Soft Magnetic Properties of High-Entropy Fe-Co-Ni-Cr-Al-Si Thin Films

Abstract

:1. Introduction

2. Experimental Procedures

3. Results and Discussion

3.1. Microstructure Identification of Fe-Co-Ni-Al-Cr-Si Thin Films

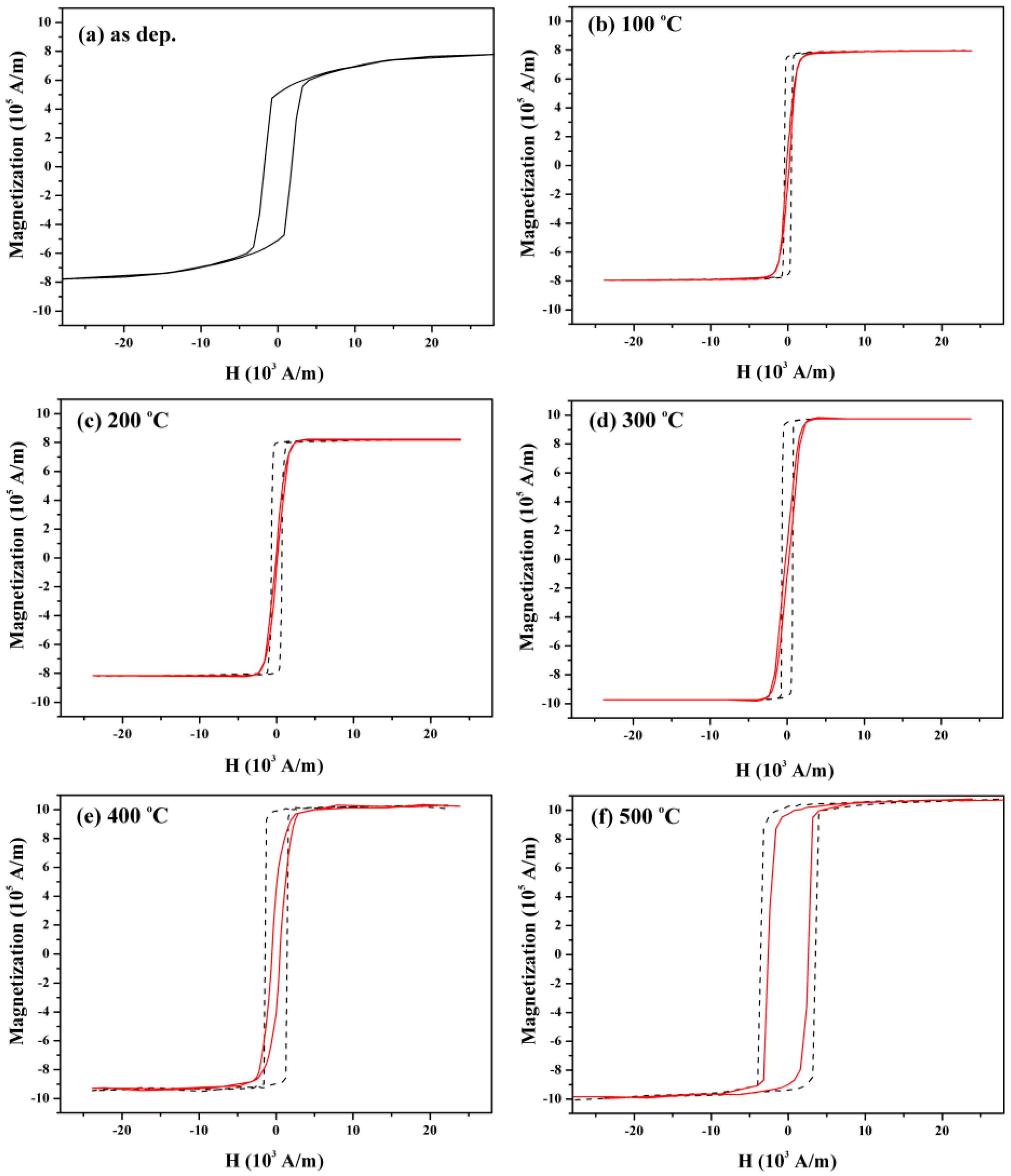

3.2. Magnetic Properties of Fe-Co-Ni-Al-Cr-Si Thin Films

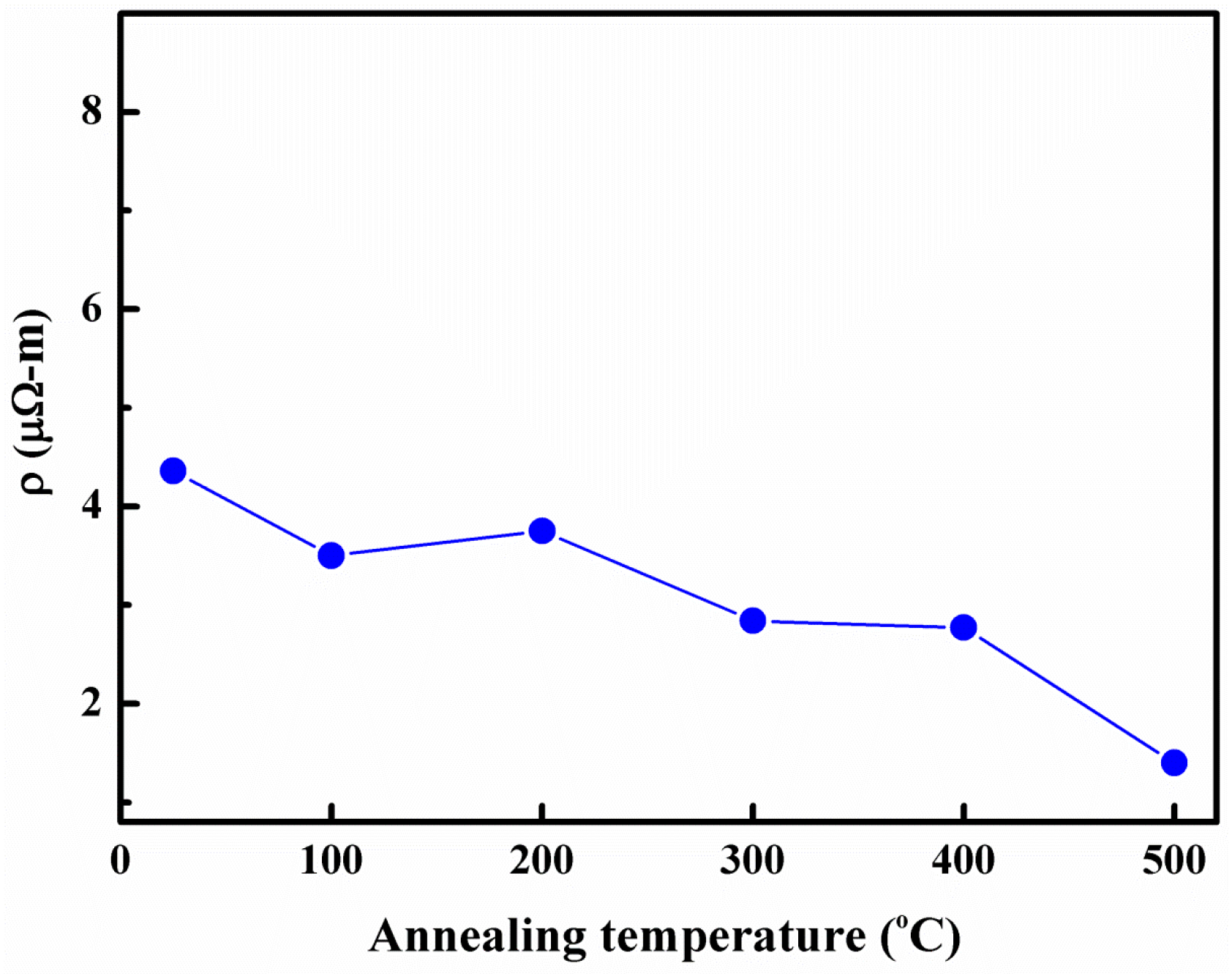

3.3. Electrical Resistivity of Fe-Co-Ni-Al-Cr-Si Thin Films

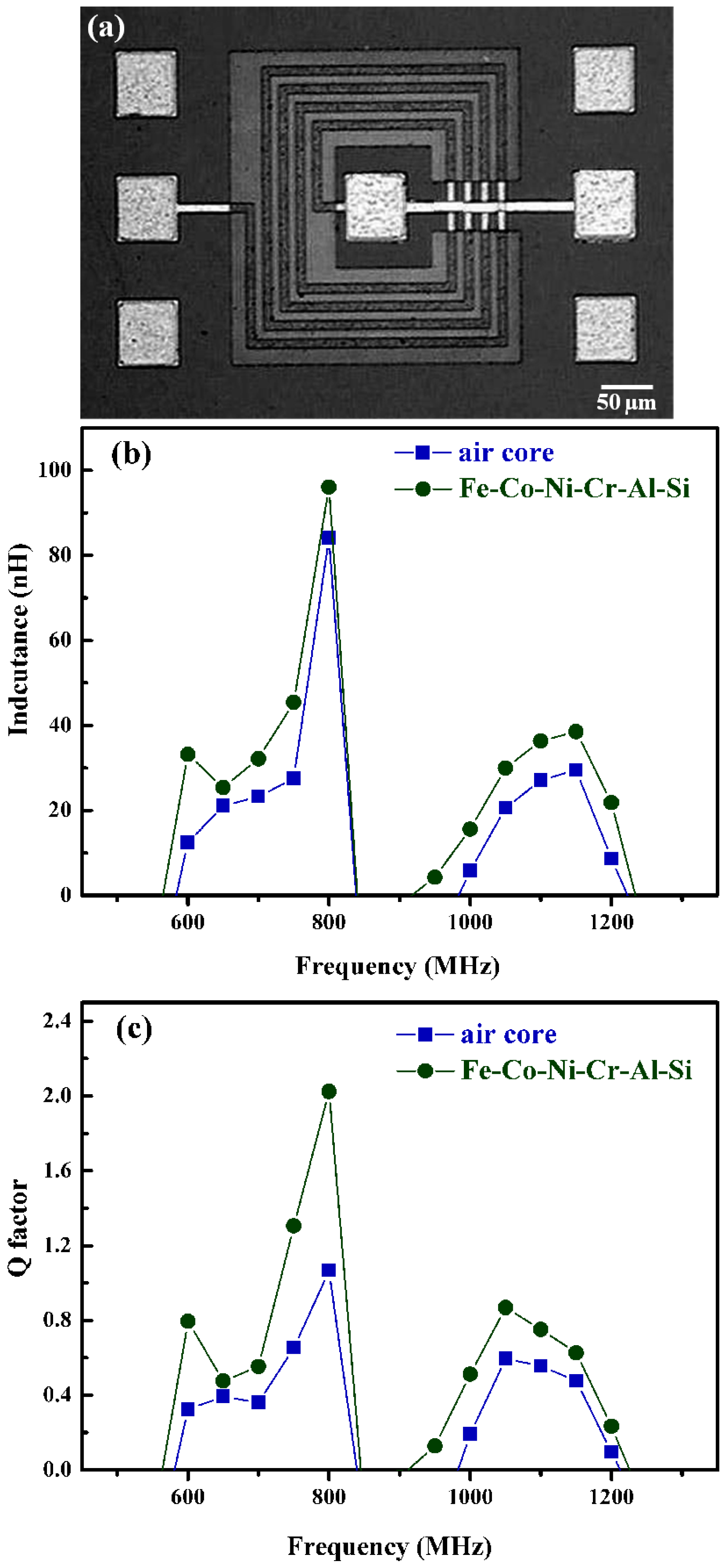

3.4. Inductance and Q Factor of the Fe-Co-Ni-Al-Cr-Si Magnetic Thin Film Inductor

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Chikazumi, S. Physics of Magnetism; Wiley: New York, NY, USA, 1964. [Google Scholar]

- Bozorth, R.M. Ferromagnetism; D. Van Nostrand Co.: Princeton, NJ, USA, 1951. [Google Scholar]

- Chen, L.H.; Zhu, W.; Tiefel, T.H.; Jin, S.; van Dover, R.B.; Korenivski, V. Fe-Cr-Hf-N and Fe-Cr-Ta-N soft magnetic thin films. IEEE Trans. Magn. 1997, 33, 3811–3813. [Google Scholar] [CrossRef]

- Jin, S.; Zhu, W.; Tiefel, T.H.; Korenivski, V.; van Dover, R.B.; Chen, L.H. Fe-Cr-N soft magnetic thin films. J. Appl. Phys. 1997, 81, 4042–4044. [Google Scholar] [CrossRef]

- Lee, C.H.; Shin, D.H.; Ahn, D.H.; Nam, S.E.; Kim, H.J. Fabrication of thin film inductors using FeTaN soft magnetic films. J. Appl. Phys. 1999, 85, 4898–4900. [Google Scholar] [CrossRef]

- Klemmer, T.J.; Ellis, K.A.; Chen, L.H.; van Dover, B.; Jin, S. Ultrahigh frequency permeability of sputtered Fe-Co-B thin films. J. Appl. Phys. 2000, 87, 830–833. [Google Scholar] [CrossRef]

- Fergen, I.; Seemann, K.; von der Weth, A.; Schuppen, A. Soft ferromagnetic thin films for high frequency applications. J. Magn. Magn. Mater. 2002, 242, 146–151. [Google Scholar] [CrossRef]

- Chen, L.H.; Chen, H.K.; Hsieh, C.T.; Shih, Y.H.; Chen, I.G.; Chen, S.Y.; Liu, H.P. Soft magnetic properties of Co-Fe-Zr-B-Al-O films. J. Appl. Phys. 2002, 91, 8450–8452. [Google Scholar] [CrossRef]

- Chen, H.K.; Li, S.H.; Duh, J.G. Structure and soft magnetic properties of Fe-Co-Ni-based multicomponent thin films. J. Electron. Mater. 2005, 34, 1480–1483. [Google Scholar] [CrossRef]

- Aoqui, S.I.; Munakata, M. Uniaxial anisotropy field and crystalline structures of (CoFe)-(SiO2) magnetic thin film for operating in the GHz frequency. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2005, 413, 550–554. [Google Scholar] [CrossRef]

- Ha, N.D.; Phan, M.H.; Kim, C.O. Novel nanostructure and magnetic properties of Co-Fe-Hf-O films. Nanotechnology 2007, 18, 155705. [Google Scholar] [CrossRef]

- Kuo, C.L.; Li, S.D.; Duh, J.G. Development and optimisation of FeCoHfN soft magnetic thin films with high-frequency characteristics. Appl. Surf. Sci. 2008, 254, 7417–7420. [Google Scholar] [CrossRef]

- Liu, M.M.; Li, S.D.; Duh, J.G. High-Frequency Ferromagnetic Properties and Magnetic Domain Structures of FeNdBO Thin Films. J. Nanosci. Nanotechnol. 2009, 9, 836–839. [Google Scholar] [CrossRef] [PubMed]

- Kuo, Y.M.; Li, S.D.; Duh, J.G. High-frequency ferromagnetic properties of multilayered FeCoHfO/AlOx films. Mater. Res. Bull. 2010, 45, 1916–1920. [Google Scholar] [CrossRef]

- Huang, S.W.; Lai, Y.T.; Duh, J.G. Effects of the Hf content on the microstructure and magnetic properties of Co-Hf-Ta thin films. Appl. Surf. Sci. 2011, 257, 2042–2045. [Google Scholar] [CrossRef]

- Chang, H.W.; Huang, Y.H.; Hsieh, C.C.; Shih, C.W.; Chang, W.C.; Xue, D.S. Study on the soft magnetic properties and high frequency characteristics of Co-M (M = Ti, Zr, and Hf) thin films. J. Appl. Phys. 2012, 111, 07A333. [Google Scholar] [CrossRef]

- Chang, H.W.; Huang, Y.H.; Hsieh, C.C.; Shih, C.W.; Chang, W.C.; Xue, D.S. Magnetic properties and high frequency characteristic of obliquely sputtered Co-M (M = V and Nb) thin films. J. Alloys Compd. 2012, 539, 276–279. [Google Scholar] [CrossRef]

- Chang, H.W.; Chuang, L.C.; Shih, C.W.; Chang, W.C.; Xue, D.S. Optimization of high frequency characteristics in Co-Ta thin films. J. Appl. Phys. 2014, 115, 17A312. [Google Scholar] [CrossRef]

- Naoe, M.; Kobayashi, N.; Ohnuma, S.; Iwasa, T.; Arai, K.I.; Masumoto, H. Ultra-high resistive and anisotropic CoPd-CaF2 nanogranular soft magnetic films prepared by tandem-sputtering deposition. J. Magn. Magn. Mater. 2015, 391, 213–222. [Google Scholar] [CrossRef]

- Yeh, J.W.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Tsau, C.H.; Chang, S.Y. Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Chou, H.P.; Chang, Y.S.; Chen, S.K.; Yeh, J.W. Microstructure, thermophysical and electrical properties in AlxCoCrFeNi (0 ≤ x ≤ 2) high-entropy alloys. Mater. Sci. Eng. B 2009, 163, 184–189. [Google Scholar] [CrossRef]

- Murty, B.S.; Yeh, J.W.; Ranganathan, S. High-Entropy Alloys; Butterworth-Heinemann: Boston, MA, USA, 2014. [Google Scholar]

- Chen, S.K.; Kao, Y.F. Near-constant resistivity in 4.2–360 K in a B2 Al2.08CoCrFeNi. AIP Adv. 2012, 2, 012111. [Google Scholar] [CrossRef]

- Yamaguchi, M.; Suezawa, K.; Takahashi, Y.; Arai, K.I.; Kikuchi, S.; Shimada, Y.; Tanabe, S.; Ito, K. Magnetic thin-film inductors for RF-integrated circuits. J. Magn. Magn. Mater. 2000, 215, 807–810. [Google Scholar] [CrossRef]

- Lai, C.H.; Lin, S.J.; Yeh, J.W.; Chang, S.Y. Preparation and characterization of AlCrTaTiZr multi-element nitride coatings. Surf. Coat. Technol. 2006, 201, 3275–3280. [Google Scholar] [CrossRef]

- Chang, H.W.; Huang, P.K.; Yeh, J.W.; Davison, A.; Tsau, C.H.; Yang, C.C. Influence of substrate bias, deposition temperature and post-deposition annealing on the structure and properties of multi-principal-component (AlCrMoSiTi)N coatings. Surf. Coat. Technol. 2008, 202, 3360–3366. [Google Scholar] [CrossRef]

- Huang, P.K.; Yeh, J.W. Inhibition of grain coarsening up to 1000 degrees C in (AlCrNbSiTiV)N superhard coatings. Scr. Mater. 2010, 62, 105–108. [Google Scholar] [CrossRef]

- Chikazumi, S. Ferromagneticf Properties and Superlattice Formation of Iron Nickel Alloys (II). J. Phys. Soc. Jpn. 1950, 5, 327–333. [Google Scholar] [CrossRef]

- Wang, S.G.; Ong, C.K.; Li, Z.W. Thickness and angle dependence of the coercivity on highly uniaxial anisotropy FeTaN thin films. Phyica B 2004, 349, 129–135. [Google Scholar] [CrossRef]

- Frey, H.; Khan, H.R. Handbook of Thin-Film Technology; Springer: Berlin/Heidelberg, Germany, 2015. [Google Scholar]

- Fu, C.M.; Kao, P.C.; Tsai, M.S.; Hsu, H.S.; Yu, C.C.; Huang, J.C.A. Magnetic anisotropy of permalloy thin film on Mo stepped surface. J. Magn. Magn. Mater. 2002, 239, 17–21. [Google Scholar] [CrossRef]

- Comstock, R.L. Introduction to Magnetism and Magnetic Recording; Wiley: New York, NY, USA, 1999. [Google Scholar]

- Jiles, D.C. Introduction to Magnetism and Magnetic Materials; CRC Press: Boca Raton, FL, USA, 1998. [Google Scholar]

- Liu, J.P.; Fullerton, E.; Gutfleisch, O.; Sellmyer, D.J. Nanoscale Magnetic Materials and Applications; Springer: Boston, MA, USA, 2009. [Google Scholar]

- Saito, T. Electrical resistivity and magnetic properties of Nd-Fe-B alloys produced by melt-spinning technique. J. Alloys Compd. 2010, 505, 23–28. [Google Scholar] [CrossRef]

- Canulescu, S.; Borca, C.N.; Rechendorff, K.; Davidsdottir, S.; Almtoft, K.P.; Nielsen, L.P.; Schou, J. Optical and electrical properties of polycrystalline and amorphous Al-Ti thin films. Appl. Phys. Lett. 2016, 108, 141909. [Google Scholar] [CrossRef] [Green Version]

- Hummel, R.E. Electronic Properties of Materials, 3rd ed.; Springer: New York, NY, USA, 2001. [Google Scholar]

- Kao, Y.F.; Chen, S.K.; Chen, T.J.; Chu, P.C.; Yeh, J.W.; Lin, S.J. Electrical, magnetic, and Hall properties of AlxCoCrFeNi high-entropy alloys. J. Alloys Compd. 2011, 509, 1607–1614. [Google Scholar] [CrossRef]

- Li, S.D.; Duh, J.G.; Liao, C.N. High-frequency ferromagnetic inductors covered by as-deposited FeCoAlO films with stress-induced uniaxial anisotropy. Thin Solid Films 2008, 516, 7748–7752. [Google Scholar] [CrossRef]

- Davies, R.P.; Cheng, C.; Sturcken, N.; Bailey, W.E.; Shepard, K.L. Coupled inductors with crossed anisotropy CoZrTa/SiO2 multilayer cores. IEEE Trans. Magn. 2013, 49, 4009–4012. [Google Scholar] [CrossRef]

- Bechir, M.H.; Yaya, D.D.; Kahlouche, F.; Soultan, M.; Youssouf, K.; Capraro, S.; Chatelon, J.P.; Rousseau, J.J. Planar inductor equivalent circuit model taking into account magnetic permeability, loss tangent, skin and proximity effects versus frequency. Analog Integr. Circuits Process 2016, 88, 105–113. [Google Scholar] [CrossRef]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, P.-C.; Cheng, C.-Y.; Yeh, J.-W.; Chin, T.-S. Soft Magnetic Properties of High-Entropy Fe-Co-Ni-Cr-Al-Si Thin Films. Entropy 2016, 18, 308. https://doi.org/10.3390/e18080308

Lin P-C, Cheng C-Y, Yeh J-W, Chin T-S. Soft Magnetic Properties of High-Entropy Fe-Co-Ni-Cr-Al-Si Thin Films. Entropy. 2016; 18(8):308. https://doi.org/10.3390/e18080308

Chicago/Turabian StyleLin, Pei-Chung, Chun-Yang Cheng, Jien-Wei Yeh, and Tsung-Shune Chin. 2016. "Soft Magnetic Properties of High-Entropy Fe-Co-Ni-Cr-Al-Si Thin Films" Entropy 18, no. 8: 308. https://doi.org/10.3390/e18080308