Application of Mutual Information-Sample Entropy Based MED-ICEEMDAN De-Noising Scheme for Weak Fault Diagnosis of Hoist Bearing

Abstract

:1. Introduction

2. Basic Theory

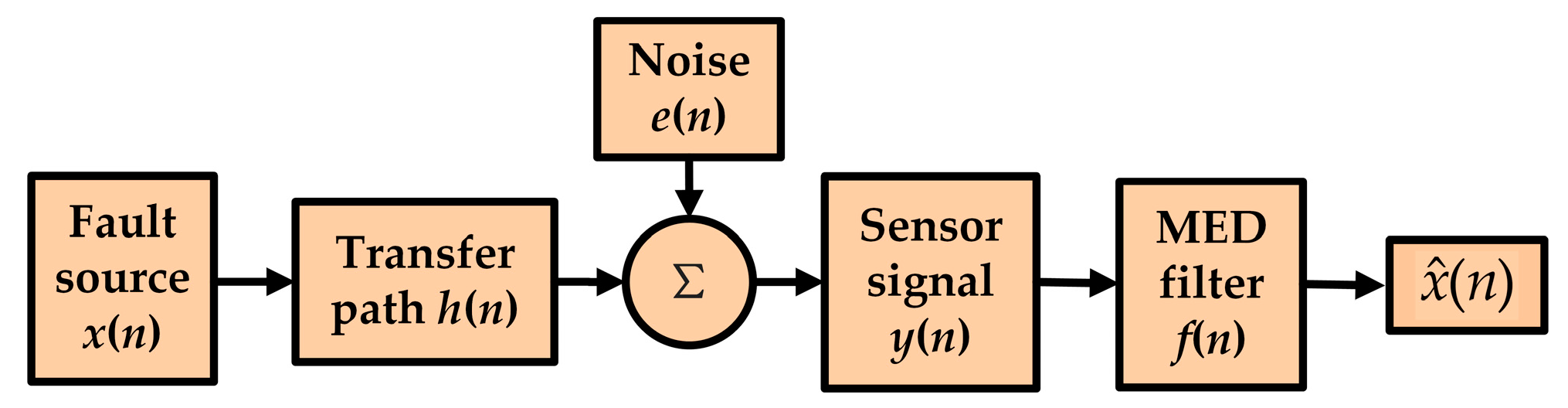

2.1. Minimum Entropy Deconvolution

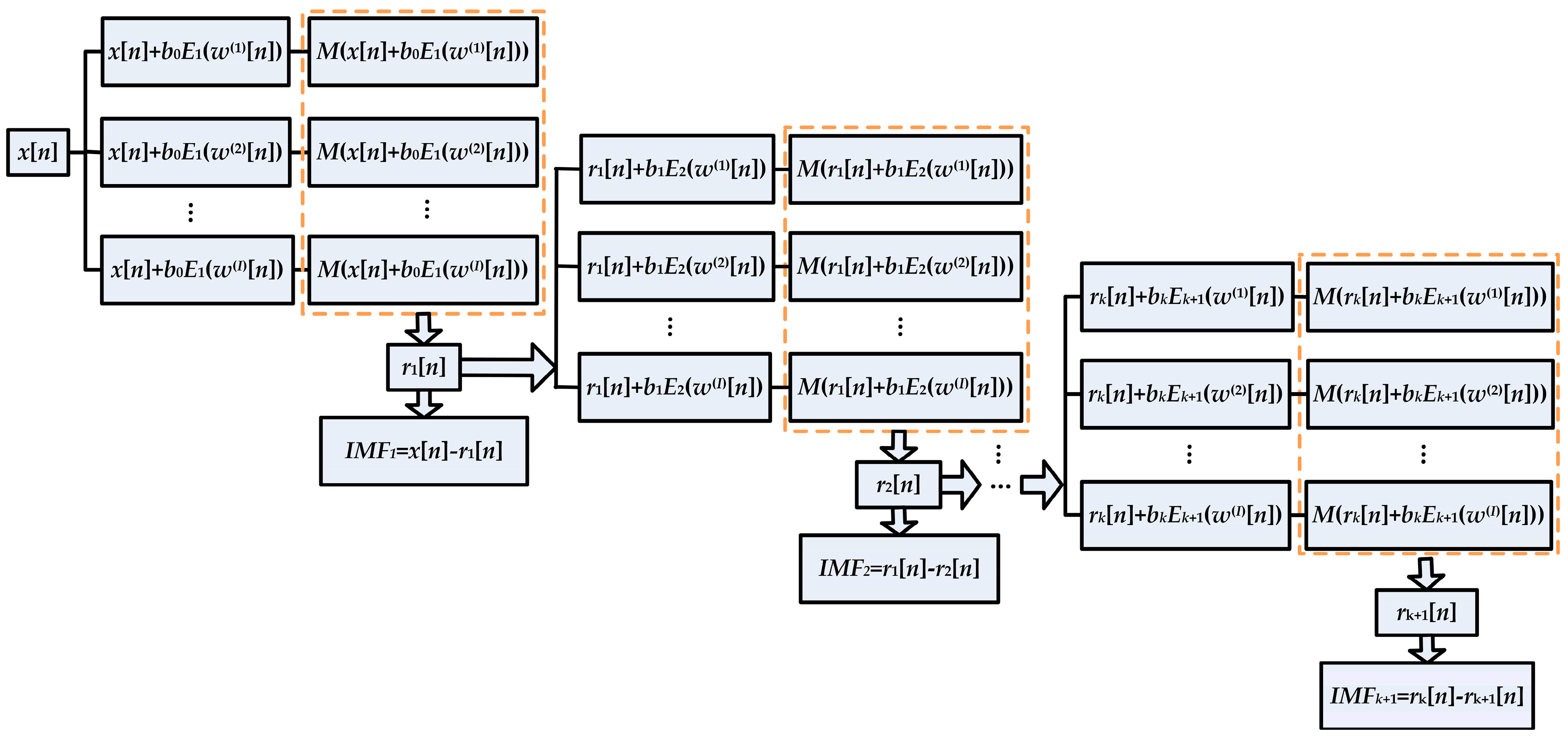

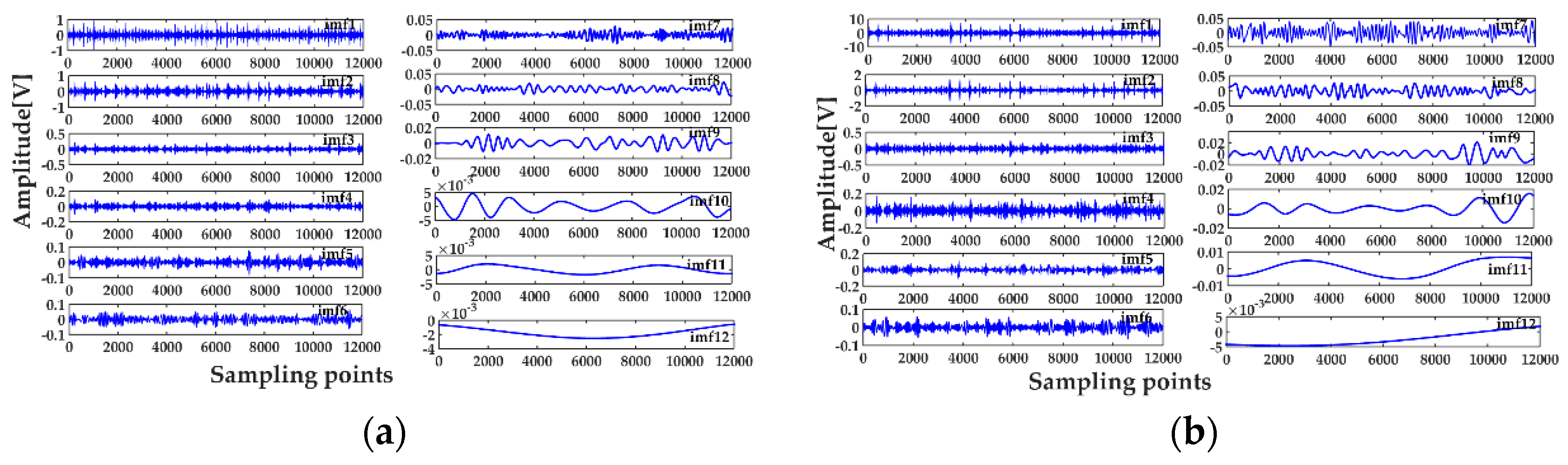

2.2. Improved Complete Ensemble EMD

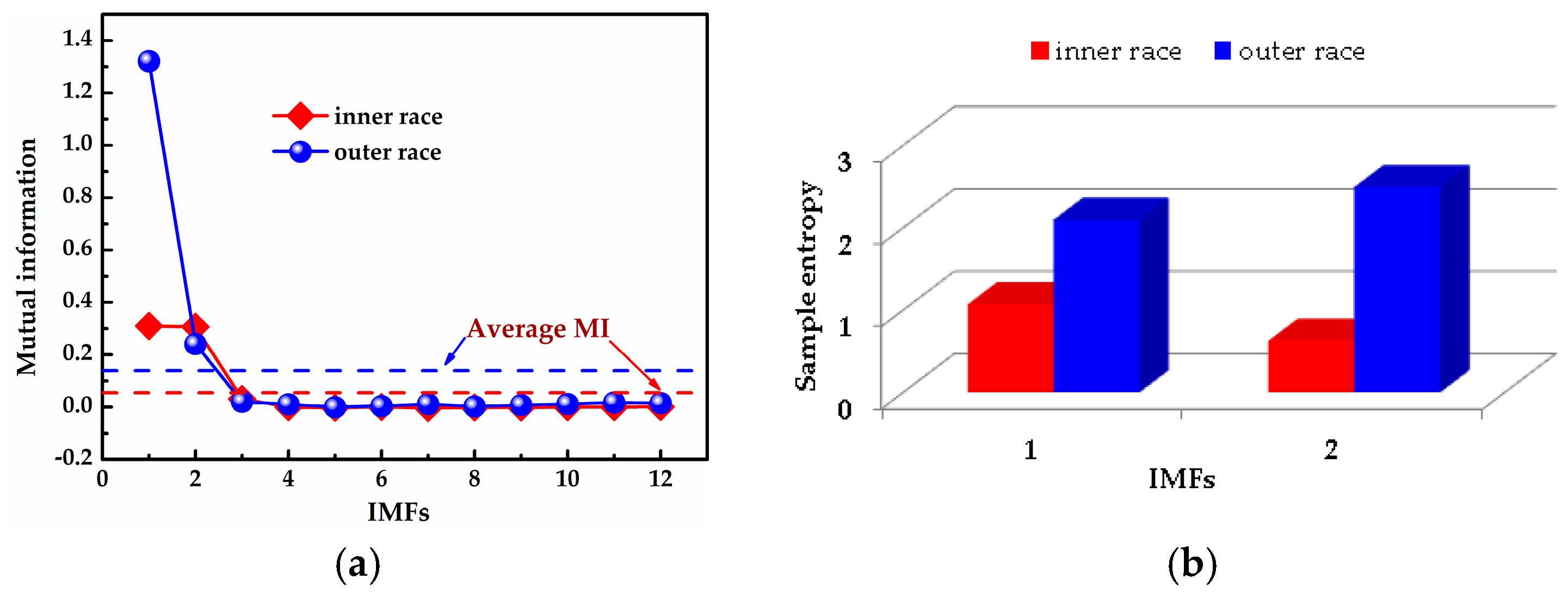

2.3. Mutual Information Based Sample Entropy

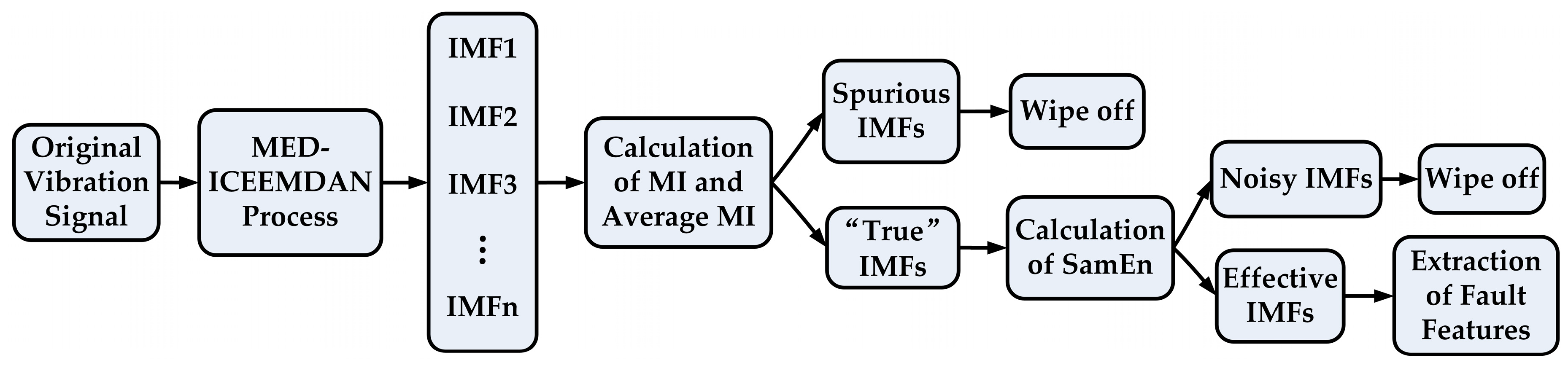

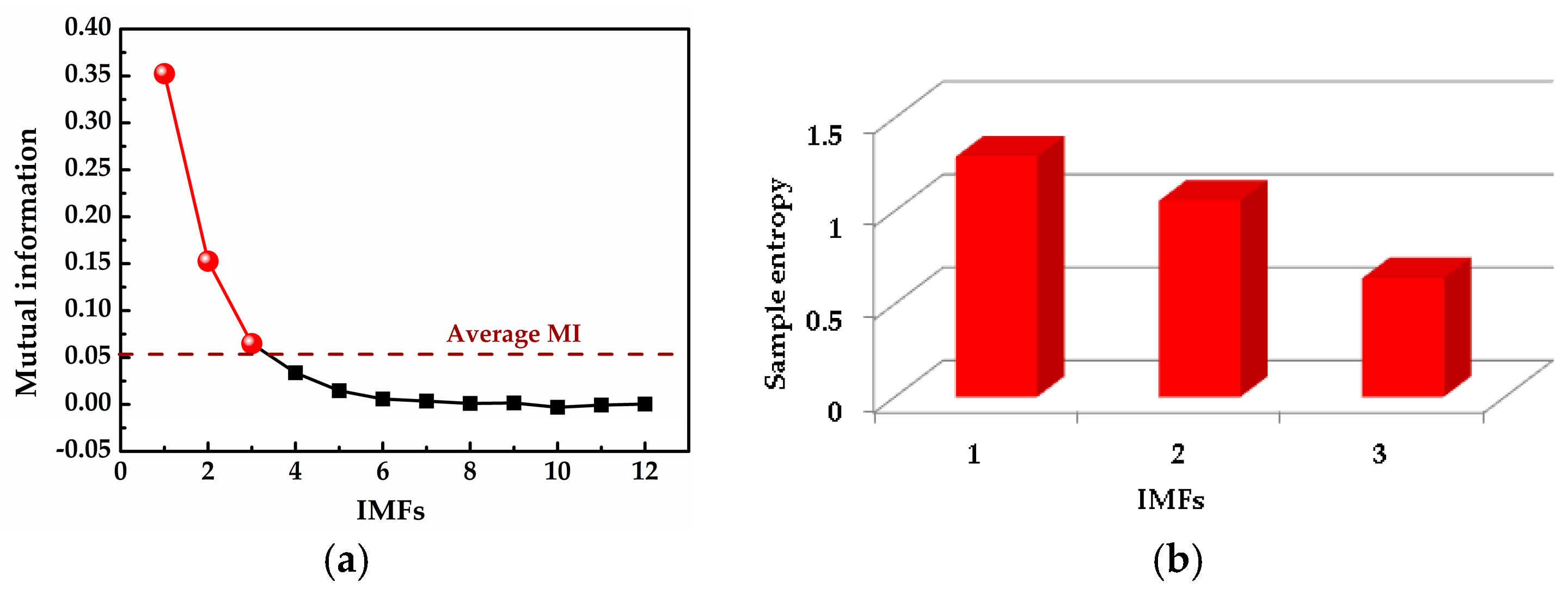

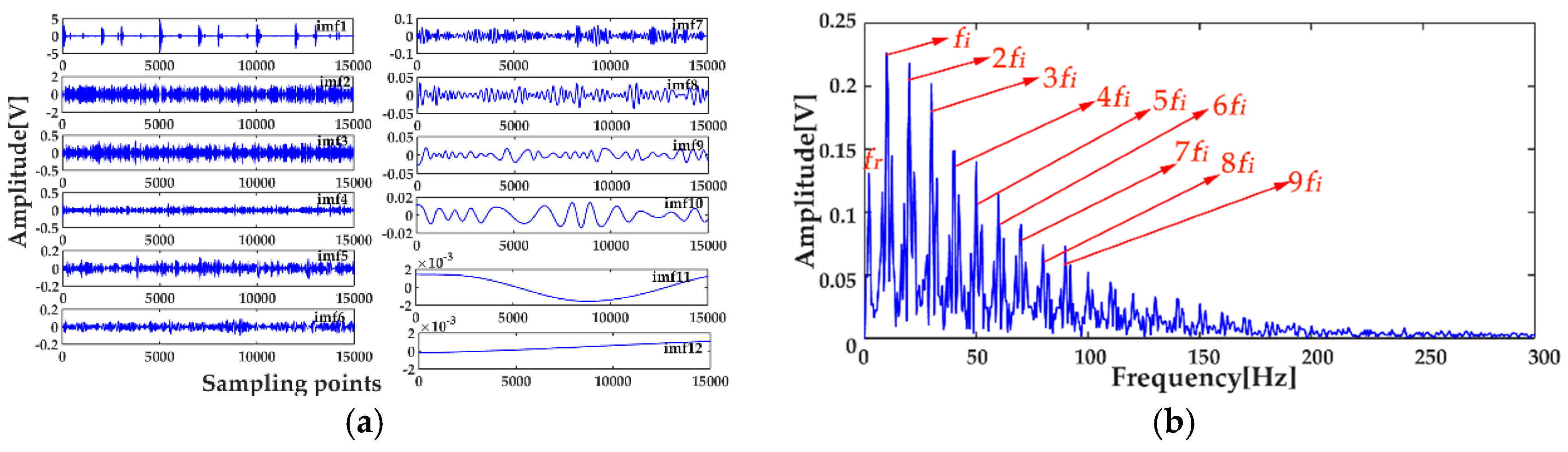

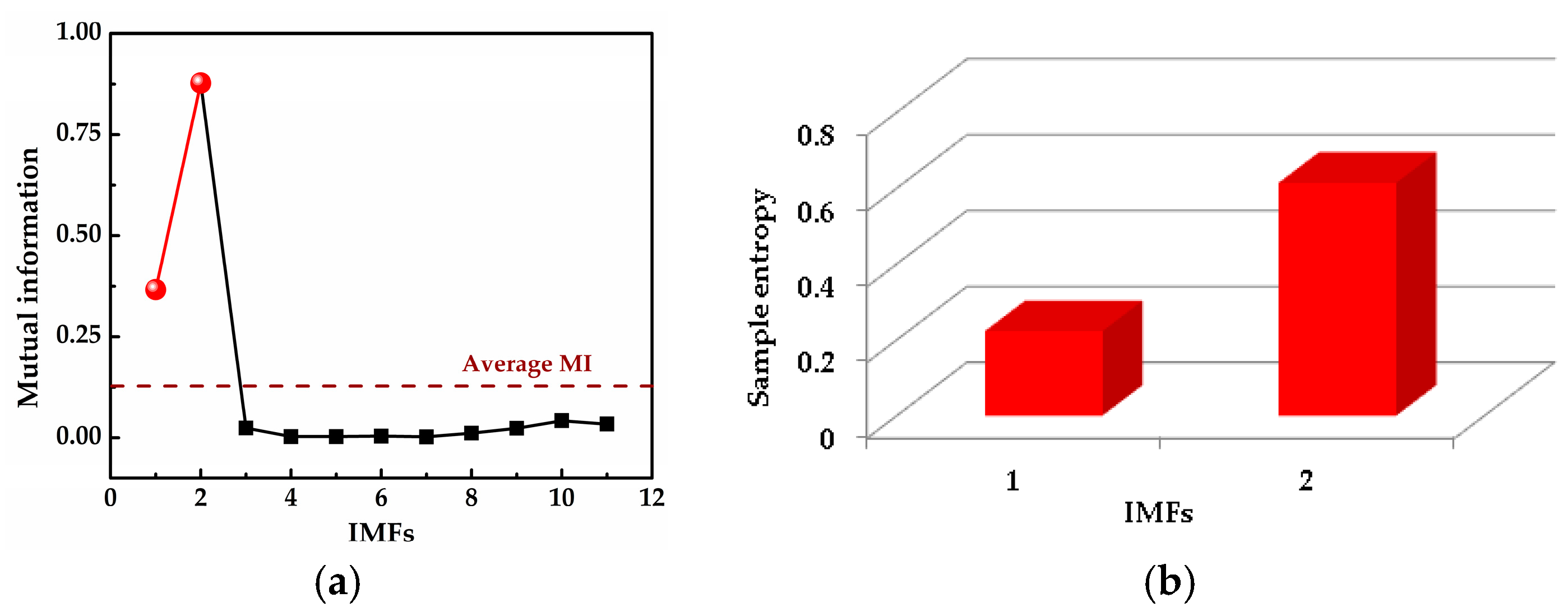

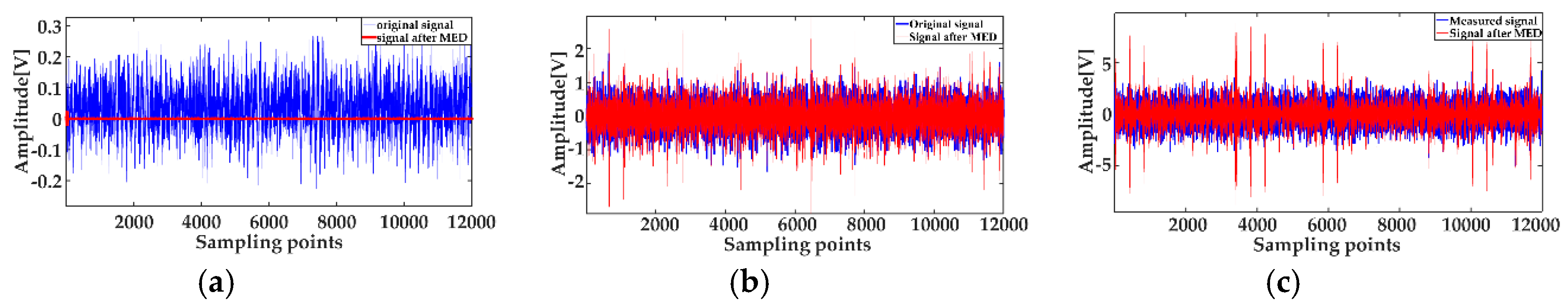

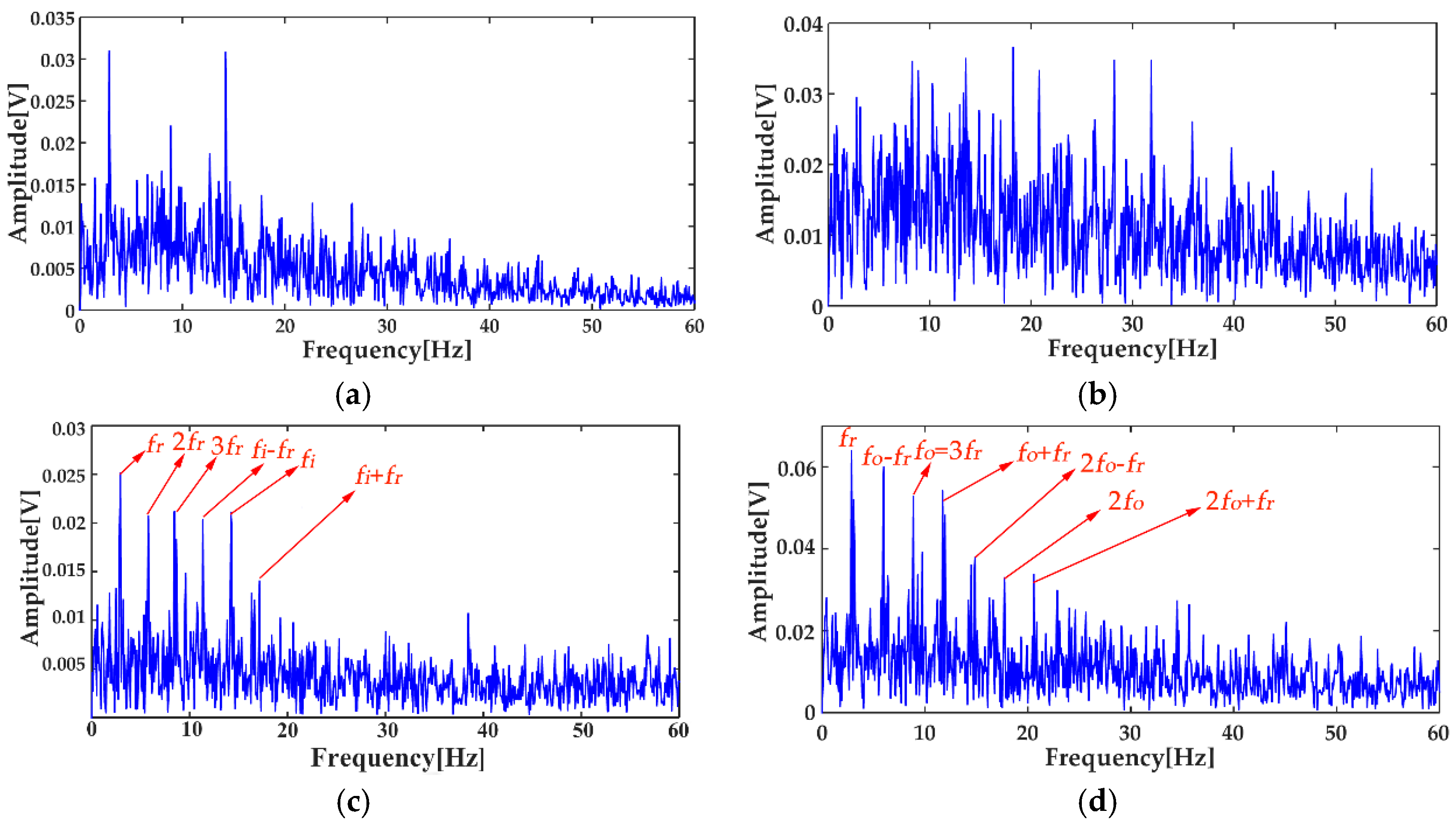

3. Weak Fault Features Extraction Based on MED-ICEEMDAN

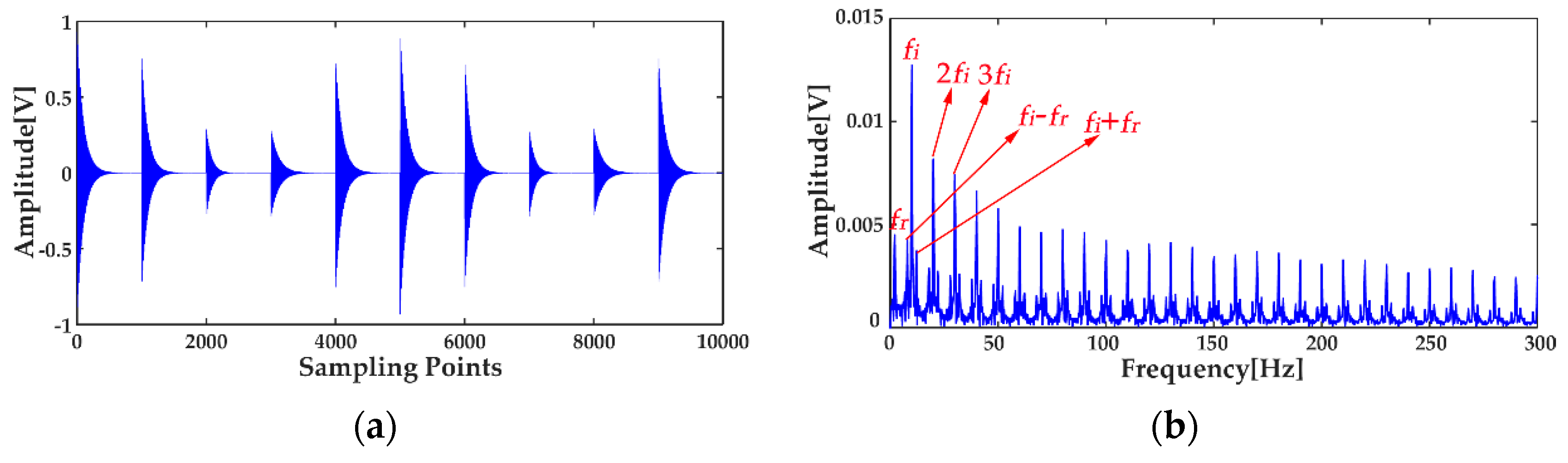

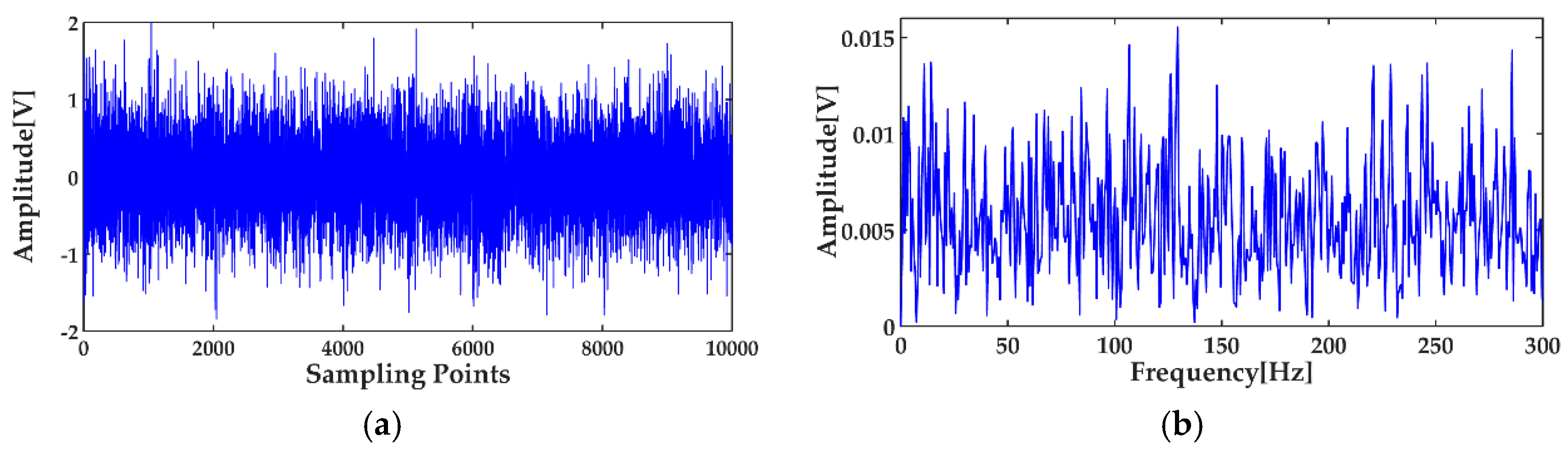

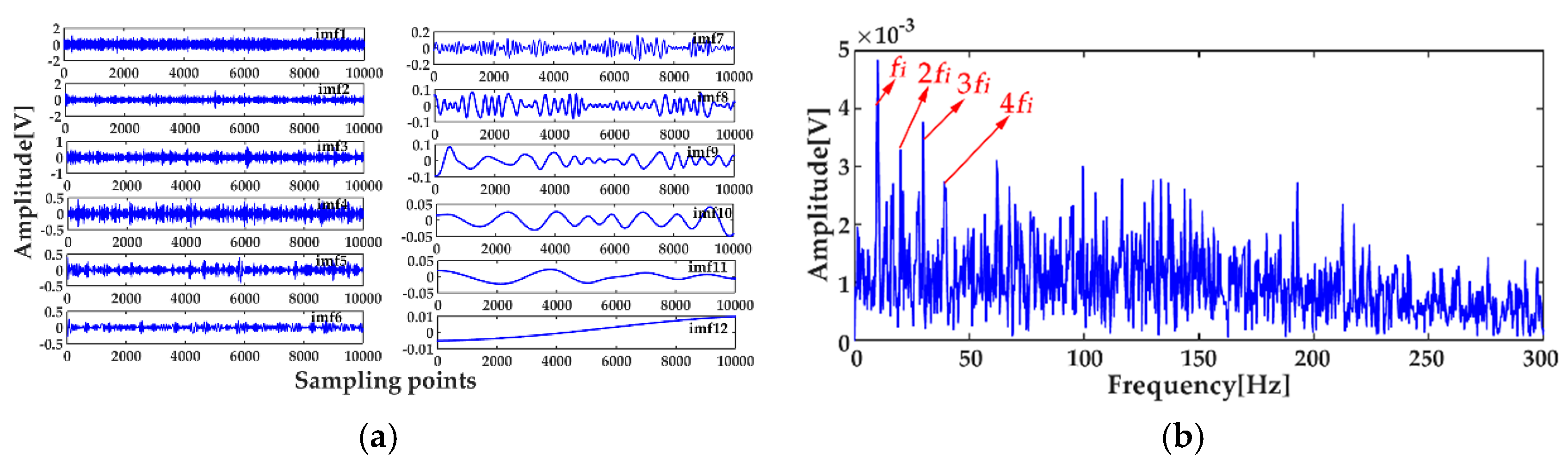

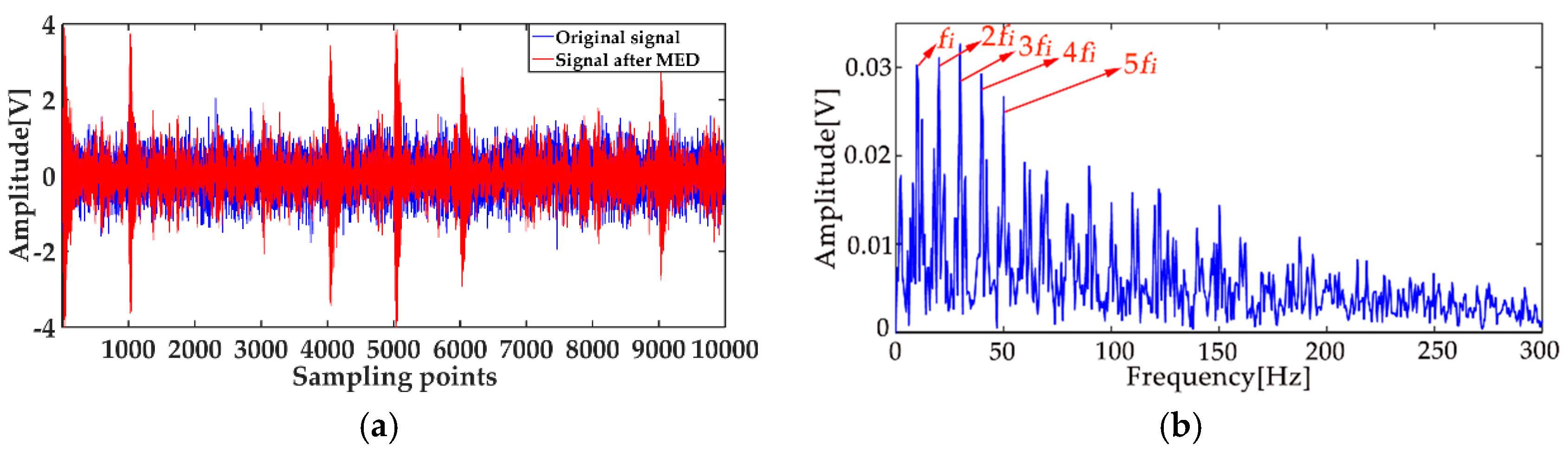

4. Simulation Analysis of Faulted Rolling Bearings Based on MED-ICEEMDAN

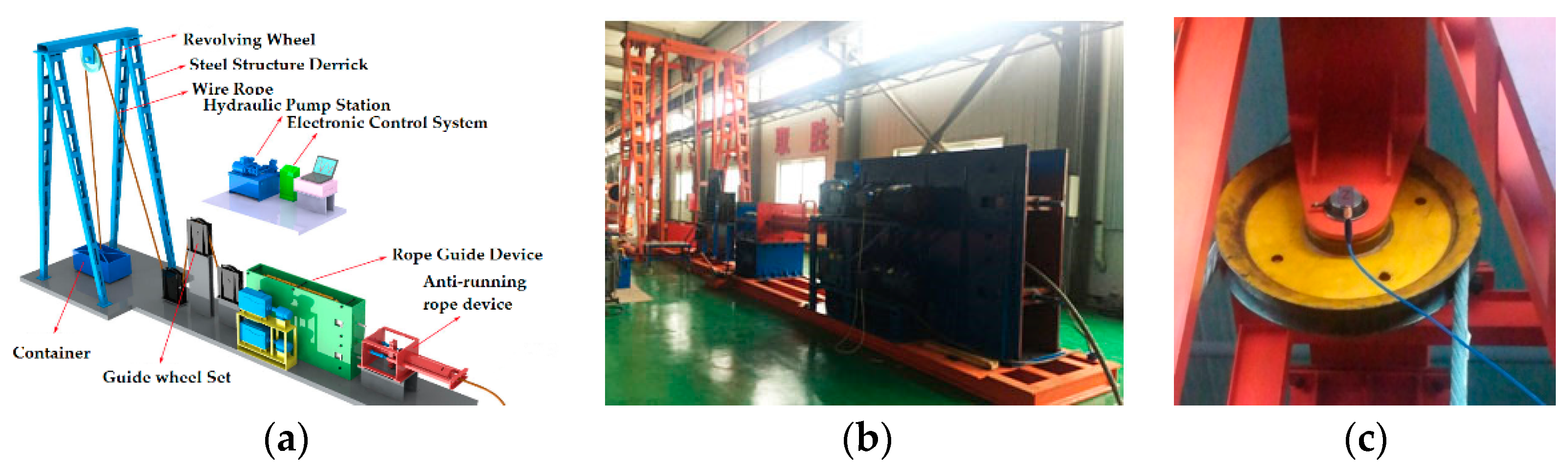

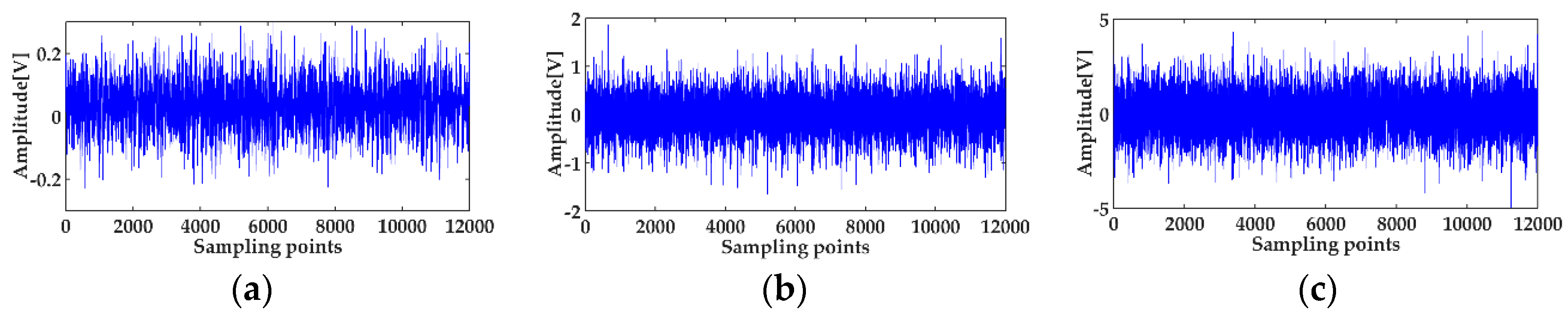

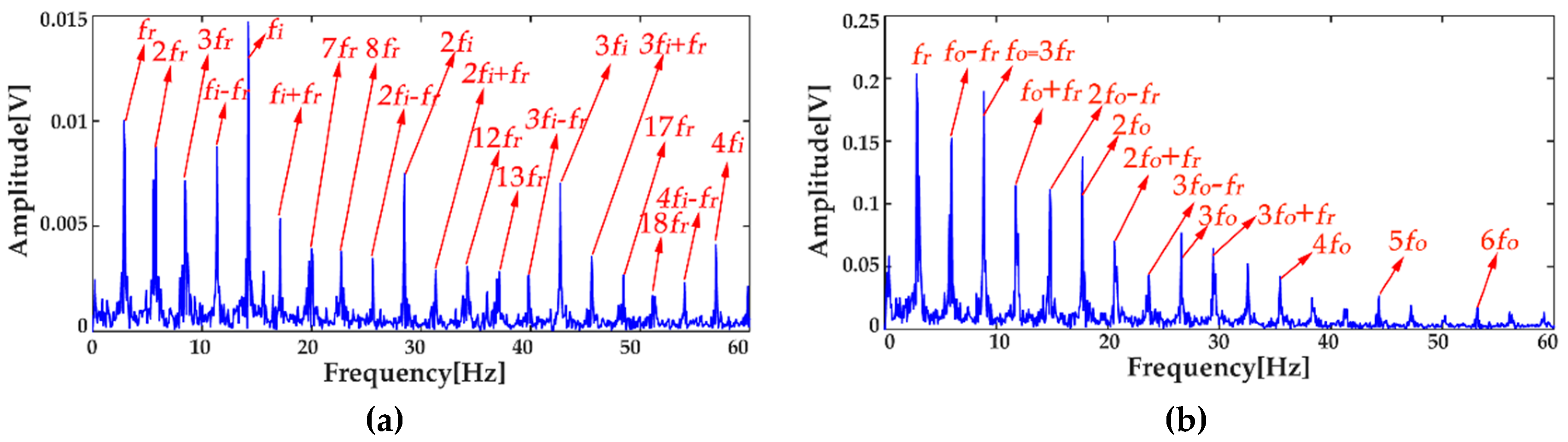

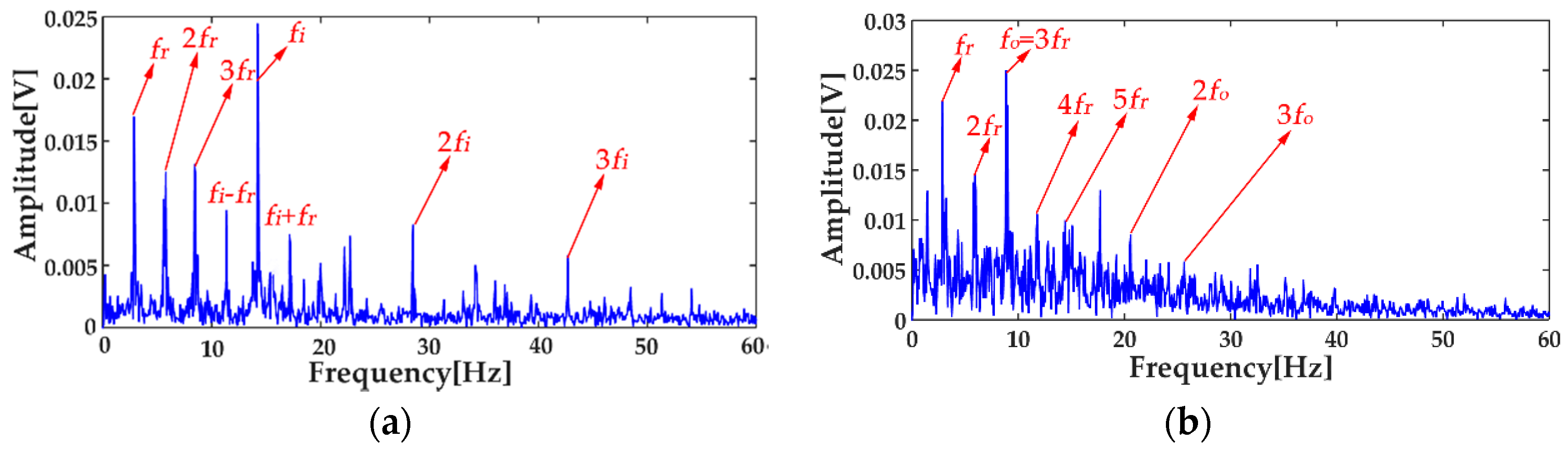

5. Experiments and Results

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Glowacz, A.; Glowacz, W.; Glowacz, Z.; Kozik, J. Early fault diagnosis of bearing and stator faults of the single-phase induction motor using acoustic signals. Measurement 2018, 113, 1–9. [Google Scholar] [CrossRef]

- Li, Z.X.; Jiang, Y.; Hu, C.; Peng, Z. Recent progress on decoupling diagnosis of hybrid failures in gear transmission systems using vibration sensor signal: A review. Measurement 2016, 90, 4–19. [Google Scholar] [CrossRef]

- Berredjem, T.; Benidir, M. Bearing faults diagnosis using fuzzy expert system relying on an improved range overlaps and similarity method. Expert Syst. Appl. 2018, 108, 134–142. [Google Scholar] [CrossRef]

- Bin, G.F.; Gao, J.J.; Li, X.J.; Dhillon, B.S. Early fault diagnosis of rotating machinery based on wavelet packets—Empirical mode decomposition feature extraction and neural network. Mech. Syst. Signal Process. 2012, 27, 696–711. [Google Scholar] [CrossRef]

- Mishra, C.; Samantaray, A.K.; Chakraborty, G. Rolling element bearing fault diagnosis under slow speed operation using wavelet de-noising. Measurement 2017, 103, 77–86. [Google Scholar] [CrossRef]

- Huang, N.E.; Shen, Z.; Long, S.R.; Wu, M.C.; Shih, H.H.; Zheng, Q.; Yen, N.C.; Tung, C.C.; Lui, H.H. The empirical mode decomposition and the Hilbert spectrum for nonlinear and nonstationary time series analysis. Proc. R. Soc. Lond. A 1998, 454, 903–995. [Google Scholar] [CrossRef]

- Yu, D.; Cheng, J.; Yang, Y. Application of EMD method and Hilbert spectrum to the fault diagnosis of roller bearings. Mech. Syst. Signal Process. 2005, 19, 259–270. [Google Scholar] [CrossRef]

- Zhang, Y.G.; Zhang, C.H.; Sun, J.B.; Guo, J. Improved wind speed prediction using empirical mode decomposition. Adv. Electr. Comput. Eng. 2018, 18, 3–10. [Google Scholar] [CrossRef]

- Zhang, Z.; Entezami, M.; Stewart, E.; Roberts, C. Enhanced fault diagnosis of roller bearing elements using a combination of empirical mode decomposition and minimum entropy deconvolution. Proc. Inst. Mech. Eng. Part C-J. Eng. Mech. Eng. Sci. 2015, 231, 655–671. [Google Scholar] [CrossRef]

- Wu, Z.; Huang, N.E. Ensemble empirical mode decomposition: A noise-assisted data analysis method. Adv. Adapt. Data Anal. 2009, 1, 1–41. [Google Scholar] [CrossRef]

- Jiang, F.; Zhu, Z.; Li, W.; Chen, G. Fault identification of rotor-bearing system based on ensemble empirical mode decomposition and self-zero space projection analysis. J. Sound Vibr. 2014, 333, 3321–3331. [Google Scholar] [CrossRef]

- Zhang, C.; Li, Z.X.; Chen, S.; Wang, J.; Zhang, X. Optimised ensemble empirical mode decomposition with optimised noise parameters and its application to rolling element bearing fault diagnosis. Insight 2016, 58, 494–501. [Google Scholar] [CrossRef]

- Žvokelj, M.; Zupan, S.; Prebil, I. EEMD-based multiscale ICA method for slewing bearing fault detection and diagnosis. J. Sound Vibr. 2016, 370, 394–423. [Google Scholar] [CrossRef]

- Jiang, H.; Li, C.; Li, H. An improved EEMD with multiwavelet packet for rotating machinery multi-fault diagnosis. Mech. Syst. Signal Process. 2013, 36, 225–239. [Google Scholar] [CrossRef]

- Yeh, J.R.; Shieh, J.S.; Huang, N.E. Complementary ensemble empirical mode decomposition: A noise -assisted data analysis method. Adv. Adapt. Data Anal. 2010, 02, 135–156. [Google Scholar] [CrossRef]

- Torres, M.E.; Colominas, M.A.; Schlotthauer, G.; Flandrin, P. A complete ensemble empirical mode decomposition with adaptive noise. ICASSP 2011, 125, 4144–4147. [Google Scholar] [CrossRef]

- Kanoga, S.; Mitsukura, Y. Eye blink artifact rejection in single-channel electroencephalographic signals by complete ensemble empirical mode decomposition and independent component analysis. EMBC 2015, 121. [Google Scholar] [CrossRef]

- Chen, W.; Chen, Y.K.; Liu, W. Ground roll attenuation using improved complete ensemble empirical mode decompoistion. J. Seism Explor. 2016, 25, 485–495. [Google Scholar]

- Colominas, M.A.; Schlotthauer, G.; Torres, M.E. Improved Complete Ensemble EMD: A Suitable Tool for Biomedical Signal Processing. Biomed. Signal Process. 2014, 14, 19–29. [Google Scholar] [CrossRef]

- Han, H.; Cho, S.; Kwon, S.; Cho, S.B. Fault Diagnosis using improved complete ensemble empirical mode decomposition with adaptive noise and power-based intrinsic mode function selection algorithm. Electronics 2018, 7, 16. [Google Scholar] [CrossRef]

- Peng, H.; Long, F.; Ding, C. Feature selection based on mutual information criteria of max-dependency, max-relevance, and min-redundancy. IEEE Trans. Pattern Anal. Mach. Intell. 2005, 27, 1226–1238. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ning, S.H.; Han, Z.N.; Wang, Z.J.; Wu, X. Application of sample entropy based LMD-TFPF de-noising algorithm for the gear transmission system. Entropy 2016, 18, 414. [Google Scholar] [CrossRef]

- Wiggins, R.A. Minimum entropy deconvolution. Geoexploration 1980, 16, 21–35. [Google Scholar] [CrossRef]

- Caesarendra, W.; Tjahjowidodo, T. A Review of feature extraction methods in vibration-based condition monitoring and its application for degradation trend estimation of low-speed slew bearing. Machines 2017, 5, 21. [Google Scholar] [CrossRef]

- Li, Y.B.; Xu, M.Q.; Liang, X.H.; Huang, W. Application of Bandwidth EMD and Adaptive Multiscale Morphology Analysis for Incipient Fault Diagnosis of Rolling Bearings. IEEE Trans. Ind. Electron. 2017, 64, 6506–6517. [Google Scholar] [CrossRef]

| Inside Diameter | Outside Diameter | Thickness | Ball Diameter | Pitch Diameter |

|---|---|---|---|---|

| 17 mm | 40 mm | 12 mm | 6.7 mm | 28.5 mm |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, F.; Kou, Z.; Wu, J.; Li, T. Application of Mutual Information-Sample Entropy Based MED-ICEEMDAN De-Noising Scheme for Weak Fault Diagnosis of Hoist Bearing. Entropy 2018, 20, 667. https://doi.org/10.3390/e20090667

Yang F, Kou Z, Wu J, Li T. Application of Mutual Information-Sample Entropy Based MED-ICEEMDAN De-Noising Scheme for Weak Fault Diagnosis of Hoist Bearing. Entropy. 2018; 20(9):667. https://doi.org/10.3390/e20090667

Chicago/Turabian StyleYang, Fen, Ziming Kou, Juan Wu, and Tengyu Li. 2018. "Application of Mutual Information-Sample Entropy Based MED-ICEEMDAN De-Noising Scheme for Weak Fault Diagnosis of Hoist Bearing" Entropy 20, no. 9: 667. https://doi.org/10.3390/e20090667