a New Technology Utilizing Melt Crystallization for the Production of Coated Tablets. Ph.D. Thesis, Martin Luther University Halle-Wittenberg, Halle, Germany, February 2015. Available online: http://141.48.65.178/hs/content/titleinfo/2258727 (accessed on 17 February 2016). [Google Scholar]

- Wendt, K. Necessary Requirements for an Industrial Application of the in situ Coating Process. Ph.D. Thesis, Martin Luther-University Halle-Wittenberg, Halle, Germany, April 2015. [Google Scholar]

- Nguyen, P.T.N.; Ulrich, J. Fast Dispersible Cocoa Tablets: A Case Study of Freeze-casting Applied to Foods. Chem. Eng. Technol. 2014, 37, 1376–1382. [Google Scholar] [CrossRef]

- Petersen, S.; Abouzeid, A.; Nguyen, P.T.N.; Wendt, K.; Ulrich, J. Crystallization technology for product design. Trends Heat. Mass Transf. 2013, 13, 97–105. [Google Scholar]

- Nguyen, P.T.N.; Ulrich, J. Sugar alcohols—Multifunctional agents in the freeze casting process of foods. J. Food Eng. 2015, 153. [Google Scholar] [CrossRef]

- Nguyen, P.T.N.; Ulrich, J. Production of High-Tensile-Strength Paracetamol Tablets Using the Freeze-Casting Process. Chem. Eng. Technol. 2015, 38, 991–998. [Google Scholar] [CrossRef]

- Nguyen, P.T.N. Freeze Casting—A New Formulation for Fast Dissolving Tablets or Foods. Ph.D. Thesis, Martin Luther-University Halle-Wittenberg, Halle, Germany, 2015. [Google Scholar]

- Nguyen, P.T.N.; Ulrich, J. Preconditions for designing a freeze casting process of drugs—Rheological properties of suspensions. Chem. Eng. Technol. 2016. [Google Scholar] [CrossRef]

- Pradzynski, C.C.; Forck, R.M.; Zeuch, T.; Slavíček, P.; Buck, U. A Fully Size-Resolved Perspective on the Crystallization of Water Clusters. Science 2012, 337, 1529–1532. [Google Scholar] [CrossRef] [PubMed]

- Deville, T.S. Freeze-Casting of Porous Ceramics: A Review of Current Achievements and Issues. Adv. Eng. Mater. 2008, 10, 155–169. [Google Scholar] [CrossRef]

- Pachulski, N.; Ulrich, J. Production of Tablet-Like Solid Bodies without Pressure by Sol-Gel Processes. Lett. Drug Des. Discov. 2007, 4, 78–81. [Google Scholar] [CrossRef]

- Pachulski, N.; Ulrich, J. New Fields of Application for Sol-gel Processes: Cold and Vacuum-free “Compacting” of Pharmaceutical Materials to Tablets. Chem. Eng. Res. Des. 2007, 85, 1013–1019. [Google Scholar] [CrossRef]

- Pachulski, N. Herstellung von Pharmazeutischen Tablettenkörpern Mit Einem Gefrierguss-/Sol-Gel-Prozess. Ph.D. Thesis, Martin Luther University Halle-Wittenberg, Halle, Germany, December 2007. [Google Scholar]

- Szepes, A.; Ulrich, J.; Frakas, Z.; Kovács, J.; Szabó-Révész, P. Freeze-casting technique in the development of solid drug delivery systems. Chem. Eng. Process. 2007, 46, 230–238. [Google Scholar] [CrossRef]

- Szepes, A.; Feher, A.; Szabó-Révész, P.; Ulrich, J. Influence of Freezing Temperature on Product Parameters of Solid Dosage Forms Prepared via the Freeze-Casting Technique. Chem. Eng. Technol. 2007, 30, 511–516. [Google Scholar] [CrossRef]

- Shlyakhtina, O.A.; Oha, Y.; Tretyakov, Y.D. Preparation of dense La0.7Ca0.3MnO3 ceramics from freeze-dried precursors. J. Eur. Ceram. Soc. 2000, 20, 2047–2054. [Google Scholar] [CrossRef]

- Deville, S.; Saiz, E.; Tomsia, A.P. Freeze casting of hydroxyapatite scaffolds for bone tissue engineering. Biomaterials 2006, 27, 5480–5489. [Google Scholar] [CrossRef] [PubMed]

- Li, W.L.; Lu, K.; Walz, J.Y. Freeze casting of porous materials: Review of critical factors in microstructure evolution. Int. Mater. Rev. 2012, 57, 37–60. [Google Scholar] [CrossRef]

- Berg, J.M.; Tymoczko, J.L.; Stryer, L. Biochemistry, 7th ed.; W.H. Freeman and Company: New York, NY, USA, 2012. [Google Scholar]

- Voet, D.; Voet, J.G. Biochemistry, 4th ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2011. [Google Scholar]

- Büttner, K.; Marx, C.K.; Hertel, T.C.; Pietzsch, M. Optimierung einer rekombinanten mikrobiellen Transglutaminase. Chem. Ing. Tech. 2010, 82, 43–49. [Google Scholar] [CrossRef]

- Kashiwagi, T.; Yokoyama, K.-I.; Ishikawa, K.; Ono, K.; Ejima, D.; Matsui, H.; Suzuki, E.-I. Crystal Structure of Microbial Transglutaminase from Streptoverticillium mobaraense. J. Biol. Chem. 2002, 277, 44252–44260. [Google Scholar] [CrossRef] [PubMed]

- Guilbert, S.; Cuq, B. Material Formed from Proteins. In Handbook of Biodegradable Polymers, 2nd ed.; Bastioli, C., Ed.; Smithers Rapra Ltd: Shawbury, UK, 2014; pp. 369–420. [Google Scholar]

- Krochta, J.M. Proteins as raw materials for films and coatings: Definitions, current status, and opportunities. In Protein-Based Films and Coatings; Gennadios, A., Ed.; CRC Press LLC: Boca Raton, FL, USA, 2002; pp. 1–41. [Google Scholar] [CrossRef]

- Gomes, S.; Leonor, I.B.; Mano, J.F.; Reis, R.L.; Kaplan, D.L. Natural and genetically engineered proteins for tissue engineering. Prog. Polym. Sci. 2012, 37. [Google Scholar] [CrossRef] [PubMed]

- Hu, X.; Cebe, P.; Weiss, A.S.; Omenetto, F.; Kaplan, D.L. Protein-based composite materials. Mater. Today 2012, 15, 208–215. [Google Scholar] [CrossRef]

- Avérous, L.; Pollet, E. Macro-, Micro-, and Nanocomposites Based on Biodegradable Polymers. In Handbook of Biopolymer-Based Materials; Thomas, S., Durand, D., Chassenieux, C., Jyotishkumar, P., Eds.; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2013; pp. 173–210. [Google Scholar]

- Heeres, H.J.; van Maastrigt, F.; Picchioni, F. Polymeric Blends with Biopolymers. In Handbook of Biopolymer-Based Materials; Thomas, S., Durand, D., Chassenieux, C., Jyotishkumar, P., Eds.; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2013; pp. 143–171. [Google Scholar]

- Niaounakis, M. Biopolymers: Processing and Products; Elsevier Inc.: Oxford, UK, 2015. [Google Scholar]

- Pilla, S. Engineering Applications of Bioplastics and Biocomposites—An Overview. In Handbook of Bioplastics and Biocomposites Engineering Applications; Pilla, S., Ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2011; pp. 1–15. [Google Scholar] [CrossRef]

- Frohberg, P. Reactive extrusion of proteins: Sodium caseinate films enhanced by crystallization. Trends Chem. Eng. 2014, 15, 1–13. [Google Scholar]

- Verbeek, C.J.R.; Berg, L.E.V.D. Extrusion Processing and Properties of Protein-Based Thermoplastics. Macromol. Mater. Eng. 2010, 295, 10–21. [Google Scholar] [CrossRef]

- Belyamani, I.; Prochazka, F.; Assezat, G. Production and characterization of sodium caseinate edible films made by blown-film extrusion. J. Food Eng. 2014, 121, 39–47. [Google Scholar] [CrossRef]

- Jerez, A.; Partal, P.; Martinez, I.; Gallegos, C.; Guerrero, A. Protein-based bioplastics: Effect of thermo-mechanical processing. Rheol. Acta 2007, 46, 711–720. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Tummala, P.; Liu, W.; Misra, M.; Mulukutla, P.V.; Drzal, L.T. Injection molded biocomposites from soy protein based bioplastic and short industrial hemp fiber. J. Polym. Environ. 2005, 13, 279–285. [Google Scholar] [CrossRef]

- Zubeldía, F.; Ansorena, M.R.; Marcovich, N.E. Wheat gluten films obtained by compression molding. Polym. Test. 2015, 43, 68–77. [Google Scholar] [CrossRef]

- Frohberg, P.; Pietzsch, M.; Ulrich, J. Effect of crystalline substances in biodegradable films. Chem. Eng. Res. Des. 2010, 88, 1148–1152. [Google Scholar] [CrossRef]

- Stolte, I.; Frohberg, P.; Pietzsch, M.; Ulrich, J. Crystals in protein films: What are they good for? Chem. Eng. Sci. 2012, 77, 196–200. [Google Scholar] [CrossRef]

- Gennadios, A. Edible films and coatings from proteins. In Proteins in Food Processing; Yada, R.Y., Ed.; CRC Press: Cambridge, UK, 2004; pp. 442–467. [Google Scholar]

- González, A.; Strumia, M.C.; Igarzabal, C.I.A. Modification Strategies of Proteins for Food Packaging Applications. In Functional Polymers in Food Science; Cirillo, G., Spizzirri, U.G., Iemmi, F., Eds.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2015; Volume 1, pp. 127–145. [Google Scholar]

- Sample Availability: Samples of drop formed pastilles, freeze-casted tablets and protein-based biocomposites are available from the authors.

| New Technologies | Cost Reduction through Less Process Steps | Better Drug Delivery Control by | Improved Product Properties by |

|---|---|---|---|

| In situ coating |

| crystalline coats | crystalline coats |

| Freeze casting |

| controllable surface areas and additives | low temperature and non-external pressure processing |

| Protein-based biocomposites | continuous reactive extrusion processing, including crystallization and shaping | carrier and release systems with controllable physical properties | cross-linked and tailored protein matrix |

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Frohberg, P.; Nguyen, T.N.P.; Ulrich, J. New Aspects in the Formulation of Drugs Based on Three Case Studies. Molecules 2016, 21, 577. https://doi.org/10.3390/molecules21050577

Frohberg P, Nguyen TNP, Ulrich J. New Aspects in the Formulation of Drugs Based on Three Case Studies. Molecules. 2016; 21(5):577. https://doi.org/10.3390/molecules21050577

Chicago/Turabian StyleFrohberg, Patrick, Thi Nhat Phuong Nguyen, and Joachim Ulrich. 2016. "New Aspects in the Formulation of Drugs Based on Three Case Studies" Molecules 21, no. 5: 577. https://doi.org/10.3390/molecules21050577