Ultrasound-Assisted Extraction (UAE) and Solvent Extraction of Papaya Seed Oil: Yield, Fatty Acid Composition and Triacylglycerol Profile

Abstract

:1. Introduction

2. Results and Discussion

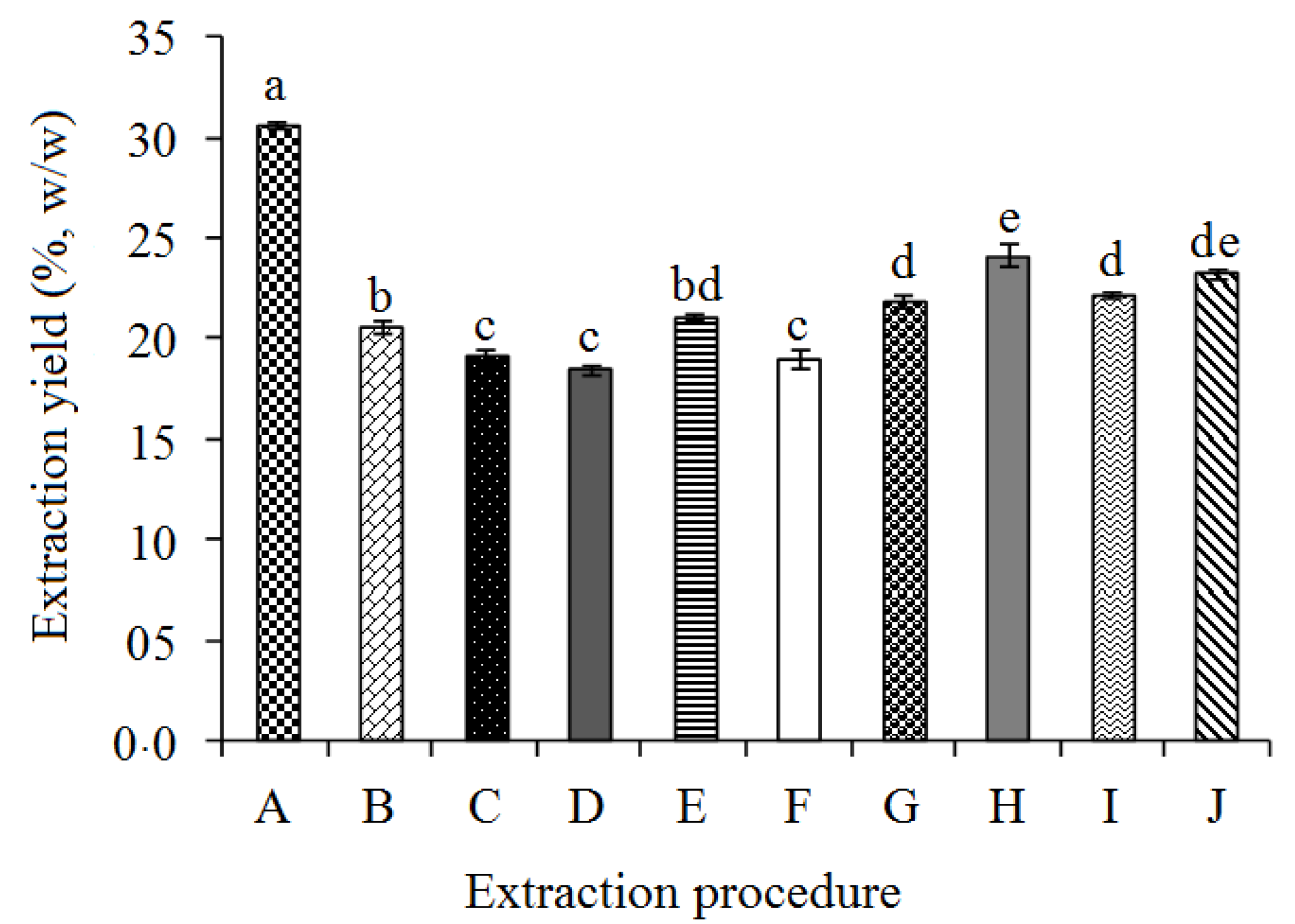

2.1. Yield and Fatty Acid Composition of Differently Extracted Papaya Seed Oils

| Oil Source | Oil content % | PUFA 1% | MUFA 2% | SFA 3% | Reference |

|---|---|---|---|---|---|

| Papaya seed oil | 30–34 | 2.1–6.3 | 67.5–77.6 | 18.6–29.0 | Puangsri et al. [5]; Lee et al. [6] |

| Olive oil 4 | 22–24 | 3.5–22.5 | 55.3–86.5 | 10.5–20.0 | Salvador et al. [14]; Codex [16] |

| Grape seed oil | 8–15 | 50.0–83.0 | 13.7–36.5 | 5.8.0–23.5 | Passos et al. [15]; Shahidi [17] |

| Orange seed oil | 32–35 | 43.5–45.0 | 26.0–27.0 | 28.0–29.0 | Shahidi [17]; Ajewole [18] |

| Apple seed oil | 21–24 | 48.4–65.3 | 24.7–43.0 | 6.3–12.4 | Shahidi [17]; Tian et al. [19] |

| Watermelon seed oil | 50 | 60.0 | 18.4 | 21.6 | Baboli and Kordi [20] |

| Pumpkin seed oil | 42–45 | 55.6 | 20.8 | 23.5 | Shahidi [21]; Schinas et al. [22] |

| Extraction | Fatty Acids | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 14:0 | 16:0 | 16:1 | 18:0 | 18:1 | 18:2 | 18:3 | 20:0 | 20:1 | Others | |

| SXE 1 | 0.21 ± 0.02 a | 14.9 ± 0.05 a | 0.27 ± 0.04 a | 5.21 ± 0.01 a | 74.2 ± 0.21 a | 3.50 ± 0.03 a | 0.17 ± 0.01 a | 0.38 ± 0.01 a | 0.42 ± 0.03 a | 0.74 ± 0.02 a |

| UAE 2 | 0.19 ± 0.01 a | 15.1 ± 0.06 a | 0.27 ± 0.00 a | 5.12 ± 0.00 a | 74.2 ± 0.09 a | 3.54 ± 0.03 a | 0.15 ± 0.00 a | 0.37 ± 0.00 a | 0.40 ± 0.01 a | 0.57 ± 0.02 b |

| SE 3 (3 h/25 °C) | 0.19 ± 0.00 a | 15.3 ± 0.06 a | 0.28 ± 0.00 a | 5.13 ± 0.00 a | 74.2 ± 0.06 a | 3.51 ± 0.02 a | 0.15 ± 0.00 a | 0.36 ± 0.01 a | 0.40 ± 0.01 a | 0.48 ± 0.03 c |

| SE (3 h/50 °C) | 0.19 ± 0.01 a | 15.2 ± 0.20 a | 0.28 ± 0.00 a | 5.23 ± 0.02 a | 74.4 ± 0.40 a | 3.61 ± 0.03 a | 0.15 ± 0.00 a | 0.41 ± 0.00 a | 0.42 ± 0.01 a | 0.11 ± 0.01 d |

| SE (6 h/25 °C) | 0.20 ± 0.00 a | 15.3 ± 0.10 a | 0.30 ± 0.00 a | 5.00 ± 0.09 a | 74.6 ± 0.23 a | 3.60 ± 0.05 a | 0.16 ± 0.00 a | 0.41 ± 0.01 a | 0.41 ± 0.01 a | 0.02 ± 0.0 e |

| SE (6 h/50 °C) | 0.18 ± 0.02 a | 15.3 ± 0.14 a | 0.27 ± 0.01 a | 5.14 ± 0.04 a | 74.5 ± 0.23 a | 3.63 ± 0.03 a | 0.15 ± 0.00 a | 0.40 ± 0.00 a | 0.41 ± 0.00 a | 0.02 ± 0.0 e |

| SE (9 h/25 °C) | 0.20 ± 0.01 a | 15.1 ± 0.06 a | 0.31 ± 0.01 a | 5.12 ± 0.05 a | 74.4 ± 0.26 a | 3.59 ± 0.01 a | 0.16 ± 0.01 a | 0.39 ± 0.03 a | 0.42 ± 0.01 a | 0.31 ± 0.01 e |

| SE (9 h/50 °C) | 0.20 ± 0.00 a | 15.4 ± 0.01 a | 0.30 ± 0.00 a | 5.25 ± 0.01 a | 74.2 ± 0.06 a | 3.63 ± 0.06 a | 0.16 ± 0.00 a | 0.41 ± 0.01 a | 0.41 ± 0.00 a | 0.04 ± 0.0 e |

| SE (12 h/25 °C) | 0.19 ± 0.00 a | 15.1 ± 0.10 a | 0.28 ± 0.00 a | 5.14 ± 0.02 a | 74.3 ± 0.03 a | 3.54 ± 0.01 a | 0.15 ± 0.00 a | 0.37 ± 0.00 a | 0.40 ± 0.00 a | 0.53 ± 0.02 c |

| SE (12 h/50 °C) | 0.18 ± 0.01 a | 15.2 ± 0.10 a | 0.28 ± 0.00 a | 5.21 ± 0.01 a | 74.5 ± 0.16 a | 3.59 ± 0.02 a | 0.15 ± 0.00 a | 0.40 ± 0.00 a | 0.41 ± 0.01 a | 0.08 ± 0.02 f |

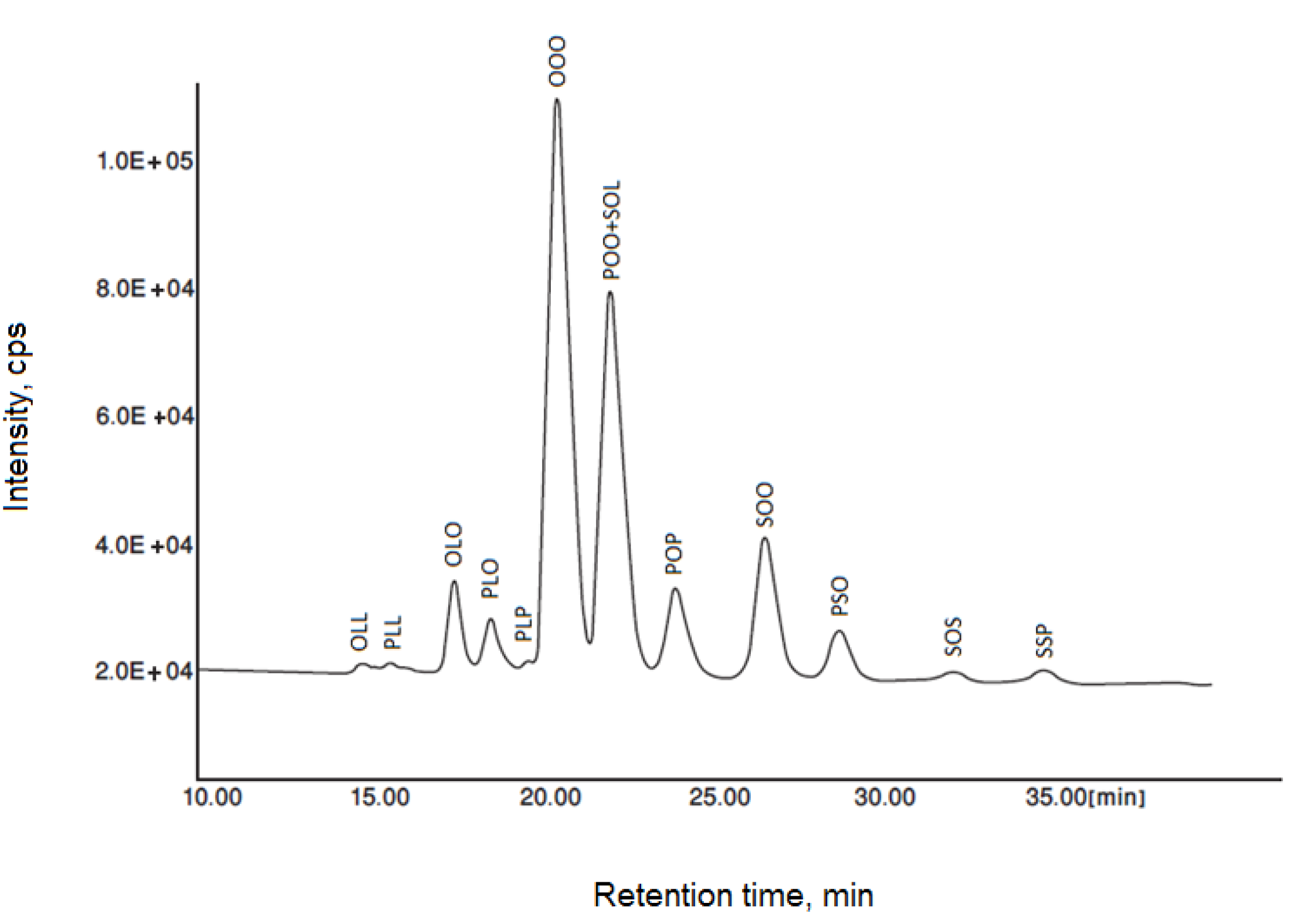

2.2. Triacylglycerol Profile of Differently Extracted Papaya Seed Oils

| Triacylglycerol (TAG) | Papaya fruit varieties | ||

|---|---|---|---|

| Sekaki 1 | BatekBatu 2 | Tainoung 3 | |

| OOL | 4.40 | 3.70 | 2.54 |

| POL | 2.80 | 2.30 | 1.72 |

| OOO | 41.3 | 44.6 | 43.8 |

| POO + SOL | 27.7 | 30.5 | 33.8 |

| PPO | 6.15 | 5.10 | 6.19 |

| SOO | 9.70 | 9.80 | 8.37 |

| POS | 3.15 | 3.80 | 2.41 |

| Others | 4.8 | 0.2 | 1.17 |

| Extraction | Triacylglycerol area% | |||||||

|---|---|---|---|---|---|---|---|---|

| OOL | POL | OOO | POO + SOL | PPO | SOO | POS | Others | |

| SXE 1 | 4.40 ± 0.14 a | 2.80 ± 0.14 a | 41.3 ± 1.84 a | 27.7 ± 1.84 a | 6.15 ± 0.21 a | 9.70 ± 0.42 a | 3.15 ± 0.10 a | 4.80 ± 0.23 a |

| UAE 2 | 4.90 ± 0.30 a | 3.80 ± 0.30 c | 37.0 ± 0.00 b | 25.3 ± 0.42 b | 5.90 ± 0.21 a,b | 8.40 ± 0.14 b | 2.75 ± 0.10 c | 11.95 ± 0.50 b |

| SE 3 (3 h/25 °C) | 4.35 ± 0.10 a | 2.75 ± 0.10 a | 42.2 ± 0.00 a | 29.0 ± 0.00 a | 6.40 ± 0.00 a | 10.0 ± 0.00 a | 3.25 ± 0.10 a | 2.05 ± 0.30 c |

| SE (3 h/50 °C) | 4.35 ± 0.10 a | 2.70 ± 0.00 a | 42.0 ± 0.00 a | 28.8 ± 0.35 a | 6.25 ± 0.10 a | 10.0 ± 0.10 a | 3.30 ± 0.00 a | 2.60 ± 0.40 c |

| SE (6 h/25 °C) | 4.45 ± 0.10 a | 2.90 ± 0.00 a | 41.0 ± 1.40 a | 27.2 ± 1.20 a,b | 5.60 ± 0.30 b | 10.0 ± 0.42 a | 3.35 ± 0.10 a,b | 5.5 ± 0.7 a |

| SE (6 h/50 °C) | 4.10 ± 0.30 a | 2.45 ± 0.20 a,b | 41.7 ± 0.42 a | 28.2 ± 0.14 a | 6.20 ± 0.00 a | 10.0 ± 0.00 a | 3.40 ± 0.00 a | 3.95 ± 0.6 a |

| SE (9 h/25 °C) | 4.25 ± 0.10 a | 2.80 ± 0.14 a | 41.0 ± 1.40 a | 27.7 ± 0.90 a | 5.75 ± 0.20 a,b | 9.80 ± 0.42 a | 3.20 ± 0.14 a | 5.5 ± 0.5 a |

| SE (9 h/50 °C) | 4.00 ± 0.00 a | 2.40 ± 0.00 a,b | 42.3 ± 0.14 a | 28.2 ± 0.14 a | 6.20 ± 0.00 a | 10.0 ± 0.10 a | 3.30 ± 0.00 a | 3.6 ± 0.5 a |

| SE (12 h/25 °C) | 4.25 ± 0.10 a | 2.80 ± 0.00 a | 42.4 ± 0.14 a | 28.3 ± 0.10 a | 6.10 ± 0.00 a | 10.0 ± 0.00 a | 3.35 ± 0.10 a | 2.8 ± 0.4 c |

| SE (12 h/50 °C) | 3.65 ± 0.90 a | 2.60 ± 0.00 a | 42.15 ± 0.10 a | 28.6 ± 0.00 a | 6.25 ± 0.10 a | 10.0 ± 0.00 a | 3.30 ± 0.00 a | 3.45 ± 0.5 a |

3. Experimental

3.1. Chemicals and Materials

3.2. Sample Preparation

3.3. Solvent Extraction

3.4. Ultrasound-Assisted Extraction (UAE)

3.5. Analytical Tests

3.5.1. Fatty Acid Composition (FAC)

3.5.2. Triacylglycerol (TAG) Profile

3.5.2.1. Qualitative Analysis of Triacylglycerol Composition of Papaya Seed Oil

3.5.2.2. Quantitative Analysis of Triacylglycerol Composition of Papaya Seed Oil

3.6. Statistical Design and Data Analysis

4. Conclusions

Acknowledgments

Conflicts of Interest

References

- Federici, F.; Fava, F.; Kalogerakisc, N.; Mantzavinosc, D. Valorisation of agro-industrial by-products, effluents and waste: Concept, opportunities and the case of olive mill wastewaters. J. Chem. Technol. Biotechnol. 2009, 84, 895–900. [Google Scholar] [CrossRef]

- Arumugam, R.; Manikandan, M. Fermentation of pretreated hydrolyzates of banana and mango fruit wastes for ethanol production. AJEBS 2011, 2, 246–256. [Google Scholar]

- Kumar, D.; Yadav, K.K.; Singh, M.; Garg, N. Biochemical utilization of agro-industrial lignocelluloses rich waste for cellulose production. RJAS 2012, 44, 184–191. [Google Scholar]

- Hameed, B.H. Evaluation of papaya seeds as a novel non-conventional low-cost adsorbent for removal of methylene blue. J. Hazard. Mater. 2009, 162, 939–944. [Google Scholar] [CrossRef]

- Puangsri, T.; Abdulkarim, S.M.; Ghazali, H.M. Properties of Carica papaya L. (Papaya) seed oil following extraction using solvent and aqueous enzymatic methods. J. Food Lipids 2005, 12, 62–67. [Google Scholar] [CrossRef]

- Lee, W.K.; Lee, M.H.; Su, N.W. Characteristics of papaya seed oil obtained by extrusion-expelling processes. J. Sci. Food Agric. 2011, 91, 2348–2354. [Google Scholar] [CrossRef]

- Yon, R.M. Papaya: Fruit Development, Postharvest Physiology, Handling and Marketing in ASEAN; ASEAN food Handling Bureau: Kuala Lumpur, Malaysia, 1994. [Google Scholar]

- Chan, Y.K. Breeding Horticulture Crops at MARDI. In Papaya (Carica papaya), 1st ed.; Chan, Y.K., Tan, S.L., Jamaluddin, S.H., Eds.; Malaysian Agriculture Research and Development institute (MARDI): Serdang, Selangor, Malaysia, 2008; pp. 175–206. [Google Scholar]

- Mani, S.; Jaya, S.; Vadivambal, R. Optimization of solvent extraction of Moringa (Moringa Oleifera) seed kernel oil using response surface methodology. Food BioProd. Process. 2007, 85, 328–335. [Google Scholar] [CrossRef]

- Li, X.M.; Tian, S.L.; Pang, Z.C.; Shi, J.Y.; Feng, Z.S.; Zhang, Y.M. Extraction of Cuminumcyminum essential oil by combination technology of organic solvent with low boiling point and steam distillation. Food Chem. 2009, 115, 1114–1119. [Google Scholar] [CrossRef]

- Bimakr, M.; Abdul Rahman, R.; Taip, F.S.; Adzahan, N.M.; Sarker, M.Z.I.; Ganjloo, A. Optimization of ultrasound-assisted extraction of crude oil from winter melon (Benincasahispida) seed using response surface methodology and evaluation of its antioxidant activity, total phenolic content and fatty acid composition. Molecules 2012, 17, 11748–11762. [Google Scholar] [CrossRef]

- Chen, X.P.; Wang, W.X.; Li, S.B.; Xue, J.L.; Fan, L.J.; Sheng, Z.J.; Chen, Y.G. Optimization of ultrasound-assisted extraction of Lingzhi polysaccharides using response surface methodology and its inhibitory effect on cervical cancer cells. Carbohydr. Polym. 2010, 80, 944–948. [Google Scholar] [CrossRef]

- Li, T.; Qua, X.Y.; Zhang, A.A.; Wang, Z.Z. Ultrasound-assisted extraction and profile characteristics of seed oil from Isatisindigotica fort. Ind. Crop. Prod. 2012, 35, 98–104. [Google Scholar] [CrossRef]

- Salvador, M.D.; Aranda, F.; Gómez-Alonso, S.; Fregapane, G. Cornicabra virgin olive oil: A study of five crop seasons. Composition, quality and oxidative stability. Food Chem. 2001, 74, 267–274. [Google Scholar] [CrossRef]

- Passos, C.P.; Yilmaz, S.; Silva, C.M.; Coimbra, M.A. Enhancement of grape seed oil extraction using a cell wall degrading enzyme cocktail. Food Chem. 2009, 115, 48–53. [Google Scholar] [CrossRef]

- Codex Standard for Olive oil, Virgin and Refined, and for Refined Olive-Pomace Oil. In Codex Alimentarius; Codex Alimentarius Commission: Quebec, Canada, 2001; Codex Stan 33-1981 (Rev. 1-1989); pp. 1–8.

- Shahidi, F. Nutraceutical and Specialty Lipids and Their Co-Products; Taylor Francis Group: Boca Raton, Palm Beach County, FL, USA, 2006; pp. 73–90. [Google Scholar]

- Ajewole, K. Characterisation of Nigerian citrus seed oils. Food Chem. 1993, 47, 77–78. [Google Scholar] [CrossRef]

- Tian, H.L.; Ping Zhan, P.; Li, K.X. Analysis of components and study on antioxidant and antimicrobial activities of oil in apple seeds. Int. J. Food Sci. Nutr. 2010, 4, 395–403. [Google Scholar] [CrossRef]

- Moaddabdoost Baboli, Z.; Safe Kordi, A.K. Characteristics and composition of watermelon seed oil and solvent extraction parameters effects. J. Am. Oil Chem. Soc. 2010, 87, 667–671. [Google Scholar] [CrossRef]

- Shahidi, F. Quality Assurance of Fats and Oils. In Bailey’s Industrial Oil and Fat Products Edible, Oil and Fat Products: Chemistry, Properties, and Health Effects, 6th ed.; Shahidi, F., Ed.; John Wiley Sons: Hoboken, NJ, USA, 2006; Volume 1, pp. 565–575. [Google Scholar]

- Schinas, P.; Karavalakis, G.; Davaris, C.; Anastopoulos, G.; Karonis, D.; Zannikos, F.; Stournas, S.; Lois, E. Pumpkin (Cucurbitapepo L.) seed oil as an alternative feed stock for the production of biodiesel in Greece. Biomass Bioenergy 2009, 33, 44–49. [Google Scholar] [CrossRef]

- Huertas, E.L. Health effects of oleic acid and long chain omega-3 fatty acids (EPA and DHA) enriched milks. Rev. Interv. Stud. Pharmacol. Res. 2010, 61, 200–207. [Google Scholar]

- Abdulkarim, S.M.; Long, K.; Lai, O.M.; Muhammad, S.K.S.; Ghazali, H.M. Frying quality and stability of high-oleic Moringaoleifera seed oil in comparison with other vegetable oils. Food Chem. 2007, 105, 1382–1389. [Google Scholar] [CrossRef] [Green Version]

- García, M.J.L.; Lusardi, R.; Chiavaro, E.; Cerretani, L.; Bendini, A. Use of triacylglycerol profiles established by high performance liquid chromatography with ultraviolet–visible detection to predict the botanical origin of vegetable oils. J. Chromatogr. A 2011, 1218, 7521–7527. [Google Scholar] [CrossRef]

- Piravi-Vanak, Z.; Ghavami, M.; Ezzatpanah, H.; Arab, J.; Safafar, H.; Ghasemi, J.B. Evaluation of authenticity of Iranian olive oil by fatty acid and triacylglycerol profiles. J. Am. Oil Chem. Soc. 2009, 86, 827–833. [Google Scholar] [CrossRef]

- Lam, P.F.; Zaipun, M.Z. Changes association with ripening stages of harvesting and ripening of Eksotika papaya at ambient temperature. MARDI Res. Bull. 1987, 15, 21–26. [Google Scholar]

- AOCS. Official Methods and Recommended Practices of the American Oil Chemists’ Society, 4th ed.; AOCS Press: Champaign, IL, USA, 1993. [Google Scholar]

- AOCS. Official Methods and Recommended Practices of the American Oil Chemists’ Society, 6th ed.; AOCS Press: Champaign, IL, USA, 2009. [Google Scholar]

- Chua, S.C.; Tan, C.P.; Mirhosseini, H.; Lai, O.M.; Long, K.; Baharin, B.S. Optimization of ultrasound extraction condition of phospholipids from palm-based fiber. J. Food Eng. 2009, 92, 403–409. [Google Scholar] [CrossRef]

- Zhang, Q.A.; Zhang, Z.Q.; Yue, X.F.; Fan, X.H.; Li, T.; Chen, S.F. Response surface optimization of ultrasound–assisted oil extraction from autoclaved almond powder. Food Chem. 2009, 116, 513–518. [Google Scholar] [CrossRef]

- Cheong, K.W.; Tan, C.P.; Mirhosseini, H.; Chin, S.T.; Che Man, Y.; Abdul Hamid, N.S.; Osman, A.; Basri, M. Optimization of equilibrium headspace analysis of volatile flavor compounds of Malaysian soursop (Annonamuricata): Comprehensive two-dimensional gas chromatography time-of-flight mass spectrometry (GC-GC-TOFMS). Food Chem. 2011, 125, 1481–1489. [Google Scholar] [CrossRef]

- David, F.; Sandra, P.; Vickers, A.K. Column Selection for the Analysis of Fatty Acids Methyl Esters; Agilent Technologies, Inc.: Santa Clara, CA, USA, 2005. [Google Scholar]

- Knothe, G. Analyzing biodiesel. Standards and other methods. (Review). J. Am. Oil Chem. Soc. 2006, 83, 823–833. [Google Scholar] [CrossRef]

- Holcapek, M.; Jandera, P.; Fischer, J. Analysis of acylglycerols and methyl esters of fatty acids in vegetable oils and in biodiesel. Crit. Rev. Anal. Chem. 2001, 31, 53–56. [Google Scholar] [CrossRef]

- Soleimany, F.; Jinap, S.; Abas, F. Determination of mycotoxins in cereals by liquid chromatography tandem mass spectrometry. Food Chem. 2012, 130, 1055–1060. [Google Scholar] [CrossRef]

- Mirhosseini, H.; Tan, C.P.; Aghlara, A.; Hamid, N.S.A.; Yusof, S.; Chern, B.H. Influence of pectin and CMC on physical stability, turbidity loss rate, cloudiness and flavor release of orange beverage emulsion during storage. Carbohydr. Polym. 2008, 73, 83–91. [Google Scholar] [CrossRef] [Green Version]

- Sample Availability: Samples of differently extracted papaya seed oils are available from the authors.

© 2013 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Samaram, S.; Mirhosseini, H.; Tan, C.P.; Ghazali, H.M. Ultrasound-Assisted Extraction (UAE) and Solvent Extraction of Papaya Seed Oil: Yield, Fatty Acid Composition and Triacylglycerol Profile. Molecules 2013, 18, 12474-12487. https://doi.org/10.3390/molecules181012474

Samaram S, Mirhosseini H, Tan CP, Ghazali HM. Ultrasound-Assisted Extraction (UAE) and Solvent Extraction of Papaya Seed Oil: Yield, Fatty Acid Composition and Triacylglycerol Profile. Molecules. 2013; 18(10):12474-12487. https://doi.org/10.3390/molecules181012474

Chicago/Turabian StyleSamaram, Shadi, Hamed Mirhosseini, Chin Ping Tan, and Hasanah Mohd Ghazali. 2013. "Ultrasound-Assisted Extraction (UAE) and Solvent Extraction of Papaya Seed Oil: Yield, Fatty Acid Composition and Triacylglycerol Profile" Molecules 18, no. 10: 12474-12487. https://doi.org/10.3390/molecules181012474