An Entropy Based Low-Cycle Fatigue Life Prediction Model for Solder Materials

Abstract

:1. Introduction

2. Fatigue Theory

3. Experiments

4. Results and Discussion

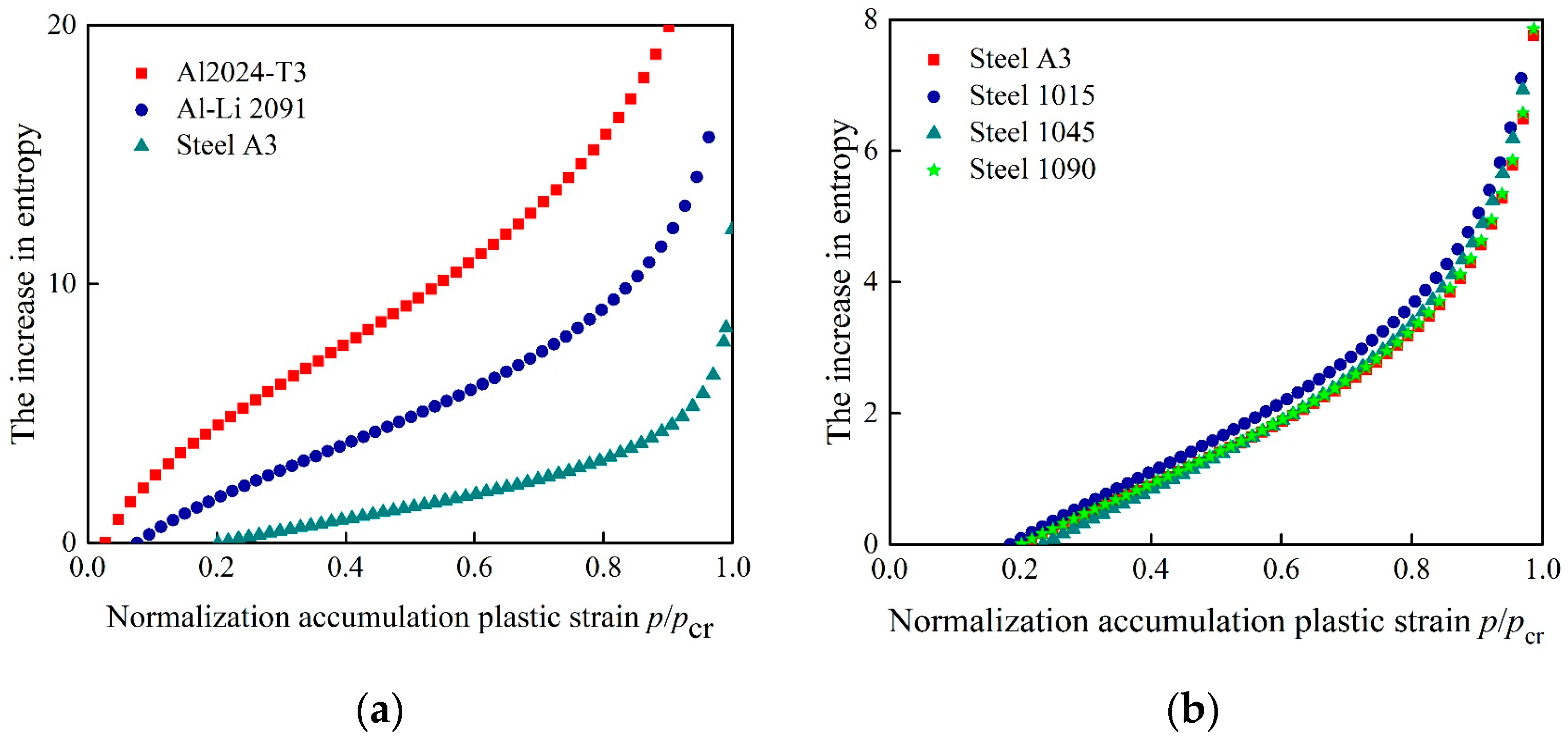

4.1. The Increment of Entropy for Different Materials

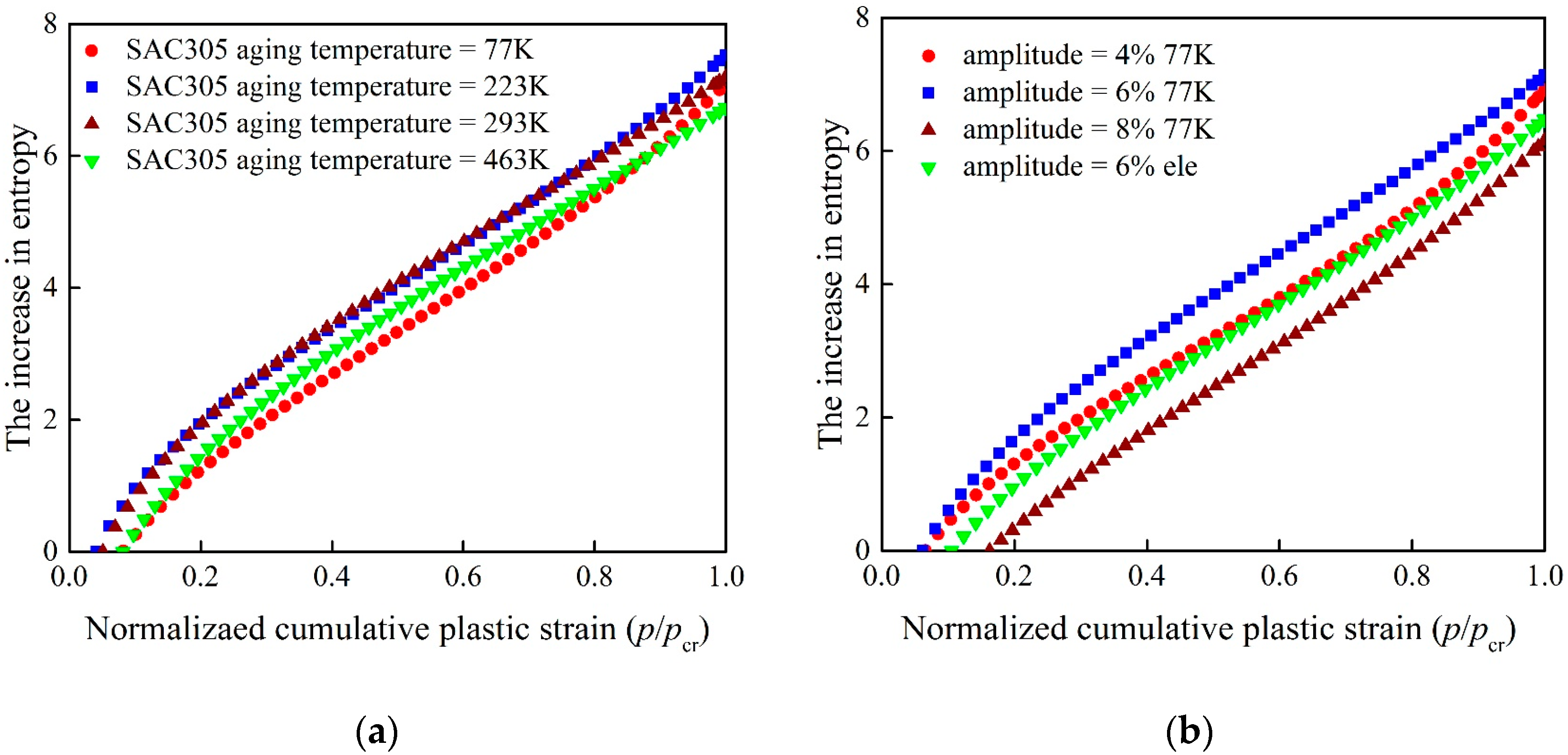

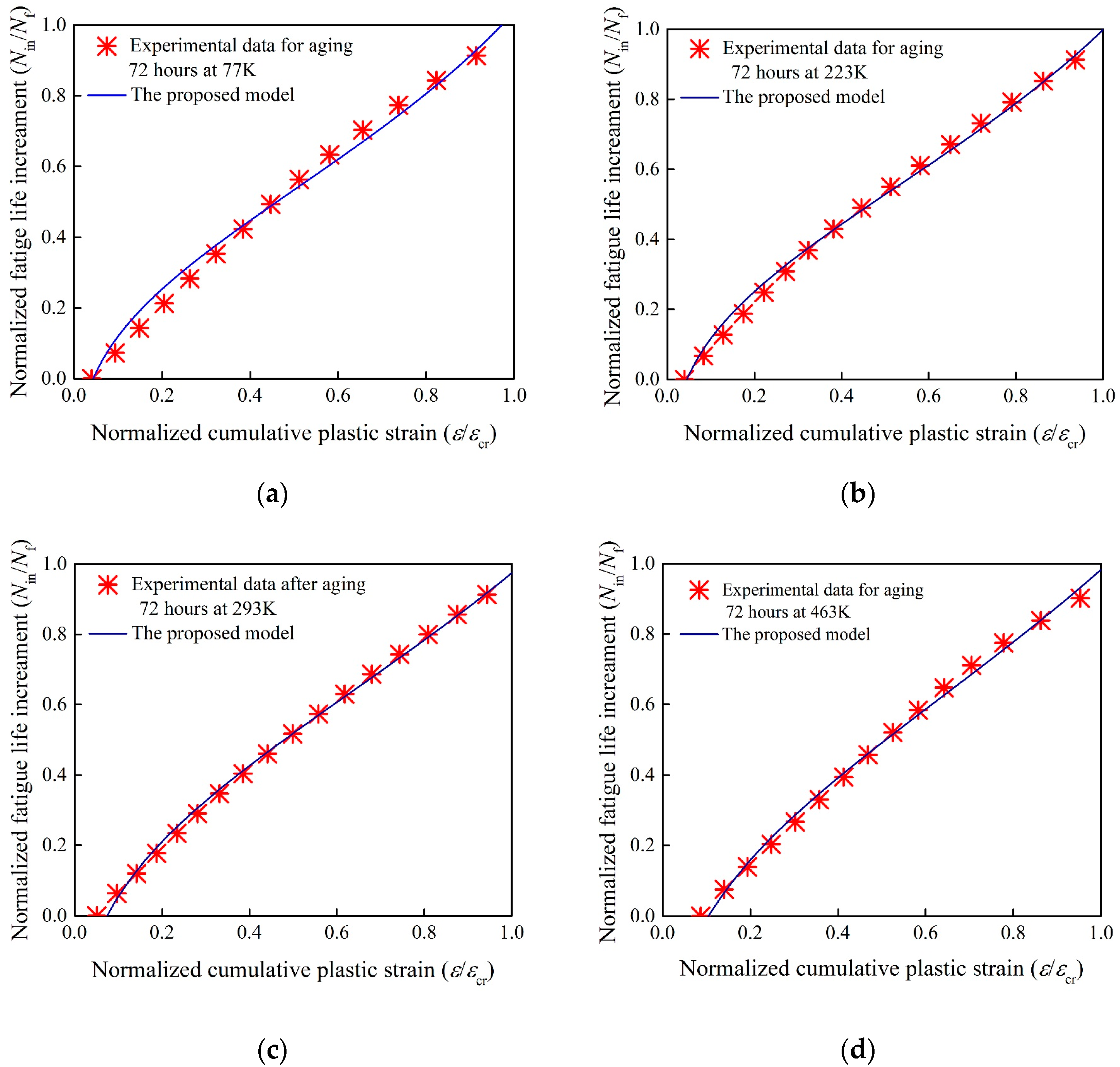

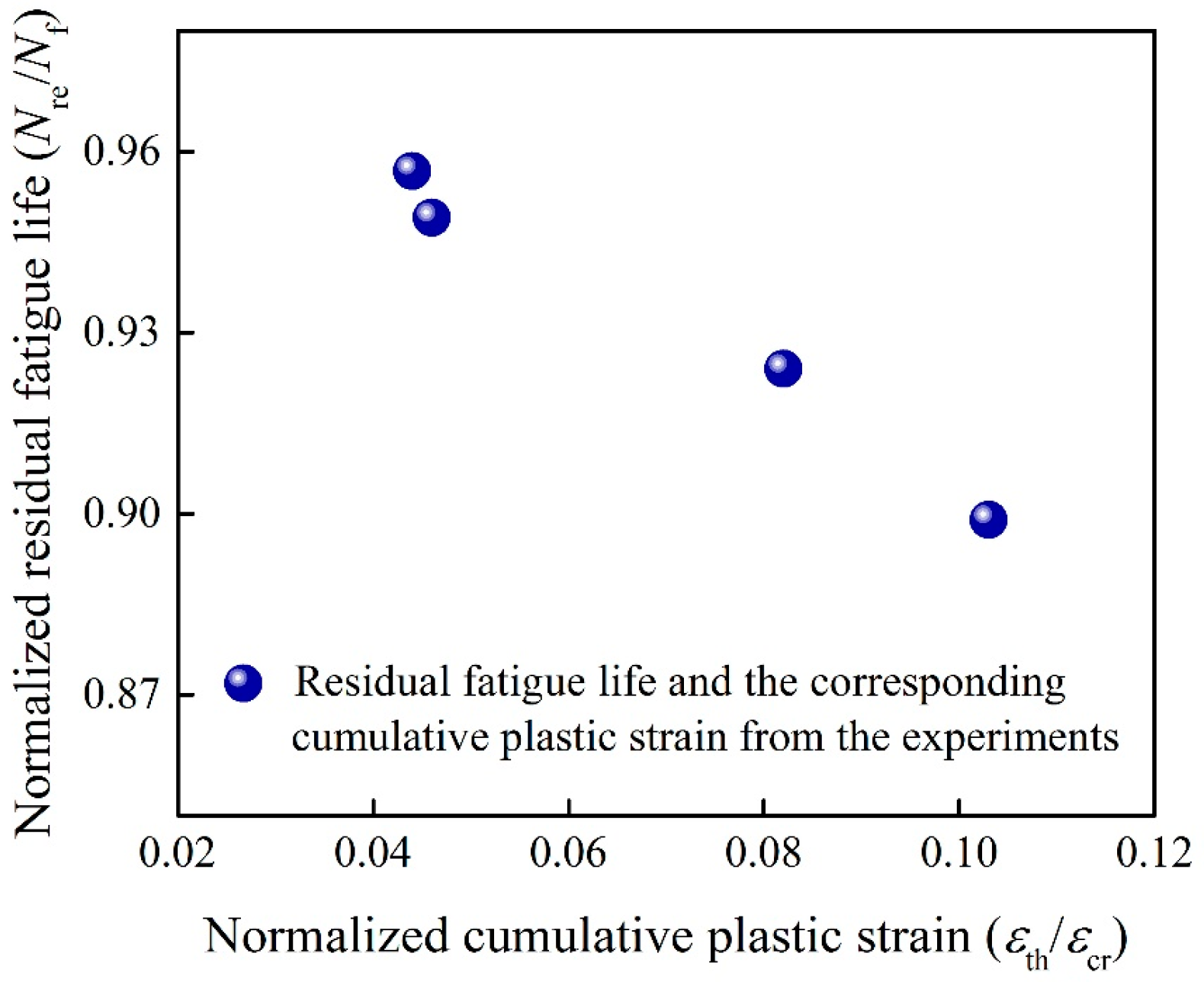

4.2. Fatigue Behavior of Sn-3.0Ag-0.5Cu Solder Joints at Different Temperatures and Experimental Conditions

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Yao, Y.; Fiedler, B.A.; Keer, L.M.; Fine, M.E. Fatigue crack propagation behavior of Sn–Ag–Cu solder interconnects. IEEE Trans. Compon. Packag. Technol. 2009, 32, 317–324. [Google Scholar] [CrossRef]

- Yao, Y.; Keer, L.M.; Fine, M.E. Modeling the failure of intermetallic/solder interfaces. Intermetallics 2010, 18, 1603–1611. [Google Scholar] [CrossRef]

- Yao, Y.; He, X.; Keer, L.M.; Fine, M.E. A continuum damage mechanics-based unified creep and plasticity model for solder materials. Acta Mater. 2015, 83, 160–168. [Google Scholar] [CrossRef]

- Yao, Y.; Wang, J.; Keer, L.M. A phase transformation based method to predict fatigue crack nucleation and propagation in metals and alloys. Acta Mater. 2017, 127, 244–251. [Google Scholar] [CrossRef]

- Wang, J.; Long, X.; Yao, Y. Effects of aging temperature on tensile and fatigue behavior of Sn-3.0Ag-0.5Cu solder joints. J. Mater. Sci. Mater. Electron. 2017, 28, 14884–14892. [Google Scholar] [CrossRef]

- Ihara, C.; Tanaka, T. A stochastic damage accumulation model for crack initiation in high-cycle fatigue. Fatigue Fract. Eng. Mater. Struct. 2000, 23, 375–380. [Google Scholar] [CrossRef]

- Pugno, N.; Ciavarella, M.; Cornetti, P.; Carpinteri, A. A generalized Paris’ law for fatigue crack growth. J. Mech. Phys. Solids 2006, 54, 1333–1349. [Google Scholar] [CrossRef]

- Khelif, R.; Chateauneuf, A.; Chaoui, K. Statistical analysis of HDPE fatigue lifetime. Meccanica 2008, 43, 567–576. [Google Scholar] [CrossRef]

- Carpinteri, A.; Paggi, M. The effect of crack size and specimen size on the relation between the Paris and Wöhler curves. Meccanica 2014, 49, 765–773. [Google Scholar] [CrossRef]

- Suresh, S. Fatigue of Materials; Cambridge University Press: Cambridge, UK, 1998. [Google Scholar]

- Ellyin, F. Fatigue Damage, Crack Growth and Life Prediction; Chapman & Hall: London, UK, 1997. [Google Scholar]

- Basaran, C.; Yan, C.-Y. A Thermodynamic Framework for Damage Mechanics of Solder Joints. J. Electron. Packag. 1998, 120, 379–384. [Google Scholar] [CrossRef]

- Basaran, C.; Tang, H. Implementation of a Thermodynamic Framework for Damage Mechanics of Solder Interconnects in Microelectronic Packaging. Int. J. Damage Mech. 2002, 11, 87–108. [Google Scholar] [CrossRef]

- Basaran, C.; Lin, M.; Ye, H. A thermodynamic model for electrical current induced damage. Int. J. Solids Struct. 2003, 40, 7315–7327. [Google Scholar] [CrossRef]

- Basaran, C.; Gomez, J.; Lin, M. Damage Mechanics Modeling of Concurrent Thermal and Vibration Loading on Electronics Packaging. Multidiscip. Model. Mater. Struct. 2013, 2, 309–326. [Google Scholar]

- Kozyrev, Y.P.; Sedakova, E.B. Application of a thermodynamic model for analysis of wear resistance of materials. J. Mach. Manuf. Reliab. 2008, 37, 60–62. [Google Scholar]

- Bryant, M.D. Entropy and Dissipative Processes of friction and Wear. FME Trans. 2009, 37, 55–60. [Google Scholar]

- Amiri, M.; Khonsari, M.M. On the Thermodynamics of Friction and Wear—A Review. Entropy 2010, 12, 1021–1049. [Google Scholar] [CrossRef]

- Sosnovskiy, L.A.; Sherbakov, S.S. A Model of Mechanothermodynamic Entropy in Tribology. Entropy 2016, 19, 115. [Google Scholar] [CrossRef]

- Sosnovskiy, L.A.; Sherbakov, S.S. Mechanothermodynamic Entropy and Analysis of Damage State of Complex Systems. Entropy 2016, 18, 268. [Google Scholar] [CrossRef]

- Sosnovskiy, L.A.; Sherbakov, S.S. Mechanothermodynamical system and its behavior. Contin. Mech. Thermodyn. 2012, 24, 239–256. [Google Scholar] [CrossRef]

- Sosnovskiy, L.A.; Sherbakov, S.S. Mechanothermodynamics; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- Lemaitre, J. A Course on Damage Mechanics; Springer: Berlin/Heidelberg, Germany, 1996. [Google Scholar]

- Bonora, N. A nonlinear CDM model for ductile failure. Eng. Fract. Mech. 1997, 58, 11–28. [Google Scholar] [CrossRef]

- Attard, P. Non-Equilibrium Thermodynamics and Statistical Mechanics; OUP Oxford: Oxford, UK, 2012. [Google Scholar]

- Boltzmann, L. Lectures on Gas Theory; University of California Press: Berkeley, CA, USA, 1964. [Google Scholar]

- Basaran, C.; Nie, S. An Irreversible Thermodynamics Theory for Damage Mechanics of Solids. Int. J. Damage Mech. 2004, 13, 205–223. [Google Scholar] [CrossRef]

- Naderi, M.; Amiri, M.; Khonsari, M.M. On the thermodynamic entropy of fatigue fracture. Proc. Math. Phys. Eng. Sci. 2010, 466, 423–438. [Google Scholar] [CrossRef]

- Naderi, M.; Khonsari, M.M. An experimental approach to low-cycle fatigue damage based on thermodynamic entropy. Int. J. Solids Struct. 2010, 47, 875–880. [Google Scholar] [CrossRef]

- Amiri, M.; Naderi, M.; Khonsari, M.M. An Experimental Approach to Evaluate the Critical Damage. Int. J. Damage Mech. 2011, 20, 89–112. [Google Scholar] [CrossRef]

- Lemaitre, J.; Chaboche, J.L. Mechanics of Solids Materials; Cambridge University Press: Cambridge, UK, 1985. [Google Scholar]

- Bonora, N.; Newaz, G.M. Low cycle fatigue life estimation for ductile metals using a nonlinear continuum damage mechanics model. Int. J. Solids Struct. 1998, 35, 1881–1894. [Google Scholar] [CrossRef]

| Material | |||

|---|---|---|---|

| Alloy Al2024-T3 | 0.0092 | 0.33 | 0.679 |

| Alloy Al-Li | 0.0077 | 0.1 | 0.446 |

| Steel A3 | 0.202 | 1.0 | 1.98 |

| Steel 1015 | 0.259 | 1.4 | 0.2175 |

| Steel 1045 | 0.223 | 0.95 | 0.2173 |

| Steel 1090 | 0.129 | 0.64 | 0.2 |

| Conditions | |||

|---|---|---|---|

| 77 K 72 h | 0.789 | 22.21 | 0.39 |

| 223 K 72 h | 0.705 | 15.625 | 0.40 |

| 293 K 72 h | 1.172 | 12.07 | 0.48 |

| 453 K 72 h | 0.702 | 6.12 | 0.4 |

| 77 K 4% strain | 0.9279 | 14.14 | 0.41 |

| 77 K 6% strain | 0.789 | 9.44 | 0.48 |

| 77 K 8% strain | 0.59 | 4.12 | 0.45 |

| 293 K ele | 0.53 | 5.07 | 0.37 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Yao, Y. An Entropy Based Low-Cycle Fatigue Life Prediction Model for Solder Materials. Entropy 2017, 19, 503. https://doi.org/10.3390/e19100503

Wang J, Yao Y. An Entropy Based Low-Cycle Fatigue Life Prediction Model for Solder Materials. Entropy. 2017; 19(10):503. https://doi.org/10.3390/e19100503

Chicago/Turabian StyleWang, Jundong, and Yao Yao. 2017. "An Entropy Based Low-Cycle Fatigue Life Prediction Model for Solder Materials" Entropy 19, no. 10: 503. https://doi.org/10.3390/e19100503