Neutral- and Multi-Colored Semitransparent Perovskite Solar Cells

Abstract

:1. Introduction

2. Neutral-Colored Semitransparent Perovskite Solar Cells

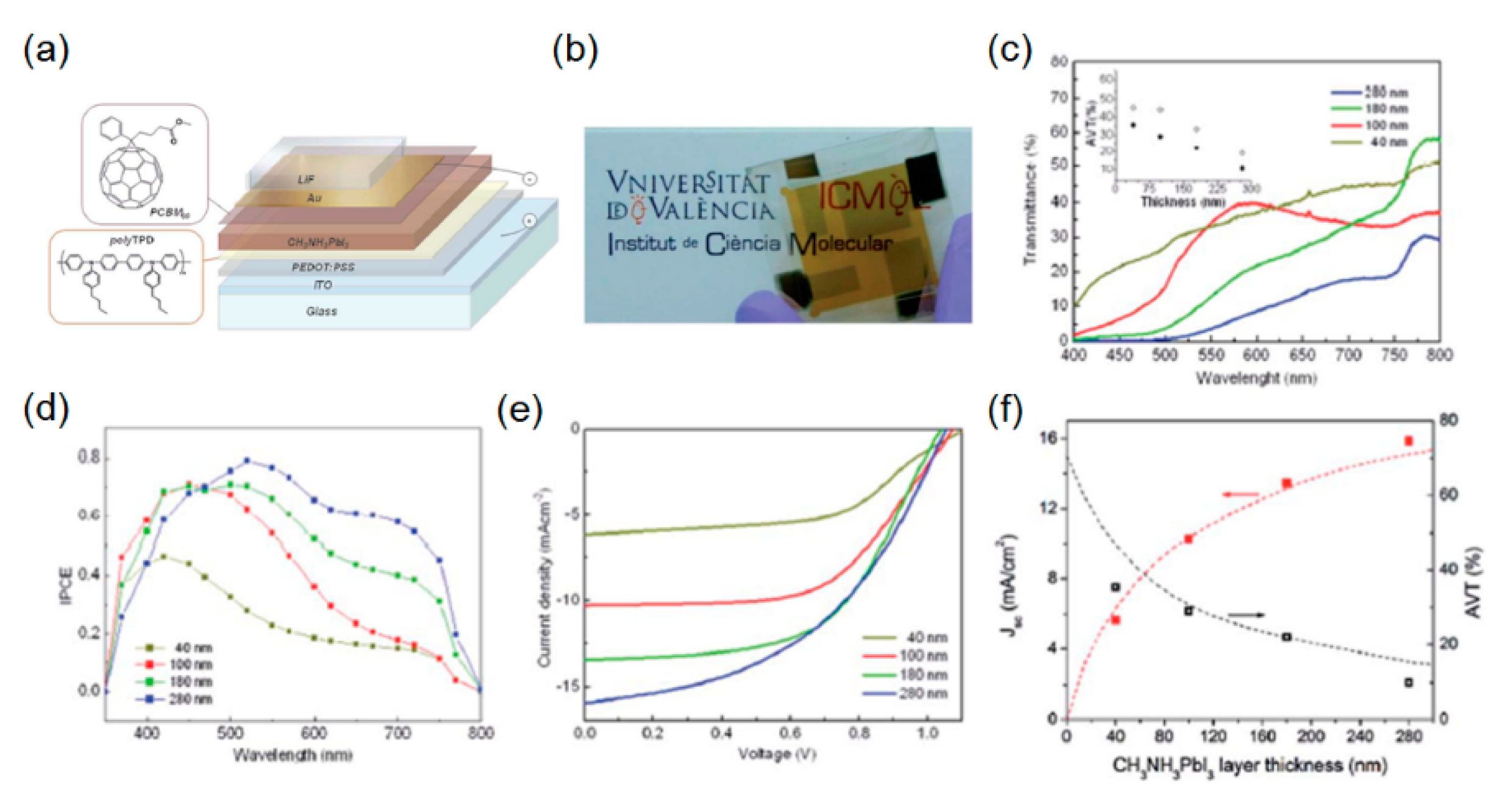

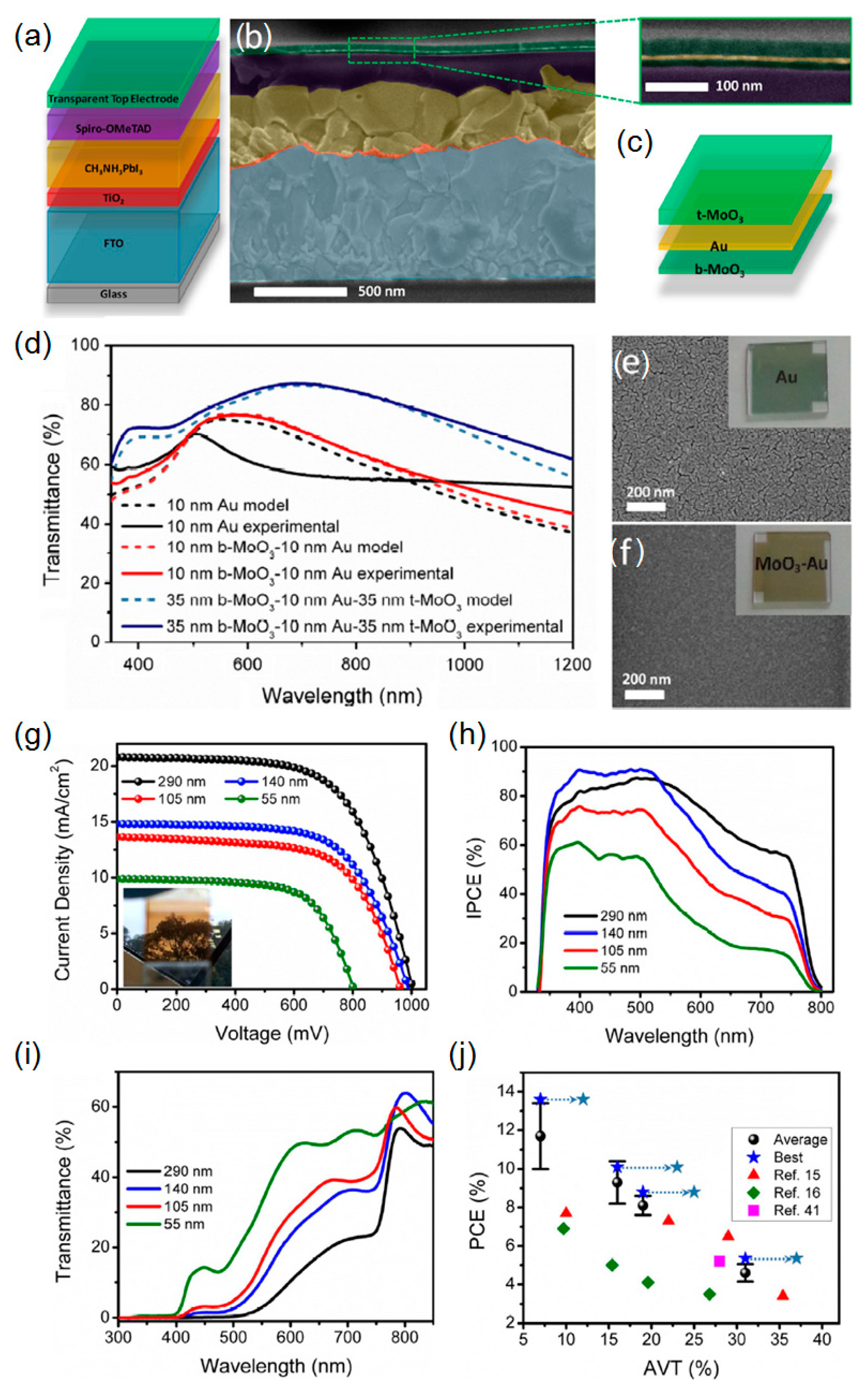

2.1. Thin Metal Electrodes

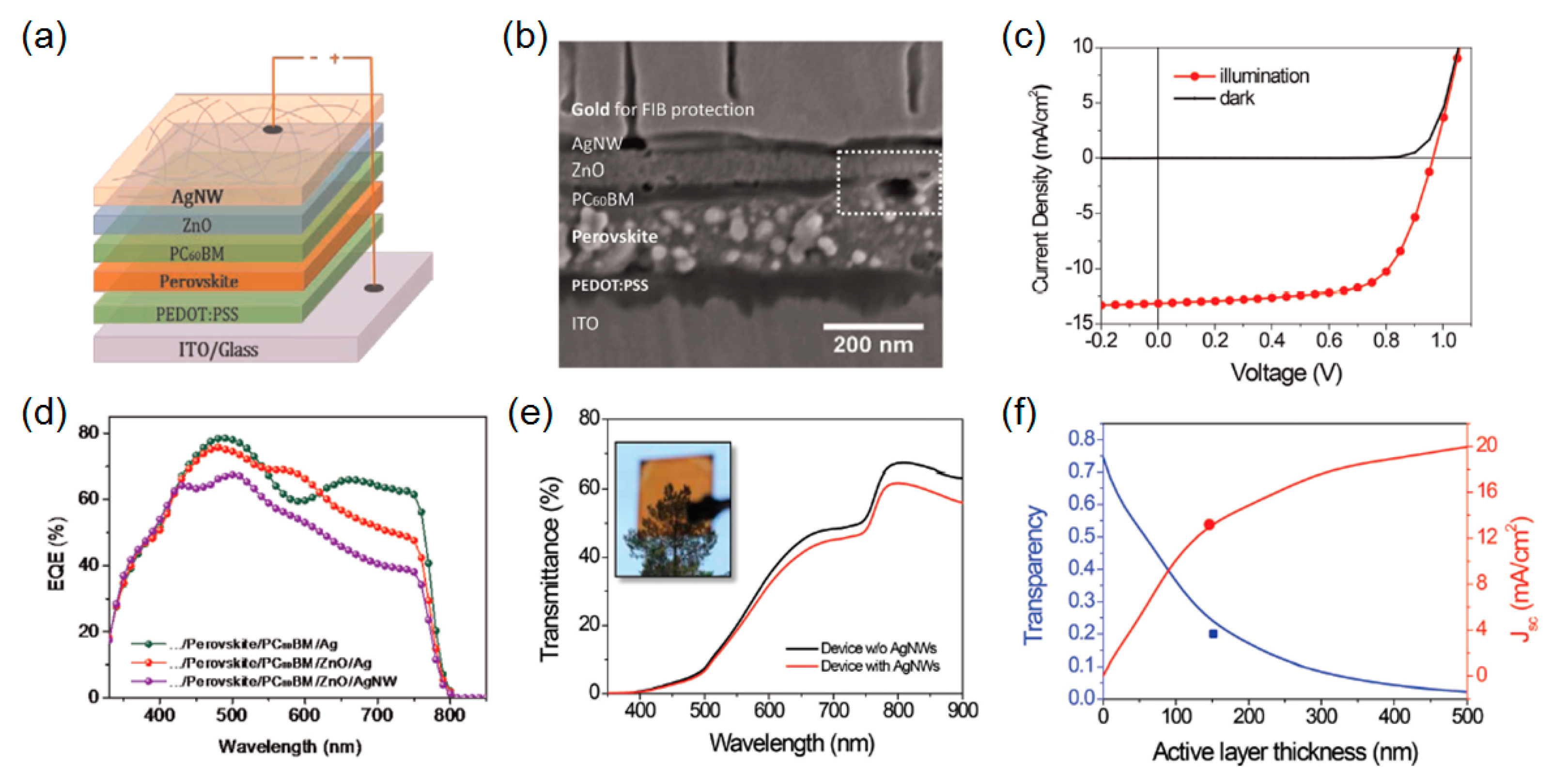

2.2. Solution-Processed Ag Nanowires

2.3. Carbon Nanotube- and Graphene-Based Transparent Electrodes

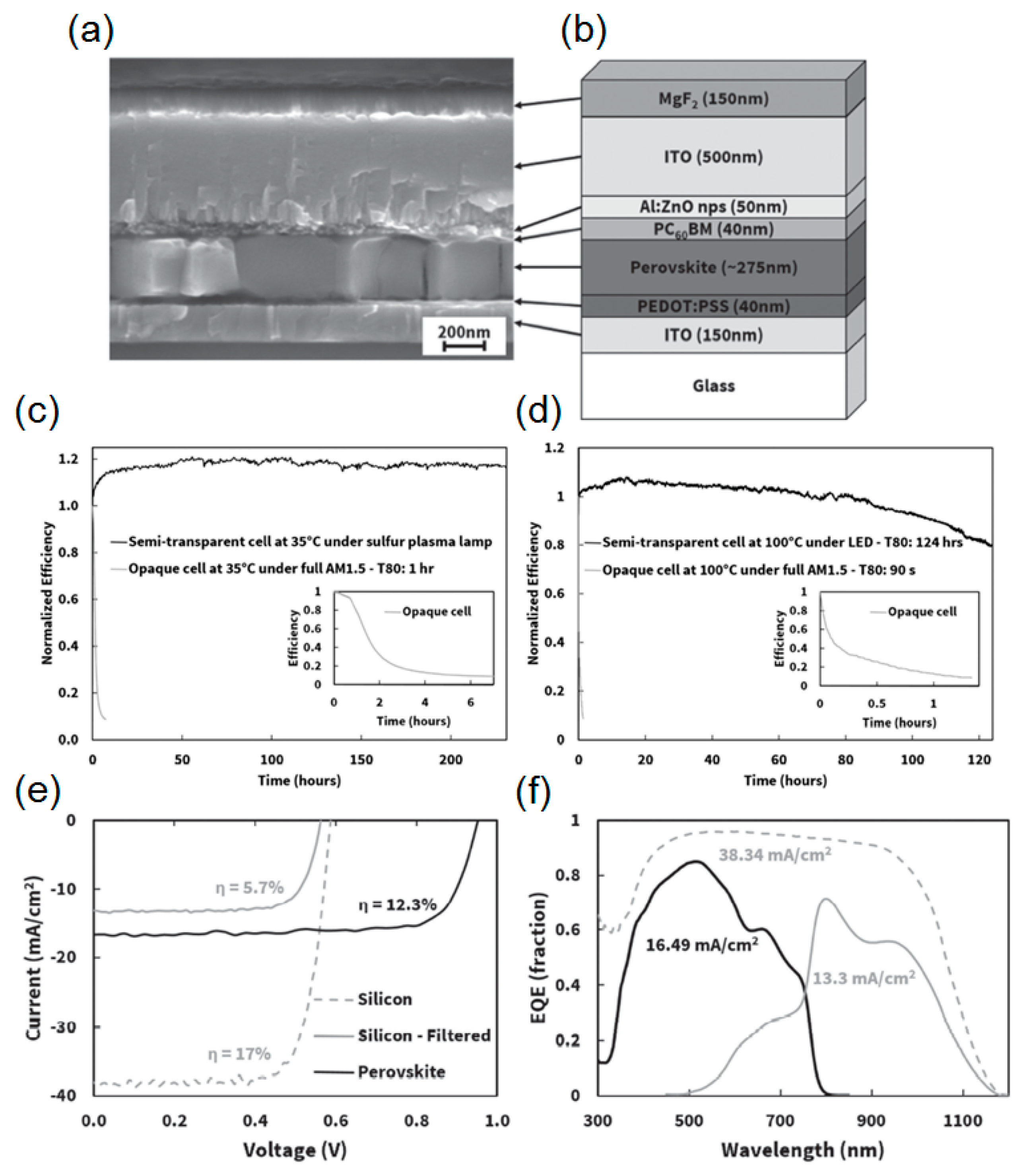

2.4. Transparent Conductive Oxides

2.5. Microstructured Arrays of Perovskite “Islands”

3. Multi Colored Perovskite Solar Cells

3.1. Band Gap Tuning by a Chemical Management

3.2. Microcavity Integrated Cathodes

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Lee, K.-T.; Lee, J.Y.; Seo, S.; Guo, L. Colored ultrathin hybrid photovoltaics with high quantum efficiency. Light Sci. Appl. 2014, 3, e215. [Google Scholar] [CrossRef]

- Ameri, T.; Dennler, G.; Waldauf, C.; Azimi, H.; Seemann, A.; Forberich, K.; Hauch, J.; Scharber, M.; Hingerl, K.; Brabec, C.J. Fabrication, optical modeling, and color characterization of semitransparent bulk-heterojunction organic solar cells in an inverted structure. Adv. Funct. Mater. 2010, 20, 1592–1598. [Google Scholar] [CrossRef]

- Bailie, C.D.; Christoforo, M.G.; Mailoa, J.P.; Bowring, A.R.; Unger, E.L.; Nguyen, W.H.; Burschka, J.; Pellet, N.; Lee, J.Z.; Gratzel, M.; et al. Semi-transparent perovskite solar cells for tandems with silicon and CIGS. Energy Environ. Sci. 2015, 8, 956–963. [Google Scholar] [CrossRef]

- Lee, K.-T.; Lee, J.Y.; Seo, S.; Guo, L.J. Microcavity-integrated colored semitransparent hybrid photovoltaics with improved efficiency and color purity. IEEE J. Photovolt. 2015, 5, 1654–1658. [Google Scholar] [CrossRef]

- Bryant, D.; Greenwood, P.; Troughton, J.; Wijdekop, M.; Carnie, M.; Davies, M.; Wojciechowski, K.; Snaith, H.J.; Watson, T.; Worsley, D. A transparent conductive adhesive laminate electrode for high-efficiency organic-inorganic lead halide perovskite solar cells. Adv. Mater. 2014, 26, 7499–7504. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.-H.; Chen, C.-W.; Huang, Z.-Y.; Lin, W.-C.; Lin, L.-Y.; Lin, F.; Wong, K.-T.; Lin, H.-W. Microcavity-embedded, colour-tuneable, transparent organic solar cells. Adv. Mater. 2014, 26, 1129–1134. [Google Scholar] [CrossRef] [PubMed]

- Eperon, G.E.; Bryant, D.; Troughton, J.; Stranks, S.D.; Johnston, M.B.; Watson, T.; Worsley, D.A.; Snaith, H.J. Efficient, semitransparent neutral-colored solar cells based on microstructured formamidinium lead trihalide perovskite. J. Phys. Chem. Lett. 2015, 6, 129–138. [Google Scholar] [CrossRef] [PubMed]

- Fukuda, M.; Lee, K.-T.; Lee, J.Y.; Guo, L.J. Optical simulation of periodic surface texturing on ultrathin amorphous silicon solar cells. IEEE J. Photovolt. 2014, 4, 1337–1342. [Google Scholar] [CrossRef]

- Eperon, G.E.; Burlakov, V.M.; Goriely, A.; Snaith, H.J. Neutral color semitransparent microstructured perovskite solar cells. ACS Nano 2014, 8, 591–598. [Google Scholar] [CrossRef] [PubMed]

- Guo, F.; Azimi, H.; Hou, Y.; Przybilla, T.; Hu, M.; Bronnbauer, C.; Langner, S.; Spiecker, E.; Forberich, K.; Brabec, C.J. High-performance semitransparent perovskite solar cells with solution-processed silver nanowires as top electrodes. Nanoscale 2015, 7, 1642–1649. [Google Scholar] [CrossRef] [PubMed]

- Lee, K.-T.; Fukuda, M.; Joglekar, S.; Guo, L.J. Colored, see-through perovskite solar cells employing an optical cavity. J. Mater. Chem. C 2015, 3, 5377–5382. [Google Scholar] [CrossRef]

- Li, Z.; Kulkarni, S.A.; Boix, P.P.; Shi, E.; Cao, A.; Fu, K.; Batabyal, S.K.; Zhang, J.; Xiong, Q.; Wong, L.H.; et al. Laminated carbon nanotube networks for metal electrode-free efficient perovskite solar cells. ACS Nano 2014, 8, 6797–6804. [Google Scholar] [CrossRef] [PubMed]

- Roldan-Carmona, C.; Malinkiewicz, O.; Betancur, R.; Longo, G.; Momblona, C.; Jaramillo, F.; Camacho, L.; Bolink, H.J. High efficiency single-junction semitransparent perovskite solar cells. Energy Environ. Sci. 2014, 7, 2968–2973. [Google Scholar] [CrossRef]

- Della Gaspera, E.; Peng, Y.; Hou, Q.; Spiccia, L.; Bach, U.; Jasieniak, J.J.; Cheng, Y.-B. Ultra-thin high efficiency semitransparent perovskite solar cells. Nano Energy 2015, 13, 249–257. [Google Scholar] [CrossRef]

- Long, W.; Qin, C.; Shichao, S.; Yan, Y.; Lin, J.; Xin, H. Photon harvesting, coloring and polarizing in photovoltaic cell integrated color filters: Efficient energy routing strategies for power-saving displays. Nanotechnology 2015, 26, 265203. [Google Scholar]

- Zhang, W.; Anaya, M.; Lozano, G.; Calvo, M.E.; Johnston, M.B.; Míguez, H.; Snaith, H.J. Highly efficient perovskite solar cells with tunable structural color. Nano Lett. 2015, 15, 1698–1702. [Google Scholar] [CrossRef] [PubMed]

- Lu, J.-H.; Yu, Y.-L.; Chuang, S.-R.; Yeh, C.-H.; Chen, C.-P. High-performance, semitransparent, easily tunable vivid colorful perovskite photovoltaics featuring Ag/ITO/Ag microcavity structures. J. Phys. Chem. C 2016, 120, 4233–4239. [Google Scholar] [CrossRef]

- Lee, J.Y.; Lee, K.-T.; Seo, S.; Guo, L.J. Decorative power generating panels creating angle insensitive transmissive colors. Sci. Rep. 2014, 4, 4192. [Google Scholar] [CrossRef] [PubMed]

- Wen, L.; Chen, Q.; Sun, F.; Song, S.; Jin, L.; Yu, Y. Theoretical design of multi-colored semi-transparent organic solar cells with both efficient color filtering and light harvesting. Sci.Rep. 2014, 4, 7036. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, S.; Guillen, E.; Kavan, L.; Gratzel, M.; Nazeeruddin, M.K. Metal free sensitizer and catalyst for dye sensitized solar cells. Energy Environ. Sci. 2013, 6, 3439–3466. [Google Scholar] [CrossRef]

- Kumaresan, D.; Thummel, R.P.; Bura, T.; Ulrich, G.; Ziessel, R. Color tuning in new metal-free organic sensitizers (bodipys) for dye-sensitized solar cells. Chem. Eur. J. 2009, 15, 6335–6339. [Google Scholar] [CrossRef] [PubMed]

- Park, H.J.; Xu, T.; Lee, J.Y.; Ledbetter, A.; Guo, L.J. Photonic color filters integrated with organic solar cells for energy harvesting. ACS Nano 2011, 5, 7055–7060. [Google Scholar] [CrossRef] [PubMed]

- Staebler, D.L.; Wronski, C.R. Reversible conductivity changes in discharge-produced amorphous Si. Appl. Phys. Lett. 1977, 31, 292–294. [Google Scholar] [CrossRef]

- Xing, G.; Mathews, N.; Sun, S.; Lim, S.S.; Lam, Y.M.; Grätzel, M.; Mhaisalkar, S.; Sum, T.C. Long-range balanced electron- and hole-transport lengths in organic-inorganic CH3NH3PbI3. Science 2013, 342, 344–347. [Google Scholar] [CrossRef] [PubMed]

- Stranks, S.D.; Eperon, G.E.; Grancini, G.; Menelaou, C.; Alcocer, M.J.P.; Leijtens, T.; Herz, L.M.; Petrozza, A.; Snaith, H.J. Electron-hole diffusion lengths exceeding 1 micrometer in an organometal trihalide perovskite absorber. Science 2013, 342, 341–344. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.-S.; Lee, C.-R.; Im, J.-H.; Lee, K.-B.; Moehl, T.; Marchioro, A.; Moon, S.-J.; Humphry-Baker, R.; Yum, J.-H.; Moser, J.E.; et al. Lead iodide perovskite sensitized all-solid-state submicron thin film mesoscopic solar cell with efficiency exceeding 9%. Sci. Rep. 2012, 2, 591. [Google Scholar] [CrossRef] [PubMed]

- Jeon, N.J.; Noh, J.H.; Yang, W.S.; Kim, Y.C.; Ryu, S.; Seo, J.; Seok, S.I. Compositional engineering of perovskite materials for high-performance solar cells. Nature 2015, 517, 476–480. [Google Scholar] [CrossRef] [PubMed]

- Green, M.A.; Ho-Baillie, A.; Snaith, H.J. The emergence of perovskite solar cells. Nat. Photonics 2014, 8, 506–514. [Google Scholar] [CrossRef]

- Kazim, S.; Nazeeruddin, M.K.; Grätzel, M.; Ahmad, S. Perovskite as light harvester: A game changer in photovoltaics. Angew. Chem. Int. Ed. 2014, 53, 2812–2824. [Google Scholar] [CrossRef] [PubMed]

- Babayigit, A.; Thanh, D.D.; Ethirajan, A.; Manca, J.; Muller, M.; Boyen, H.G.; Conings, B. Assessing the toxicity of Pb- and Sn-based perovskite solar cells in model organism Danio rerio. Sci. Rep. 2015, 6, 18721. [Google Scholar] [CrossRef] [PubMed]

- Niu, G.; Guo, X.; Wang, L. Review of recent progress in chemical stability of perovskite solar cells. J. Mater. Chem. A 2015, 3, 8970–8980. [Google Scholar] [CrossRef]

- Ameen, S.; Rub, M.A.; Kosa, S.A.; Alamry, K.A.; Akhtar, M.S.; Shin, H.S.; Seo, H.K.; Asiri, A.M.; Nazeeruddin, M.K. Perovskite solar cells: Influence of hole transporting materials on power conversion efficiency. ChemSusChem 2016, 9, 10–27. [Google Scholar] [CrossRef] [PubMed]

- Yang, K.; Li, F.; Zhang, J.; Veeramalai, C.P.; Guo, T. All-solution processed semi-transparent perovskite solar cells with silver nanowires electrode. Nanotechnology 2016, 27, 095202. [Google Scholar] [CrossRef] [PubMed]

- Ono, L.K.; Wang, S.; Kato, Y.; Raga, S.R.; Qi, Y. Fabrication of semi-transparent perovskite films with centimeter-scale superior uniformity by the hybrid deposition method. Energy Environ. Sci. 2014, 7, 3989–3993. [Google Scholar] [CrossRef]

- You, P.; Liu, Z.; Tai, Q.; Liu, S.; Yan, F. Efficient semitransparent perovskite solar cells with graphene electrodes. Adv. Mater. 2015, 27, 3632–3638. [Google Scholar] [CrossRef] [PubMed]

- Hecht, D.S.; Hu, L.; Irvin, G. Emerging transparent electrodes based on thin films of carbon nanotubes, graphene, and metallic nanostructures. Adv. Mater. 2011, 23, 1482–1513. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Li, J.; Sun, Z.-H.; Tai, G.; Lau, S.-P.; Yan, F. The application of highly doped single-layer graphene as the top electrodes of semitransparent organic solar cells. ACS Nano 2012, 6, 810–818. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Niu, L.; Zheng, Z.; Yan, F. Photosensitive graphene transistors. Adv. Mater. 2014, 26, 5239–5273. [Google Scholar] [CrossRef] [PubMed]

- Hellstrom, S.L.; Vosgueritchian, M.; Stoltenberg, R.M.; Irfan, I.; Hammock, M.; Wang, Y.B.; Jia, C.; Guo, X.; Gao, Y.; Bao, Z. Strong and stable doping of carbon nanotubes and graphene by moox for transparent electrodes. Nano Lett. 2012, 12, 3574–3580. [Google Scholar] [CrossRef] [PubMed]

- Chen, T.; Qiu, L.; Cai, Z.; Gong, F.; Yang, Z.; Wang, Z.; Peng, H. Intertwined aligned carbon nanotube fiber based dye-sensitized solar cells. Nano Lett. 2012, 12, 2568–2572. [Google Scholar] [CrossRef] [PubMed]

- Czolk, J.; Puetz, A.; Kutsarov, D.; Reinhard, M.; Lemmer, U.; Colsmann, A. Inverted semi-transparent polymer solar cells with transparency color rendering indices approaching 100. Adv. Energy Mater. 2013, 3, 386–390. [Google Scholar] [CrossRef]

- Alemu, D.; Wei, H.-Y.; Ho, K.-C.; Chu, C.-W. Highly conductive PEDOT:PSS electrode by simple film treatment with methanol for ito-free polymer solar cells. Energy Environ. Sci. 2012, 5, 9662–9671. [Google Scholar] [CrossRef]

- Yu, Z.; Li, L.; Zhang, Q.; Hu, W.; Pei, Q. Silver nanowire-polymer composite electrodes for efficient polymer solar cells. Adv. Mater. 2011, 23, 4453–4457. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.-C.; Dou, L.; Zhu, R.; Chung, C.-H.; Song, T.-B.; Zheng, Y.B.; Hawks, S.; Li, G.; Weiss, P.S.; Yang, Y. Visibly transparent polymer solar cells produced by solution processing. ACS Nano 2012, 6, 7185–7190. [Google Scholar] [CrossRef] [PubMed]

- Mailoa, J.P.; Bailie, C.D.; Johlin, E.C.; Hoke, E.T.; Akey, A.J.; Nguyen, W.H.; McGehee, M.D.; Buonassisi, T. A 2-terminal perovskite/silicon multijunction solar cell enabled by a silicon tunnel junction. Appl. Phys. Lett. 2015, 106, 121105. [Google Scholar] [CrossRef]

- Kranz, L.; Abate, A.; Feurer, T.; Fu, F.; Avancini, E.; Löckinger, J.; Reinhard, P.; Zakeeruddin, S.M.; Grätzel, M.; Buecheler, S.; et al. High-efficiency polycrystalline thin film tandem solar cells. J. Phys. Chem. Lett. 2015, 6, 2676–2681. [Google Scholar] [CrossRef] [PubMed]

- Albrecht, S.; Saliba, M.; Correa Baena, J.P.; Lang, F.; Kegelmann, L.; Mews, M.; Steier, L.; Abate, A.; Rappich, J.; Korte, L.; et al. Monolithic perovskite/silicon-heterojunction tandem solar cells processed at low temperature. Energy Environ. Sci. 2016, 9, 81–88. [Google Scholar] [CrossRef]

- Bush, K.A.; Bailie, C.D.; Chen, Y.; Bowring, A.R.; Wang, W.; Ma, W.; Leijtens, T.; Moghadam, F.; McGehee, M.D. Thermal and environmental stability of semi-transparent perovskite solar cells for tandems enabled by a solution-processed nanoparticle buffer layer and sputtered ito electrode. Adv. Mater. 2016. [Google Scholar] [CrossRef] [PubMed]

- Loper, P.; Moon, S.-J.; Martin de Nicolas, S.; Niesen, B.; Ledinsky, M.; Nicolay, S.; Bailat, J.; Yum, J.-H.; de Wolf, S.; Ballif, C. Organic-inorganic halide perovskite/crystalline silicon four-terminal tandem solar cells. Phys. Chem. Chem. Phys. 2015, 17, 1619–1629. [Google Scholar] [CrossRef] [PubMed]

- Fu, F.; Feurer, T.; Jager, T.; Avancini, E.; Bissig, B.; Yoon, S.; Buecheler, S.; Tiwari, A.N. Low-temperature-processed efficient semi-transparent planar perovskite solar cells for bifacial and tandem applications. Nat. Commun. 2015, 6, 8932. [Google Scholar] [CrossRef] [PubMed]

- Werner, J.; Dubuis, G.; Walter, A.; Löper, P.; Moon, S.-J.; Nicolay, S.; Morales-Masis, M.; de Wolf, S.; Niesen, B.; Ballif, C. Sputtered rear electrode with broadband transparency for perovskite solar cells. Sol. Energy Mater. Sol. Cells 2015, 141, 407–413. [Google Scholar] [CrossRef]

- Kang, M.-G.; Xu, T.; Park, H.J.; Luo, X.; Guo, L.J. Efficiency enhancement of organic solar cells using transparent plasmonic ag nanowire electrodes. Adv. Mater. 2010, 22, 4378–4383. [Google Scholar] [CrossRef] [PubMed]

- Ball, J.M.; Lee, M.M.; Hey, A.; Snaith, H.J. Low-temperature processed meso-superstructured to thin-film perovskite solar cells. Energy Environ. Sci. 2013, 6, 1739–1743. [Google Scholar] [CrossRef]

- Kato, Y.; Ono, L.K.; Lee, M.V.; Wang, S.; Raga, S.R.; Qi, Y. Silver iodide formation in methyl ammonium lead iodide perovskite solar cells with silver top electrodes. Adv. Mater. Interfaces 2015, 2, 1500195. [Google Scholar] [CrossRef]

- Chang, C.-Y.; Chang, Y.-C.; Huang, W.-K.; Lee, K.-T.; Cho, A.-C.; Hsu, C.-C. Enhanced performance and stability of semitransparent perovskite solar cells using solution-processed thiol-functionalized cationic surfactant as cathode buffer layer. Chem. Mater. 2015, 27, 7119–7127. [Google Scholar] [CrossRef]

- Park, H.J.; Kang, M.-G.; Ahn, S.H.; Guo, L.J. A facile route to polymer solar cells with optimum morphology readily applicable to a roll-to-roll process without sacrificing high device performances. Adv. Mater. 2010, 22, E247–E253. [Google Scholar] [CrossRef] [PubMed]

- Youn, H.; Lee, T.; Guo, L.J. Multi-film roll transferring (mrt) process using highly conductive and solution-processed silver solution for fully solution-processed polymer solar cells. Energy Environ. Sci. 2014, 7, 2764–2770. [Google Scholar] [CrossRef]

- Ok, J.G.; Shin, Y.J.; Park, H.J.; Guo, L.J. A Step Towards Next-generation nanoimprint lithography: Extending productivity and applicability. Appl. Phys. A 2015, 121, 343–356. [Google Scholar] [CrossRef]

- Youn, H.; Park, H.J.; Guo, L.J. Printed technologies for nanostructured organic photovoltaic cells and organic light-emitting diodes. Energy Technol. 2015, 3, 340–350. [Google Scholar] [CrossRef]

- Youn, H.; Park, H.J.; Guo, L.J. Organic photovoltaic cells: from performance improvement to manufacturing processes. Small 2015, 11, 2228–2246. [Google Scholar] [CrossRef] [PubMed]

- Park, H.J.; Kim, H.; Lee, J.Y.; Guo, L.J. Optimization of polymer solar cells with bulk heterojunction layers hundreds of nanometers thick: modifying the morphology and cathode interface. Energy Environ. Sci. 2013, 6, 2203–2210. [Google Scholar] [CrossRef]

- Park, H.J.; Lee, J.Y.; Lee, T.; Guo, L.J. Advanced heterojunction structure of polymer photovoltaic cell generating high photocurrent with internal quantum efficiency approaching 100%. Adv. Energy Mater. 2013, 3, 1135–1142. [Google Scholar] [CrossRef]

- Yang, Y.; Chen, Q.; Hsieh, Y.-T.; Song, T.-B.; Marco, N.D.; Zhou, H.; Yang, Y. Multilayer transparent top electrode for solution processed perovskite/Cu(In,Ga)(Se,S)2 four terminal tandem solar cells. ACS Nano 2015, 9, 7714–7721. [Google Scholar] [CrossRef] [PubMed]

- Hong, K.; Kim, K.; Kim, S.; Lee, I.; Cho, H.; Yoo, S.; Choi, H.W.; Lee, N.-Y.; Tak, Y.-H.; Lee, J.-L. Optical properties of WO3/Ag/WO3 multilayer as transparent cathode in top-emitting organic light emitting diodes. J. Phys. Chem. C 2011, 115, 3453–3459. [Google Scholar] [CrossRef]

- Winkler, T.; Schmidt, H.; Flügge, H.; Nikolayzik, F.; Baumann, I.; Schmale, S.; Weimann, T.; Hinze, P.; Johannes, H.-H.; Rabe, T.; et al. Efficient large area semitransparent organic solar cells based on highly transparent and conductive ZTO/Ag/ZTO multilayer top electrodes. Org. Electron. 2011, 12, 1612–1618. [Google Scholar] [CrossRef]

- Jin, H.; Tao, C.; Velusamy, M.; Aljada, M.; Zhang, Y.; Hambsch, M.; Burn, P.L.; Meredith, P. Efficient, large area ITO-and-PEDOT-free organic solar cell sub-modules. Adv. Mater. 2012, 24, 2572–2577. [Google Scholar] [CrossRef] [PubMed]

- Zhang, N.; Hu, Y.; Liu, X. Transparent organic thin film transistors with WO3/Ag/WO3 source-drain electrodes fabricated by thermal evaporation. Appl. Phys. Lett. 2013, 103, 033301. [Google Scholar] [CrossRef]

- Kim, H.; Lee, K.-T.; Zhao, C.; Guo, L.J.; Kanicki, J. Top illuminated organic photodetectors with dielectric/metal/dielectric transparent anode. Org. Electron. 2015, 20, 103–111. [Google Scholar] [CrossRef]

- Schubert, S.; Meiss, J.; Müller-Meskamp, L.; Leo, K. Improvement of transparent metal top electrodes for organic solar cells by introducing a high surface energy seed layer. Adv. Energy Mater. 2013, 3, 438–443. [Google Scholar] [CrossRef]

- Zhang, C.; Zhao, D.; Gu, D.; Kim, H.; Ling, T.; Wu, Y.-K.R.; Guo, L.J. An ultrathin, smooth, and low-loss Al-doped Ag film and its application as a transparent electrode in organic photovoltaics. Adv. Mater. 2014, 26, 5696–5701. [Google Scholar] [CrossRef] [PubMed]

- Gu, D.; Zhang, C.; Wu, Y.-K.; Guo, L.J. Ultrasmooth and thermally stable silver-based thin films with subnanometer roughness by aluminum doping. ACS Nano 2014, 8, 10343–10351. [Google Scholar] [CrossRef] [PubMed]

- Zhao, D.; Zhang, C.; Kim, H.; Guo, L.J. High-performance Ta2O5/Al-doped Ag electrode for resonant light harvesting in efficient organic solar cells. Adv. Energy Mater. 2015, 5, 1500768. [Google Scholar] [CrossRef]

- Huang, F.; Dkhissi, Y.; Huang, W.; Xiao, M.; Benesperi, I.; Rubanov, S.; Zhu, Y.; Lin, X.; Jiang, L.; Zhou, Y.; et al. Gas-assisted preparation of lead iodide perovskite films consisting of a monolayer of single crystalline grains for high efficiency planar solar cells. Nano Energy 2014, 10, 10–18. [Google Scholar] [CrossRef]

- Zhao, Y.; Nardes, A.M.; Zhu, K. Effective hole extraction using moox-al contact in perovskite CH3NH3PbI3 solar cells. Appl. Phys. Lett. 2014, 104, 213906. [Google Scholar] [CrossRef]

- Guo, F.; Kubis, P.; Stubhan, T.; Li, N.; Baran, D.; Przybilla, T.; Spiecker, E.; Forberich, K.; Brabec, C.J. Fully solution-processing route toward highly transparent polymer solar cells. ACS Appl. Mater. Interfaces 2014, 6, 18251–18257. [Google Scholar] [CrossRef] [PubMed]

- Guo, F.; Kubis, P.; Li, N.; Przybilla, T.; Matt, G.; Stubhan, T.; Ameri, T.; Butz, B.; Spiecker, E.; Forberich, K.; et al. Solution-processed parallel tandem polymer solar cells using silver nanowires as intermediate electrode. ACS Nano 2014, 8, 12632–12640. [Google Scholar] [CrossRef] [PubMed]

- Chang, C.-Y.; Lee, K.-T.; Huang, W.-K.; Siao, H.-Y.; Chang, Y.-C. High-performance, air-stable, low-temperature processed semitransparent perovskite solar cells enabled by atomic layer deposition. Chem. Mater. 2015, 27, 5122–5130. [Google Scholar] [CrossRef]

- Guo, F.; Li, N.; Fecher, F.W.; Gasparini, N.; Quiroz, C.O.R.; Bronnbauer, C.; Hou, Y.; Radmilovic, V.V.; Radmilovic, V.R.; Spiecker, E.; et al. A generic concept to overcome bandgap limitations for designing highly efficient multi-junction photovoltaic cells. Nat. Commun. 2015, 6, 7730. [Google Scholar] [CrossRef] [PubMed]

- Barnes, T.M.; Wu, X.; Zhou, J.; Duda, A.; van de Lagemaat, J.; Coutts, T.J.; Weeks, C.L.; Britz, D.A.; Glatkowski, P. Single-wall carbon nanotube networks as a transparent back contact in CdTe solar cells. Appl. Phys. Lett. 2007, 90, 243503. [Google Scholar] [CrossRef]

- Phillips, A.B.; Khanal, R.R.; Song, Z.; Zartman, R.M.; DeWitt, J.L.; Stone, J.M.; Roland, P.J.; Plotnikov, V.V.; Carter, C.W.; Stayancho, J.M.; et al. Wiring-up carbon single wall nanotubes to polycrystalline inorganic semiconductor thin films: low-barrier, copper-free back contact to CdTe solar cells. Nano Lett. 2013, 13, 5224–5232. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Ji, C.; Bian, Z.; Yu, P.; Zhang, L.; Liu, D.; Shi, E.; Shang, Y.; Peng, H.; Cheng, Q.; et al. Porous, platinum nanoparticle-adsorbed carbon nanotube yarns for efficient fiber solar cells. ACS Nano 2012, 6, 7191–7198. [Google Scholar] [CrossRef] [PubMed]

- Chaudhary, S.; Lu, H.; Müller, A.M.; Bardeen, C.J.; Ozkan, M. Hierarchical placement and associated optoelectronic impact of carbon nanotubes in polymer-fullerene solar cells. Nano Lett. 2007, 7, 1973–1979. [Google Scholar] [CrossRef] [PubMed]

- Burschka, J.; Pellet, N.; Moon, S.-J.; Humphry-Baker, R.; Gao, P.; Nazeeruddin, M.K.; Gratzel, M. Sequential deposition as a route to high-performance perovskite-sensitized solar cells. Nature 2013, 499, 316–319. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Jia, Y.; Wei, J.; Wang, K.; Shu, Q.; Gui, X.; Zhu, H.; Cao, A.; Wu, D. Large area, highly transparent carbon nanotube spiderwebs for energy harvesting. J. Mater. Chem. 2010, 20, 7236–7240. [Google Scholar] [CrossRef]

- Wang, Y.; Tong, S.W.; Xu, X.F.; Özyilmaz, B.; Loh, K.P. Interface engineering of layer-by-layer stacked graphene anodes for high-performance organic solar cells. Adv. Mater. 2011, 23, 1514–1518. [Google Scholar] [CrossRef] [PubMed]

- Liu, P.; Liu, X.; Lyu, L.; Xie, H.; Zhang, H.; Niu, D.; Huang, H.; Bi, C.; Xiao, Z.; Huang, J.; et al. Interfacial electronic structure at the CH3NH3PbI3/MoOx interface. Appl. Phys. Lett. 2015, 106, 193903. [Google Scholar] [CrossRef]

- Noh, J.H.; Im, S.H.; Heo, J.H.; Mandal, T.N.; Seok, S.I. Chemical management for colorful, efficient, and stable inorganic–organic hybrid nanostructured solar cells. Nano Lett. 2013, 13, 1764–1769. [Google Scholar] [CrossRef] [PubMed]

| Electrodes | Jsc (mA cm−2) | Voc (V) | FF (%) | PCE (%) | AVT (%) | Ref. |

|---|---|---|---|---|---|---|

| Thin Au | 10.30 | 1.07 | 57.90 | 6.41 | 29 (400–800 nm) | [13] |

| Thin Ag | 15.87 | 1.00 | 69.90 | 11.04 | 20.8 (380–750 nm) | [60] |

| MoOx/Au-Ag/MoOx | 14.60 | 1.05 | 75.10 | 11.50 | N/A | [63] |

| MoOx/Au/MoOx | 14.70 | 0.95 | 65.00 | 10.10 | 16 (400–800 nm) | [14] |

| AgNWs | 13.18 | 0.96 | 66.80 | 8.49 | 28.4 (350–800 nm) | [10] |

| AgNWs | 15.87 | 0.96 | 69.68 | 10.55 | 25.5 (380–750 nm) | [77] |

| AgNWs | 17.50 | 1.03 | 71.00 | 12.70 | 77 at 800 nm | [3] |

| CNT | 18.10 | 1.00 | 55.00 | 9.90 | N/A | [12] |

| Graphene | 19.17 | 0.96 | 67.22 | 12.37 | 22.5 at 700 nm | [35] |

| ITO | 16.50 | 0.95 | 77.00 | 12.30 | N/A | [48] |

| ITO | 14.50 | 0.82 | 51.90 | 6.20 | 55 (800–1200 nm) | [49] |

| In2O3:H | 17.40 | 1.10 | 73.60 | 14.20 | 72 (800–1150 nm) | [50] |

| Microstructure | 12.00 | 0.85 | 63.00 | 6.40 | 12.5 (370–740 nm) | [9] |

| ZnO:Al | 16.70 | 1.03 | 70.3 | 12.1 | 71 (800–1000 nm) | [46] |

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, K.-T.; Guo, L.J.; Park, H.J. Neutral- and Multi-Colored Semitransparent Perovskite Solar Cells. Molecules 2016, 21, 475. https://doi.org/10.3390/molecules21040475

Lee K-T, Guo LJ, Park HJ. Neutral- and Multi-Colored Semitransparent Perovskite Solar Cells. Molecules. 2016; 21(4):475. https://doi.org/10.3390/molecules21040475

Chicago/Turabian StyleLee, Kyu-Tae, L. Jay Guo, and Hui Joon Park. 2016. "Neutral- and Multi-Colored Semitransparent Perovskite Solar Cells" Molecules 21, no. 4: 475. https://doi.org/10.3390/molecules21040475