Choked Flow Characteristics of Subcritical Refrigerant Flowing Through Converging-Diverging Nozzles

Abstract

:1. Introduction

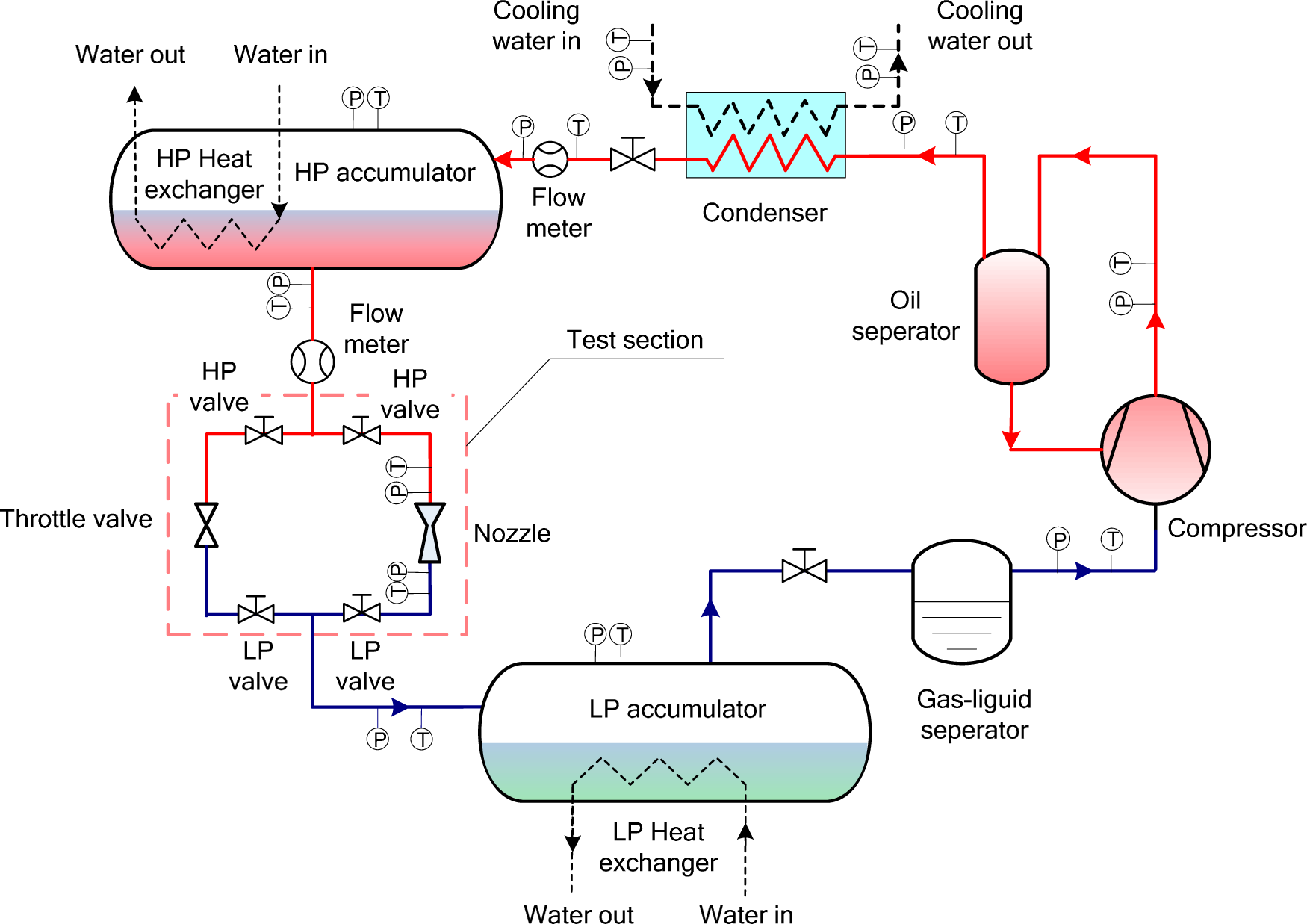

2. Experimental Setup

2.1. Experimental Apparatus and Procedure

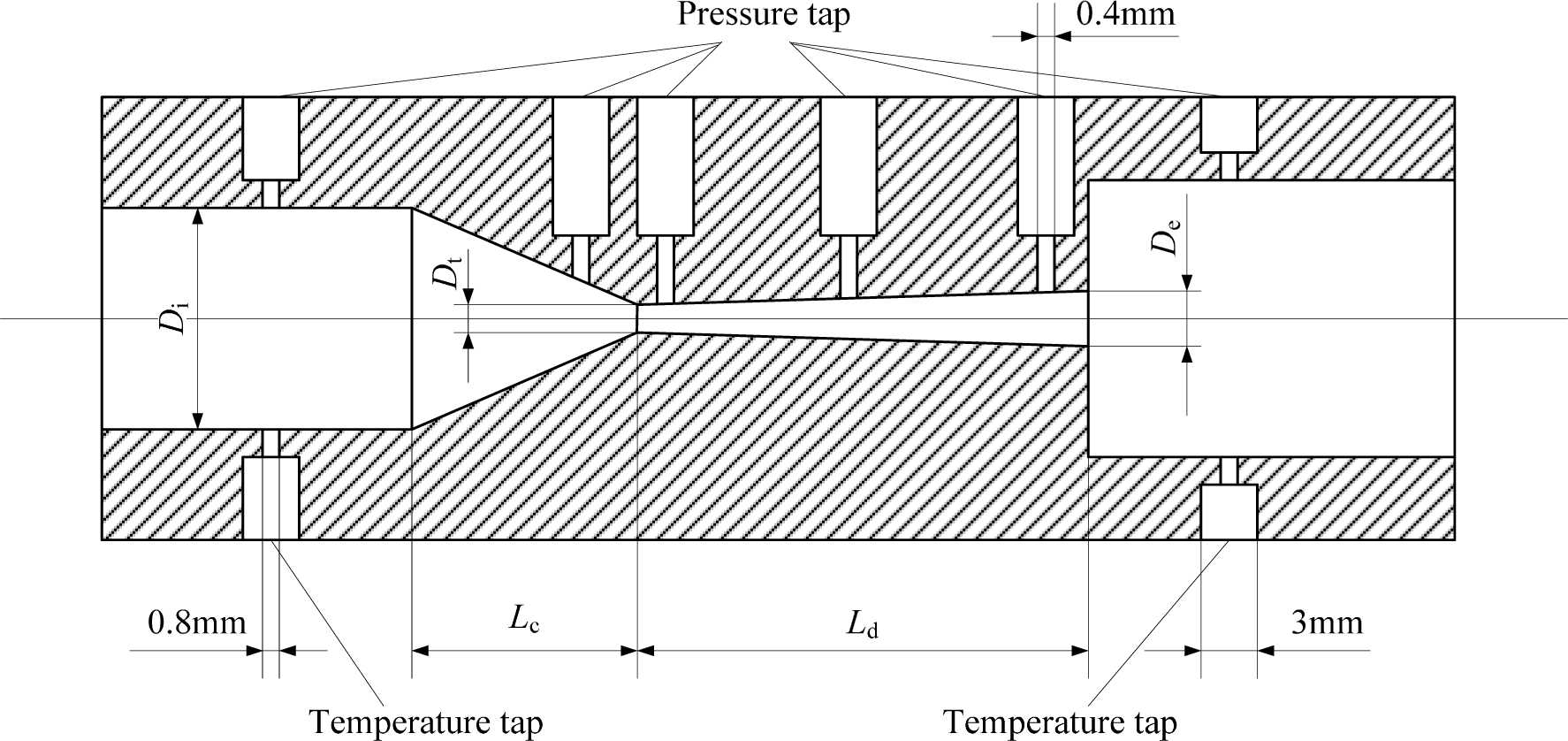

2.2. Nozzles Used in the Experiment

3. Results and Discussion

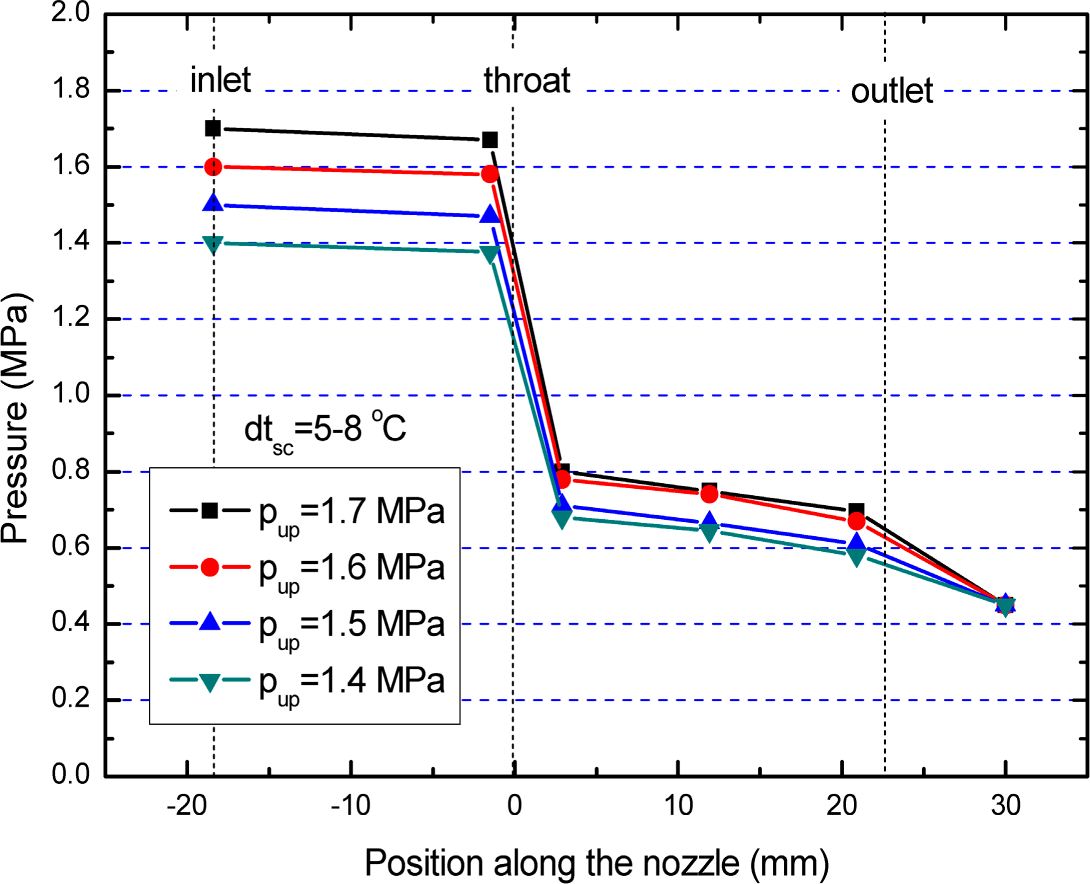

3.1. Pressure Profile

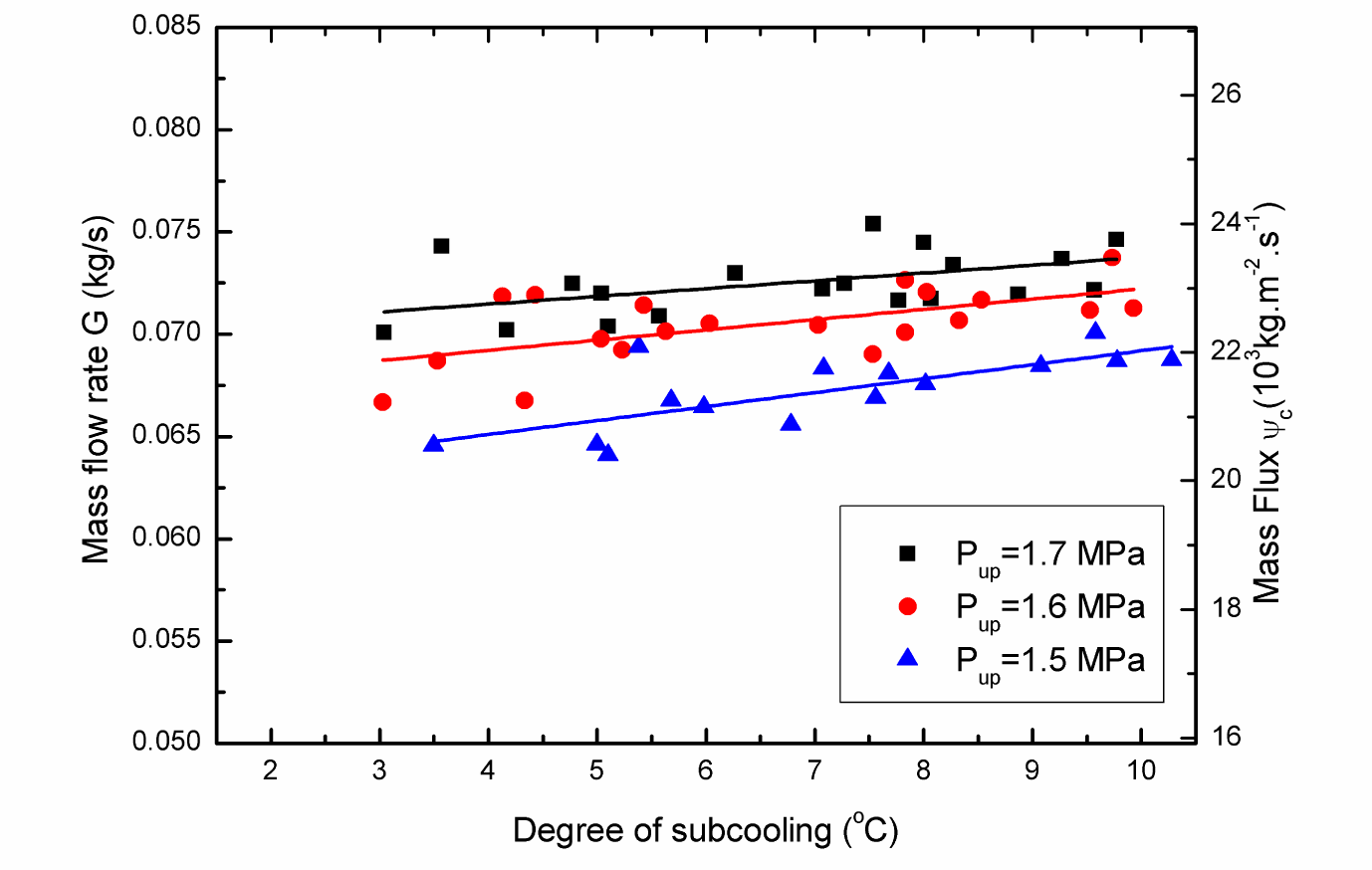

3.2. Mass Flow Rate

4. Conclusions

Acknowledgments

Nomenclature

| HEM | homogeneous equilibrium model |

| G | mass flow rate, kg/s |

| N | quantity |

| p | pressure, MPa |

| s | entropy, kJ/(kg.K) |

| v | specific volume, m3/kg |

| x | vapor quality |

| ψ | mass flux, kg/(s.m2) |

Subscripts

| 0 | stagnation |

| C | critical point |

| cal | calculated value |

| down | downstream |

| E | equilibrium |

| ex | experimental value |

| g | vapor phase |

| l | liquid phase |

| s | isentropic process |

| sat | saturated |

| sc | subcooling |

| t | throat |

| up | upstream |

Author Contributions

Conflicts of Interest

References

- Zhang, Z.; Ma, Y.; Li, M.; Zhao, L. Recent advances of energy recovery expanders in the transcritical CO2 refrigeration cycle. HVAC&R Res. 2013, 19, 376–384. [Google Scholar]

- Zhang, B.; Peng, X.; He, Z.; Xing, Z.; Shu, P. Development of a double acting free piston expander for power recovery in transcritical CO2 cycle. Appl. Therm. Eng. 2007, 27, 1629–1636. [Google Scholar]

- Yang, B.; Peng, X.; Sun, S. Study of a rotary vane expander for the transcritical CO2 cycle part I: Experimental investigation. HVAC&R Res. 2009, 15, 673–688. [Google Scholar]

- Yang, B.; Peng, X.; He, Z. Experimental investigation on the internal working process of a CO2 rotary vane expander. Appl. Therm. Eng. 2009, 29, 2289–2296. [Google Scholar]

- Wang, M.; Zhao, Y.; Cao, F. Simulation study on a novel vane-type expander with internal two-stage expansion process for R-410A refrigeration system. Int. J. Refrig. 2012, 35, 757–771. [Google Scholar]

- Nickl, J.; Will, G.; Quack, H. Integration of a three-stage expander into a CO2 refrigeration system. Int. J. Refrig. 2005, 28, 1219–1224. [Google Scholar]

- Zhao, L.; Li, M.; Ma, Y.; Liu, Z. Simulation analysis of a two rolling piston expander replacing throttling valve in conventional refrigerant heat pump system. Proceedings of the International Compressor Engineering Conference at Purdue, West Lafayette, IN, USA, 16–19 July 2012.

- Jia, X.; Zhang, B.; Pu, L. Improved rotary vane expander for trans-critical CO2 cycle by introducing high-pressure gas into the vane slots. Int. J. Refrig. 2011, 34, 732–741. [Google Scholar]

- Li, D.; Groll, E.A. Transcritical CO2 refrigeration cycle with ejector-expansion device. Int. J. Refrig. 2005, 28, 766–773. [Google Scholar]

- Lawrence, N.; Elbel, S. Theoretical and practical comparison of two-phase ejector refrigeration cycles including first and second law analysis. Int. J. Refrig. 2013, 36, 1220–1232. [Google Scholar]

- Nakagawa, M.; Marasigan, A.R.; Matsukawa, T.; Kurashina, A. Experimental investigation on the effect of mixing length on the performance of two-phase ejector for CO2 refrigeration cycle with and without heat exchanger. Int. J. Refrig. 2011, 34, 1604–1613. [Google Scholar]

- Cho, S.Y.; Cho, C.H.; Kim, C. Performance characteristics of a turbo expander substituted for expansion valve on air-conditioner. Exp. Therm. Fluid Sci. 2008, 32, 1655–1665. [Google Scholar]

- Hays, L.G.; Brasz, J.J. Two-phase turbines for compressor energy recovery. Proceedings of the International Compressor Engineering Conference at Purdue, West Lafayette, IN, USA, 23–26 July 1996.

- He, T.; Xia, C.; Zhao, Y. An experimental study on energy recovery by a pelton-type expander in a domestic refrigeration system. HVAC&R Res. 2009, 15, 785–799. [Google Scholar]

- Nakagawa, M.; Takeuchi, H. Performance of two-phase ejector in refrigeration cycle. Proceedings of the 3rd International Conference on Multiphase Flow, Lyon, France, 8–12 June 1998.

- Nakagawa, M.; Morimune, Y. Subsequent report on nozzle efficiency of two-phase ejector used in carbon dioxide refrigerator. Therm. Sci. Eng. 2003, 11, 51–52. [Google Scholar]

- Lucas, C.; Koehler, J. Experimental investigation of the COP improvement of a refrigeration cycle by use of an ejector. Int. J. Refrig. 2012, 35, 1595–1603. [Google Scholar]

- Lee, J.S.; Kim, M.S.; Kim, M.S. Experimental study on the improvement of CO2 air conditioning system performance using an ejector. Int. J. Refrig. 2011, 34, 1614–1625. [Google Scholar]

- Chaiwongsa, P.; Wongwises, S. Effect of throat diameters of the ejector on the performance of the refrigeration cycle using a two-phase ejector as an expansion device. Int. J. Refrig. 2007, 30, 601–608. [Google Scholar]

- Henry, R.E.; Fauske, H.K. The two-phase critical flow of one-component mixtures in nozzles, orifices, and short tubes. J. Heat Transf. 1971, 93, 179–187. [Google Scholar]

- Ozaki, Y.; Takeuchi, H.; Hirata, T. Regeneration of expansion energy by ejector in CO2 cycle. Proceedings of the 6 th IIR-Gustav Lorentzen Conference on Natural Working Fluids at Glasgow, Glasgow, UK, 29 August–1 September 2004.

- Starkman, E.; Schrock, V.; Neusen, K.; Maneely, D. Expansion of a very low quality two-phase fluid through a convergent-divergent nozzle. J. Fluids Eng. 1964, 86, 247–254. [Google Scholar]

- Elbel, S. Historical and present developments of ejector refrigeration systems with emphasis on transcritical carbon dioxide air-conditioning applications. Int. J. Refrig. 2011, 34, 1545–1561. [Google Scholar]

- Harrell, G.S.; Kornhauser, A.A. Performance tests of a two phase ejector. Proceedings of the 30th Intersociety Energy Conversion Engineering Conference (IECEC), Orlando, FL, USA, 30 July–4 August 1995; pp. 49–53.

- Pottker, G.; Guo, B.; Hrnjak, P.S. Experimental investigation of an R410A vapor compression system working with an ejector. Proceedings of the International Refrigeration and Air Conditioning Conference at Purdue, West Lafayette, IN, USA, 10–11 July 2010.

- He, T.; Xia, C.; Ding, L.; Li, L.; Shu, P. Influence of subcooling on nozzle efficiency. J. Xi’an Jiaotong Univ. 2009, 43, 18–21. [Google Scholar]

- Berana, M.S.; Nakagawa, M.; Harada, A. Shock waves in supersonic two-phase flow of CO2 in converging-diverging nozzles. HVAC&R Res. 2009, 15, 1081–1098. [Google Scholar]

- Nilpueng, K.; Wongwises, S. Flow mechanisms of HFC-410A inside short-tube orifices during flashing process. Int. J. Heat Mass Transf. 2010, 53, 3449–3459. [Google Scholar]

- Singh, G.M.; Hrnjak, P.S.; Bullard, C.W. Flow of refrigerant R134a through orifice tubes. HVAC&R Res. 2001, 7, 245–262. [Google Scholar]

| Parameters | Values |

|---|---|

| Dt (mm) | 2 |

| Di (mm) | 6.5 |

| De (mm) | 2.8 |

| Lc (mm) | 8.4 |

| Ld (mm) | 22.9 |

© 2014 by the authors; licensee MDPI, Basel, Switzerland This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Tian, L.; Tong, L.; Chen, Y. Choked Flow Characteristics of Subcritical Refrigerant Flowing Through Converging-Diverging Nozzles. Entropy 2014, 16, 5810-5821. https://doi.org/10.3390/e16115810

Zhang Z, Tian L, Tong L, Chen Y. Choked Flow Characteristics of Subcritical Refrigerant Flowing Through Converging-Diverging Nozzles. Entropy. 2014; 16(11):5810-5821. https://doi.org/10.3390/e16115810

Chicago/Turabian StyleZhang, Zhenying, Lili Tian, Lirui Tong, and Yanhua Chen. 2014. "Choked Flow Characteristics of Subcritical Refrigerant Flowing Through Converging-Diverging Nozzles" Entropy 16, no. 11: 5810-5821. https://doi.org/10.3390/e16115810